go green - PPG Industries

go green - PPG Industries

go green - PPG Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

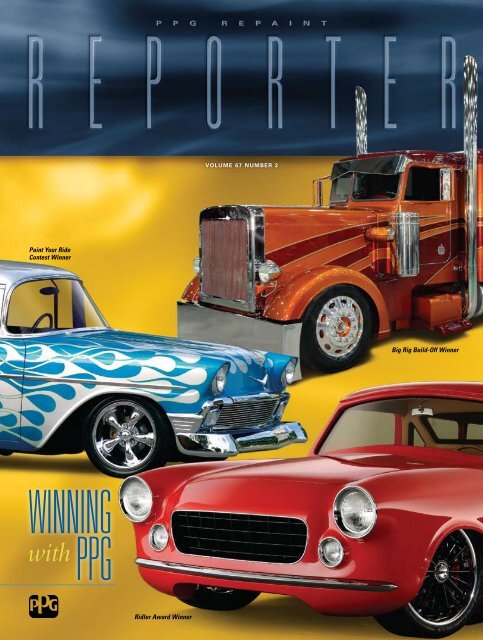

Paint Your Ride<br />

Contest Winner<br />

WINNING<br />

with <strong>PPG</strong><br />

Ridler Award Winner<br />

Volume 67 Number 3<br />

Big Rig Build-Off Winner

Innovating Repair Solutions<br />

Innovations from Nexa Autocolor<br />

Always bringing you<br />

the future<br />

© 2008 <strong>PPG</strong> <strong>Industries</strong>. All rights reserved. www.ppgrefinish.com www.nexaautocolor.com<br />

• Non-Stir Waterborne Toners<br />

• Anti-Settle Special Effects<br />

• Spectral Grey Undercoats<br />

• UV Cured Primer<br />

• Engine Bay Repair Process<br />

• Minor Repair Process<br />

The Advanced<br />

Dimension in Refinish<br />

Performance<br />

<strong>PPG</strong><br />

Repaint Reporter<br />

Volume 67, Number 3<br />

Fall 2008<br />

executive editor<br />

Ann Donati<br />

Creative Director<br />

T. Jon Worden<br />

Design Director<br />

Dave Buffington<br />

Design Staff<br />

John Janiec<br />

Kevin Nowak<br />

Mark Francisco<br />

Bob Santoro<br />

managing editor<br />

Meredith Simpson<br />

Contributing editor<br />

Cristina Fronzaglia<br />

Writers<br />

T. Jon Worden<br />

Eli Greenbaum<br />

Paul Walter<br />

Production manager<br />

Shellie Hill<br />

Contributing Photographer<br />

Dave Lehman<br />

<strong>PPG</strong> Repaint Reporter is published<br />

by the Advertising Department of<br />

<strong>PPG</strong> Automotive Refinish. Send<br />

comments and questions regarding<br />

this publication to:<br />

<strong>PPG</strong> <strong>Industries</strong><br />

Repaint Reporter Editor<br />

19699 Progress Drive<br />

Strongsville, Ohio 44149<br />

refincommdpt@ppg.com<br />

Or, fax to: (440) 572-6880<br />

looking for additional copies of<br />

this <strong>PPG</strong> repaint reporter issue?<br />

Limited copies are available via two<br />

easy ways of ordering:<br />

1) Connect to ppgCentral via<br />

www.ppgcentral.biz<br />

OR<br />

2) Fax a completed advertising<br />

order form to 1-800-982-9518<br />

Please reference part number<br />

on back cover<br />

Contents<br />

6<br />

GREEN SHOWCASE<br />

Michigan’s LaFontaine<br />

dealership <strong>go</strong>es <strong>green</strong><br />

all the way!<br />

10<br />

RidlER RAmblER<br />

“Ferrambo” rides off<br />

with the most coveted<br />

custom car award<br />

26<br />

VibRANCE<br />

COllECtiON ®<br />

GOES WAtERbORNE<br />

<strong>PPG</strong> offers compliant<br />

solution for custom color<br />

and special effects finishes<br />

16<br />

FiRSt ClASS<br />

biG RiG<br />

First Class Services wins<br />

“Big Rig Build-off”<br />

12<br />

WiNNiNG FiNiSHES<br />

of the <strong>PPG</strong> Hot Wheels ®<br />

Spectraflame ®<br />

PAINT<br />

YOUR RIDE contest!<br />

Departments<br />

4 Inside Line<br />

Randy Cremeans, <strong>PPG</strong> Refinish marketing director, discusses<br />

