Tachometer

0 515 010 561 -- PRT Tachometer.p65 - Vehicle Controls

0 515 010 561 -- PRT Tachometer.p65 - Vehicle Controls

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE INSTRUCTIONS FOR INSTALLATION AND ELECTRICAL WIRING FOR THESE TACHOMETERS FOLLOW. USE IS RESTRICTED TO 12 VOLT NEGATIVE GROUND ELECTRICAL SYSTEMS.<br />

Parts List<br />

Item Description Quantity<br />

1. <strong>Tachometer</strong> 1<br />

2. Decals, 2” x 4” (not contingency decals) 2<br />

3. Posi-Lock Connectors 3<br />

Optional Items Which May Be Needed:<br />

Flush In-Dash Mounting Bracket #240 104<br />

On-Dash Mounting Bracket #240 103<br />

CAUTION: Read these instructions thoroughly before making installation.<br />

Always wear safety glasses, and always disconnect the battery<br />

ground before making any electrical connections. If in doubt,<br />

please contact your dealer or VDO Instruments at 1-800-265-1818.<br />

<strong>Tachometer</strong><br />

Installation and Operation Instructions<br />

Siemens<br />

Allentown, Pennsylvania USA<br />

VDO<br />

<strong>Tachometer</strong> Installation<br />

Installing the tachometer is a three-step process.<br />

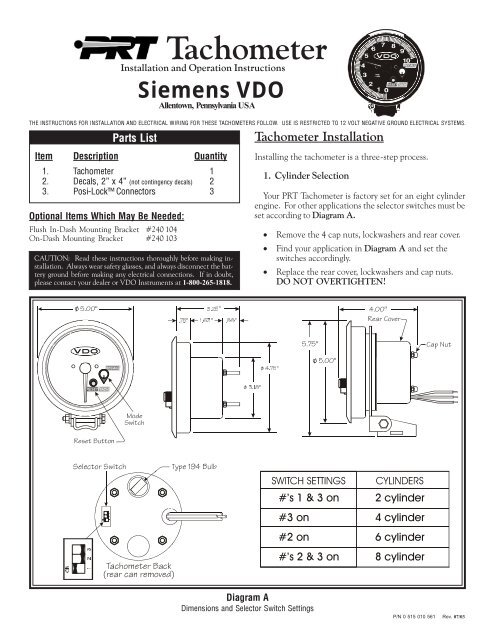

1. Cylinder Selection<br />

Your PRT <strong>Tachometer</strong> is factory set for an eight cylinder<br />

engine. For other applications the selector switches must be<br />

set according to Diagram A.<br />

· Remove the 4 cap nuts, lockwashers and rear cover.<br />

· Find your application in Diagram A and set the<br />

switches accordingly.<br />

· Replace the rear cover, lockwashers and cap nuts.<br />

DO NOT OVERTIGHTEN!<br />

% <br />

#"%<br />

'% !&# ((<br />

$ <br />

BUQb3_fUb<br />

%'%<br />

3Q`>ed<br />

$'%<br />

% <br />

#!(<br />

=_TU<br />

CgYdSX<br />

BUcUd2edd_^<br />

CU\USd_bCgYdSX<br />

Di`U!)$2e\R<br />

·V RQ<br />

F\OLQGHU<br />

1<br />

<br />

2<br />

RQ<br />

F\OLQGHU<br />

RQ<br />

F\OLQGHU<br />

1<br />

<br />

2<br />

DQSX_]UdUb2QS[<br />

bUQbSQ^bU]_fUT<br />

·V RQ<br />

F\OLQGHU<br />

Diagram A<br />

Dimensions and Selector Switch Settings<br />

P/N 0 515 010 561 Rev. 07/03

&ROXPQ0RXQW<br />

2Q'DVK<br />

9^4QcX<br />

8QGHU'DVK<br />

5ROO%DU<br />

0RXQW<br />

Diagram B<br />

Possible mounting locations for the Extreme <strong>Tachometer</strong><br />

2. Mounting the <strong>Tachometer</strong><br />

Your PRT tachometer can be mounted almost anywhere.<br />

Several suggestions are illustrated in Diagram B. Some<br />

installation techniques may require optional accessories,<br />

cutting, or drilling new holes.<br />

MOUNTING NOTES:<br />

· The most common mounting location is on the steering<br />

column or roll cage using a band clamp and the<br />

included short mounting bracket.<br />

· For mounting in the dash, optional flush mounting<br />

bracket [P/N 240 104] is recommended. The rear<br />

cover may also be used as a mounting clamp for in<br />

dash mounting.<br />

· For mounting on top of the dash, optional longer<br />

mounting bracket [P/N 240 103] is recommended.<br />

MOUNTING CAUTIONS:<br />

· Make sure your PRT <strong>Tachometer</strong> does not rest against<br />

any glass, windshield A pillars, or any roll cage tubes.<br />

· VDO does not recommend mounting your PRT<br />

