Unimog

Download magazine - Mercedes-Benz Norge

Download magazine - Mercedes-Benz Norge

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.mercedes-benz.com | June 2003<br />

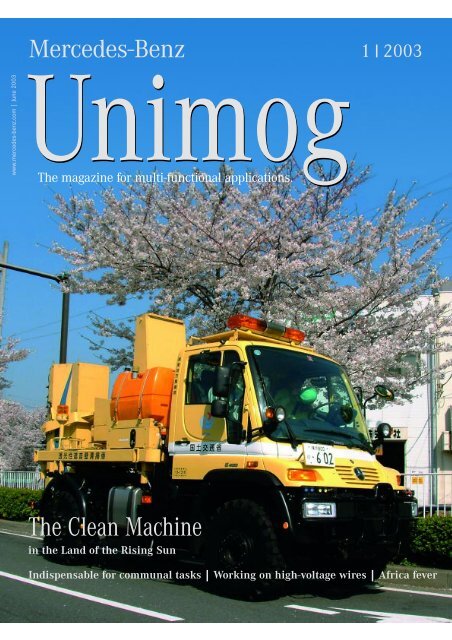

Mercedes-Benz<br />

<strong>Unimog</strong><br />

The magazine for multi-functional applications.<br />

1 | 2003<br />

The Clean Machine<br />

in the Land of the Rising Sun<br />

Indispensable for communal tasks | Working on high-voltage wires | Africa fever<br />

<strong>Unimog</strong> 1|2003 1

Contents<br />

Road maintenance 14<br />

The roads must be clean! This is an attitude<br />

shared by employees of the Salzburg road<br />

maintenance authorities<br />

Power industry 8<br />

Not the usual kind<br />

of workplace. A<br />

U 500 is an<br />

important element<br />

in the tasks carried<br />

out by the e.on<br />

company’s<br />

engineers on highvoltage<br />

wires<br />

Fighting forest fires 20<br />

Pushing back the flames. A U 400 is a reliable tool for firefighters in<br />

the mountains around Salamanca, Spain<br />

P u b l i s h e r ’ s d a t a<br />

Publisher:<br />

DaimlerChrysler AG, <strong>Unimog</strong> Division<br />

Responsible at publisher:<br />

Dieter Sellnau, <strong>Unimog</strong> Division<br />

Co-ordination:<br />

Martin Adam, <strong>Unimog</strong> Division<br />

Editorial committee:<br />

Martin Adam, Dieter Mutard,<br />

Karin Weidenbacher<br />

Contributors to this issue:<br />

Texts and photos: Dieter Mutard, Stefan Loeffler,<br />

Petra Forberger, <strong>Unimog</strong> Division<br />

English translations: Colin Brazier, Munich<br />

Editorial office address:<br />

DaimlerChrysler AG, <strong>Unimog</strong> Division,<br />

Sales Marketing, 76568 Gaggenau, Germany<br />

Production:<br />

Dieter Mutard DWM Pressebüro und Verlag,<br />

Ringstrasse 11, 89081 Ulm, Germany<br />

The next issue will be published in the autumn of<br />

2003. The publishers accept no responsibility for<br />

unsolicited copy or photographs.<br />

Printed on paper bleached without chlorine<br />

Printed in the Federal Republic of Germany<br />

Public-authority use 4<br />

An indispensable helper at the municipal<br />

construction yard in Gummersbach<br />

Winter services 7<br />

How Marktleuthen in Germany’s Fichtelgebirge<br />

region keeps its roads free of snow<br />

Power industry 8<br />

Working on high-voltage wires<br />

Presentations 10<br />

Winter realities<br />

DaimlerChrysler Worldwide 12<br />

Road maintenance 14<br />

Spring-clean in Salzburg<br />

Power industry 16<br />

Unbeatable in Toggenburg<br />

Official snow clearing machines 18<br />

at the World Skiing Championships<br />

Fighting forest fires 20<br />

A U 400 guarantees safe working conditions<br />

for firemen in Spain<br />

UNISCOPE 22<br />

<strong>Unimog</strong> museum in the Murg valley<br />

5,555 <strong>Unimog</strong>s in Switzerland<br />

Tourist vehicle<br />

Africa fever<br />

DaimlerChrysler Worldwide<br />

The Shinkansen goes to Taiwan 12<br />

Cleaning up in the Land of the 13<br />

Rising Sun<br />

<strong>Unimog</strong> 1|2003 3

Communal use<br />

An indispensable helper<br />

The public works experts in the town of Gummersbach know very well<br />

how important the <strong>Unimog</strong> is for their job. It can be used all the year<br />

round. For external municipal service providers, too, the <strong>Unimog</strong> is an<br />

