Letters Editor

Akshay Urja New Renewables - Energy Access

Akshay Urja New Renewables - Energy Access

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

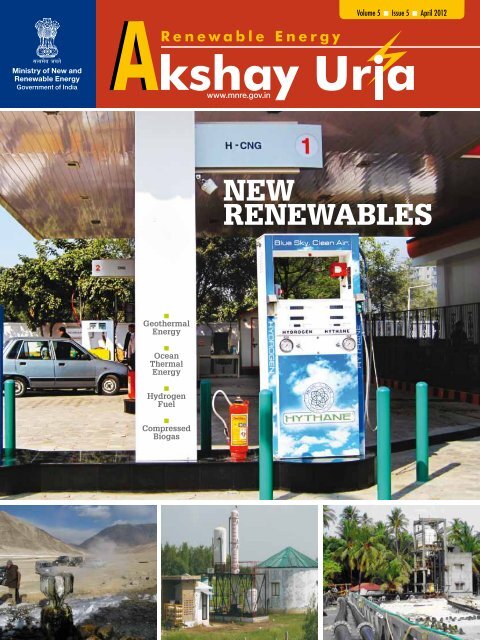

ContentsApril 2012RE NewsNational 4-7● Kolkata Gets a New RenewableEnergy College● India, China Focussing onRenewable Energy Sources: WEF● Tamil Nadu to add 3,000 MWSolar Energy● REC Raising New €100 mn Loan● Railways Plans to Turn a GreenLeaf Through Renewable Energy● India’s Wind Energy Potential isOver 2,000 GW● Committee on Renewable EnergySet Up● Fedders Lloyd to Expand WindEnergy Equipments facility atBharuch● Government Extends PopularAccelerated Depreciation Schemefor Wind Power Producers● Hybrid Guide Lights for Fishermenat Night● Rice Husk, Solar Energy to SolvePower Issues● India to be a Global Sourcing Hubfor Solar Projects● India’s Installed Power GenerationCapacity Crosses 2 Lakh MW MarkInternational 8-9● Germany Could Become StorageTechnology Hotspot● Nanotrees Harvest the Sun’sEnergy to Turn Water IntoHydrogen Fuel● Smart Paint Could RevolutioniseStructural Safety of Bridges,Mines and More● Abu Dhabi Bets on Anti-DustSolar Panels● Total Green Electricity Generationfor ScotlandCover Story10 Hydrogen Energy and Fuel CellTechnologies Recent Developmentsand Future Prospects in IndiaRE Feature16 Evolution of Geothermal Energyin India19 Geothermal Energy: AnOverview25 Harnessing Bioelectricity throughMicrobial Fuel Cell fromWastewater 30 Hydrogen – A PromisingRenewable Fuel33 Electric Cars - The ‘Green Answer’to the Energy Crisis37 Tapping the Oceans for EnergyCase Study41 Biogas Bottling in IndiaSuccess Story44 Biogas Plant for a SchoolEvent46 TEDA’s Renergy 2012 - AStupendous Success47 RE and Energy Conservation - 201132 Cartoon48 Tech Update49 Children’s Corner50 Web/Book Alert51 Forthcoming Events52 RE StatisticsA detailed study of the use andapplicability of geothermal energy in theIndian context.Power from a biogas plant in the residentialschool which has helped an institute to meettheir needs in everyday life from cooking torunning various machines.Today’s fast world is overly dependent onenergy to fulfill requirements related to dailylife. Compressed biogas comes as a efficientand cost effective method to meet this need.April 2012Volume 5 ● Issue 53

NationalRenewable Energy NewsKolkata Gets a NewRenewable EnergyCollegeKolkata can now boast of a renewableenergy college that opened in the cityin January 2012. The college is locatedoff EM Bypass at Madurdaha. Studentspassing out from the college receive adiploma jointly certified by the IndiraGandhi National Open University(IGNOU) and the TechnicalEducation Department of the Stateof Queensland, Australia. The collegeis the brainchild of renewable energyexpert and Ashden award winnerS P Gon Chaudhuri, who is presentlyAdvisor to the state government’s powerdepartment. “Students who pass outfrom this college will be recognisedas renewable energy engineers,” statedGon Chaudhuri, who will head thecollege as its chairman.www.energynext.in27 December 2011India, China Focussingon Renewable EnergySources: WEFIndia, China and South Korea areincreasingly focussing on renewableenergy sources, including wind andsolar, as potential growth sectors fortheir economies, as per the WorldEconomic Forum report released on 9March 2012.However, the report, Energy forEconomic Growth - Energy VisionUpdate 2012, which provides aframework for understanding thelarger economic role of the energyindustry, added that the higher costsof these technologies create trade-offsthat must be considered.“Energy prices will always be volatileand thus represent a challenge forlong-term economic planning,” saidKenneth Rogoff and Thomas D Cabot,Professor of Public Policy and Professorof Economics, Harvard University.“The question is how to make thisvolatility less economically damaging,”added Rogoff, who is part of the WEFadvisory board. While multiplier effectsfor solar and wind energy were lowerduring operation, their contributionduring the construction phase reachedas high as 3.3 indirect jobs per energyjob. “The energy industry is unique inits economic importance and has thepotential to be a tremendous catalystfor job creation and sustainable growthwithout harming the sector’s overallperformance,” said Chairman DanielYergin of IHS CERA, which haspartnered in the preparation of theWEF report. The energy industry thushas the ability to generate significantcontributions to GDP growth, thereport said.www.renewsindia.com9 March 2012Tamil Nadu to add 3,000MW Solar EnergyTamil Nadu has set a target to add3,000 MW of solar energy as part ofits solar mission programme by 2015-16. This is more than 33 per cent ofIndia’s target. The State Governmentis also planning to bring in a newpolicy for solar energy was disclosedby Natham R Viswanathan, Ministerfor Electricity and Prohibition andExcise in a recent conference organisedby Tamil Nadu Energy DevelopmentAgency (TEDA). The Minister alsoadded, “We need financial assistanceto boost the renewable energy sector soas to address the power deficit.” Withthis move, Tamil Nadu, according tohim, would become a power surplusstate by 2015-16. The State is facinga shortage of around 4,000 MW atpresent.www.indianpowersector.com8 March 2012.REC Raising New€100 mn LoanThe Rural Electrification Corp. Ltd.(REC) is set to raise €100 million(Rs. 656 crore) from Germany-basedKfW Bankengruppe for financingrenewable energy projects in Indiaat concessional interest rates. TheREC has sanctioned loans worth Rs.50,000 crore and disbursed loansestimated at around Rs. 25,000 crorein the current fiscal (2012-13). “TheREC is borrowing from a foreignlender to tide over the acute shortageof funds facing power companiesin India. Also, funds raised fromglobal markets are cheaper, given thehigh interest rates in India” said RSharma, CMD, REC. The REC andthe Power Finance Corporation of4April 2012Volume 5 ● Issue 5

NationalIndia which accounts for 60 per centof lending to the power sector, haveformulated guidelines for lending torenewable energy projects for the firsttime. India’s power sector, alreadystruggling with fund shortfalls, willneed an investment of $400 billionduring the 12th Five-Year Plan(2012-17).www.livemint.com14 March 2012Railways Plans to Turna Green Leaf ThroughRenewable Energysolar energy to run 200 stations andprovide lighting systems at 1,000manned, level crossing gates. As partof its green energy initiative, it plansto run a train on pilot basis, in northBengal, with low-emission diesellocomotive and bio-toilets. There arealso plans to commission two biodieselplants in 2012-13 at Raipurin Chhattisgarh and Tondiarpet inTamil Nadu.www.sustainabilityoutlook.in15 March 2012India’s Wind EnergyPotential is Over 2,000 GWcoal and natural gas based plants,and wind can play a significant rolein addressing energy security andenvironmental concerns in a costeffective manner.www.infraline.com27 March 2012Committee on RenewableEnergy Set UpIn an attempt to become environmentfriendly, the Indian Railways plansto set up renewable energy generationcapacities - such as wind power, solarenergy and bio-diesel plants - for itsown use, railway Minister DineshTrivedi said in his budget speech on14 March 2012 .The renewable energy plans of therailways include setting up 72 MWwind power plants in Andhra Pradesh,Karnataka, Kerala, Tamil Nadu andWest Bengal. This will also helpthe carrier to avail fiscal incentives,including tax breaks for 10 years anddepreciation benefits, besides a chanceto earn carbon credits. In addition,the railways will also install bio-toiletsdeveloped by the Defence Researchand Development Organisation in2,500 coaches in the next fiscal yearto stem environmental degradationand corrosion of tracks due to humanwaste. The railways also plans to useAccording to a recent study bythe US based Lawrence BerkeleyNational Laboratory, the real windenergy potential of India is well over2 million MW. After reassessingthe land that can be used for windpower development, so as to take intoaccount previously excluded lands,Lawrence Berkeley concluded that thetrue potential of wind energy in Indiais between “20 and 30 times higherthan the current official estimate of102 GW.” It was previously thoughtthat only 2 per cent of land in windyareas could be used for putting upwind power projects. The studylooked at wind speeds at heights of 80m, 100 m and 120 m and has foundthat nearly 1,629 sq km of area isavailable for setting up wind turbinesat a height of 80 m, with a plant loadfactor (PLF) of more than 25 percent. The cost of wind power is nowcomparable to that from importedThe government has set up acommittee to suggest legislativeand policy changes to speed upcapacity addition from renewablepower sources like wind, biomassand the Sun. The committee willbe headed by a senior official fromthe Power Ministry and includerepresentatives from the Ministry ofNew and Renewable Energy, powerdistribution companies (discoms),Central Electricity RegulatoryCommission, electricity regulatorycommissions from renewableresource-rich states like Tamil Nadu,Gujarat and Rajasthan and powerproject funding agencies, like PowerFinance Corporation (PFC) and RuralElectrification Corporation (REC).The committee’s terms of referenceinclude suggesting legislative changesto make it binding for discoms tocomply with the renewable purchaseobligation (RPO). It is also mandatedto outline measures to penalise discomsin case of violation of the obligation.The panel also has the mandate tosuggest amendments to the ElectricityAct 2003 to empower the regulators toframe innovative market instrumentsApril 2012Volume 5 ● Issue 55