<strong>Tachometer</strong> close to other electrical components or<br />

their associated wiring. For example, the ignition<br />

system box, the ignition coil, electric fuel pump, etc.<br />

IGNITION<br />

Standard<br />

CD<br />

Electronic<br />

TYPE<br />

points/ breakerless<br />

points<br />

breakerless<br />

MSD, ACCEL,<br />

MALLORY, DDIS<br />

(distributorless),etc.<br />

CONNECTIONS<br />

negative terminal on coil<br />

points connection to CD box<br />

positive terminal on coil<br />

Tach output terminal on ignition<br />

box, or points connection to<br />

ignition box, or negative coil<br />

· Be sure to connect the tachometer using the supplied<br />

Posi-Lock Connectors. Use them as shown in the<br />

following illustration:<br />

¯<br />

°<br />

CdbY`gYbUU^TcQR_ed<br />

9^cUbdUQSXgYbUY^d_Q]Q\UU^T<br />

Uh`_cY^W_^\iRQbUgYbU<br />

3. Wiring the <strong>Tachometer</strong><br />

· Turn off the ignition and disconnect the negative<br />

terminal from the battery post if you haven’t already<br />

done so.<br />

· Wire the tachometer to the vehicle as shown in<br />

Diagram C *.<br />

±<br />

8Q^TdYWXdU^]Q\UU^Tc<br />

Y^d_U^Tc_VRQbbU\<br />

* Refer to your vehicle’s owner/service manual or the<br />

aftermarket ignition manufacturer’s instructions for<br />

a recommended place to tap the signal. Typical<br />

examples are shown in the table to the right.<br />

· Reconnect the battery and start your vehicle to test<br />

the installation.

5('<br />

%/$&.<br />

*5((1<br />

YROWSRZHUDQGLOOXPLQDWLRQFRQQHFWWRIXVHSDQHO<br />

7DFKJURXQGFRQQHFWWRFRPPRQFKDVVLVJURXQG<br />

,JQLWLRQ7DFKRPHWHUVLJQDOFRQQHFWLRQ<br />

Diagram C<br />

General Wiring Information<br />

PRT <strong>Tachometer</strong> Operation<br />

For normal operation and display of current engine speed,<br />

rotate the Mode Switch to the TACH position.<br />

=_TU<br />

CgYdSX<br />

High RPM Recall Operation<br />

²DQSX³<br />

@_cYdY_^<br />

The PRT will store and display the highest engine speed<br />

achieved during a race. The high RPM recall is displayed by<br />

the tachometer pointer when in “RECALL” mode.<br />

1. Display high RPM memory.<br />

· Turn the igniton ON. The engine MAY be running.<br />

· Rotate the Mode Switch to the “RECALL” position.<br />

=_TU<br />

CgYdSX<br />

²BUSQ\\³<br />

@_cYdY_^<br />

· The pointer will move to indicate the high RPM stored<br />

by the tachometer.<br />

· Rotate the Mode Switch to the “TACH” position to<br />

return to normal tachometer operation.<br />

2. Resetting the memory.<br />

· Turn the ignition ON. The engine MAY be running.<br />

· Rotate the Mode Switch to the “RECALL” position.<br />

NOTE: The PRT memory cannot be RESET if<br />

the Mode Switch is not in the “RECALL”<br />

position.<br />

· The pointer will move to indicate the high RPM stored<br />

by the tachometer.<br />

· Press the RESET button.<br />

BUcUd<br />

2edd_^<br />

=_TU<br />

CgYdSX<br />

=ecd2U<br />

Y^dXU<br />

²BUSQ\\³<br />

@_cYdY_^<br />

· The pointer will drop to zero. (If the engine is running,<br />

the pointer will drop to the current engine speed.)<br />

· Rotate the Mode Switch to the “TACH” position to<br />

return to normal tachometer operation.<br />

VDO North America, LLC. warrants all merchandise against defects in factory workmanship<br />