“winning with <strong>PPG</strong>.”<br />

5 Team <strong>PPG</strong><br />

Up-to-date news and announcements from the world of <strong>PPG</strong>.<br />

18 Tech Talk<br />

How TouchMix ®<br />

Paint Manager TM<br />

helps monitor and manage<br />

the efficiency and costs of a refinish paint operation.<br />

20 In Living Color<br />

<strong>PPG</strong>’s Mike Henry discusses the causes and solutions for<br />

dealing with OE color variations.<br />

22 Training Update<br />

Technician training is now available online at ppgrefinish.com.<br />

24 Taking Care of Business<br />

MVP Director Jim Berkey discusses how collision centers<br />

can gain the competitive edge when dealing with today’s<br />

challenges.<br />

28 <strong>PPG</strong> Spotlight<br />

Holiday gift ideas and 2009 calendars available through<br />

<strong>PPG</strong> Refinish.<br />

31 Gallery<br />

A showcase of eye-catching finishes created by<br />

<strong>PPG</strong> customers.<br />

32 What’s New<br />

D8152 clearcoat—the ultimate in gloss and appearance<br />

is here.

I N S I D e l I N e T e A m P P G<br />

Winning with <strong>PPG</strong><br />

By Randy Cremeans<br />

Marketing Director, <strong>PPG</strong> Automotive Refinish<br />

The cover of this Repaint Reporter<br />

showcases three exceptional, awardwinning<br />

vehicles—great examples of<br />

how our customers are “Winning with<br />

<strong>PPG</strong>.” But as you read the entire issue, it<br />

should reinforce the many other ways <strong>PPG</strong><br />

Refinish is working to help our customers<br />

succeed and win at what they do.<br />

The amazing article on LaFontaine Automotive Group’s<br />

“Green Showcase” is but one example of how <strong>PPG</strong> leads the<br />

way in bringing new, advanced waterborne technologies to<br />

the marketplace—solutions that answer the need for <strong>green</strong>er,<br />

more ecologically-sound products. Key to our unrivalled<br />

success in winning collision centers over to waterborne<br />

compliant solutions has been our very informative “Convert<br />

with Confidence” training process that provides shop<br />

personnel with all the training and knowledge they need to<br />

make a successful conversion as seamless as possible.<br />

Providing our customers with solutions for succeeding<br />

in stiffly-regulated VOC regions now extends to the custom<br />

color segment where custom builders, designers and<br />

enthusiasts depend on our Vibrance Collection ®<br />

line-up of hot<br />

colors to create winning finishes. These customers will be<br />

glad to know that <strong>PPG</strong> is again taking the lead in providing<br />

a compliant solution for custom color finishes. Thanks to<br />

our expert color matchers and the countless hours spent<br />

matching all of our custom colors for use with Envirobase ®<br />

High Performance basecoat—and a new Vibrance Collection<br />

midcoat—a complete waterborne system for the Vibrance<br />

Collection will be available the first of the new year.<br />

Now, with all the focus lately on “<strong>green</strong>” product<br />

initiatives, don’t think that <strong>PPG</strong> is taking our collective “eye<br />