Nationallike renewable energy certificates(REC) to facilitate development of therenewable power market.www.financialexpress.com28 March 2012Fedders Lloyd to ExpandWind Energy Equipmentsfacility at BharuchThe Lloyd Group owned FeddersLloyd plans to invest Rs 200 crorefor expanding its newly builtmanufacturing facility for windturbine towers, heavy precisionfabrication and machining facility inBharuch district, Gujarat. The groupcommissioned the first phase of theunit and it has already acquired landfor the phased expansion.Commenting on the projectcommissioning, Fedders Lloyd CMDBrij Raj Punj said that renewableenergy represents the next big frontierin the technology industry and thenew facility is a testament to FeddersLloyd’s commitment to contributetowards India’s growing energyrevolution in India.The Union Minister for New andRenewable Energy, Farooq Abdullahand Gujarat Chief Minister NarendraModi inaugurated the new facility ofFedders Lloyd on 13 April 2012. Theplant is capable of manufacturingwind turbine powers up to 3 MWand heavy precision fabricationof components up to 80 tonne.Established in 1957, Fedders Lloyd isengaged in executing turnkey projectsin the areas of energy, infrastructureand climatic control equipment withmanufacturing facilities at Noida,Sikandrabad and now Bharuch.www.economictimes.indiatimes.com15 April 2012Government ExtendsPopular AcceleratedDepreciation Scheme forWind Power ProducersThe government has decided toextend the popular accelerateddepreciation incentive for wind powerproducers beyond 31 March this year,when it was due to be terminated,as the alternative generation basedschemes have not found enoughtakers. Power producers can opt foreither of these incentive schemes, andsince as many as 70 per cent haveopted for accelerated depreciation,an overwhelming majority of thecompanies have been lobbying forextension of this scheme whichprovides subsidies for setting up windgeneratedpower plants.At the same time, the generationbasedincentives, introduced in2009, have fallen way short of thegovernment’s target of 4,000 MW,yielding just 1,500 MW so far.Officials and industry persons reactedto the news positively. “ We haveasked the Finance Ministry to letaccelerated depreciation continue as itwill help us achieve the earlier missedtargets” said GB Pradhan, Secretary,Ministry of New and RenewableEnergy. “Accelerated depreciation hasbeen a major support to industrieslooking for captive power capacityfor energy security and to freezepower costs, making the sector evenmore globally competitive,” said theofficial spokesperson of Suzlon, theleader in the domestic market. VSubramaniam, Secretary General ofIndian Wind Energy Association,said the extension of the scheme willprove to be a boon to companies.‘This will help attract more orders’,said Subramaniam, calculating aninvestment of Rs 15,000 cr at anestimated installation of 3,000 MWof wind-generated power this year.www.articles.economictimes.indiatimes.com27 March 2012Hybrid Guide Lights forFishermen at NightThe Fisheries Department has decidedto install 10 hybrid guide lights in thefishing hamlets of coastal Tamil Naduto enable fishermen to reach theirdestinations at night, with ease.Fishermen set out for sail, keepingmajor lighthouses as an identificationmark. Due to lack of proper lightingsystem and high winds, they oftenland a few kilometres away from theirdestinations. Hence, they sought thehelp of Fisheries Department.Based on reports of the costeffective hybrid system installedat Tamil Nadu DevelopmentCorporation’s Raindrop BoatHouse in Mudaliarkuppam, threeyears ago, the officials of theFisheries Department approachedCoimbatore-based Viviann Electric.The firm developed three deviceswhich have been functioningat Panaiyur Chinnakuppam in6April 2012Volume 5 ● Issue 5

NationalKancheepuram district, Tranquebarnear Nagapattinam and SomanathanPattinam in Thanjavur districtsince January 2011. The deviceuses both solar and wind energy.These solar and wind hybrid guidelights comprising LEDs with 40watts capacity and 500 watts windgenerator, are visible several kilometresfrom the shore. Sources stated thatCoast Guard officials too have startedusing them as a landmark.www.thehindu.com26 March 2012Rice Husk, Solar Energyto Solve Power Issuesrun a cold storage with a capacity of15 tonnes. The project, undertaken incollaboration with Thermax and TheEnergy and Resources Institute, ispast the experiment stage and is set tobe rolled out in rural India.www.hindustantimes.com29 March 2012India to be a GlobalSourcing Hub for SolarProjectsrequired for assembling and for thisthey will rope in local contractors.Gallo added that the ConcentratedSolar Power (CSP) systems used byAREVA are suited for a variety ofpower plants from 50 MW to severalhundred MW, as well as a diverserange of industrial steam applicationsand that they are cost effective, landconservative and water efficient.www.fastindia.in16 April 2012India’s Installed PowerGeneration CapacityCrosses 2 Lakh MW MarkIf all goes well, rice husk and solarpower - two very unlikely partners-will together provide rural Indiawith a twin solution to its problemsof power shortage and lack of storagefor agriculture produce. What’s more,the evolving system promises zeroemission of pollutants as well.The government’s Solar EnergyCentre, New Delhi, has managedto make use of rice husk and solarpower, both of which are beingwasted at present, to come up witha technological marvel that wouldprevent wastage of food grains inrural India. The rice husk is burnt toproduce enough energy for poweringa turbine and producing electricity.As of now, there are 60 mini-rice huskpowered electricity plants that light25,000 households in different partsof the country. The emission from therice husk plants is coupled with energygenerated by solar thermal plates toAREVA Solar, the US-headquarteredrenewable energy subsidiary ofthe French nuclear energy group,AREVA, has an ambitious plan totap the growing solar market in Indiaas a technology provider. William DGallo, president and chief executiveofficer, has promised to make Indiaa hub to source solar technology fortheir international operations. Galloinformed that India enjoys 250 to 300sunny days a year and is, therefore, apotentially privileged location for solarpower plant projects. The companyhas also been awarded a contract byReliance Power to set up a 250 MWproject in Rajasthan.The AREVA group aims to positionitself as a strategic player in thedevelopment of renewable energysources. India will be a global sourcinghub for solar projects, remarked Gallo.He said that as a technologyprovider, AREVA will source most ofthe steel and glass from the domesticmarket, and has plans to set up a largenumber of plants in India. Besides,there is availability of the skillsIndia’s installed total power generationcapacity has crossed the 2 lakh MWmark with the commissioning of a 660MW unit of a power plant in Jhajjar inHaryana. The total installed capacity inthe country has now reached 2,00,287MW, per an official press release. Thisincludes 1,32,013 MW capacity inthe thermal sector, 38,991 MW inthe hydro sector, 4,780 MW in thenuclear sector and 24,503 MW in therenewable energy sector. At the end ofthe 11th Plan, i.e. on 31 March 2012the total installed capacity stood at1,99,627 MW. There was a capacityaddition of 54,964 MW in the 11thPlan period, up 159 per cent over the10th Plan period when 21,180 MWcapacity was added. During the NinthPlan, the capacity addition stood at19,010 MW. In 2011-12, a capacity of20,501 MW was added, out of which5,482 MW was added in March 2012alone, the release added.www.netindian.in14 April 2012April 2012Volume 5 ● Issue 57