essential precondition for doing business with public works departments.<br />

Köln<br />

Zentrum<br />

Genkeltalsperre<br />

Aggertal<br />

sperre<br />

Hagen<br />

Dortmund<br />

Siegen<br />

Giessen<br />

Frankfurt<br />

The town of Gummersbach, in Germany’s<br />

Oberbergisches Land region and within<br />

the city triangle formed by Cologne/Bonn,<br />

Hagen/Dortmund and Siegen, has one or two<br />

exceptional things to offer. It may not be<br />

widely known that the German record champion<br />

handball team and multiple European<br />

Handball Cup winner VfL Gummersbach<br />

hails from here. The town’s total area of<br />

100 square kilometres (according to the map)<br />

is surprising enough, as is the fact that its<br />

public works department has to maintain<br />

300 kilometres of public roads and another<br />

300 of agricultural tracks. This is no easy<br />

task, in view of Gummersbach’s topography,<br />

which extends from 200 metres above sea<br />

level at the lowest to 512 m at the highest<br />

point.<br />

Ekkehard Mesch, the active and highly experienced<br />

manager of Gummersbach’s public<br />

works depot, knows what he is talking about,<br />

and confesses frankly: “We couldn’t do without<br />

our <strong>Unimog</strong> implement carriers.” This is<br />

because of the region’s special geographical<br />

features and also the depot’s organisational<br />

tasks within the overall pattern of municipal<br />

services, which include road maintenance in<br />

town, canal maintenance, gully emptying and<br />

various environmental protection measures.<br />

Köln<br />

Gummersbach, Germany, is very close to the densely<br />

populated urban areas of Cologne and Dortmund<br />

Olpe<br />

Mesch’s team is responsible for the structural<br />

maintenance of municipal buildings<br />

and also various tasks for the horticultural<br />

and cemetery authorities, grass and woodland<br />

area care and of course playgrounds<br />

and sports fields. Ekkehard Mesch commissions<br />

selected external municipal service<br />

providers from the Gummersbach area for<br />

some of these extensive tasks. One of the<br />

fundamental preconditions when choosing<br />

the service providers has always been that<br />

they should have one or more <strong>Unimog</strong> implement<br />

carriers in their fleet, so that the<br />

working attachments are fully compatible<br />

with <strong>Unimog</strong> technology – and therefore<br />

with the equipment available at the municipal<br />

depot. Three service providers based in<br />

the direct vicinity and their <strong>Unimog</strong> implement<br />

carriers work on behalf of the Gummersbach<br />

public works department. Additional<br />

trucks only have to be hired in the<br />

winter, when large quantities of snow often<br />

have to be removed.<br />

The main tasks of the yard’s own <strong>Unimog</strong>s<br />

(two U 300, two U 1400 and one U 1000) and<br />

the external service providers’ vehicles are<br />

winter services, mowing and trimming work<br />

and road maintenance. Ekkehard Mesch and<br />

the group of qualified craftsmen and foremen<br />

who work with the <strong>Unimog</strong> daily are<br />

convinced: “In urban streets and similar often<br />

confined spaces, the <strong>Unimog</strong>s are considerably<br />

faster and easier to manoeuvre<br />

than conventional trucks. What’s more,<br />

these implement carriers built in Wörth possess<br />

a high safety potential in addition to all<br />

their other advantages.”<br />

The public works depot with its 67 employees<br />

is an established element in the activities<br />

of the town of Gummersbach, partly<br />

due to the fact that it has frequently been at<br />

the centre of events during very bad weather<br />

in the recent past. A sandbag filling machine<br />

designed by Ekkehard Mesch and his colleagues<br />

Reinhard Sauermann and Oliver<br />

Karp, which passed its first crucial test at the<br />

turn of the year, has attracted a lot of attention.<br />

It was used by the depot staff to fill<br />

1,000 sandbags within a very short time in<br />

order to protect an industrial company’s<br />

premises during a flood.<br />

Ekkehard Mesch had the idea for this device<br />

when he saw TV pictures of hundreds of<br />

helpers with shovels filling sandbags during<br />

The complete <strong>Unimog</strong><br />

fleet operated by the<br />

public works authority in<br />

Gummersbach –<br />

including three U 1000s<br />

owned by external<br />

communal service<br />

providers (left)<br />

4 <strong>Unimog</strong> 1|2003

The public works department’s Mercedes-Benz <strong>Unimog</strong> and Atego are a familiar sight on Gummersbach’s streets<br />

the River Elbe floods in 2002. He didn’t<br />

understand why they had to do it this way,<br />

and immediately started developing a simple<br />

yet practical piece of equipment with the<br />

help of his colleagues. They modified a winter-service<br />

spreader attachment – and the result<br />

of this inventive work is today highly<br />

praised by the Gummersbach fire brigade<br />

and the disaster teams of the Technisches<br />

Hilfswerk (THW). It is particularly useful to<br />

be able to work directly where the sandbags<br />

are needed. “We are logistically much more<br />

flexible with this piece of equipment,” confirms<br />

the senior Gummersbach fire officer,<br />

Friedhelm Köster.<br />

Thanks to the dedication of its manager<br />

and the hard work of its staff, the municipal<br />

public works department has become wellknown<br />

throughout the Oberbergisches Land<br />

region. Its staff members are ever present,<br />

helpful and alert during practical day-to-day<br />

activities and at special events. It comes as<br />

no surprise, then, that shortly after reunification<br />

a partnership with the East German<br />

town of Burg in Saxony-Anhalt was established.<br />

The aim of this was for Ekkehard<br />

Mesch and his team to support their colleagues<br />

in Eastern Germany in word and<br />

deed. The present handed over at the start of<br />

this partnership, incidentally, was a <strong>Unimog</strong><br />

U 1000 that had been technically overhauled<br />

and prepared for use in Gummersbach. ■<br />

25-kilogram sandbags can be filled in a matter of seconds: With no injuries, no shovel and no lost sand! The<br />

<strong>Unimog</strong> allows this important dam strengthening material to be stacked and built up directly in the flooded area<br />

<strong>Unimog</strong> 1|2003 5

Communal use<br />

The <strong>Unimog</strong> is a regular<br />

sight in day-to-day work<br />

Ekkehard Mesch, public works department manager<br />

in the largest town of Germany’s Oberbergisches Land<br />

region for more than 35 years, has developed a<br />

sandbag filling machine with his colleagues that is an<br />

invaluable and logistically efficient aid in disaster<br />

situations<br />

In the interview below, Ekkehard Mesch,<br />

who has been the Gummersbach municipal<br />

works department’s manager for more<br />

than 3 decades, answers questions that<br />

come up again and again in day-to-day communal<br />

service work. With his many years of<br />

experience, he can certainly speak on behalf<br />

of many municipal authorities, since the<br />

tasks required in their daily work are largely<br />

identical. The decisive factors here are for<br />

vehicles and equipment to be used to optimum<br />

capacity, for economy, efficient work<br />

methods and absolute reliability.<br />

? When did the town of Gummersbach start<br />

to use Mercedes-Benz <strong>Unimog</strong> implement carriers<br />

and how many vehicles do you have, including<br />

those owned by external service<br />

providers? What are their main tasks?<br />

➜ E. M.: “Gummersbach has been using<br />

<strong>Unimog</strong>s for more than 35 years now. The<br />

municipal depot currently operates two<br />

U 300s, two U 1400s and one U 1000. The<br />

service providers working for us own three<br />

more U 1000s. The main tasks are carrying<br />

out winter services, mowing and trimming<br />

work and road maintenance.”<br />

? Was their use of <strong>Unimog</strong> equipment an this is asking too much of our service<br />

important precondition when choosing external<br />

service providers?<br />

providers, so in busy periods trucks are<br />

sometimes used. But as you see, the answer<br />

➜ E. M.: “The service providers are mostly to your question is a definite ‘yes’!”<br />

engaged to perform winter services. In urban<br />

areas, the <strong>Unimog</strong> allows them to work faster ? An important purchasing criterion for a<br />

and with better manoeuvrability and flexibility<br />

than any other vehicle.”<br />

vehicle system is economy. What makes the<br />

<strong>Unimog</strong> interesting in this particular respect<br />

for the Gummersbach public works department?<br />

? Why are there such frequent floods in the<br />

Oberbergisches Land region and what is the ➜ E. M.: “The fact that no comparable im-<br />

<strong>Unimog</strong> used for in the event of flooding?<br />

➜ E. M.: “The floods are mainly caused by<br />

climatic changes and different altitudes. In<br />

the flooded areas, the <strong>Unimog</strong> is primarily<br />

used for logistic tasks and for supplying the<br />

helpers with road signs, sandbags etc., but<br />

also for recovering floating objects.”<br />

? Have you been able to pass on your sandbag<br />

filling technique to other rescue and public<br />

works organisations?<br />

➜ E. M.: “The fire brigade and the German<br />

THW are most enthusiastic about the sandbag<br />

filling machine. It makes filling the large<br />

quantities of sandbags so urgently required<br />

in flood situations much easier and guarantees<br />

fast and efficient action.”<br />

? Can the <strong>Unimog</strong> all-terrain implement<br />

carrier be used for all the tasks that have to be<br />

performed in Gummersbach?<br />

➜ E. M.: “The <strong>Unimog</strong> has greater manoeuvrability,<br />

is faster, provides a better view<br />

of the work area and is more practical to use<br />

than many of its competitors. The service<br />

providers’ other vehicles are naturally suitable<br />

for certain situations, but none of them<br />

cover such a broad range of applications as<br />

our <strong>Unimog</strong> implement carriers do, thanks to<br />

their basic concept. The service providers<br />

have a truck which they use for transport<br />

purposes and modify for winter service.<br />

With our topography, we would prefer to use<br />

only <strong>Unimog</strong> implement carriers for winter<br />

service, but for just a few weeks per year,<br />

plement carrier is available as far as usability,<br />

functionality and safety are concerned,<br />

especially for winter services, has so<br />

far fully convinced all the decision committees,<br />

despite the fact that the vehicle seems<br />

relatively expensive at first glance.”<br />

? Let’s talk about driver satisfaction. Do<br />

they appreciate the many improvements that<br />

have been incorporated into the latest U 300 –<br />

U 500 implement-carrier family? How important<br />

is driving comfort for municipal use?<br />

➜ E. M.: “If you will allow me to exaggerate<br />

slightly, a new era began for the Gummersbach<br />

public works staff when the first<br />

U 300 joined the fleet in January 2001. As<br />

far as comfort and convenience are<br />

concerned, I would like to mention the lownoise<br />

driver’s cab and the 360-degree view<br />

in particular, which is ideal for the driver or<br />

operator. My colleagues also very much appreciate<br />

the air-sprung driver’s seat. Other<br />

positive factors are having air conditioning<br />

as standard equipment, the ergonomically<br />

arranged controls and, last but not least, the<br />

EPS gear shift system for top-class driving<br />

comfort. The U 300 covered more than<br />

16,000 kilometres (800 operating hours) in<br />

its first full year of winter and summer service.<br />

From the drivers’ point of view, the concept<br />

on which the <strong>Unimog</strong> U 300 – U 500 implement<br />

carriers are based offers them<br />

excellent driving and operating comfort,<br />

which is an aspect not to be underestimated<br />

in day-to-day work.”<br />

■<br />

6 <strong>Unimog</strong> 1|2003

Convincing arguments<br />

Glittering snow everywhere, piled deeply in the forests. This wonderful winter scenery is attractive, but can<br />

be treacherous too. In the little town of Marktleuthen in the midst of Germany’s Fichtelgebirge region, a<br />