off the ball” in regards to enhancing our line-up of solventbased<br />

refinish systems. Our new D8152 Performance +<br />

Glamour Clearcoat and our continued effort to consolidate<br />

hardeners required for our premium systems, are <strong>go</strong>od<br />

signs that we’re not standing still when it comes to our<br />

refinish product offering. This is further supported by our<br />

Product and Color teams’ initiatives to bring you the best<br />

in color capability. Fruits of their work can be found in<br />

the 19 new toners that were recently introduced to help<br />

paint technicians keep pace with the OE color space—not<br />

to mention <strong>PPG</strong>’s accelerated effort to offer the latest<br />

information on variant formulas.<br />

With a new training center in Northern California, the<br />

launch of online tech training at our refinish website and<br />

our MVP team’s industry-leading Green Belt Training that<br />

is helping progressive shops take the steps they need to<br />

compete successfully, there should be no doubt that we at<br />

<strong>PPG</strong> Refinish are doing more than just blocking and tackling<br />

to help our customers win in today’s highly competitive<br />

marketplace.<<br />

<strong>PPG</strong> approved by Volvo Car<br />

Corporation as one of the preferred<br />

suppliers for global dealership and<br />

independent repairs<br />

<strong>PPG</strong> AUtomotiVe ReFiniSh<br />

<strong>PPG</strong> Automotive Refinish has been<br />

named as one of the preferred<br />

suppliers by Volvo Car Corporation for<br />

its worldwide network of dealerships<br />

as well as for independent<br />

collision centers around the globe.<br />

The designation includes <strong>PPG</strong>’s<br />

innovative and advanced waterborne<br />

Envirobase ®<br />

High Performance, and<br />

Nexa Autocolor <br />

Aquabase ®<br />

Plus<br />

basecoats.<br />

Volvo’s objective is to provide<br />

its customers with premium-level<br />

repair quality in the aftermarket.<br />

Consequently, Volvo ri<strong>go</strong>rously tests<br />

all materials to make certain they<br />

meet the company’s strict standards<br />

before they are approved.<br />

“Being designated as one of<br />

the preferred suppliers by Volvo<br />

is something to take great pride<br />

in,” said Ken Davis, <strong>PPG</strong> manager,<br />

Get latest <strong>PPG</strong><br />

news via e-mail<br />

newsletter<br />

<strong>PPG</strong> AUtomotiVe ReFiniSh<br />

You now can receive in your e-mail<br />

inbox the latest news on products,<br />

programs and services for <strong>PPG</strong><br />

Automotive Refinish and Commercial<br />

Coatings. It’s easy. Sign up for our<br />

e-newsletter at www.ppgrefinish.<br />

com/newsletter and select the<br />

paint brands and topics of interest<br />

to you.<<br />

OEM business development.<br />

“Volvo is well known for its quality<br />

and to be one of their approved<br />

suppliers is recognition of the<br />

quality of our products. We will, of<br />

course, work closely with them to<br />

provide complete support to Volvo<br />

dealerships and independent shops<br />

around the world.”<br />

Peter Larsson, Volvo’s deputy<br />

director, painted body engineering,<br />

said, “One of the major criteria<br />

for selecting preferred suppliers<br />

is quality assurance which will<br />

safeguard the Volvo repair quality<br />

in our network. <strong>PPG</strong> continues<br />

to demonstrate high quality and<br />

commitment for its paint products<br />

and processes. I am very pleased<br />

to say this collaboration will<br />

bring benefits to our international<br />

network.”<<br />

Big Flake is<br />

a Winner<br />

<strong>PPG</strong> AUtomotiVe ReFiniSh<br />

Ditzler ®<br />

Big Flake <br />

, <strong>PPG</strong>’s new bold<br />

metal flake finish reminiscent of<br />

’70s-era show<br />

cars and custom<br />

bikes, has been<br />

named the 2008<br />

New Product<br />

Winner for<br />

Paint and Car<br />