InternationalGermany CouldBecome StorageTechnology HotspotNanotrees Harvestthe Sun’s Energy toTurn Water IntoHydrogen FuelSmart Paint CouldRevolutionise StructuralSafety of Bridges, Minesand MoreDuring the International Summitfor the Storage of Renewable Energy,Germany’s Environment Minister,Norbert Röttgen spoke about marketincentives for storage systems. These, hesaid, are important for the developmentof market applications. He went on totell the audience of over 300 experts,from 28 countries, that the immediatetask is to develop renewable energyand energy efficiency technologies,and integrate them into the market.Eicke Weber, spokesman for theFraunhofer Energy Alliance and headof the Fraunhofer Institute for SolareEnergy Systems (ISE), during hispresentation asserted, “Energy storageis part of a paradigm shift in renewableenergy adoption and usage. Storageat its basic is about being able to useharvested renewable energy producedat a very low cost exactly when weneed it.” He said that there is a widerange of storage technologies, whichwill create an important role for energystorage systems in Germany’s future.According to Weber, the country isparticularly well-positioned to become ahotspot for energy storage technologies,due to plans to phase out nuclearpower and its clear goals on continuingthe expansion of the deployment offluctuating renewable energy.www.pv-magazine.com13 March 2012Electrical engineers at the Universityof California, San Diego are buildinga forest of tiny nanowire trees inorder to cleanly capture solar energywithout using fossil fuels and harvestit for hydrogen fuel generation.Reporting in the journal, Nanoscale,the team said nanowires, whichare made from abundant naturalmaterials like silicon and zinc oxide,also offer a cheap way to deliverhydrogen fuel on a mass scale.The trees’ vertical structure andbranches are key to capturing themaximum amount of solar energy,according to Deli Wang, professorin the Department of Electrical andComputer Engineering at the UCSan Diego Jacobs School ofEngineering. In the long run, whatWang’s team is aiming for is evenbigger: artificial photosynthesis.In photosynthesis, as plants absorbsunlight they also collect carbondioxide (CO 2) and water fromthe atmosphere to createcarbohydrates to fuel their owngrowth. Wang’s team hopes to mimicthis process to capture CO2 fromthe atmosphere, reducing carbonemissions and converting it intohydrocarbon fuel.www.sciencedaily.com7 March 2012An innovative low-cost smart paintthat can detect microscopic faultsin wind turbines, mines and bridgesbefore structural damage occurs isbeing developed by researchers at theUniversity of Strathclyde in Glasgow.The environment-friendly paintuses nanotechnology to detectmovement in large structures, andcould shape the future of safetymonitoring. Traditional methods ofassessing large structures are complex,time consuming and use expensiveinstrumentation, with costs spiralinginto millions each year.However, the smart paint costsjust a fraction of the cost and canbe simply sprayed onto any surface,with electrodes attached to detectstructural damage long before failureoccurs. Dr Mohamed Saafi, of theUniversity’s Department of CivilEngineering, said: “The developmentof this smart paint technology couldhave far-reaching implications for theway we monitor the safety of largestructures all over the world.8April 2012Volume 5 ● Issue 5

International“There are no limitations asto where it could be used and thelow-cost nature gives it a significantadvantage over the current optionsavailable in the industry. The processof producing and applying the paintalso gives it an advantage as noexpertise is required and monitoringitself is straightforward, he said.” Thepaint is formed using a recycled wasteproduct known as fly ash and highlyaligned carbon nanotubes. Whenmixed, it has a cement-like propertywhich makes it particularly useful inharsh environments.www.esciencenews.com30 January 2012Abu Dhabi Bets onAnti-Dust Solar PanelsAbu Dhabi is teaming up witha global electronics company todevelop better coatings for solarpanels to make them cheaperand easier to keep clean in desertconditions. The Middle East andNorth Africa (MENA) regionstands to benefit from concentratedsolar power (CSP) – a technologythat uses lenses or mirrors to focuslarge amounts of sunlight onto asmall area. This light is convertedto heat, which generates electricity.But harsh desert conditions inparts of the MENA region generatelarge amounts of airborne dustwhich collects on the solar panelsused in CSP systems, reducingtheir efficiency. They need regularcleaning, which consumes largeamounts of water.Now, the Masdar Institute ofScience and Technology says it willwork with Siemens AG to developcoatings using water-repellentmaterials, commonly used tomanage oil spills. These materialsforce water droplets to form beadsthat then trap dust, meaning thatless water would be needed to keepthe panels clean.Matteo Chiesa, AssociateProfessor of Mechanical Engineeringat the Masdar Institute said that theteam is also developing a modellingtool that will incorporate weatherdata, to predict how often the panelswill need cleaning. He also addedthat the field tests are underway totest the coating and predictive tool,and the adapted solar panels couldreach the market within five years.www.scidev.net5 March 2012Total Green ElectricityGeneration for ScotlandScotland will be able to generateall its domestic electricity usingrenewable methods by 2020,the government has confirmed.However, it will be a challengeto reach the target and greenenergy generation will need to besupported by at least 2.5 GW fromthermal power units that will beincreasing their carbon captureand storage rates. The governmentalso aims to completely removecarbon from electricity generationby 2030, under plans outlined inthe Electricity Generation PolicyStatement (EGPS), which has justbeen released.Fergus Ewing, Scotland’s EnergyMinister, says, “We know there isdoubt and scepticism about our 100per cent renewables target, and thefinancial and engineering challengesrequired to meet it. But we willmeet these challenges. I want todebate, engage and co-operate withevery knowledgeable, interestedand concerned party to ensurewe achieve our goals.” The plansmean there will be no need to buildany new nuclear power stations inScotland. By 2020, the governmentaims to support local andcommunity ownership of at least500 MW of renewable electricityand heat energy. It also plans toreduce final energy consumptionin Scotland by 12 per cent andcomplete full carbon capture andstorage at power stations from2025-2030. In the related ‘ThePower of Scotland Secured’document, green campaigners‘Friends of the Earth’ commissioneda report saying that by 2030renewable methods could provideenough electricity for all ofScotland’s energy needs plus 85 percent extra for export.www.earthtimes.org6 March 2012April 2012Volume 5 ● Issue 59

Cover StoryHydrogen Energy andFuel Cell TechnologiesRecent Developments and Future Prospects in IndiaEnergy security is a major challenge that needs imaginative and innovativesolutions for a country like India. Therefore, options for diversificationof fuels and energy sources need to be pursued vigorously to enhance theeconomic growth rate for socio-economic development.M R NouniFuel cell bus developed by TATA motorsThe growing concern about depleting oil reserves,harmful effects of greenhouse gas emissions andthe necessity to reduce emissions from powerplants and vehicles are some of the key factorsencouraging the development of new and renewable energytechnologies. Hydrogen: the zero carbon fuel, excels incomparison to other fuels including bio-fuels, with regardto first the decrease and then the elimination of the effectof climate change. Thus, hydrogen is a clean energy carrierwith potential to replace liquid and gaseous fossil fuels in thecoming decades. In recent years, notable progress has beenmade globally for the development and demonstration ofhydrogen energy and fuel cell technologies. Hydrogen canstore and deliver usable energy, but it doesn’t exist by itself innature. It must be produced from compounds that containit - using available resources - natural gas, coal and nuclear;biomass and other renewables including solar, wind, hydroelectric,or geothermal energy. This diversity of being ableto use diverse energy sources makes hydrogen a promisingenergy carrier and important from the energy security viewpoint. Hydrogen is high in energy content as it contains120.7 MJ/kg, which is the highest for any known fuel.However, its energy content on volume basis is rather low.This poses challenges with regard to its storage for civilianapplications, when compared to storage of liquid fossil fuels.With primary emphasis on energy security andenvironment improvement, various Research, Developmentand Demonstration (RD&D) activities on different aspects10April 2012Volume 5 ● Issue 5

Cover Storyof hydrogen energy that includes hydrogen production,its storage and applications for motive power and powergeneration through internal combustion engine and fuel cellbased systems, have been pursued by academic institutions,Council for Scientific and Industrial Research (CSIR)laboratories, industry etc. with the support of Government ofIndia, for more than two decades. As a result, laboratory scaleprototypes have been developed and some of them include:(a) bio-hydrogen production using distillery wastes; (b) ProtonExchange Membrane (PEM) based electrolysers for hydrogenproduction through splitting of water and water-methanolmixture; (c) inter-metallic hydride with storage capacity upto2.42 wt per cent; (d) liquid organic hydrides for hydrogenstorage with storage capacity of about 6 wt per cent ; (e)methanol reformer for production of hydrogen, which canbe used in PEM fuel cells; (f) hydrogen catalytic combustioncookers; (g) hydrogen fuelled motor-cycles and three wheelerswith hydrogen storage in metal hydrides; (h) hydrogenfuelled three wheelers with hydrogen storage in high pressurecomposite cylinders; (i) hydrogen fuelled internal combustionengine for stationary power generation; (j) phosphoric acid fuelcells with stacks up to 25 kW capacity; (k) PEM fuel cells withstacks up to 5 kW capacity; (l) UPS system based on PEMfuel cell; (m) fuel cell battery hybrid van; (n) hydrogen blendedCNG (H-CNG) fuelled vehicles; etc. Use and applications ofhydrogen are in the early demonstration stages in the countryboth for transport and for stationary power generation.National Hydrogen Energy Road MapWith a view to accelerate the development of hydrogen energysector in the country, a National Hydrogen Energy Board,which included all the stakeholders, was constituted in 2003.They created a National Hydrogen Energy Road Map thatprovides the broad pathway to be followed for development andintroduction of hydrogen energy technologies in the country.For achieving the overall growth of the entire hydrogen energysector, the Road Map suggested ambitious targets for transportsector and power generation for the period up to 2020. It alsoemphasised the need for taking up a wide ranging R&Dprogramme in the country including eight projects in missionmode relating to (a) clean coal gasification technologies forhydrogen production; (b) hydrogen production throughbiological sources; (c) hydrogen production through renewableenergy sources; (d) hydrogen production through nuclearthermo-chemical water splitting method; (e) hydrogen storagein hydrides; (f) hydrogen storage in carbon nano-structures;(g) development of internal combustion (IC) engine forhydrogen fuel; and (h) development of PEM and solid oxidefuel cell (SOFC) technologies.Hydrogen can be produced using locallyavailable resources including naturalgas, coal and nuclear, biomass and otherrenewables including solar, wind, hydroelectricor geothermal energy.Efforts made during 11th PlanHydrogen energy and fuel cell activities in the country receivedan impetus after the acceptance of the National HydrogenEnergy Road Map in 2006. From 2006-07 onwards a totalof 54 new RD&D projects, of which 38 projects in the areaof hydrogen, its storage and applications and 16 projectsrelated to different fuel cell technologies are being supportedby the Ministry of New and Renewable Energy (MNRE).The extent of the support provided to hydrogen energy andfuel cell activities is clear from the fact that out of 169 newRD&D projects supported by the MNRE during the 11thPlan Period (2007-08 to 2011-12), 44 projects(26 per cent)were related to hydrogen energy and fuel cells. In terms of thetotal financial support provided by the MNRE during the11th Plan Period, hydrogen energy and fuel cell projects wereprovided with a budget of about Rs. 118 crore out of the totalRD&D support of about Rs. 507 crore.Hydrogen productionIt is pertinent to note that a large number of projectsconcerning hydrogen production, have been sanctionedduring the 11th Plan and are shown in Fig. 1. Further,for meeting the requirement of hydrogen up to 2020, theNational Hydrogen Energy Road Map had suggestedFuel Cells, 12Applicationsin Engines, 8Others, 2HydrogenProduction 15HydrogenStorage, 7Fig 1. Sector wise distribution of sanctioned RD&D Projects related toHydrogen Energy and Fuel Cells during the 11th PlanApril 2012Volume 5 ● Issue 511