U 1400 and a U 400 make sure that the roads remain passable at all times.<br />

Wolfgang Theinert and his team have<br />

been responsible for maintaining the<br />

roads and paths in Marktleuthen for 26<br />

years, and have used <strong>Unimog</strong>s for almost as<br />

long a period. A U 406 was a reliable tool for<br />

24 years before being succeeded by a U 400<br />

in 2002. Just a year before, the community<br />

had purchased an additional U 1400. “The<br />

<strong>Unimog</strong> has never let us down. The infrequent<br />

need for repairs and its demonstrably<br />

long operating life were the most convincing<br />

arguments in favour of the decision<br />

to buy another <strong>Unimog</strong>,” the communal public<br />

works manager explains.<br />

Four drivers and three road workers perform<br />

maintenance work on Marktleuthen’s<br />

narrow roads and hilly gradients all the year<br />

round. Snow has to be cleared from some 80<br />

kilometres of road, often several times a day,<br />

and both <strong>Unimog</strong> are equipped with a<br />

Schmidt snow plough and a Gmeiner spreading<br />

attachment. In summer, the roads have<br />

to be swept and repaired, grass must be cut<br />

and sandbags transported when, as was the<br />

case last year, the River Eger, although<br />

small, bursts its banks.<br />

“At the beginning, we had to get accustomed<br />

to the new-look U 400,” grins Wolfgang<br />

Thumser, Wolfgang Theinert’s colleague and<br />

U 1400 driver, but he became convinced of<br />

the U 400’s merits quite a while back. “On<br />

narrow roads in particular, where you sometimes<br />

have only millimetres to spare when<br />

manoeuvring, the high seat position and the<br />

panorama window provide a unique view that<br />

makes our work so much easier,” explains<br />

Wolfgang Theinert. Wolfgang Thumser<br />

praises the new joystick gearshift that “is intelligent<br />

and makes frequent, rapid gear<br />

changes easy.” Anybody who has spent<br />

many years of his working life in a <strong>Unimog</strong><br />

appreciates how comfortable this workplace<br />

has now become. “When I drive the new<br />

U 400, I sometimes feel like the pilot of an<br />

airliner!” says Theinert with a smile. For<br />

him, there is no doubt: “The <strong>Unimog</strong> has<br />

been dramatically improved. There are<br />

worlds between past-generation <strong>Unimog</strong>s<br />

and the U 400 as far technology and other<br />

design features are concerned.” The power<br />

output of the implement carrier naturally<br />

adds to this positive impression. With its<br />

177-hp (130-kW) engine, the U 400 has more<br />

tractive power, which is evident on uphill<br />

gradients in particular. The ability to get<br />

from place to place rapidly and the higher<br />

payload make it very economical to use,<br />

which in turn has a positive effect on the local<br />

authority’s budget. This is why the people<br />

in Marktleuthen are satisfied with their<br />

investment and proud to be able to provide a<br />

“safe” winter environment for locals and visitors<br />

alike.<br />

■<br />

Hof<br />

Marktleuthen<br />

Bayreuth Landkreis<br />

Wunsiedel<br />

Nürnberg<br />

Bayern<br />

München<br />

Wolfgang Thumser (left)<br />

and Wolfgang Theinert<br />

(in small photograph)<br />

agree: “The <strong>Unimog</strong> has<br />

been dramatically<br />

improved.”<br />

<strong>Unimog</strong> 1|2003 7

Power industry<br />

Working on high-voltage wires<br />

Simply unimaginable for the uninitiated, but daily routine for the Bavarian<br />

power supply company e.on Bayern’s technicians: working on 20,000-Volt<br />

high-tension wires. The necessary safety preconditions for this work are<br />

provided by a <strong>Unimog</strong> and an elevating platform from equipment-system<br />

