Updating Bituminous Stabilized Materials Guidelines Mix Design Report Phase II

Moisture Sensitivity: Part II (Validation) - Asphalt Academy

Moisture Sensitivity: Part II (Validation) - Asphalt Academy

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

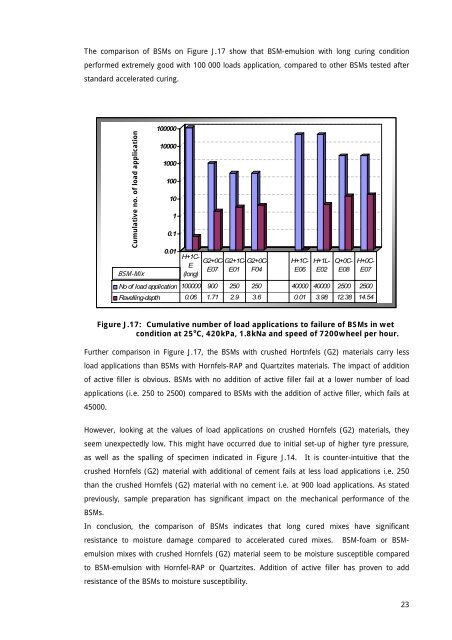

The comparison of BSMs on Figure J.17 show that BSM-emulsion with long curing condition<br />

performed extremely good with 100 000 loads application, compared to other BSMs tested after<br />

standard accelerated curing.<br />

Cumulative no. of load application<br />

BSM-<strong>Mix</strong><br />

100000<br />

10000<br />

1000<br />

100<br />

10<br />

1<br />

0.1<br />

0.01<br />

H+1C-<br />

E<br />

(long)<br />

G2+0C-<br />

E07<br />

G2+1C-<br />

E01<br />

G2+0C-<br />

F04<br />

H+1C-<br />

E06<br />

H+1L-<br />

E02<br />

Q+0C-<br />

E08<br />

H+0C-<br />

E07<br />

No of load application 100000 900 250 250 40000 40000 2500 2500<br />

Ravelling-depth 0.06 1.71 2.9 3.6 0.01 3.98 12.38 14.54<br />

Figure J.17: Cumulative number of load applications to failure of BSMs in wet<br />

condition at 25 o C, 420kPa, 1.8kNa and speed of 7200wheel per hour.<br />

Further comparison in Figure J.17, the BSMs with crushed Hortnfels (G2) materials carry less<br />

load applications than BSMs with Hornfels-RAP and Quartzites materials. The impact of addition<br />

of active filler is obvious. BSMs with no addition of active filler fail at a lower number of load<br />

applications (i.e. 250 to 2500) compared to BSMs with the addition of active filler, which fails at<br />

45000.<br />

However, looking at the values of load applications on crushed Hornfels (G2) materials, they<br />

seem unexpectedly low. This might have occurred due to initial set-up of higher tyre pressure,<br />

as well as the spalling of specimen indicated in Figure J.14. It is counter-intuitive that the<br />

crushed Hornfels (G2) material with additional of cement fails at less load applications i.e. 250<br />

than the crushed Hornfels (G2) material with no cement i.e. at 900 load applications. As stated<br />

previously, sample preparation has significant impact on the mechanical performance of the<br />

BSMs.<br />

In conclusion, the comparison of BSMs indicates that long cured mixes have significant<br />

resistance to moisture damage compared to accelerated cured mixes. BSM-foam or BSMemulsion<br />

mixes with crushed Hornfels (G2) material seem to be moisture susceptible compared<br />

to BSM-emulsion with Hornfel-RAP or Quartzites. Addition of active filler has proven to add<br />

resistance of the BSMs to moisture susceptibility.<br />

23