Cover StoryThe National Hydrogen Energy RoadMap provides the broad pathwayto be followed for development andintroduction of hydrogen energytechnologies in the country.different processes as shown in Fig. 2. In order to meetthe immediate requirement of hydrogen for transport andpower generation applications, it was suggested to tap byproduct/ spare hydrogen available in industries like chloralkaliindustries, fertiliser plants and petroleum refineries.A study conducted by the University of Petroleum andEnergy Studies estimated a theoretical surplus of 0.0313MMT, out of a total hydrogen generation capacity of0.0732MMT from chlor-alkali units during 2007-08. Nosurplus hydrogen is available in petroleum refineries andfertiliser plants. As per information compiled by the Alkali-Manufacturers Association of India, hydrogen produced by37 chlor-alkali units in India was about 666.29 million Ncu m (0.0598 MMT) during 2010-11. About 86.39 per centof it was being utilised for production of hydrochloric acid,as fuel for captive use sold after bottling it, in downstreamunits and other applications. Therefore, about 0.0081MMT of surplus hydrogen was available from chlor-alkaliunits during 20101-11. However, it seems that the amountof surplus hydrogen from chlor-alkali units is progressivelyreducing after analysing the hydrogen consumption patternfor the years 2008-09, 2009-10 and 2010-11.A demonstration project for on-site hydrogen productionPrimary EnergySourceHydrocarbonsElectricityCoalBiomassNuclearSolarRenewableUpto 2007Immediatesupplies2007- 2017Mid & long-termsuppliesIndustrialEffluentsBeyond 2017SuppliesProcessBy-product H2Reforming etcElectrolysisGasificationShif:Reactionliquid fuelprocessBiologicalWater splitting processesThermochemicalHigh Temp ElectrolysisBiologicalFig 2. Hydrogen supply processes suggested in the NationalHydrogen Road MapApplication1.Transport(IC engines/Fuel Cells)2. Power(IC engines/Turbines/Fuel Cells)3. ProcessIndustry(Fertilisers/petroleumRefining etc.)using alkaline electrolyser of 5 N cu m/hr capacity, blendingit with compressed natural gas and dispensing of H-CNGwas commissioned at Dwarka in New Delhi by the IndianOil Corporation Limited (IOCL) in March, 2009. A similarunit was installed by IOCL in its R&D Centre at Faridabad in2005. These facilities are being currently used for dispensingH-CNG fuel in some demonstration vehicles. The ElectricalResearch and Development Association (ERDA), Vadodarahas developed a prototype demonstration project for windhydrogen based stand-alone electrical generation. Underthis project, 2x5 kW small wind turbines have been usedto meet the electrical energy requirement of a load eitherdirectly through a battery bank or through a gen-set, whichused hydrogen as a fuel produced by an electrolyser operatedby direct current (DC) drawn from the battery bank. Witha view to generate hydrogen from solar energy, a hydrogenproduction and dispensing facility is scheduled to be setup at the Solar Energy Centre (SEC), Gwalpahari usingPV generated electricity for operating an electrolyser. Thedemonstration project, being implemented by the Universityof Petroleum and Energy Studies (UPES), Dehradun is likelyto be commissioned by 2013-14. For hydrogen productionthrough gasification of biomass, one project each is beingimplemented by the Indian Institute of Science (IISc),Bangalore and the National Institute of Technology (NIT),Rourkela. The IISc is working on the development of theoxy-steam gasification unit using an open top downdraftgasification system for hydrogen production rate of about0.1 kg/kg biomass at various steam-to-biomass ratios. TheNIT, Rourkela will be developing a bench scale fluidisedbed gasifier of 5 kW capacity for hydrogen production rateof about 0.09 kg/kg of feed stock.A pilot plant of 800 litres capacity for bio-hydrogenproduction was installed at Indian Institute of Technology(IIT) Kharagpur under a project that concluded in 2007.Hydrogen yield was observed to be 5.5 moles of hydrogenper mole of sucrose after 25 hours of fermentation, whichamounted to about 2.4 cu m of hydrogen production perday from the reactor (the average hydrogen production is inthe range of 3-5 volumes per day per volume of the reactor).In a mission mode project, under implementation from2009 to 2014, IIT Kharagpur in association with AllahabadUniversity, Banaras Hindu University (BHU), IndianInstitute of Chemical Technology (IICT) Hyderabad,Jawaharlal Nehru Technological University (JNTUH)Hyderabad, and The Energy Research Institute (TERI),New Delhi would be designating, developing and installingthree 10 m 3 capacity pilot demonstration plants with12April 2012Volume 5 ● Issue 5

Cover Storyhydrogen generation capacity of 30,000 to 50,000 litresper day. This project would aim at making bio-hydrogenproduction commercially viable by way of selection ofsuitable organic waste as substrate; development of suitableconsortia for the process; use of thermophiles to avoid thesterilisation of the waste materials; and development of anintegrated (two stage fermentation) process.The IICT has undertaken work relating to catalystdevelopment and bench scale reactor development forhydrogen production studies from biomass derived glycerolduring 2008-11. The bench scale reactor is being scaled upfor the development of a pilot demonstration plant of 2 Ncu m/hr capacity of hydrogen production by IICT. TheCentral Institute of Mining and Fuel Research (CIMFR),Dhanbad developing a novel process for production ofhydrogen from renewable and fossil fuel based liquidand gaseous hydrocarbons, by the non-thermal plasmareformation technique.The Centre for Materials for Electronics Technology(C-MET), Pune and IICT are working on developingprocesses for decomposition of hydrogen sulphide forproduction of hydrogen by photo-catalytic and nonthermalplasma assisted methods respectively. For splittingwater using solar energy directly, which is dubbed as theultimate and sustainable method for hydrogen production,Institute of Minerals and Materials Technology (IMMT),Bhubaneswar; IICT and Yogi Vemana University, Kadapaare some of the institutions that are engaged in carrying outR&D work in India.Hydrogen StorageHydrogen storage remains a major problem for thedevelopment and viability of hydrogen-fuelled vehiclesand is considered by many to be the most technologicallychallenging aspect for achieving a hydrogen-based economy.As per the experts, on-board hydrogen storage capacity inthe range of approximately 5–13 kg is required to enablea driving range of about 500 kms for typical automotivevehicles using fuel cell power plants. Presently hydrogencan be stored in three forms; gaseous, liquid or as a solidcombined with a metal hydride. The most suitable storagemethod is dependent upon safety aspects, environmentalissues, economic criteria and the end-use of hydrogen.The R&D work carried out so far in the country has beenfocussed on metal hydrides, inter-metallic hydrides, complexhydrides, liquid organic hydrides etc. While three R&Dprojects were completed during 11th Plan (Fig 3), seven newR&D projects were sanctioned during this period in the areaFuel Cells, 10Applications, 3Others, 2HydrogenProduction, 10HydrogenStorage, 3Fig 3. Sector wise distribution of RD&D Projects related to HydrogenEnergy and Fuel Cells completed during the 11th Planof hydrogen storage (Fig 1). The completed projects wererelated to synthesis and evaluation of complex hydrides;development of liquid organic hydrides; and theoreticalinvestigation on ‘likely to be favourable factors’ of helicalcarbon nano-tubes for enhanced hydrogen absorptionundertaken by IIT, Mumbai; National EnvironmentalEngineering Institute (NEERI), Nagpur and ThiagarajarCollege of Engineering, Madurai, respectively. The NEERIidentified and tested a catalyst for dehydrogenation ofcyclohexane and methylcyclohexane. Hydrogen storagecapacity for the process was found to be 6.1- 6.8 wt per cent.With a view to achieve about 5 wt per cent storagecapacity in hydrides and carbon materials with cycle life ofmore than 1000, one mission mode project each is beingimplemented by BHU, Varanasi and IIT Madras, Chennai.Non Ferrous Materials Technology Development Centre,Hyderabad and NIT, Tiruchirappalli are working ondifferent aspects of magnesium hydride material. The IIT,Fig 4. Hydrogen fuelled three wheelerApril 2012Volume 5 ● Issue 513