partner TIME Versalift.<br />

The e.on Bayern company uses a <strong>Unimog</strong><br />

U 500 all-terrain implement carrier for<br />

installation and maintenance tasks on its<br />

high-voltage electricity network. This model<br />

from the U 300 – U 500 product line is<br />

equipped with a special lifting work platform<br />

from US manufacturer and <strong>Unimog</strong><br />

equipment-system partner TIME Versalift.<br />

What’s so special about this, the first<br />

equipment combination of its kind in Germany,<br />

is that the installation technicians’<br />

working platform is insulated against contact<br />

with power supplies of up to 69,000<br />

Volts. This permits service and maintenance<br />

work on the medium-voltage overhead lines<br />

(MS) of the Bavarian electricity network at<br />

up to 20,000 Volts without having to switch<br />

off the entire power supply system. Nor does<br />

the all-terrain <strong>Unimog</strong> have any problems in<br />

quickly and easily accessing locations where<br />

the masts and lines are situated, thanks to<br />

its permanent four-wheel drive, although the<br />

lines are usually spread out across open<br />

country.<br />

Working on high-voltage wires is still a<br />

fairly new technology for Germany’s energy<br />

suppliers, but it has already been tested successfully<br />

in many European countries. The<br />

technicians at e.on Bayern complete as many<br />

as four jobs under power (AuS) every day at<br />

heights of up to 19 metres on their mediumvoltage<br />

overhead lines operating at up to<br />

20,000 Volts that supply both private households<br />

and industry. Multiple safety systems<br />

protect the service team, the <strong>Unimog</strong> U 500<br />

and its highly insulated TIME Versalift lifting<br />

work platform against exposure to anything<br />

up to 69,000 Volts.<br />

The advantage of this technology is that<br />

most maintenance and repair work can be<br />

Nobody is interested in the view from up there right<br />

now! Before repairs can start, extensive insulating<br />

measures have to be carried out on the power lines<br />

carried out without switching off the power<br />

supply to customers. This is made possible<br />

solely by insulation of the work baskets and,<br />

consequently, of the vehicle and its superstructure.<br />

The TIME Versalift superstructure<br />

with elevating work platform (working<br />

height: up to 19 metres), a maximum load of<br />

900 kg, two personnel cages and an insulated<br />

boom that can be used with the<br />

power switched on, also has various storage<br />

The U 500’s well-planned elevating work-platform<br />

superstructure includes a number of practical storage<br />

compartments for insulating and protective material<br />

8 <strong>Unimog</strong> 1|2003

Power industry<br />

compartments for equipment, tools and<br />

working materials.<br />

The implement carrier is an all-terrain<br />

<strong>Unimog</strong> U 500 with a gross weight limit of<br />

14.3 tonnes and the powerful, well-proven<br />

205 kW (280 bhp) OM 906 LA 6-cylinder inline<br />

engine with charge-air intercooling. The<br />

only optional extra on e.on Bayern’s <strong>Unimog</strong><br />

with its four-wheel drive, but none the less a<br />

very important one, is the “tirecontrol” tyre<br />

pressure control system, which is ideal for<br />

off-road applications, particularly on surfaces<br />

that are not particularly firm. “The offroad<br />

<strong>Unimog</strong> U 500 implement carrier, with<br />

its progressive technology, is unparalleled in<br />

its versatility and range of applications –<br />

particularly with the Versalift work platform<br />

when we have to deal with power failures,”<br />

says Norbert Bursian, who is the vehicle coordination<br />

manager responsible for the entire<br />

service area at e.on Bayern’s Upper Franconian<br />

regional management offices, which<br />

are in the town of Bayreuth.<br />

Even though working on high-voltage<br />

wires is still classified as a pilot project, the<br />

financial advantages of the “<strong>Unimog</strong> plus<br />

equipment” system are already evident.<br />

Switching off the affected power supply<br />

lines, notifying customers of the power cut,<br />

the expensive installation of emergency<br />

power generating sets and comprehensive<br />

and cost-intensive switching work on the<br />

group control lines all become unnecessary<br />

with this equipment. No matter how long the<br />

repair work takes, the power never has to be<br />

switched off.<br />

■<br />

This peaceful scene on a meadow in Germany’s<br />

Fichtelgebirge mountains is somewhat misleading,<br />

since work on the electric lines requires the utmost<br />

concentration. The technicians are repairing the lines<br />

while the U 500 stands safely in the wet, low-lying<br />

terrain. The technicians can operate their equipment<br />

from the personnel cage<br />

<strong>Unimog</strong> 1|2003 9

Presentations<br />

Winter<br />

realities<br />

The <strong>Unimog</strong> Division held winter<br />

service presentations at nine<br />

locations all over Germany in<br />

February and March. One of these<br />

was at the Nürburg Ring motor<br />

racing circuit, where weather<br />

conditions were quite realistic.<br />

Nature still does it best! At the <strong>Unimog</strong><br />

Division’s winter service events in Germany,<br />

held this year from January 30 to<br />

March 6, there was no shortage of snow anywhere.<br />

At the Nürburg Ring, too, real-life<br />

winter weather supplied ideal conditions for<br />

the various equipment combinations to be<br />

demonstrated.<br />

An average of 500 guests attended each<br />

event and watched these well-prepared presentations<br />

of sample equipment applications<br />

with the satisfying feeling that “the <strong>Unimog</strong><br />

masters any situation”. This also confirmed<br />

that their companies’ decisions to purchase<br />

the <strong>Unimog</strong> were correct. The morning presentations<br />

at the Nürburg Ring, with the<br />

thermometer reading minus two degrees<br />

Celsius, heavy snowfall, icy roads and, in<br />

some places, deep snow on the track itself<br />

(which is usually reserved for potent racing<br />

cars), made it clear that the system combination<br />

of <strong>Unimog</strong> plus winter-service<br />

equipment is currently the most professional<br />

choice available on the market.<br />

A total of 14 presentation vehicles<br />

(three U 300s, eight U 400s and three<br />

U 500s) were equipped with the latest generations<br />

of snowplough and spreader equipment<br />

from system partners Gmeiner and<br />

Schmidt Winterdienst, as well as snow tillers<br />

and rotary snow-ploughs, also from Schmidt.<br />

The latter, made by the company based in<br />

St. Blasien in Germany’s Black Forest, are<br />

driven by the vehicle’s engine via the front<br />

power take-off shaft, which in most cases<br />

makes expensive superstructure modifications<br />

unnecessary.<br />

Regional Manager West Erich Mahler, who<br />

was largely responsible for the event tour,<br />

was very satisfied with customer attendance<br />

and the ideal weather conditions: “The<br />

equipment presentations and also the safety<br />

demonstrations with four-channel ABS were<br />

convincing evidence of the <strong>Unimog</strong>’s outstanding<br />

driving behaviour even in critical<br />

conditions.”<br />

■<br />

Above: Nürburg Castle in the winter light and a U 400<br />

equipped with a Schmidt snow tiller on its way to a<br />

presentation<br />

As the snow melted in the warm February sun, the<br />

experts gathered to discuss what they had seen<br />

10 <strong>Unimog</strong> 1|2003

Advertisements<br />

HIGH AND LOW PRESSURE TECHNOLOGY<br />

FOR THE NEW UNIMOG U 300 / U 400 / U 500<br />

MODEL SERIES<br />

Our range of products for the <strong>Unimog</strong>:<br />

✻ Universal high pressure cleaning<br />

equipment for front and rear installation<br />

✻ High-pressure surface cleaning<br />

equipment, also combined with front-end<br />

sweepers<br />

✻ High-pressure drain cleaning equipment<br />

for mounting on the platform subframe<br />

✻ Suction and rinsing containers with a<br />

total capacity of up to 7,000 litres<br />

✻ Municipal sludge suction vehicles with a<br />

total capacity of up to 8,000 litres<br />

✻ Water containers of up to 7,000 l<br />

✻ Special superstructures upon request<br />

(e.g. low pressure equipment, watering<br />

arms, hot water devices)<br />

Joachim Leistikow GmbH<br />

Altkönigstraße 2<br />

D-61138 Niederdorfelden<br />

Tel. (0) 6101 / 5364-0<br />

Fax. (0) 6101 / 33461<br />

Internet: http://www.leistikow-gmbh.de<br />

E-Mail: Vertrieb@leistikow-gmbh.de

DaimlerChrysler Worldwide Japan<br />

The Shinkansen goes to Taiwan<br />

In December 2000, the Taiwan High Speed Rail Corporation took the decision to purchase the Japanese<br />

Shinkansen high-speed train. Japanese companies were also commissioned to build the 330-kilometre rail track.<br />

Versatile German Mercedes-Benz <strong>Unimog</strong> implement carriers are being used on this large-scale Asian project.<br />