and materials for a period of 24 months after purchase. This warranty<br />

applies to the first retail purchaser and covers only those products exposed to<br />

normal use or service. Provisions of this warranty shall not apply to a VDO product<br />

used for a purpose for which it is not designed, or which has been altered in any<br />

way that would be detrimental to the performance or life of the product, or misapplication,<br />

misuse, negligence or accident. On any part or product found to be<br />

defective after examination by VDO North America, VDO North America will only<br />

Siemens VDO Limited Warranty<br />

repair or replace the merchandise through the original selling dealer or on a direct<br />

basis. VDO North America assumes no responsibility for diagnosis, removal and/<br />

or installation labor, loss of vehicle use, loss of time, inconvenience or any other<br />

consequential expenses. The warranties herin are in lieu of any other expressed or<br />

implied warranties, including any implied warranty of merchantability or fitness,<br />

and any other obligation on the part of VDO North America, or selling dealer.<br />

(NOTE: This is a “Limited Warranty” as defined by the Magnuson-Moss Warranty<br />

Act of 1975.)<br />

Siemens VDO . http://sso-usa.siemensvdo.com/ . Phone: 1-800-265-1818

PP<br />

<br />

3DQHO<br />

*DXJH<br />

➊ BEGIN HERE<br />

CAUTION: Read these instructions thoroughly<br />

before making installation. Do not deviate from<br />

assembly or wiring instructions. Always<br />

disconnect battery ground before making any<br />

electrical connections. If in doubt, please<br />

contact your dealer or VDO Instruments at 1-800-<br />

265-1818.<br />

General Information:<br />

Your VDO mechanical temperature gauge<br />

features the latest illumination technology<br />

and a rugged design to insure years of durable<br />

and reliable operation. This instrument<br />

may require additional adapters to<br />

complete installation with various engines.<br />

You may purchase these adapters from your<br />

VDO dealer.<br />

Gauge Installation:<br />

1. Select the location where you will mount<br />

the gauge, and mark a center point for a<br />

hole (or use a VDO Mounting Accessory<br />

[1,2, & 3 hole chrome and black] or a VDO<br />

Mounting Cup [chrome or black]).<br />

2. Cut a 2⁵⁄₈" (65 mm) diameter hole for<br />

the temperature gauge. Place the instrument<br />

into the hole. If the gauge is too snug,<br />

use a file to slightly enlarge the opening<br />

until the gauge fits properly. (Diagram A)<br />

4. Slip the mounting bracket over the<br />

mounting bolts on the back of the gauge.<br />

Screw on the accompanying nuts. Tighten<br />

the nuts until the gauge can no longer be<br />

rotated by hand. DO NOT OVER-<br />

TIGHTEN!<br />

Diagram A<br />

Gauge Dimensions<br />

0RXQWLQJ<br />

%UDFNHW<br />

Parts List<br />

Item Description Quantity<br />

1. Temperature Gauge (2⁵⁄₈" [65 mm] diameter) 1<br />

2. ½" Adapter 1<br />

3. Lamp Socket 1<br />

4. Light Bulb 1<br />

5. VDO Mounting Bracket and nuts 1<br />

6. Installation Instructions 1<br />

CAUTION!!!<br />

The bezel diameter is only a few millimeters<br />

larger than the gauge itself.<br />

With that in mind, measure and precisely<br />

mark the gauge location before<br />

cutting any holes!<br />

Siemens VDO Limited Warranty<br />

VDO North America warrants all merchandise against defects in factory workmanship and materials for a period of 24 months after purchase. This<br />

warranty applies to the first retail purchaser and covers only those products exposed to normal use or service. Provisions of this warranty shall not<br />

apply to a VDO product used for a purpose for which it is not designed, or which has been altered in any way that would be detrimental to the<br />

performance or life of the product, or misapplication, misuse, negligence or accident. On any part or product found to be defective after examination<br />

by VDO North America, VDO North America will only repair or replace the merchandise through the original selling dealer or on a direct basis. VDO<br />