Care Products<br />

by the Goodguys Rod and Custom<br />

Association. The announcement was<br />

made at the 11 th<br />

annual Goodguys<br />

<strong>PPG</strong> Nationals in Columbus, Ohio,<br />

where over 50 companies entered<br />

products.<<br />

<strong>PPG</strong> products featured in eight of<br />

year’s top ten <strong>green</strong> building projects<br />

<strong>PPG</strong> ARChiteCtURAl GlASS<br />

The American Institute of Architects’<br />

Committee on the Environment<br />

(COTE) has named its top ten <strong>green</strong><br />

building projects for 2008, and<br />

eight of them feature architectural<br />

glass and paint from EcoLogical<br />

Building Solutions by <strong>PPG</strong> <strong>Industries</strong>.<br />

Six projects were built using<br />

low-emissivity glass by <strong>PPG</strong>, and<br />

Pittsburgh ®<br />

Paints were used in<br />

two more.<br />

To learn more about EcoLogical<br />

Building Solutions by <strong>PPG</strong>, visit<br />

www.ppgideascapes.com or call<br />

1-888-<strong>PPG</strong>-IDEA (774-4332).<<br />

(Above) The Baltimore Visitor Center<br />

showcases the use of <strong>PPG</strong>’s energyefficient<br />

Solarban ®<br />

60 glass.<br />

<strong>PPG</strong> and Bayer earn environmental<br />

honors<br />

<strong>PPG</strong> <strong>Industries</strong> and the Bayer<br />

Corporation are among 21 companies<br />

nationwide that the Wildlife<br />

Habitat Council will recognize as<br />

Signature of Sustainability sites.<br />

<strong>PPG</strong> and Bayer received the honor<br />

at a reception at the Pittsburgh Zoo<br />

and <strong>PPG</strong> Aquarium. The companies<br />

were recognized for the natural<br />

habitat sites they maintain and for<br />

the public education they provide on<br />

environmental issues.<<br />

<strong>PPG</strong> donates to<br />

SkillsUSA<br />

<strong>PPG</strong> Automotive Refinish recently<br />

donated $10,000 to SkillsUSA, a<br />

national nonprofit organization<br />

serving teachers and high school<br />

and college students preparing<br />

for careers in trade, technical and<br />

skilled-service occupations.<br />

The <strong>PPG</strong> donation supported<br />

the 2008 National SkillsUSA<br />

Championships, held this summer in<br />

Kansas City, Missouri. The national<br />

competition involved more than 5,000<br />

students participating in 91 handson<br />

skill and leadership contests<br />

including collision repair technology<br />

and, for the first time, automotive<br />

refinishing. Each SkillsUSA<br />

Championships contestant is a<br />

state-level <strong>go</strong>ld medalist.<<br />

Chrysler chooses<br />

Aquabase ®<br />

Plus<br />

for national<br />

training center<br />

Chrysler Corp. has announced it has<br />

installed a system using Aquabase ®<br />

Plus waterborne basecoat at its<br />

National Technical Training Center,<br />

located in Auburn Hills, Michigan.<br />

According to Chrysler, the move<br />

to using waterborne paint brings the<br />

training center into conformance<br />

with other Chrysler facilities, such<br />

as the majority of assembly plants,<br />

which already use <strong>PPG</strong> waterborne<br />

coatings.<br />

The National Technical Training<br />

Center evaluates equipment and<br />

materials and approves aftermarket<br />

refinish products for the originalequipment<br />

manufacturer (OEM).<br />

Implementing the use of waterborne<br />

coatings at the center had been<br />

considered since California and<br />

Canada mandated their use in an<br />

effort to reduce volatile organic<br />

compound (VOC) emissions.<<br />

CORRECTION: In the previous<br />

issue of Repaint Reporter, our<br />

story profiling Superior Auto<br />

Body misstated the type of dryer<br />

and filtration system installed<br />

at their shop. They are the<br />

Tsunami Dryer System and Tsunami<br />

Filtration Systems distributed by<br />

Sheppard Mechanical Sales &<br />

Service, Inc.<br />

4 5<br />