The state-owned company Japan Railway<br />

Construction Public Corporation (JRCC)<br />

was founded in 1964. JRCC built the existing<br />

systems, infrastructure and rail network for<br />

the Shinkansen and took delivery of its first<br />

<strong>Unimog</strong> implement carriers, U 1450 and<br />

U 1650 road-rail models equipped by <strong>Unimog</strong>’s<br />

equipment system partner Zweiweg,<br />

in 1993. No fewer than 79 have been purchased<br />

since, making the JRCC Japan’s<br />

largest customer for the ‘two-way <strong>Unimog</strong>’.<br />

The JRCC’s <strong>Unimog</strong>s are used as locomotives<br />

to pull freight cars containing railway<br />

construction materials and equipment, or as<br />

driverless antenna platforms when making<br />

electrical connections. “We bought the first<br />

<strong>Unimog</strong> during the Hokuriku Shinkansen<br />

construction phase,” says Mitsumi Iwasaki,<br />

JRCC’s deputy fleet manager. “This is one of<br />

the most difficult routes in the world. Our<br />

<strong>Unimog</strong>s are used to pull six work trains, each<br />

200 metres long with a weight of 12 tonnes,<br />

the rail vehicles on which these trains are<br />

transported and a tracklaying machine,<br />

which amounts to a total weight of 150<br />

Well-planned work processes and the wide range of<br />

tasks that the road-rail <strong>Unimog</strong> can perform are major<br />

features of the day-to-day working routines on the new<br />

lines being built for the Japanese high-speed trains<br />

tonnes. When we calculated the performance<br />

on the basis of the data specification,<br />

we found out that two <strong>Unimog</strong>s connected in<br />

tandem can perform the same task as the<br />

vehicles we used in the past, which were<br />

much heavier and more expensive.”<br />

The Hokuriku Shinkansen is the sixth<br />

Shinkansen track in Japan. It is used exclusively<br />

as a high-speed train route through<br />

the country’s very mountainous interior.<br />

Some sections of the Shinkansen track between<br />

Karuizawa and Nagano run in tunnel.<br />

During construction of this track, the<br />

JRCC developed its “building material transport<br />

by train” method, for which temporary<br />

tracks with a length of 200 metres are laid<br />

on the planned sections of the route and<br />

used to move construction materials to the<br />

actual track-laying point. The <strong>Unimog</strong>s are<br />

used to pull the freight cars with the rail<br />

tracks, the vehicles carrying concrete slabs<br />

and an actual construction vehicle in which<br />

the buffer layer of concrete mortar beneath<br />

the slabs is mixed, poured and kneaded.<br />

24 of the 79 <strong>Unimog</strong>s are used not for load<br />

movement but as ‘antenna platforms’ without<br />

drivers, for installing the Shinkansen’s<br />

power supply lines and insulators. No timeconsuming<br />

shunting movements are needed<br />

with the <strong>Unimog</strong>, which results in faster<br />

completion of the building projects, shorter<br />

work times and a reduction of some 30 percent<br />

in the construction costs.<br />

After the Hokuriku Shinkansen railway<br />

track had been completed in 1993, the<br />

JRCC’s road-rail <strong>Unimog</strong>s were next used for<br />

construction of the Tohoku Shinkansen<br />

(Morioka-Aomori) and have now been transferred<br />

to the Kyushu Shinkansen (Shin<br />

Yatsushiro-Nishi Kagoshima). The Kyushu<br />

Shinkansen is due to be opened in spring<br />

next year, but construction work is already<br />

almost finished. During work on this 127.6-<br />

kilometre track, a total of some 520 km of<br />

rails and 46,000 concrete slabs was transported<br />

by the <strong>Unimog</strong>s. At peak times during<br />

Kyushu Shinkansen track construction,<br />

nearly 70 <strong>Unimog</strong>s were in use at certain<br />

times.<br />

■<br />

12 <strong>Unimog</strong> 1|2003

Japan DaimlerChrysler Worldwide<br />

Cleaning up in the Land of<br />

the Rising Sun<br />

120 million people live in Japan, and own a total of 77 million cars.<br />

Residential areas are often located in the vicinity of busy roads. To keep<br />

these clean, the Road Maintenance authority of the Japanese Land,<br />

Infrastructure and Transport Ministry in Yokohama has been operating a<br />

<strong>Unimog</strong> U 400 since the spring of 2002.<br />

The Yokohama road maintenance authority<br />

is responsible for roads with a total<br />

length of 240 kilometres. A <strong>Unimog</strong> U 1450,<br />

initially used for snow removal in the mountains,<br />

has so far been employed on this task.<br />

More <strong>Unimog</strong>-specific equipment such as a<br />

tunnel cleaning device and a can collecting<br />

machine have now been acquired. According<br />

to the <strong>Unimog</strong> representative YANASE,<br />

based in Yokohama, no implement carrier as<br />

versatile as the Mercedes-Benz <strong>Unimog</strong> is<br />

currently available in Japan. A U 400 has<br />

now taken over from the U 1450 mentioned<br />

above. For the new U 400 implement carrier,<br />

the same equipment as on the U 1450 can be<br />

used, together with a special cleaning device<br />

for curved transparent walls.<br />

These noise insulation walls are made of<br />

polycarbonate for optimum visibility. The<br />

cleaning attachment for these transparent<br />

panels is equipped with a curved, rotating<br />

brush, 75 centimetres in diameter, that<br />

cleans the dirty area directly. The brush is<br />

mounted at the rear of the <strong>Unimog</strong> and can<br />

be rotated through 90 degrees toward the<br />

edge of the road (on an axis vertical to the<br />

direction of travel). Depending on how much<br />

the separating wall is curved, the brush can<br />

adopt a radius of between 2 and 4 metres.<br />

A private road maintenance company has<br />

leased several <strong>Unimog</strong>s from the Yokohama<br />

road maintenance authority as a subcontractor<br />

and has been using them for some time<br />

already. A company spokesperson<br />

commented on the positive effects of the<br />

<strong>Unimog</strong>’s performance in the following<br />

terms: “It used to take us six hours to clean<br />

a 600-metre noise insulation wall. Now we<br />

can clean the 600 metres within an hour.”<br />

One of the road maintenance authority’s<br />

employees with many years’ standing has<br />

the following to say about his new vehicle:<br />

“Some service vehicles are basically trucks.<br />

The <strong>Unimog</strong> is much better than these,<br />

particularly our U 400 with its VarioPilot<br />

changeover steering. Since we drive on the<br />

left in Japan, we can see the side of the road<br />

at all times. Using the changeover steering<br />

guarantees optimum 360-degree visibility<br />

and safe working. What’s more, our working<br />

conditions are more pleasant all year round<br />

thanks to the standard air-conditioning.”<br />

Smiling, he adds: “I am very happy to have<br />

this vehicle to work with!”<br />

The person responsible for the equipment<br />

adds to his colleague’s comments: “The<br />

purchase price of a <strong>Unimog</strong> chassis certainly<br />

cannot be compared with that of a singlepurpose<br />

vehicle, but thanks to its front power<br />

take-off shaft and the hydraulic system, the<br />

<strong>Unimog</strong> is very versatile and compatible with<br />

all kinds of add-on devices.”<br />

■<br />

Above: The brush of the cleaning device adjusts to the<br />

curve of the transparent wall<br />

<strong>Unimog</strong> in Japan: cherry blossom and high-tech<br />

<strong>Unimog</strong> 1|2003 13

Spring cleaning in Salzburg<br />

For the first time this year, temperatures are rising above 20 degrees<br />

Celsius. A few tourists wearing T-shirts are sitting in street cafés and on<br />

restaurant terraces. For them, winter is over for good. It’s not quite over<br />

yet for the Salzburg road maintenance authorities and their <strong>Unimog</strong><br />