North America assumes no responsibility for diagnosis, removal and/or installation labor, loss of vehicle use, loss of time, inconvenience or any other<br />

consequential expenses. The warranties herein are in lieu of any other expressed or implied warranties, including any implied warranty of merchantability<br />

or fitness, and any other obligation on the part of VDO North America, or selling dealer.<br />

(NOTE: This is a “Limited Warranty” as defined by the Magnuson-Moss Warranty Act of 1975.)<br />

Siemens VDO . http://sso-usa.siemensvdo.com/ . Phone: 1-800-265-1818<br />

Siemens® VDO<br />

Tools and Materials Needed For Installation:<br />

16 Gauge stranded, insulated wire<br />

Insulated ¼" spade connectors<br />

2⁵⁄₈" hole saw<br />

Drill and drill bit set<br />

Instruction Sheet #0 515 011 805<br />

Half-round file<br />

Rev. 07/03<br />

Tape measure or ruler<br />

Small tools: wrench or nut driver, utility<br />

knife, pliers, etc.<br />

Various engine adapters To Begin, go to #➊<br />

Mechanical Temperature Gauge<br />

Installation Instructions<br />

INSTRUCTIONS FOR THE INSTALLATION OF THE MECHANICAL TEMPERATURE<br />

GAUGE ARE CONTAINED HEREIN. USE IS RESTRICTED TO 12-VOLT NEGATIVE<br />

GROUND ELECTRICAL SYSTEMS. LIGHT BULB, IF SUPPLIED, IS 12 VOLTS.

➋ CONTINUE HERE<br />

Gauge Hookup and Lamp Wiring:<br />

1. Drill a ⁷⁄₈" hole in the firewall. Route<br />

the capillary tube from the gauge through<br />

the hole in the firewall to the engine. DO<br />

NOT CRIMP the tubing closed during<br />

routing. A rubber grommet is recommended<br />

around the tubing where it passes<br />

through the firewall.<br />

2. Determine whether you will need the<br />

supplied ½" adapter to connect the capillary<br />

tube to the engine. (See Diagram B)<br />

3. If you do not need any adapters, attach<br />

the tubing to the engine using the ¼" selfsealing<br />

nut. If you need the ½" adapter,<br />

install it in the engine port. Then insert<br />

the heat sensing bulb and sealing nut into<br />

the ½" adapter and carefully tighten the<br />

sealing nut. (See a VDO catalog if a different<br />

type of adapter is necessary.)<br />

DO NOT OVERTIGHTEN THE SEAL-<br />

ING NUTS OR YOU WILL DAMAGE<br />

THE TUBING!<br />

4. Run the wire from the gauge lamp socket<br />

to the lighting circuit (a +12 volt source,<br />

usually after the light switch fuse in the fuse<br />

box). See Diagram B.<br />

At this point, installation is complete.<br />

Recheck the routing of the tube from the<br />

gauge to the engine.<br />

CAUTION:<br />

Make sure the tube is absolutely<br />

free from moving and/or hot<br />

engine components, and that it<br />

is totally free of kinks.<br />

Start the engine and turn on the lights to<br />

make sure the gauge illumination functions<br />

properly. If it doesn't, recheck your connections<br />

and your wiring. Make sure the<br />

housing of the gauge is grounded. Check<br />

all tubing connections for leaks.<br />

/DPS6RFNHW<br />

6HOIJURXQGHGWR<br />

LQVWUXPHQWKRXVLQJ<br />

*URXQGWR<br />

LQVWUXPHQW<br />

KRXVLQJ<br />

)XVH<br />

%R[<br />

%HVXUHKRXVLQJ<br />

LVJURXQGHG<br />

&DSLOODU\7XELQJ<br />

è$GDSWRU<br />

/LJKW<br />

6ZLWFK<br />

%DWWHU\<br />

*URXQG<br />

6HDOLQJ<br />

$GDSWRU<br />

1XW<br />

+HDW<br />

6HQVLQJ<br />

%XOE<br />

Diagram B<br />

Gauge hookup and lamp wiring information