Sikaflex Marine Handbook

Sikaflex® Marine Handbook - BlueMoment

Sikaflex® Marine Handbook - BlueMoment

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

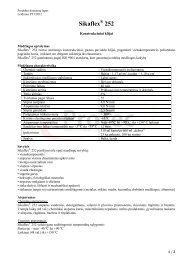

Instructions forBonding and Sealing “Organic Glass” (Plastic)WindowsDescription of ApplicationMost of the plastic glazingmaterials used in boat building areeither clear acrylic sheet (PMMA),widely marketed under tradenames such as “Perspex” and“Plexiglas” (the lattermanufactured by Röhm and Haas),or polycarbonate (PC), marketedby Röhm and Haas as“Makrolon” and by GeneralElectric as “Lexan”.All plastic glazing products possesscertain characteristics that must beclearly understood before theseproducts are installed or bondedwith adhesives. In general,incorrectly installed plastic glazingpanels are prone to stress cracking,which may be aggravated by theuse of certain adhesives.Plastic glazing products have ahigher coefficient of thermalexpansion than conventional glass.Therefore, when designing glazinginstallations, an expansion gap ofat least 5 mm (see edge sealingpage 17) all round must beincorporated between the windowrebate and the plastic glazing panelto accommodate thermalmovement. Similarly, any clearanceholes for fixing screws must bedrilled oversize, i.e. larger than theactual diameter of the screw shank.To minimise the risk of stresscracking, flat sheets of plasticglazing material should be installed16completely flat; they should not beforced to take up a curvature bythe use of mechanical fastenings.When the design calls for curvedglazing panels, these should beprefabricated to order and properlytempered by a specialist supplier toensure a stress-free installation.As many varieties of organic glassexist it is recommended to ensurethat the specific grade selected issuitable for use with<strong>Sikaflex</strong> ® -295 UV. For furtherdetails contact Sika.minimal adhesive thickness,t (mm)2 4 6 8 10ok0 0,5 1 1,5 2Largest dimension of the window (m)14521 Flange2 Window3 <strong>Sikaflex</strong> ® -295 UV4 <strong>Sikaflex</strong> ® -295 UV5 Sika ® UV Shielding Tapetoo small3tPreparation of SubstrateGRP Frame205206 G+P/215Lightly abrade contact area with avery fine sanding pad. Remove dustwith a vacuum cleaner.Clean the substrate with Sika ® Cleaner-205, using a clean, lint-free rag orpaper towel. Change frequently!Drying time: minimum 10 minutes,maximum 2 hoursApply a thin, continuous coat of Sika ®Primer-206 G+P or Sika ® Primer-215,using a clean brush or felt applicator.Drying time: minimum 30 minutes,maximum 24 hoursAnodised Aluminium Frame205210 TLightly abrade surface with ScotchBrite M 600, clean with Sika ® Cleaner-205, using a clean, lint-free rag orpaper towel. Change frequently!Drying time: minimum 10 minutes,maximum 2 hoursApply a thin, continuous coat of Sika ®Primer-210 T, using a clean brush orfelt applicator.Drying time: minimum 30 minutes,maximum 24 hoursPMMA / PC Glazing PanelsMask off perimeter bond area withmasking tape. Abrade bond area withabrasive paper or Scotch-Brite.205209Clean the substrate with Sika ® Cleaner-205, using a clean, lint-free rag orpaper towel. Change frequently!Drying time: minimum 10 minutes,maximum 2 hoursApply a continuous coat of Sika ®Primer-209, using a clean brush or feltapplicator.Drying time: minimum 30 minutes,maximum 24 hoursTimber or Aluminium Frame Coatedwith Two-Part Lacquer205Clean the substrate with Sika ® Cleaner-205, using a clean, lint-free rag orpaper towel. Change frequently!Drying time: minimum 10 minutes,maximum 2 hoursRefer to Sika ® primer chart for other substrates.