implement carriers.<br />

Despite the fact that, with an area of just<br />

over 7,150 square kilometres, Salzburg<br />

is one of the smaller federal states in Austria,<br />

it has a varied and interesting topography. In<br />

the vicinity of the capital, which bears the<br />

same name as the state itself, it is relatively<br />

flat, becoming higher towards the south and<br />

reaching an altitude of 1,805 metres at the<br />

Radstädt Tauern pass. And halfway through<br />

April, when Salzburg citizens and Easter<br />

holiday visitors from Germany and Switzerland<br />

are already lying in the warm spring<br />

sun in the northern Flachgau near the<br />

German border, there are still up to two<br />

metres of snow on the mountain crests and<br />

peaks, for instance at the 1,600-metre Gerlos<br />

pass between Salzburg and Tyrol. “As late as<br />

mid-April this year, there were 40 centimetres<br />

of new snow in some of the more<br />

mountainous areas we are responsible for,”<br />

says Hans Gehmacher, who is the Salzburg<br />

State Government’s Deputy Road Maintenance<br />

Manager. It is his responsibility to<br />

purchase vehicles and equipment, including<br />

the newly four newly acquired <strong>Unimog</strong><br />

U 400s and one U 500. The Second President<br />

of Salzburg’s State Parliament , Johann Holztrattner,<br />

took delivery of the vehicles last<br />

August with the words: “We decided to<br />

purchase the <strong>Unimog</strong> because it can be used<br />

to carry a wide variety of equipment in<br />

winter and summer, guarantees clean, snowfree<br />

roads and is safe and convenient to<br />

operate.”<br />

The 170-kW (230-hp) vehicles, all with<br />

permanent four-wheel drive, Telligent gear<br />

shift, air-operated twin-circuit disc brakes<br />

with ABS, hydraulic power steering and a<br />

dual-circuit power hydraulic system, have<br />

been in use in Austria’s northernmost<br />

federal state ever since. They are operated by<br />

the road works departments in the Flachgau,<br />

Hallein and Bruck an der Glocknerstrasse<br />

and by the Salzburg ‘autobahn’ maintenance<br />

authority, which has also purchased another<br />

U 500 with 205-kW (280-hp) engine. Hans<br />

Gehmacher is responsible for up to 90 kilometres<br />

of ‘autobahn’ highway and some<br />

1,300 kilometres of federal and state roads.<br />

Altogether, 36 <strong>Unimog</strong> implement carriers<br />

are operated by the road authorities, and<br />

14 <strong>Unimog</strong> 1|2003

Working in picturesque<br />

scenery: the road<br />

maintenance authority<br />

staff’s tasks include<br />

cleaning reflector posts,<br />

to make driving in the<br />

Austrian Federal State of<br />

Salzburg as safe as<br />

possible<br />

Road maintenance<br />

have proved to be reliable helpers throughout<br />

the year and in any weather. “When<br />

snow is still falling at higher altitudes and<br />

we are already tidying up and carrying out<br />

maintenance work down in the plains, the<br />

fact that equipment can be changed so fast<br />

on the <strong>Unimog</strong> is a decisive advantage,”<br />

explains Hans Gehmacher. Another reason<br />

why the vehicles are so important for the<br />

Salzburg region, which depends so strongly<br />

on the tourist trade, is that they offer quite a<br />

few benefits that the visitors appreciate too:<br />

“With the <strong>Unimog</strong> and its snow ploughs,<br />

snow tillers and add-on spreading equipment,<br />

we can make it possible for as many<br />

winter tourists as possible to get up into the<br />

mountains and back down again without<br />

difficulty, even though not all of them have<br />

equipped their cars with winter tyres or<br />

snow chains.” While some of the <strong>Unimog</strong>s<br />

are still clearing snow on mountain roads,<br />

the remainder of the new vehicles are using<br />

reflector-post washing attachments, frontend<br />

sweepers and front chaff-cutters for the<br />

first spring clean-up on the roads elsewhere<br />

in the Federal State of Salzburg. ■<br />

With a Schmidt front-end sweeper attachment, the U 400 cleans up the site of road works without interrupting the<br />

flow of traffic<br />

Hans Gehmacher (right) and his team appreciate the fact that equipment can be changed so fast on the <strong>Unimog</strong><br />

Installing new reflector posts on the road to Grossgmain, not far from the city of Salzburg’<br />