Cover StoryEfforts related to use of hydrogen as fuelhave been mainly focused on developmentof internal combustion engines bymodifying petrol, diesel and gaseousengines to operate with hydrogen.Fig 5. Fuel cell systemGuwahati is engaged in development of a metal hydridebased hydrogen storage device.Use of Hydrogen in Engines and forThermal ApplicationsEfforts related to use of hydrogen as fuel have been mainlyfocussed on development of internal combustion engines bymodifying petrol, diesel and gaseous engines to operate withhydrogen. To begin with, existing spark ignited engines weremodified to operate with hydrogen as a fuel. Prototypes of suchengines are small single cylinder engines. A single cylinder fourstroke, spark ignited, air cooled 5 hp engine was modified tooperate with hydrogen and integrated with a 2.5 kVA alternatorby IIT, Delhi for power generation for stationary applications.The learnings from this effort helped IIT, Delhi develop ahydrogen fuelled engine for a three wheeler in association withMahindra and Mahindra (M&M). In addition, petrol drivenmotorcycles and three wheelers have also been modified tooperate with hydrogen as a fuel by BHU, Varanasi.Blending of hydrogen with CNG was considered to bethe best strategy for not only introduction of hydrogen insome form in vehicles under Indian conditions but also forgaining experience about production, storage, dispensing andapplication of hydrogen as the infrastructure for CNG wasalready available in some parts of the country. On acceptance ofthe National Hydrogen Road Map, one of the earliest projectstaken up for implementation related to the use of hydrogen(up to 30 per cent ) as fuel, blended with CNG in an internalcombustion engine. Under this project, being implementedby the Society of Indian Automobile Manufacturers (SIAM)and R&D Centre of IOCL, two three wheelers, two cars, twomini buses and one cargo vehicle have been developed by fiveautomobile companies i.e. Ashok Leyland Limited, Bajaj AutoLimited, M&M, Tata Motors and Volvo Eicher. Based on theperformance and emission tests undertaken by IOCL, it wasdecided that blending of 18 per cent hydrogen by volume withCNG is the optimum blend to be used in the vehicles includedin the project. Currently, these vehicles are undergoing fieldendurance testing (30,000 kms for three wheelers and 50,000kms for other vehicles) between Faridabad and Dwarka, NewDelhi as the facilities for supply of H-CNG exist at R&DCentre of IOCL at Faridabad and Dwarka, New Delhi. Theproject would be completed during 2012 and may pave theway for introduction of more H-CNG fuelled vehicles onIndian roads.In order to study the impact of using hydrogen - dieseland hydrogen-straight vegetable oil (SVO) in dual fuel modeon performance and emissions of engines, two projects areunder implementation. One project is being implementedby M&M in technical collaboration with SaskatchewanResearch Council (SRC), Canada for development anddemonstration of a sports utility vehicle using hydrogenalong with diesel. Under another project, the Universityof Petroleum and Energy Studies (UPES) is developing astationary engine for using hydrogen with SVO.The M&M in association with the IIT, Delhi has developed15 three wheelers under a project named ‘DELHY-3W’ whichwas supported by the United Nations Industrial DevelopmentOrganisation (UNIDO) through the International Centre forHydrogen Energy Technologies (ICHET), Istanbul, Turkey(Fig. 4). This project was supported in March, 2009 with IITDelhi; M&M; Air Products / INOX Air Products; and IndiaTrade Promotion Organisation (ITPO) as project partners.14April 2012Volume 5 ● Issue 5

Cover StoryUnder this project, 15 hydrogen fuelled three wheelers arebeing demonstrated at New Delhi currently. Hydrogen isstored in a compressed gaseous form in composite cylinders.Limited field trials have shown that the hydrogen fuelledthree wheelers are giving around 85 km per kg of hydrogenconsumed. The facilities for transport, storage and dispensingof hydrogen has been provided and managed by the AirProducts. Under another project, BHU Varanasi is engaged indevelopment of about 10 hydrogen fuelled three wheelers withhydrogen storage in metal hydrides instead of in the gaseousform in a pressure vessel.With a view to develop a multi-cylinder hydrogen fuelledengine that can be used in a bus, a mission mode projectis under implementation by IIT, Delhi in association withM&M. The Annamalai University is working on lean limitextension for spark ignited direct injection engine throughon-board non-thermal plasma conversion for hydrogenproduction. Also IIT, Kanpur is undertaking experimentalinvestigations on combustion characteristics and emissionreduction of laser fired hydrogen engine and is engagedin design and development of hydrogen gas burner forindustrial applications.Fuel CellThe focus of R&D on fuel cells in India is on differenttypes of fuel cells namely polymer electrolyte membranefuel cell (PEMFC), phosphoric acid fuel cell (PAFC),direct methanol fuel cell (DMFC), direct ethanol fuelcell (DEFC), solid oxide fuel cell (SOFC) and moltencarbonate fuel cell (MCFC). The emphasis of research hasbeen on further improvements in fuel cell related processes,materials, components, sub-systems and fuel cell systems.Ten projects related to different aspects of fuel celltechnologies were concluded during the 11th Plan (Fig.3). IIT, Madras developed methods to prepare compositemembranes with desirable physico-chemical properties forpossible commercial exploitation.The R&D projects under implementation include thedevelopment of high performance DMFC by Universityof Kolkata; development of membranes for DMFC andPEMFC by Birla Institute of Technology and Science,Ranchi and Central Salt and Marine Chemical Institute(CSMCRI), Bhavnagar; and development of catalyst byBengal Engineering Science University, Shibpur.Industry Driven InitiativesThe Indian automobile industry and telecom tower operatorstoo have made efforts to use hydrogen for poweringTen projects related to different aspectsof fuel cell technologies were concludedduring the 11th Plan period. Several R&Dprojects are under implementation withvarious universities of India.automobiles using IC engine as well as fuel cell technologyand also for providing back up power for telecom towersusing fuel cells. In addition to M&M, Tata Motors hasdeveloped a fuel cell bus under a project supported by theCouncil of Scientific and Industrial Research (CSIR) andare planning to develop and demonstrate 10 fuel cell busesin the future. Idea cellular, a telecom tower operator hasinstalled a PEMFC system to provide backup power to atelecom tower in Madhya Pradesh using hydrogen suppliedfrom the nearby chlor-alkali unit (Fig 5). Such fuel cellsystems would replace diesel generator sets, which in turncreate environmental hazards.Capacity BuildingWith a view of capacity building in hydrogen energy sectorand as suggested in the road map, a National Centre ofExcellence for Hydrogen Energy and Fuel Cells may be setup in the country. For this purpose, a detailed project report(DPR) on setting up of National Hydrogen and Fuel CellCentre at Gwalpahari, Gurgaon has been prepared.Prospects for FutureThere is an urgent need to set up hydrogen productioncum dispensing stations at suitable locations, especially formaking operation of hydrogen fuelled vehicles possible. Wemay also see hydrogen fuelled vehicles for public transport,including three wheelers and buses using either IC engineor fuel cell technologies on Indian roads. This is highlyrealistic as the Indian automobile industry has alreadytaken a lead in this direction. However, this would requirenotifying H-CNG as well as hydrogen as automotive fuels.Fuel cell based systems may be used for power generationto provide backup power for telecom towers and stationarypower generation by using surplus by-product hydrogenfrom chlor-alkali units. bThe author is Scientist ‘F‘, in the Ministry of New and RenewableEnergy. E-mail: mrnouni@gmail.comApril 2012Volume 5 ● Issue 515

RE Featureevolution ofGeothermalenerGyin indiaThe use and applicability ofgeothermal energy in the context ofthe Indian scenario is described inthe essay. The future prospects of thisheat energy as a sustainable source ofrenewable energy is indeed promising.J. L. ThussuThe earth is a reservoir of heat energy most ofwhich is buried and is observed during episodesof volcanic eruption at the surface. It alsomanifests as hot springs, geysers and fumaroles.Thermal springs have been known to occur the worldover for centuries. This resource did not attract attentionfor energy development probably because not enough wasknown about its potential till the early twentieth century.Conventional sources of energy like coal, oil and wood arenon-renewable and are likely to deplete with the passage oftime or depth of exploration becomes cost prohibitive. Alsothese resources create inherent problems of environmentdegradation and imbalance in ecology. The ‘oil crisis’ ofthe 1970s, resulting in low supplies of oil from producingcountries led to the need for exploring alternative sources ofenergy for power production and other industrial uses. Oneof the resources was geothermal energy i.e. energy stored inthe earth’s crust.Thermal springs have been a known phenomenon inIndia for centuries. People often visit these springs as apart of religious custom and belief considering the waterto be ‘God’s Gift’ to mankind and capable of miraculoushealing of skin and other rheumatic ailments like arthritis.However, all thermal springs oozing at the surface need not16April 2012Volume 5 ● Issue 5

