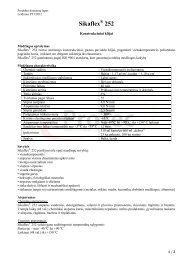

Instructions forBonding of Anti-Slip Plates for Engine RoomsDescription of ApplicationAnti-slip plates used in technicalstorage rooms or in engine roomsare traditionally fixed by rivets orother mechanical fixings. Being inan area which is subjected to a lotof vibration, these soon becomeloose and a large amount of repairwork is usually required. The useof elastic bonding technologyallows a better distribution ofstresses, thus avoiding the need forrepair work (Fig.A). In addition,fixation and sealing of plates canbe achieved in a single operation.Preparation of SubstrateGRP Floor205206 G+P/215Heavily soiled surfaces should becleaned off first with a pure solvent(Sika ® Remover-208) to remove theworst of the soiling.Lightly abrade contact area with avery fine sanding pad. Remove dustwith a vacuum cleaner.Clean the substrate with Sika ® Cleaner-205, using a clean, lint-free rag orpaper towel. Change frequently!Drying time: minimum 10 minutes,maximum 2 hoursApply a thin, continuous coat of Sika ®Primer-206 G+P or Sika ® Primer-215,using a clean brush or felt applicator.Drying time: minimum 30 minutes,maximum 24 hoursSteel FloorMechanically clean the surface bygrit-blasting to SA 2.5. Remove dustwith a vacuum cleaner.Clean the substrate with Sika ®208 Remover-208, using a clean, lint-freerag or paper towel. Changefrequently!Drying time: minimum 10 minutes,maximum 2 hoursApply a continuous coat of SikaEG 1Icosit ® EG 1 (two-component,anticorrosion primer).Drying time : minimum 14 hours,maximum 96 hoursAluminium Anti-Slip PlateLightly abrade contact area with avery fine sanding pad. Remove dustwith a vacuum cleaner.1205Clean the substrate with Sika ® Cleaner-205, using a clean, lint-free rag orpaper towel. Change frequently!Drying time: minimum 10 minutes,maximum 2 hours32210 TApply a thin, continuous coat of Sika ®Primer-210 T, using a clean brush orfelt applicator.Fig. A1 Anti-slip plate2 <strong>Sikaflex</strong> ® -2923 Floor structure(GRP or steel)Drying time: minimum 30 minutes,maximum 24 hoursApplication of <strong>Sikaflex</strong> ® -292 AdhesivePlace spacers in position (thickness 2 mm, approximately 50 Shore A hardness). Thesecan be pressed into the adhesive once applied.For the preparation of othersubstrates, please refer to thePrimer Chart.Apply parallel rows of beads of <strong>Sikaflex</strong> ® -292 in an 8 mm x 10 mm triangular profile.Assemble components within 20 minutes of applying adhesive.Apply pressure with weights or other fastening aids to compress adhesive to the height ofthe spacers.Wait at least 24 hours before walking on the bonded plates.208Traces of uncured Sika adhesives or sealants may be removed with Sika ® Remover-208. Onno account should other cleaning agents or Sika ® Cleaner-205 be used for this purpose.Important: Please refer to the current Sika Technical Data Sheets and Safety Data Sheets obtainable throughSika or their local distributor.10

Instructions forBonding Timber ComponentsDescription of ApplicationIn yachts and pleasure craft, stairs,companion ways and handrails arefrequently made from tropicalhardwoods, chosen both for theirdurability and their attractiveappearance. The use of screws tofix such items may eventuallyimpair both their durability andtheir appearance, due to moistureingress via the screw holes. For thisreason, it is advisable to fixhardwood components withadhesives. The absence of screwholes prevents water from enteringand damaging the timber. This is ofparticular importance in theconstruction of accommodationladders.In addition, bonding offers otherbenefits. The adhesive layer helpsto absorb the sound of footstepsand cushion vibrations.The integrity of painted surfacescan be preserved without loss ofcorrosion protection, and thepotentially harmful effects ofmoisture penetration into GRP areeliminated.GRP205206 G+P/215Heavily soiled surfaces should becleaned off first with a pure solvent(Sika ® Remover-208) to remove theworst of the soiling.Lightly abrade contact area with avery fine sanding pad (80/100 grit).Remove dust with a vacuum cleaner.Clean the substrate with Sika ®Cleaner-205, using a clean, lint-freerag or paper towel. Changefrequently!Drying time: minimum 10 minutes,maximum 2 hoursApply a thin, continuous coat of Sika ®Primer-215 or Sika ® Primer-206 G+P,using a clean brush or felt applicator.Drying time: minimum 30 minutes,maximum 24 hoursStainless Steel, e.g. Ladders205210 THeavily soiled surfaces should becleaned off first with a pure solvent(Sika ® Remover-208) to remove theworst of the soiling.Lightly abrade contact area with avery fine Scotch-Brite pad. Removedust with a vacuum cleaner.Clean the substrates with Sika ®Cleaner-205, using a clean, lint-freerag or paper towel. Changefrequently!Drying time: minimum 10 minutes,maximum 2 hoursApply a thin, continuous coat of Sika ®Primer-210 T, using a clean brush orfelt applicator.Drying time: minimum 30 minutes,maximum 24 hoursApplication of<strong>Sikaflex</strong>®-292 Adhesive208Place elastic spacers in position(thickness 2 mm, approximately50 Shore A hardness).Apply <strong>Sikaflex</strong> ® -292 to theproposed bond area using anotched spreader (4 x 4 mm) overthe face of the joint.Assemble components within 20minutes of applying adhesive.Apply pressure with clamps orother fastening aids to compressadhesive to the height of thespacers. Excess adhesivesqueezed out around the jointshould be trimmed off with a softplastic spatula.Note: Do not apply excessiveclamping pressure. If screws areused for additional security, theseshould only be tightened initiallyto secure the components whilethe adhesive sets. Leaveassembly for 24 hours beforetightening screws.Traces of uncured Sika adhesivesor sealants may be removed withSika ® Remover-208. On noaccount should other cleaningagents or Sika ® Cleaner-205 beused for this purpose.Clamps and other fastening aidscan be removed after 12 hours.Full service strength is attainedafter approximately 7 days.Important: Please refer to the current SikaTechnical Data Sheets and Safety Data Sheetsobtainable through Sika or their local distributor.Preparation of SubstrateUntreated Timber (Teak, Mahogany)Abrade contact area on hull withsanding pad (80/100 grit) and removedust with a vacuum cleaner.Timber, Aluminium or Steel Coated with Two-Part Lacquer205Clean the substrates with Sika ®Cleaner-205, using a clean, lint-freerag or paper towel. Changefrequently!For the preparation of othersubstrates, please refer to thePrimer Chart.290 DCApply a thin, continuous coat of Sika ®Primer-290 DC, using a clean brush orfelt applicator.Drying time: minimum 10 minutes,maximum 2 hoursGRPDrying time: minimum 60 minutes,maximum 24 hours11