15

Unbeatable in Toggenburg<br />

Working conditions for<br />

SAK’s installation staff in<br />

the Toggenburg mountain<br />

region have little to do<br />

with the traditional<br />

romance of the “Heidi”<br />

stories<br />

Service work in the mountainous Toggenburg region of<br />

Eastern Switzerland is very demanding on man and<br />

machine. The perfect task for the <strong>Unimog</strong>.<br />

Ohni de <strong>Unimog</strong> bruuchet mer gär nütz’<br />

„ versueche“ (Swiss German for “Without<br />

the <strong>Unimog</strong>, we might as well not bother at<br />

all!”), says Hans Baumann, installation<br />

manager at the St. Gallisch-Appenzeller<br />

Kraftwerk AG (SAK), after a closer look at<br />

the current weather situation. We are in the<br />

midst of the Toggenburg mountain region in<br />

the canton of St. Gallen, between the River<br />

Thur, a tributary of the Rhine, and the road<br />

pass between Wildhaus and Wil – in the<br />

yard of a SAK depot. The team of three is<br />

preparing for the task of erecting a new<br />

foundation for an overhead cable mast as<br />

part of the SAK’s power supply system – in<br />

light snowfall and an icy wind.<br />

The SAK’s supply network has an overall<br />

length of 4,058 kilometres, which amounts<br />

to some 10 percent of the earth’s circumference,<br />

and it maintains 926 transformer<br />

stations, 1,185 kilometres of high-voltage<br />

and 2,873 kilometres of low-voltage lines –<br />

hard to believe in a region as tranquil as<br />

this. The masts and cables are located in the<br />

two Appenzell cantons and the canton of<br />

St. Gallen, stretching all the way from Lake<br />

Constance to the Lake of Zurich, between the<br />

steep mountains and gentle hills of the<br />

wildly romantic Eastarn Swiss Alps. SAK<br />

delivers electricity to 400,000 users, including<br />

a high-tension supply to 162 industrial<br />

companies and a low-tension supply to<br />

almost 60,000 other customers.<br />

These are the SAK’s statistics, but all we<br />

see on this frosty afternoon in early February<br />

is winter scenery in its purest form. The<br />

depth of snow in Toggenburg is half a metre,<br />

but this varies in the hilly landscape, and is<br />

often more than a metre due to snowdrifts<br />

and snow collecting in hollows. The newest<br />

of the SAK’s five <strong>Unimog</strong>s, a U 400 equipped<br />

with various optional extras, is being<br />

prepared for this task. Its technical specification<br />

includes provision for fitting twin-<br />

16 <strong>Unimog</strong> 1|2003

Power industry<br />

St. Gallisch-Appenzellische<br />

Kraftwerke AG supply area<br />

SAK<br />

St. Gallen<br />

tyred wheels (a <strong>Unimog</strong> with a tyre pressure<br />

control system is still high up on the department’s<br />

wish list), a loading crane, a radio<br />

remote controlled Werner cable winch and a<br />

crane support frame including a bridge to<br />

carry a machine drill, the latter specially<br />

designed and fitted by Swiss <strong>Unimog</strong><br />

regional represenative LARAG AG in Wil<br />

(St. Gallen canton).<br />

Driver Engelbert Thoma, who has more<br />

than 10 years of <strong>Unimog</strong> experience, is<br />

delighted with his new “workmate”: “The<br />

U 400 has a unique standard of driving<br />

comfort, which we naturally appreciate a lot,<br />

since more than 90 percent of our work is<br />

off-road, and this is quite mountainous country.<br />

Working with this vehicle and its equipment<br />

is a pleasure, thanks to its many technical<br />

innovations and advantages.” The<br />

U 400 is primarily used by SAK for installing<br />

and erecting masts, but also for towing the<br />

cable drum trailer and transformers weighing<br />

up to 2.5 tonnes, and for transporting<br />

emergency power generators that can weigh<br />

as much as 16 tonnes.<br />

Before tackling the task in hilly terrain<br />

that this article describes, the wintry conditions<br />

call for careful preparatory work by the<br />

SAK’s technicians. Hans Baumann, Engelbert<br />

Thoma and Alois Herger together install<br />

the twin-tyred wheels that are absolutely<br />

essential due to the heavy load to be transported<br />

and the low load-bearing capacity of<br />

the soil where they will have to work. Later,<br />

when the <strong>Unimog</strong> leaves made-up roads<br />

behind it, the importance of this measure<br />

becomes clear. Even the U 400 struggles<br />

slightly through these seemingly endless<br />

masses of snow, but in the end confirms why<br />

it is considered unbeatable here in Toggenburg<br />

too. We reach the construction site at<br />

an altitude of about 1,000 metres above sea<br />

level in freezing temperatures. The hours<br />

simply fly by and evening approaches as<br />

snow is cleared from the construction site,<br />

the equipment is prepared for use and the<br />

hole for the mast is drilled. The three-man<br />

The Swiss SAK’s supply<br />

area (right)<br />

Without “tirecontrol”,<br />

only twin tires help in<br />

deep snow (centre<br />

picture)<br />

On the way to work at<br />

1,000 metres above sea<br />

level. The SAK’s U 400<br />

with Werner cable winch<br />

and crane (below)<br />

Geneva<br />

Zurich<br />

Switzerland<br />

St. Gallen<br />

Schweiz<br />

Appenzell<br />

Uznach<br />

Uznach<br />

Sargans<br />

DWM-Grafik©<br />

<strong>Unimog</strong> 1|2003 17

Power industry<br />

In stark contrast to the beautiful, tranquil scenery:<br />

hard work for the SAK team and the equipment they<br />

use to maintain electric power supplies in the Eastern<br />

Swiss Alps<br />

team is pleased with the results and returns<br />

to the valley; once again, the U 400’s<br />

performance has entirely satisfied these<br />

experienced technicians. But then: they<br />

knew from the very start that they wouldn’t<br />

make it without the <strong>Unimog</strong>!<br />

■<br />

Official snow ploughs for the World Skiing Championships<br />

400 athletes from 60 countries competed<br />

for the title of World Champion in ten disciplines<br />

in St. Moritz, the mecca of winter<br />

sport, from February 2 to 16, 2003. Altogether,<br />

fifteen <strong>Unimog</strong> implement carriers<br />

and three Actros four-wheel-drive trucks<br />

cleared some 90 kilometres of roads; the<br />

infrastructure had been specially built for<br />

this event, often with extremely steep road<br />

links to the championship sites. The vehicles<br />

passed their first test early in the first week<br />

of the championship, when approximately<br />

25 centimetres of snow fell in one night.<br />

More than 100,000 spectators,<br />

10,000 accredited persons such as officials<br />

and sponsors’ representatives, 400 athletes<br />

and 2,000 journalists and radio and TV staff<br />

from all over the world were transported<br />

from St. Moritz to Salastrains, the destination<br />

at 2,000 metres above sea level. Swiss<br />

PTT post buses were used exclusively for<br />

this purpose.<br />

The 15 <strong>Unimog</strong> implement carriers were<br />

supplied by the <strong>Unimog</strong> Division of Robert<br />

Aebi AG (responsible for <strong>Unimog</strong> sales in<br />

Switzerland), the St. Moritz municipal<br />

authorities and the neighbouring communities<br />

of Pontresina, Celerina, Samedan and<br />

Silvaplana. The “World Championship<br />

<strong>Unimog</strong>s” were equipped with snow ploughs<br />

and snow tillers by equipment-system partner<br />

Schmidt Winterdienst und Kommunaltechnik,<br />

which is based in St. Blasien. The St.<br />

Moritz public works office operated a U 400<br />

with a plough/spreader combination, a<br />

U 140 with snow plough and ice scraper and<br />

a U 1000 to clear away snow. The Actros fourwheel<br />

drive trucks (3340 AK 6x6 and 1838<br />

AK 4x4), also from the St. Moritz authorities<br />

and from DC Switzerland’s fleet, were<br />

mainly used for snow transport.<br />

In addition to permanent clearing and<br />

spreading of the access and other local<br />

roads, the car parks had to be kept clear of<br />

snow as well. Additional parking space for a<br />

total of 2,500 vehicles was laid out for the<br />

World Championships in the entire area<br />

from Silvaplana to Samedan and in Pontresina.<br />

Spectators who travelled there by car<br />

were able to use shuttle buses to get to the<br />

championship event sites.<br />

The snow clearing service experienced no<br />

problems caused either by the topography or<br />

the weather. This was confirmed by<br />

members of the organisational committee<br />

and the local road maintenance authority. ■<br />

One of the “World Championship <strong>Unimog</strong>s” at work in<br />

St. Moritz during this major skiing event<br />

18 <strong>Unimog</strong> 1|2003

Advertisements<br />

Technology that<br />

grabs you!<br />

Loader attachment<br />

Type M 213<br />

Tel. +49 (0) 83 31/94 87-0 Fax -40 Industriestrasse 6 87734 Benningen Germany www.ematec.de

Fighting forest fires<br />

Paths to safety<br />

The mountains around Salamanca are high, steep and full of dry pine trees<br />

that catch fire very easily. This is difficult terrain for fire-fighters, but no<br />