RE Featurenecessarily have geothermal energy potential.Schlagintweit (1862) and T. Oldham (1882), inventorieda total of 301 thermal springs in the Indian subcontinent.However these studies were mostly in reconnoitory statewherein documentation of the thermal springs, their surfacetemperature and assessing the medicinal qualities wererecorded. At many places, like Badrinath and Gangotriin Uttarakhand; Sohna in Haryana; Rajgir in Bihar;Bakreshwar in West Bengal and Ganeshpuri in West Coast,Maharashtra, temples have been built on thermal springsand the water has been channelised for public use. Systematicefforts to explore geothermal energy resources commencedin 1973 with the launching of the Puga geothermal projectin Ladakh, J&K and gradually the exploration work wasextended to cover Chhumathang in Ladakh, Parbativalley, Himachal Pradesh.; Sohna, Haryana; West Coast,Maharashtra and Tattapani, Sarguja in Madhya Pradesh.To achieve the objectives of this endeavour, geological,geophysical, geochemical, and drilling activities were carriedout under an integrated programme with the GeologicalSurvey of India (GSI) as the lead agency and executed withthe collaboration of many national agencies, viz. NationalGeophysical Research Institute (NGRI), Hyderabad,Atomic Minerals Division (AMD), New Delhi, CentralElectricity Authority (CEA) and others.Classification of Thermal SpringsAbout 300 thermal springs are known to occur in India.These thermal springs occur along the length and breadthof the country extending from Jammu and Kashmir in thenorth to Tamil Nadu (Kanya Kumari) in the south over adistance of about 5000 km, and from Gujarat in the westto Arunachal Pradesh in the east over a distance of 4000km. The springs have been classified on the basis of theiroccurrence in specific geotectonic set ups and have beengrouped under different geothermal provinces. However onthe basis of enthalpy characteristics the geothermal systemsin India can be classified into medium enthalpy (100-200°C)and low enthalpy (less than 100°C) geothermal systems.Medium enthalpy geothermal systems are known to beassociated with the following:● Younger intrusive granites as in the Himalayas, viz. Puga-Chhumathang, Parbati, Beas and Satluj geothermal fields.● Major tectonic features/lineaments such as the westcoast areas of Maharashtra; along the Son-Narmada-Tapi lineament zone at Salbardi, Tapi - Satpura areas inMaharashtra, Tattapani in Madhya Pradesh and Rajgir-The thermal waters have beenused for hatching poultry and forthe growth of mushrooms in a hut,500 sq m in area, by the RegionalResearch Laboratory, Jammu.Monghyr in Bihar and Eastern Ghats of Orissa.● Rift and grabens of Gondwana basins viz. Damodar,Godavari and Mahanadi.● Quaternary and Tertiary sediments in a graben, vizCambay basin off West Coast.Low enthalpy geothermal systems are associated with thefollowing:● Tertiary tectonism and neotectonic activity - north Indiangeothermal field viz. Sohna and Rajasthan.● Shield area with localised abnormal heat flow which isnormally very low - south Indian geothermal province.The medium enthalpy waters could be utilised for eitherprimary cycle power production (Puga geothermal system)or binary cycle power production using different types offreons (Tattapani geothermal system, Madhya Pradesh).The thermal water flowing at other areas, in Maharashtra,Himachal Pradesh, Haryana and Uttar Pradesh, althoughthey fall in medium enthalpy geothermal systems, can beutilised for non-electrical applications only. The thermalwater flowing from low enthalpy geothermal systems doesnot have much scope for harnessing of geothermal energyat present. Thermal water discharging from most of thegeothermal systems in India, at present, have better scopefor non-electric application.Small scale experimegntal utilisation studies have beencarried out at Puga, Chhumathang geothermal fields andat Manikaran in Parbati valley geothermal field. At present,the Puga geothermal field is the only field capable ofproducing either primary cycle electrical power or binarycycle power, that too on a very small scale. The thermalfluids have been utilised for heating of spaces, processingof borax and sulphur and extraction of salts. Its use in theextraction of the rare metal cesium is under experimentation.Poultry farming and green house cultivation are the otherindustrial applications for which geothermal energy hasbeen used. Thermal water energy has been successfully usedfor hatching poultry and for the growth of mushrooms inan enclosed hut, 500 sq m in area, by the Regional ResearchApril 2012Volume 5 ● Issue 517

RE FeatureInvitingarticles forAkshay UrjaThe need to have a sustainable supplynecessitates the exploitation of availableenergy sources, and among these,renewable resources are at the forefront.It is now an established fact that RE(renewable energy) can be an integral partof sustainable development because of itsinexhaustible nature and environmentfriendlyfeatures. RE can play animportant role in resolving the energycrisis in urban areas to a great extent.Today RE is an established sector with avariety of systems and devices availablefor meeting the energy demand of urbaninhabitants, but there is a need to createmass awareness about their adoption.Akshay Urja is an attempt to fulfil thisneed through its dissemination of 20,000copies in India and abroad. The magazinepublishes news, articles, research papers,case studies, success stories, and writeupson RE. Readers are invited to sendmaterial with original photographs andstatistical data. The photographs shouldbe provided in high resolution files on aCD or through email. Akshay Urja willpay a suitable honorarium to the authorsfor each published article of 1500 wordsand above. The publication material intwo copies, along with a soft copy on CD/DVD/e-mail may be sent to<strong>Editor</strong>, Akshay Urjaministry ofnew and renewable energyBlock – 14, CGO Complex,Lodhi Road, New Delhi – 110 003Tel. +91 11 2436 3035, Fax +91 11 2436 3035www.mnre.gov.in, April 2012E-mail aktripathi@nic.inVolume 5 ● Issue 518It is necessary to launch drilling todepths of 1500m to 2500m followedby well testing and reservoirevaluation in the promisinggeothermal areas of the country.Laboratory, Jammu. Green house cultivation has beensuccessfully tried at Chhummathang.At Manikaran (Parbati Geothermal Field) thermalwaters have been utilised for developing a 7.5 tonne capacitycold storage plant based on the ammonia absorptionsystem. A five kWe binary power plant has also been testrun successfully. The Beas Geothermal System’s watershave been utilised at Bashisht and Kalath. The waters atKalath can even be utilised for mineral water bottling. Noexperimental utilisation studies have been carried out at theTattapani Geothermal System. Installation of a 300 kWepilot binary cycle power plant as a collaborative projectbetween GSI, Oil and Natural Gas Commission (ONGC)and Madhya Pradesh Urja Vikas Nigam, Bhopal, utilisingthe thermal fluid discharge from the bore holes drilled byGSI is under consideration. No attempt has been made touse the thermal waters in the west coast geothermal fieldand although 18 thermal spring locations occur alongthe west coast, only three areas (Unhavre-Khed, Tural,Ganeshpuri) have potential for use and that too for nonelectrical purposes. Studies carried out so far have clearlypointed to the presence of geothermal fluids with limitedoutput and moderate temperatures up to a depth of500m and to the strong possibilities of encountering vastresources of geothermal fluids at high temperatures andpressures at deeper levels in many areas in the country. Theneed, therefore is to explore deeper levels of geothermalreservoirs containing sizeable quantity of thermal fluids athigh temperatures and pressures which could be dependedupon for power production of MW level and direct heatapplications on an industrial scale. It is therefore necessaryto launch drilling to depths of 1500m to 2500m followedby well testing and reservoir evaluation in promisinggeothermal areas of the country. Indeed geothermal energy,if adequately exploited, can help tide over the energy crisisand prove to be a dependable source of alternate energy. bThe author is Member (Rtd.) Geological Survey of India, G.O.I.