<strong>PPG</strong> inDUStRieS<br />

<strong>PPG</strong> AUtomotiVe ReFiniSh<br />

<strong>PPG</strong> AUtomotiVe ReFiniSh

6<br />

“No one required us to do<br />

this. We thought it was<br />

the right thing to do for<br />

our employees, for the<br />

environment and for the<br />

community. We want<br />

to set a <strong>go</strong>od example<br />

and we believe in giving<br />

back to the community.”<br />

IF YOU WANT TO GET AN IDEA<br />

OF WHAT THE FUTURE WILL LOOk<br />

LIkE, PAY A vISIT TO LAFONTAINE<br />

AUTOMOTIvE GROUP’S NEW<br />

BUICk-PONTIAC-GMC-CADILLAC<br />

DEALERSHIP IN HIGHLAND,<br />

MICHIGAN. AS GM’S FIRST<br />

GREEN DEALERSHIP IT SETS THE<br />

GOLD STANDARD FOR OTHERS<br />

TO FOLLOW.<br />

Ryan LaFontaine<br />

General Manager<br />

LaFontaine Automotive Group<br />

Green Showcase<br />

7

(Above) 85 skylights<br />

provide energy-saving,<br />

natural daylight<br />

throughout the facility.<br />

(Below right) Customers<br />

are treated to the<br />

conveniences of a café,<br />

boutique, hair salon, and<br />

kids play zone.<br />

8<br />

“Wow!” That’s the immediate<br />

reaction of most customers and<br />

visitors who enter LaFontaine’s new<br />

$15 million dealership for the first<br />

time. After all, have you ever seen a<br />

car showroom that offers customers<br />

the convenience of a café, gift<br />

boutique, hair and nail salon, and<br />

video-monitored kids play zone?<br />

What’s most impressive, however,<br />

is the commitment it took to<br />

become one of the first dealerships in<br />

the nation to “<strong>go</strong> <strong>green</strong>” and achieve<br />

Gold LEED certification. LEED<br />

certification (Leadership in Energy<br />

and Environmental<br />

Design) provides<br />

independent thirdparty<br />

verification that<br />

a building meets the<br />

highest sustainability<br />

standards.<br />

Ryan LaFontaine,<br />

general manager of<br />

the family-owned<br />

LaFontaine Automotive Group, said<br />

the dealership had been planning a<br />

new facility since 2000 because it<br />

was outgrowing its longtime location<br />

in Highland, but didn’t look to <strong>go</strong><br />

“<strong>green</strong>” until about two years a<strong>go</strong>.<br />

He estimates that the dealership<br />

spent an extra $2 million to do what<br />

was needed to qualify for LEED<br />

certification.<br />

The centerpiece of its <strong>green</strong><br />

initiative is a 64-well geothermal<br />

system that heats and cools the<br />

building by capturing energy stored<br />

in the earth, 350 feet below the<br />

building. With annual energy savings<br />

of up to 54% over conventional<br />

HvAC alternatives, it’s estimated<br />

that the geothermal investment will<br />

be recouped in five years.<br />

Throughout the facility you’ll<br />

find evidence of ecologically-wise<br />

features. Solid doors are made from<br />

compressed corn cobs and wheat.<br />

The pavement and metal decking<br />

is 60% recycled content. The car<br />

wash recycles 85% of the water<br />

conventional car washes would<br />

waste. Some 85 skylights provide<br />

energy-saving, natural daylight, and<br />

computer-controlled lighting with<br />

sophisticated photocells ensures<br />

lights are shut down in unused<br />

areas and artificial lighting is turned<br />

off when enough daylight fills<br />

the facility.<br />

Other environmentally-friendly<br />

elements include service bay lifts<br />

that use vegetable oil instead of<br />

caustic and difficult-to-dispose-of<br />

lubricants. A rainwater collection<br />

system, powered by a windmill,<br />

irrigates the landscaping. Green belts<br />

are in evidence everywhere to reduce<br />

the “heat island” effect of such a<br />

large facility. To encourage recycling,<br />

separate bins for trash and recyclables<br />

are located throughout the facility.<br />

Even the café’s cold drinking cups<br />

are corn-based and recyclable.<br />

LaFontaine employees are<br />