problem for the Mercedes-Benz <strong>Unimog</strong>.<br />

The <strong>Unimog</strong>’s engine runs smoothly as the<br />

four-wheel-drive vehicle moves down the<br />

rough slope. “Whatever happens, this vehicle<br />

will always do the job!” say the driver<br />

proudly, shifting down to the next lower gear.<br />

Like the legs of a large insect, the tyres creep<br />

across the rocks, each block of their treads<br />

fighting for grip with the thrust of 4,000<br />

litres of water to withstand. At one bend, a<br />

man with three days of beard stubble, wearing<br />

a helmet and neck protection, raises his<br />

hand to indicate that the vehicle is stable<br />

despite the 20-degree slope on which it is<br />

standing. His name is Joaquín Cascales and<br />

he is the fire brigade commander. His<br />

commands are short: “Vamos!”, “Let’s go!”,<br />

“Grab the hoses!”. The firemen open the rear<br />

flap and pull a 600-metre hose off the reel.<br />

“How far are you?”, a voice asks through the<br />

walkie-talkie hanging from Joaquín Cascales’<br />

shoulders. “We’re in a good position,” he<br />

answers. Everything is going according to<br />

20 <strong>Unimog</strong> 1|2003

A helmet and neck protection (small photograph on<br />

the left) are essential for the firemen who work in the<br />

region around the Spanish city of Salamanca,<br />

since the burning pinewood forests generate<br />

enormous heat (right)<br />

Fighting forest fires<br />

The U 400 (bottom right) is an invaluable aid to the<br />

firefighters as it can move them up into any terrain<br />

and also out of the flames safely<br />

plan, and today’s target is to test how the U<br />

400 performs when a fire breaks out. Joaquín<br />

Cascales deals with more than 100 fires a<br />

year. “The most dangerous one was over<br />

there in Los Arribes,” he says, gesticulating<br />

southwards with his helmet. “Because of the<br />

strong wind, the fire crept up on us faster<br />

than we could move with our heavy equipment,<br />

and then the wind suddenly changed<br />

direction. I can tell you, it was then I discovered<br />

how fast I could run!” Joaquín<br />

Cascales knows the risks: he is a forestry<br />

engineer who has been a forest fire expert for<br />

ten years. A sound like a roaring waterfall<br />

can be heard from the south, but it proves to<br />

come from the flames that can be seen licking<br />

up into the sky a few seconds later.<br />

Smoke fills the canyon and covers the sun.<br />

The engineer’s face is sweaty and<br />

discoloured with soot. “Get moving!” a voice<br />

demands from the walkie-talkie. It belongs to<br />

someone from the second forest fire-brigade<br />

group, which is securing the other side of the<br />

canyon with a second <strong>Unimog</strong>. A third group<br />

is waiting at the summit. Joaquín Cascales<br />

grabs an object shaped like a watering can<br />

that spits fire, lighting a counter-fire in the<br />

bushes so the flames cannot cross over the<br />

the pine forest on the other side of the firebreak<br />

that his men are creating down the hill<br />

with chainsaws. Behind him, firemen with<br />

huge rubber beaters are trying to suppress<br />

the sparks that jump over the fire-break. The<br />

<strong>Unimog</strong> follows Cascales downhill, occasionally<br />

stopping so that the smooth sound of its<br />

230-hp engine can be heard. The U 400 was<br />

in frequent use last summer; sometimes four<br />

fires had to be put out in one day. Joaquín<br />

Cascales knows that the fires are often<br />

started by arsonists: “Some people try to gain<br />

additional pasture land for their animals by<br />

dishonest means.” He thinks the <strong>Unimog</strong> is<br />

great: “It makes the work so much easier for<br />

our men. We used to have fire-fighting vehicles<br />

from the Spanish Army, but they simply<br />

weren’t able to tackle these steep hills.”<br />

Despite intensive service, the U 400’s yellow<br />

paint still looks brand new. From the air, red<br />

vehicles are hard to distinguish from the<br />

flames, which is why pilots of fire-fighting<br />

aircraft sometimes give their colleagues on<br />

the ground a shower instead of putting out<br />

the flames. For this reason the vehicles are<br />

now painted yellow. In addition to the<br />

<strong>Unimog</strong> implement carriers’ notable reliability,<br />

the most important features for the firemen<br />

on the ground, who are often<br />

confronted with smouldering fires that grow<br />

into impenetrable fire walls within seconds,<br />

are their robust engines and legendary offroad<br />

capabilities. “Every second counts,”<br />

says Joaquín Cascales, “and it’s good to know<br />

that the vehicles are reliable and will always<br />

get you out safely.” He tells his men to be<br />

absolutely cautious: “Don’t overestimate<br />

yourselves. Always leave the key in the ignition<br />

switch and park the <strong>Unimog</strong> so that the<br />

front end is away from the fire so that you<br />

don’t have to reverse it if you have to leave<br />

the area in a hurry!” Jaime Vazquez, aged 33,<br />

wearing a pair of jeans and a leather jacket,<br />

strolls over from the mountain summit – a<br />

safe distance away. He is fleet manager at<br />

Mercedes-Benz Credit España (MBCE), a<br />

DaimlerChrysler Services subsidiary, and<br />

wants to see the U 400 in action after the<br />

stressful leasing negotiations. Metaphorically<br />

speaking, he too went through fire for<br />

the extinguishing vehicle’s financing and<br />

insurance. The Castilla y León government’s<br />

invitation to tender was a total challenge for<br />

his company: insurance covering all risks, a<br />

limited budget for 30 vehicles including 20<br />

<strong>Unimog</strong>s. These were considered obstacles<br />

nearly impossible to overcome in the trade,<br />

but not for Jaime Vazquez: “I knew we would<br />

make it!” And this is why the firemen can<br />

fight their fires with the <strong>Unimog</strong> today. ■<br />

<strong>Unimog</strong> 1|2003 21

UNISCOPE<br />

The <strong>Unimog</strong> museum in the Murg valley<br />

On November 5, 2002, some 150 <strong>Unimog</strong><br />

enthusiasts founded the “<strong>Unimog</strong>-<br />

Museum e. V.” association with the purpose<br />

of establishing a <strong>Unimog</strong> museum at the<br />

entry to the Murg valley in front of Rotenfels<br />

Castle in Gaggenau, in Germany’s South<br />

Baden region. “We intend to give the<br />

<strong>Unimog</strong>’s successful history a permanent<br />

new home at its former production site”,<br />

explains Hans-Jürgen Schöpfer, chairman of<br />

the new museum association. The association<br />

is supported by a committee chaired by<br />

Hans-Jürgen Wischhof, an<br />

avid supporter of the plan to<br />

build a museum. Various<br />

models – the association<br />

already owns almost a<br />

dozen exhibits, among<br />

them the last <strong>Unimog</strong> built in Gaggenau –<br />

add-on equipment and sectioned models of<br />

the principal <strong>Unimog</strong> working equipment<br />

will document the vehicle’s development<br />

history and its many applications all around<br />

the world. DaimlerChrysler has already<br />

agreed to supply the museum with interesting<br />

exhibits on loan. A shop with miniature<br />

models, <strong>Unimog</strong> books and posters is also<br />

planned. The initiators also consider it<br />

important to describe the<br />

industrial history of the<br />

Murg valley and acknowledge<br />

local peoples’ work.<br />

Vehicles had after all been<br />

built in Gaggenau for more<br />

than fifty years before <strong>Unimog</strong> production<br />

started. The newly established association<br />

already has more than 500 members.<br />

You can obtain further information and<br />

download the application form at<br />

www.unimog-museum.de.<br />

■<br />

The <strong>Unimog</strong> museum will probably look like this one<br />

day. Construction is scheduled to start in 2004<br />

The 5,555th <strong>Unimog</strong> for Switzerland<br />

From left to right: Arthur Bühler, head of Meggen<br />

district council, Markus Imboden from supplier<br />

Gebrüder Mengis and Markus Staubli from Robert<br />

Aebi AG at the key handover ceremony for the 5,555th<br />

<strong>Unimog</strong><br />

Various <strong>Unimog</strong> models in front of Meggen fire station<br />

(below)<br />

This is a very unusual jubilee indeed. Last<br />

November, the 5,555th civil <strong>Unimog</strong> was<br />

delivered to Switzerland. It is a U 400 for use<br />

in Meggen, on the Vierwaldstättersee (Lake<br />

Lucerne). This municipality. located in the<br />

heart of central Switzerland between the<br />

Pilatus and Rigi mountains, began to operate<br />

<strong>Unimog</strong>s 20 years ago. In order to meet<br />

growing demands for road maintenance<br />

even more effectively, the town authorities<br />

decided to purchase an implement carrier<br />

that could handle the entire scope of<br />

summer and winter service work. Among<br />

other items, the U 400 is equipped with a<br />

Hiab goods handling crane and a three-way<br />

tipping body.<br />

■<br />

Tourist transport<br />

The Plitvic lakes are located in Croatia’s<br />

most popular national park and are among<br />

Europe’s most beautiful sights. Surrounded<br />

by dense forests, the 16 lakes are connected<br />

by waterfalls. The organisers invite tourists to<br />

tour the area in a U 400, which pulls two<br />

passenger-carrying trailers. The total capacity<br />

of this unusual outfit enables 105 tourists to<br />

enjoy the beautiful scenery.<br />

22 <strong>Unimog</strong> 1|2003

UNISCOPE<br />

Powered by an uprated<br />

OM 906 LA engine, the<br />

U 500 entered by the<br />

Italian Overlook<br />

Promotion team drives<br />

through a canyon in the<br />

Sahara at full speed<br />

Africa fever<br />

Many international rally specialists are infected with ‘Africa fever’<br />

every year, including seasoned professionals such as the highly<br />

successful Italian Overlook Promotion team with the<br />

Panseri brothers and their colleagues Cambiaghi, Paccani, Vismara<br />

and Sangalli, who invest tens of thousands of Euros in order to participate<br />

in the Pharoah Rally in Egypt and the legendary Paris-Dakar<br />

event. Other participants are “true amateurs”, such as <strong>Unimog</strong> test<br />

driver Klaus Bäuerle, for whom simply taking part is the most satisfying<br />

aspect of the whole adventure. This year, he sacrificed a promising<br />

position in the Paris-Dakar event to help recover a broken-down<br />

Mitsubishi after many hours of hard work. The <strong>Unimog</strong> first enjoyed<br />

the limelight during the world’s toughest rally back in 1982, when<br />

the French team George Groine, Thierry de Saulieu and Bernard<br />

Malfériol won in a U 1700 L and the Frenchmen Laleu/Langlois came<br />

in second in a U 1300. In 1985, the Italian team Capito/Capito won<br />

this event.<br />

■<br />

Klaus Bäuerle, <strong>Unimog</strong><br />

test driver and rally<br />

enthusiast (at the right<br />

in the left picture), took<br />

part in the 7,000-<br />

kilometre Paris – Dakar<br />

rally, both in the race<br />

itself and as service<br />

support for the Polish<br />

Orlen team. In the<br />

overall evaluation, he<br />

“only” managed 16th<br />

place, as the help he<br />

provided cost him a lot<br />

of time. He was very<br />

much in demand as the<br />

“Good Samaritan with<br />

the <strong>Unimog</strong>” and often<br />

saved the day in extreme<br />

emergencies<br />

Another aspect of the<br />

Paris – Dakar rally:<br />

atmospheric pictures of<br />

the desert and savanna<br />

<strong>Unimog</strong> 1|2003 23