RE FeatureGeothermal Energy:An OverviewThe article focuses on the great potential of geothermal energy andindicates the possible developments that can be achieved with greaterbenefits in terms of the use for the new renewable resource.Sukanta Roy and Harsh GuptaThe benefits of using geothermal energy as analternative resource are immense. Renewable,low running cost, capability to provide baseload power, and small environmental footprintmake this resource a preferred choice among other energyresources. However, considerable research and developmentis needed to take advantage of this buried wealth. Thefuture use of geothermal energy would depend not onlyon overcoming technical barriers related to its utilisationand the economic viability compared to other energyresources but also on favourable policy initiatives from thegovernment.With rapidly increasing energy demands in growingeconomies such as India, it is important to includeApril 2012Volume 5 ● Issue 519

RE Feature60 0120 0-120 00 0 0 0NAMAF JALLKRAFLASVARTSENGI60 0NESJAVELLIRLARDERELLOMUTNOVKAREYKJANESTRAVALEMT. AMIATAPAUZHETKASODAMORILAKE YELLOWSTONEMASTSUKAWASUMIKAWAKAKKONDATHE GEYSERSLATERAKIZILDERE PUGAONIKOBEROOSEVELTLONG VALLEYYANGBAJINGOTAKE HATCHOBARU30 0 MILOSYANAIZU-NISHIYAMAIMPERIAL VALLEYYUNNANYAMAGAWACERRO PRIETOPHLEGRAEANFIELDSMAK-BANLOS AZUFERSBERLINTIWILOS HUMEROS MORAVALLESDAVAO BAC-MANAHUACHAPAN0 0 LANGANOTONGONAN(HAWAI)MOMOTOMBOSALAKLAHENDONGWAYANG-OLKARIAWINDU DIENGPUCHULDIZADARAJATEL TATIO-30 0KAWAH-KAMOJANGNGAWAHMOKAI WAIRAKEIKAWERAUROTOKAWAREPOROA-60 0 Geothermal field under productionGeothermal field under developmentSeismic beltFig 1. Map showing the distribution of geothermal fields underproduction (filled triangles) and under development (open triangles)[H. Gupta and S. Roy, Geothermal Energy: An Alternative Resourcefor the 21st Century, Elsevier, 2006]. Geothermal fields cluster nearthe tectonically active plate boundaries that are characterized byQuaternary volcanism.180 0sustainable energy resources in its fossil-fuel-dominatedprimary energy mix. Geothermal energy is one such resourcederived from the Earth’s internal heat, which has beencatering successfully to both industrial as well as domesticenergy requirements in many parts of the world over thepast few decades. Being abundant, environmentally benignand renewable, it is a preferred choice for an alternativeenergy resource. Besides conversion to electric power, thedirect uses of geothermal heat have the potential to replacesubstantial quantities of fossil fuels.The worldwide utilisation of geothermal energy hasincreased rapidly during the last three decades mainly fromvariable capacity additions by Phillipines, United States,Italy, New Zealand, Iceland, Costa Rica, El Salvador,Guatemala and Russia (Table 1.). Today, besides beingused in at least 24 countries to generate electricity totalling-60 0Table 1. Countries Generating Geothermal Power in 2010CountriesInstalled Capacity Rank(MW)United States 3,086 1Philippines 1,904 2Indonesia 1,197 3Mexico 958 4Italy 843 5New Zealand 628 6Iceland 575 7Japan 536 8El Salvador 204 9Kenya 167 10Costa Rica 166 11Nicaragua 88 12Russia 82 13Turkey 82 14Papua New Guinea 56 15Guatemala 52 16Portugal 29 17China 24 18France 16 19Ethiopia 7.3 20Germany 6.6 21Austria 1.4 22Australia 1.1 23Thailand 0.3 24Source: www.geo-energy.orgto about 10,700 MW installed capacity (R. Bertani,Proceedings, World Geothermal Congress, Indonesia,2010), geothermal energy is being used in more than 58Table 2. Major hot spring groups in India, their tectonic settings and temperatures of surface waters@Major hot spring groups Tectonic setting Temperature rangeof surface discharge, o CIndus valley (Puga, Chhumathang)Higher Himalaya (active 75-100tectonic zone)Parbati valley (Manikaran), Beas valley, Satluj valley, Tapoban group Central to Lesser Himalaya 50-90in Uttarakhand, etcTattapani group, ChhattisgarhCentral Indian shield (stable 75-100craton)Son-Narmada-Tapti lineament zone (SONATA) Central Indian shield 30-65Bakreshwar-Tantloi, Monghyr, Rajgir, Surajkund, etc Eastern India (stable craton) 45-71West Coast group, Maharashtra Deccan Traps (stable craton) 35-70@ In addition to the major hot spring groups listed above, several low-to-moderate temperature springs occur in Haryana, Gujarat, Andhra Pradesh,Karnataka, Odisha, Assam, Meghalaya and Arunachal Pradesh20April 2012Volume 5 ● Issue 5

RE FeatureFig 2. Steam leaking out of an old well drilled in Puga valley in mid-1980scountries for direct uses (space heating and cooling, healthspas, fish farming, agricultural and industrial purposes). Inseveral developing nations, devoid of adequate conventionalfossil fuels, there is a large potential for use of geothermalresources. For example in Tibet, with no readily availablefossil fuels, the Nagqu geothermal field provides a usefulenergy source for the local population with the help of a 1MW binary plant built in 1993.Geothermal Exploration in IndiaIn most precambrian terrains including India, moderate-to-lowtemperature hot water spring systems represent the potentialgeothermal energy resources. This scenario is in contrast tosteam and/or steam and hot water based geothermal fieldsunder production in other parts of the world, which are locatedpredominantly in quaternary volcanic / magmatic settings(Fig 1). The major groups of hot springs in India occur in theIndus valley (Fig 2, Puga - Chhumathang), Parbati valley(Manikaran) and Tapoban areas in the Himalaya; along thewest coast of Maharashtra in western India; the Son-Narmada-Tapti lineament zone in central India; Tattapani (Fig 3), Rajgir-Monghyr, Surajkund and Bakreshwar in eastern India. Thedistribution of major groups of hot springs in India is shownin Fig 4 and temperature ranges of geothermal waters are listedin Table 2. Most hot springs occur in the foothills or rivervalleys and the waters are predominantly meteoric in origin.No evidence of quaternary magmatism is reported, exceptin the case of Puga-Chhumathang areas where conclusiveevidence is lacking. Therefore, the preferred model for mosthot springs in India is that of rainwater/snowmelt infiltratinginto the subsurface, the downgoing waters picking up heatfrom the Earth’s normal heat flow and returning to the surfacethrough fault / fracture systems. Geothermal springs havebeen used mainly for balneological purposes and religioustourism. However, India is yet to produce electric power fromgeothermal energy, except for a nominal, 5kW, binary plantat Manikaran that was operational for a very short time only.Among the most notable achievements during the pastfive decades has been the assessment of geothermal fieldsby the Government of India in 1966 and publication of acomprehensive report in 1968 recommending preliminaryIndia is yet to produce electricpower from geothermal energy,except for a nominal, 5kW, binaryplant at Manikaran that wasoperational for a very short time.April 2012Volume 5 ● Issue 521

RE FeatureIn recent years, the Ministryof New and RenewableEnergy (MNRE), has shownrenewed interest in geothermalexploration in differentgeothermal areas of the country.prospecting of the Puga and Manikaran geothermal fields inthe Himalaya (Report of the Hot Springs Committee, Govt.of India, 1968). A major, systematic, multi-disciplinary,multi-institutional programme (including drilling upto 385 m) covering the Puga-Chumathang geothermalfields in Ladakh was mounted during 1972-74 under thestewardship of V.S. Krishnaswamy of the GeologicalSurvey of India (GSI) and complemented by scientistsfrom the Council for Scientific and Industrial Research-National Geophysical Research Institute (CSIR-NGRI),Central Electricity Authority and others. The shallowsubsurface features were delineated in considerable detailthat resulted in building a proposal to set up a pilot-scale,1 MWe binary-cycle power plant at Puga. The proposal isyet to be implemented. Attempts to revisit the geothermalexploration in the area include a number of geochemicalstudies (see for example, Geothermal Energy in India, U.L.Pitale and R.N. Padhi (Eds.), Geological Survey of India,Special Publication 45) and recent magnetotelluric studies(Abdul Azeez and Harinarayana, Curr. Sci., v. 93, p. 323-329, 2007). An expert group set up in 2008 by the Ministryof New and Renewable Energy, Government of Indiamade strong recommendations to install pilot-scale plantsby drilling exploration cum demonstration wells in thearea (Report of Expert Group on Power Generation fromGeothermal Energy at Puga, Jammu and Kashmir, India: Ministry of New and Renewable Energy, Govt. of India,2008). This would be useful not only for monitoring therates of hot water discharge and temperatures over a periodof time but also studying the reservoir characteristics.Another major initiative, directed towards the hot springsof the West Coast belt and the Son-Narmada-Tapti belt thatwas taken up by the GSI with assistance from the UnitedNations Development Programme (UNDP) during 1976-77 and later extended for a few years, included deep drillingup to depth of 500 m (Records of the Geological Surveyof India, v. 118, Pt. 6, 1987). The Tattapani hot springs inChhattisgarh were identified for setting up of a 300 kWeFig 3. Hot water flowing out of one of the wells in Tattapani area,Surguja district in Chhattisgarhbinary-cycle power plant. Although substantial geologicinformation on the Puga and Tattapani geothermal fields hasbeen acquired, the lack of deep exploration, at least to depthsof a few kilometres, hinders reservoir characterisation andevaluation of realistic geothermal energy potential. Muchless information is available about the other geothermalfields in the country.In recent years, the Ministry of New and RenewableEnergy (MNRE), Government of India has shown renewedinterest in geothermal exploration in different geothermalareas of the country besides creating the framework fora national policy on exploitation of geothermal energyresources. Results emerging from these programmeswill provide useful information and guide furtherexploration efforts in the country. Direct uses of warmto-hotgeothermal waters for greenhouse heating in coldclimates, development of tourist spas, agricultural productprocessing, and extraction of rare materials like cesium alsoprovide significant economic and environmental benefitsfrom replacement of fossil-fuel use in environmentallysensitive areas.Additionally, the CSIR-NGRI has a dedicated heat flowstudies programme since its inception in 1962, which has22April 2012Volume 5 ● Issue 5

