Unimog

Download magazine - Mercedes-Benz

Download magazine - Mercedes-Benz

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

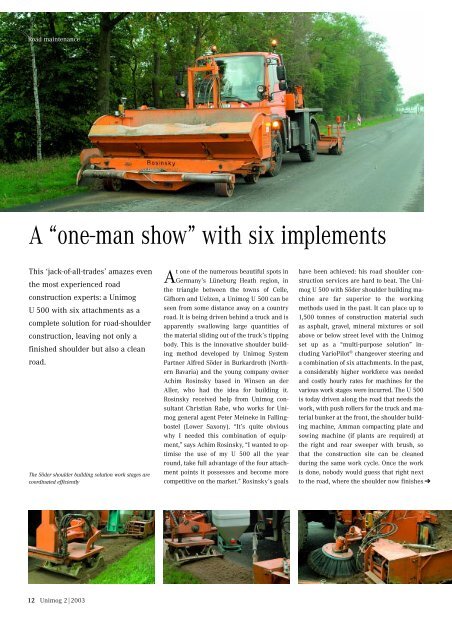

Road maintenance<br />

A “one-man show” with six implements<br />

This ‘jack-of-all-trades’ amazes even<br />

the most experienced road<br />

construction experts: a <strong>Unimog</strong><br />

U 500 with six attachments as a<br />

complete solution for road-shoulder<br />

construction, leaving not only a<br />

finished shoulder but also a clean<br />

road.<br />

The Söder shoulder building solution work stages are<br />

coordinated efficiently<br />

At one of the numerous beautiful spots in<br />

Germany’s Lüneburg Heath region, in<br />

the triangle between the towns of Celle,<br />

Gifhorn and Uelzen, a <strong>Unimog</strong> U 500 can be<br />

seen from some distance away on a country<br />

road. It is being driven behind a truck and is<br />

apparently swallowing large quantities of<br />

the material sliding out of the truck’s tipping<br />

body. This is the innovative shoulder building<br />

method developed by <strong>Unimog</strong> System<br />

Partner Alfred Söder in Burkardroth (Northern<br />

Bavaria) and the young company owner<br />

Achim Rosinsky based in Winsen an der<br />

Aller, who had the idea for building it.<br />

Rosinsky received help from <strong>Unimog</strong> consultant<br />

Christian Rabe, who works for <strong>Unimog</strong><br />

general agent Peter Meineke in Fallingbostel<br />

(Lower Saxony). “It’s quite obvious<br />

why I needed this combination of equipment,”<br />

says Achim Rosinsky, “I wanted to optimise<br />

the use of my U 500 all the year<br />

round, take full advantage of the four attachment<br />

points it possesses and become more<br />

competitive on the market.” Rosinsky’s goals<br />

have been achieved: his road shoulder construction<br />

services are hard to beat. The <strong>Unimog</strong><br />

U 500 with Söder shoulder building machine<br />

are far superior to the working<br />

methods used in the past. It can place up to<br />

1,500 tonnes of construction material such<br />

as asphalt, gravel, mineral mixtures or soil<br />

above or below street level with the <strong>Unimog</strong><br />

set up as a “multi-purpose solution” including<br />

VarioPilot® changeover steering and<br />

a combination of six attachments. In the past,<br />

a considerably higher workforce was needed<br />

and costly hourly rates for machines for the<br />

various work stages were incurred. The U 500<br />

is today driven along the road that needs the<br />

work, with push rollers for the truck and material<br />

bunker at the front, the shoulder building<br />

machine, Amman compacting plate and<br />

sowing machine (if plants are required) at<br />

the right and rear sweeper with brush, so<br />

that the construction site can be cleaned<br />

during the same work cycle. Once the work<br />

is done, nobody would guess that right next<br />

to the road, where the shoulder now finishes ➔<br />

12 <strong>Unimog</strong> 2|2003