fast facts

Fast Facts -- Lockout/Tagout, April 2008 - Office of Compliance

Fast Facts -- Lockout/Tagout, April 2008 - Office of Compliance

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

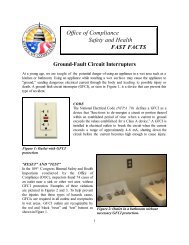

<strong>fast</strong> <strong>facts</strong>advancing safety, health, and workplace rights in the legislative branchAprilLockout/TagoutEmployers must establish and implementan energy control program whenever anemployee services or maintains machinery,equipment, or systems whose unexpectedenergizing, start up, or release of energy haspotential to injure them. All forms of energyare covered by the Occupational Safety andHealth Administration (OSHA) standards,including the Control of Hazardous Energy(Lockout/Tagout) and the ElectricalSafety-Related Work Practices. Themost common type is electrical energy,whether from generated power, storagedevices (batteries and capacitors), or static.However, the program must also protectagainst injury from thermal energy (high orlow temperature). Sources of kinetic energy(mechanical energy from moving parts), aswellaspotentialenergy(storedinpressurizedvessels, hydraulic and pneumatic systems,and springs), must also be addressed.The energy control program requires thatan authorized person must disconnectthe machinery or equipment from itsenergy sources and block it as necessary toprevent any unexpected movement beforeFigure 1: A Proper Circuit Breaker Lock and Tagservice or maintenance work is performed.Additionally, the program requires thatauthorized employees either lock or tag itsenergy-isolating device(s) to prevent therelease of hazardous energy and take steps toverify effective isolation of the energy.Energy-isolating devices prevent thetransmission or release of energy. Theyinclude items such as electrical switches,circuit breakers, disconnect switches, linevalves, slide gates, slip blinds, and mechanicalblocks. Because procedures are requiredfor applying lockout or “tagout” devices toenergy-isolating devices, these programs areoften referred to as lockout/tagout (LOTO)programs.It is crucial that personnel developing theLOTO program identify every energysource and energy-isolating device for eachpiece of machinery or equipment includedin the program. The steps to be followed toprovide absolute control of each source andisolating device must be incorporated intothe specific procedures developed for eachpiece of machinery or equipment.As the name implies, lockout devices areitems such as locks that are used to keepenergy-isolating devices in safe positions.Their function is to secure energy-isolatingdevices in positions that prevent machinesfrom becoming energized during servicingand similar activities.Tagout is used when it is not possible toapply a lockout device. It involves attachinga danger tag on or as close as possible toan energy-isolating device. The tag mustindicate that the machine being servicedwww.compliance.gov2008Figure 2: A Plug LO/TO on Metal Working Lathecannot be operated until it is removed by theperson who applied it. The tag must identifywho applied it and indicate when the tagwas applied. It may only be removed by theauthorized person who applied it. Use oftagout alone creates potential for prematureactivation of an energy-isolating device, so itis less safe than using a lockout procedure.LocksandtagsusedintheLOTOprogrammust be standardized in color, shape, or sizeso they are readily recognizable by anyone inthe work area. Additionally, all employeeswithaccesstotheareawheretheyareappliedmust betrained torecognizethese itemsandtheir purpose.Locks and tags used in LOTO programsmust also be durable and unable to beremoved without excessive force or unusualtechniques. Nylon tie-wraps may be easilycut off, so they may not be used as lockoutdevices.Authorized personnel must verify that allenergy sources are effectively controlledbefore servicing work begins. When thework is finished, they must remove theircontrol devices.

All authorized employees must be providedwithtrainingthatallowsthemtounderstandthe purpose and function of the energycontrol program. Their training must alsoallow them to develop the knowledge andskills needed for safe implementation ofthe program. Mere distribution of lockout/tagout procedures is not adequate.An employee other than the one using theindividual energy control procedure mustevaluate and certify it at least annually. Eachevaluation must include a review by theinspector and each employee authorizedto implement the program, and include areviewoftheemployee’sresponsibilities.Anyidentified deviations from the procedure orinadequacies in it must be corrected.Figure 3: An Untagged LO Device on a PipeValve HandleGoing Beyond the BasicsWhenmultipleworkersmustsimultaneouslyservice a machine, each should be assigneda separate lock and key. If work is notcompleted before the end of a shift and newworkers are to continue the work, the newarrivals should apply their locks before thedeparting ones remove theirs. Each workermust move away from the machine before itis re-energized.Though a combination lock may be used ina LOTO program, it is possible for manypeople to know its combination. This enablesmultiple people to remove it prematurely,potentially injuring anyone still working onthe machine. Instead, key-operated locksare more controllable lockout devices. Byproviding one copy of the key to the userand one to the program’s coordinator foruse only during unusual circumstancesafter confirming that the person assignedto the lock is safely away, the opportunity toremove the lock prematurely is much morelimited.Whenever an outside contractor oremployees from other divisions orjurisdictions are involved with the work,all affected groups must inform each otherof their LOTO procedures. Further, ifa program for entry of confined spacesis needed, the hazardous energy controlFigure 4: A LO/TO Device Prevents Use of PlugShown in Figure 2program must be integrated with it whenneeded.OSHA also has a similar standardmentioned above that primarilyconcentrates on electrical energy.Specifically, OSHA requires the deenergizationand disconnection of electricalequipment. This includes removal ofisolating circuits and the opening of extrapower disconnect devices. It also includesminimum safe distances for approach tohigh voltage. Steps to safely re-energizeduring maintenance and the removal ofLOTO devices are also addressed.<strong>fast</strong> stats· OSHA requires employers to develop and implement procedures and practices to protect employees during servicing and maintenance of machines and equipment.(29CFR§1910.147 and 1910.333(b)(2)).· OSHA Accident Investigation Summaries from OSHA-170 forms for 2000-2002 on Lockout lists a total of 355 incidents investigated. This includes 63 killed workers and 121amputated. Death and amputation account for 52% of the Lockout incidents investigated, indicating severe trauma where machines or equipment started unexpectedly.Peter Ames EvelethGeneral CounselRachel Berg SchererEditorIf you spot a safety hazard in your legislative branch workplace,The Offce of Compliance advances safety, health,contact the Offce of Compliance to report it:and workplace rights in the U.S. Congress and theRoom LA 200, John Adams BuildingLegislative Branch. Established as an independent110 Second Street, SE agency by the Congressional Accountability Act ofWashington, DC 205401995, the Offce educates employees and employingt/ 202-724-9250; tdd/ 202-426-1912; f/ 202-426-1913 offces about their rights and responsibilities under theRecorded Information Line/ 202-724-9260Act, provides an impartial dispute resolution process,and investigates and remedies violations of the Act.www.compliance.govThis information does not constitute advice or an offcial ruling of the Offce of Compliance or the Board of Directors and is intended for educationalpurposes only. For further information, please refer to the Congressional Accountability Act (2 U.S.C 1301 et seq.) and the regulations issued by theBoard, or you may contact the Offce of Compliance.