RE Feature36 028 020 0Mumbai120 0 N68 0 E 76 0 84 0 92 0SrinagarDelhiChennai0 300 900 kmSCALEPuge-Chumathanggeothermal areaGuwahatiHot springsTattapanigeothermal area75- 100 0 C55-75 0 C35-55 0 C< 35 0 C68 0 E 76 0 84 0 92 0PortBlairFig 4. Outline of India showing the distribution of major groups of warm andhot springs [modified after Krishnaswamy, Proc. Second UN Symposium onDevelopment and Use of Geothermal Resources, USA, 1975]. Temperatures ofthe hot spring waters are indicated using symbols (see legend). Shaded regions(exaggerated scale) show the major clusters of hot springs.generated valuable data sets on the geothermal gradientand regional heat flow from temperature measurements inmore than 500 boreholes covering a number of geologicand tectonic provinces in the country (S. Roy, Heat flowstudies in India during the past five decades, Memoir 68,Geological Society of India, pp. 89-122, 2008). Detailedcharacterisation of thermophysical properties of major rockformations are carried out routinely to facilitate modellingof the temperature distribution in the crust in different partsof the country. Areas with anomalous high temperaturesin the top 1-4 km of the crust, appropriate for enhancedgeothermal systems (EGS) and hot sedimentary aquifers(HSA) could be delineated from such datasets.Perspectives for Development ofGeothermal EnergyRe-assessment of Energy Potential of ConventionalGeothermal Resources: Temperature of hot spring watersat the surface is not the sole indicator of energy potential.The major question to be addressed is the sustainability ofthe resource, i.e., for how many years the production of hotwaters at a certain minimum temperature and flow rate canbe sustained. Answers to these questions require aprioriinformation about characteristics of the subsurface reservoirand the nature of the heat source.In view of the growing energy demands and the emphasison renewable energy in India, a re-assessment of the geothermalenergy potential of the Puga Valley hot springs in Ladakhand Tattapani hot springs in Chhattisgarh should be carriedout. Critical gaps in information need to be covered throughacquisition of new data, combined interpretation of geothermaldatasets and existing geological, hydrological, geochemicaland geophysical datasets to throw light on the nature of theheat source of the hot springs and their sustainability for powerproduction, undertaking drilling and setting up of pilot-scalebinary-cycle power plants. Scientific and statistical datasetsincluding estimates of benefits from using geothermal energyshould be compiled. These datasets could influence nationalpolicy decisions for providing tax incentives to investors andhelping them tide over the increased upfront production costsof geothermal power when compared to conventional fuels.Development of appropriate power generationtechnologies: Geothermal resources vary widely from onelocation to another, depending on the temperature and depthof the resource, the rock chemistry, and the abundance ofgroundwater. The type of geothermal resource determinesthe method of its utilisation. Variants of binary cyclesappropriate to optimum utilisation of geothermal heat frommoderate-to-low enthalpy springs in non volcanic settingssuch as those in India, need to be developed.Efficient deep drilling technology is another importantarea requiring research and development in the countryas drilling and distribution account for the largest costs,development of improved technologies to help contractorsin difficult drilling environments help make deeper drillingeconomically viable, thereby providing access to highertemperature resources for power generation. Technologicalsolutions to problems of corrosion and calcite deposition inpipelines, usually associated with geothermal systems, mustbe sought. Appropriate re-injection strategies, deep drillingand well stimulation are the key drivers for the producingfields to remain potential and economical in the long run.Direct heat uses: The heat extracted from warm-to-hotwaters emerging from other hot spring systems in thecountry can be gainfully employed for a number of directuses such as development of tourist spas for bathing,swimming and balneology, greenhouse cultivation in coldclimates, extraction of borax and rare materials such ascesium, and agricultural product processing. The significanteconomic and environmental benefits of using moderateto-lowenthalpy geothermal waters to replace even smallApril 2012Volume 5 ● Issue 523

RE FeatureThe viability of geothermalheat pumps for heating insidebuildings should be exploredin the states of Jammu andKashmir, Himachal Pradesh andparts of Uttarakhand.quantities of conventional fuels for direct uses cannot beignored today in view of the steep increase in costs of fossilfuels and associated greenhouse gas emissions.Geothermal Heat Pumps: A geothermal (or ground-source)heat pump makes use of the relatively stable temperatureat a depth of a few meters in the ground. During winter,the subsurface temperature is warmer than the roomtemperature inside a house, whereas during summer thesubsurface temperature may be cooler. Geothermal heatpumps, therefore, can be extensively used for space heatingin winter and cooling in summer, replacing fossil-fuel drivenelectrical heating and cooling systems. Heat pump systemsuse groundwater aquifers and soil temperatures in the range5 o C to 30 o C. Heat pumps utilising very low-to-moderatetemperature fluids have extended geothermal developmentsto countries that have not been using geothermal energyextensively such as France, Switzerland, Sweden, and areasof the mid-western and eastern United States of America.An assessment of the technology for suitability to Indianconditions is yet to be carried out.The viability of geothermal heat pumps for heating insidebuildings should be explored in the states of Jammu andKashmir, Himachal Pradesh and parts of Uttarakhandwhich experience severe winter conditions for long periods.Space cooling requirements in most parts of India have grownseveral fold in the recent years with the growth in economy.There is enormous scope for developing the capabilitiesin geothermal cooling of buildings by modifying existingtechnologies to suit Indian conditions. A proper assessmentof the technology for application to different climaticenvironments existing in the region, and its exploitation byintegrating it with building designs should be encouraged.Exploration for Enhanced Geothermal Systems: A nonconventionalgeothermal resource traditionally referred toas ‘hot dry rock’ and more recently as ‘enhanced geothermalsystems (EGS)’, has not yet been explored in India. Theprimary requirement for such a resource is the occurrenceof high temperatures (typically upwards of 150 o C) ateconomically viable depths (typically the top 1-4 km of theEarth’s crust). Areas of anomalous high heat flow, highheat-producinggranites and other silicic igneous intrusivebodies having a depth extent of a few kilometres, could bepossible targets for future exploration efforts in the country(Roy, 2008). These considerations reinforce the need forcarrying out systematic heat flow as well as radiogenic heatproduction investigations on a country-wide scale.SummaryModerate-to-low enthalpy hot spring systems primarilyrepresent the known geothermal energy resources in India.These resources are distributed in diverse physiographicand tectonic settings, viz., the Himalayan belt and thePrecambrian shield. Detailed geological and geochemicalexploration followed by limited geophysical exploration andshallow drilling investigations up to a few hundred metresonly, have resulted in first-order geothermal models forthe major hot spring zones in the country. However, thedevelopment of the geothermal resources has remained ata very low level mainly due to inadequate characterisationof the deeper thermal regime, leading to low confidencein proposed reservoir models and sustainability of theheat source. There is therefore an urgent need to carryout a reassessment of the geothermal energy potential ofhot springs by employing new geophysical probing toolsand computational techniques available today, both forelectric power generation as well as for direct uses. Efficientexploitation technologies appropriate to non-volcanicareas need to be developed. Systematic heat flow and heatproduction investigations need to be carried out for theidentification of areas where high temperatures in the top fewkilometers below the ground surface indicate potential for‘hot sedimentary aquifers’ as well as ‘enhanced geothermalsystems’. The vast potential for geothermal heat pumps isyet to be tapped. The existing heat pump technology mustbe modified and made accessible to individuals and smallcommunities to serve as a low-cost alternative to use of fossilfuels for their space heating and cooling needs. Developmentof ocean thermal energy conversion technologies must bepromoted and the benefits from low temperature thermaldesalination of seawater made available to widespread islandcommunities. Enabling policy guidelines from the MNREwill facilitate rapid progress in exploration and developmentof geothermal energy resources. bThe authors are Scientist,Council of Scientific and Industrial Research-National Geophysical Research Institute, Hyderabad and Member,National Disaster Management Authority, New Delhi, respectively.E-mail: sukantaroy@yahoo.com24April 2012Volume 5 ● Issue 5

RE FeatureHarneSSingbioelectricitytHrougHmicrobialfuel cellfroMwaStewaterBioelectric effects of ‘electric’fish like the Nile Catfishand Electric Eel are wellknown since ancient times.Bioelectricity is the processthat is produced by or occursin a living organism which canbe transformed chemically toproduce bioenergy which isboth sustainable and renewable.Dr S Venkata MohanThe microbial fuel cell (MFC) has garneredsignificant interest in both basic and appliedresearch due to its sustainable and renewablenature in the contemporary energy scenario andis all set to be the trendsetter in the arena of answers to thecomplex environmental pollution problems and the energycrisis, with a unified approach. The MFC is essentiallya hybrid bio-electrochemical system which directlytransforms chemical energy stored in the biodegradablesubstrate to electrical energy via microbial catalysed redoxreactions involving microorganisms as biocatalysts underambient temperature/pressure. The biocatalytic activity ofthe microorganisms present in the anode chamber generatesthe reducing equivalents [protons (H+) and electrons (e-)] through a series of bio-electrochemical redox reactionsduring substrate degradation in absence of oxygen.These protons and electrons are the source of electricitygeneration in MFC. The electrochemically active natureof a microorganism supports the effective pumping ofredox powers. The MFC has multiple applications basedApril 2012Volume 5 ● Issue 525