encouraged and rewarded for<br />

adopting <strong>green</strong> practices. For<br />

example, preferred parking spots are<br />

reserved for employees who carpool<br />

to work or anyone who drives lowemissions<br />

or alternative fuel vehicles.<br />

Storage areas and changing rooms<br />

are also provided for employees who<br />

bicycle to work.<br />

Green body shop<br />

Once the decision was made to<br />

incorporate a collision repair<br />

center into the dealership’s service<br />

capabilities, the search began for<br />

the latest technologies and systems<br />

that could best support their <strong>green</strong><br />

initiative.<br />

“After visiting the NACE Expo,<br />

we weighed the pros and cons of<br />

<strong>go</strong>ing with a waterborne paint<br />

system versus solvent-based,” said<br />

Todd McCallum, fixed operations<br />

director for LaFontaine. “In the end,<br />

we decided to get a jump start on the<br />

technology we feel will inevitably be<br />

mandated for the Great Lakes region<br />

in the not too distant future.”<br />

After deciding to convert to<br />

a waterborne system, settling on<br />

<strong>PPG</strong> as the refinish partner was not<br />

difficult according to McCallum.<br />

“They made it easy for us,” he said.<br />

“We did our due diligence and<br />

brought in all the paint companies,<br />

but the overall commitment from<br />

<strong>PPG</strong>, as well as their distributor<br />

Painters Supply & Equipment<br />

Company, and the<br />

excellence of<br />

the product sealed<br />

the deal.”<br />

Aside from all the<br />

environmental benefits<br />

of waterborne paint, McCallum<br />

said the production aspects were<br />

also critical in weighing the move<br />

to waterborne. “We wouldn’t<br />

compromise on quality and the<br />

Envirobase ®<br />

High Performance system<br />

proved outstanding for ease of<br />

application and color matching.<br />

<strong>PPG</strong> also gave our paint technicians<br />

complete training and support.”<br />

McCallum became particularly<br />

impressed with the Envirobase HP<br />

waterborne basecoat when he and<br />

11 technicians attended a hands-on<br />

demonstration at <strong>PPG</strong>’s Training<br />

Center in Wixom, Michigan.<br />

“They handed me a spray gun<br />

and asked me to try my hand at<br />

painting a panel,” he recalled.<br />

“Given that the only painting I ever<br />

did was with a brush, I was surprised<br />

and impressed with how easy it is<br />

to apply. I thought to myself, ‘if I<br />

can paint a <strong>go</strong>od match, our skilled<br />

painters will sure be<br />

able to.’”<br />

Paint technician<br />

Bennie Miller echoed the<br />

praise. “I’ve been using<br />

<strong>PPG</strong> products for over<br />

30 years, and this time they really<br />

have outdone themselves with this<br />

Envirobase waterborne paint. It offers<br />

high productivity, and application is<br />

so easy, anyone can spray it.”<br />

To accommodate the waterborne<br />

system, LaFontaine installed a stateof-the-art<br />

waterborne spray booth<br />

with the AdvanceCure <br />

Accelerated<br />

Airflow System from GFS. The<br />

curing system uses high-velocity air<br />

blower towers to speed flash off and<br />

drying times.<br />

After opening for business this<br />

past June, the LaFontaine collision<br />

center is off and running smoothly.<br />

In the first month alone, some 55<br />

customers brought their vehicles<br />

in to be repaired and painted at<br />

the state-of-the-art, eco-friendly<br />

body shop. The success they’re<br />

experiencing with waterborne<br />

convinced the LaFontaine group<br />

to make the switch to Envirobase at<br />

the collision center it operates in<br />

Dexter too.<br />

Ryan LaFontaine says the “buzz”<br />

on its <strong>green</strong> showcase is spreading far<br />

and wide. To date, representatives<br />

of some 35 other dealers and body<br />

shops have toured the facility.<br />

McCallum adds, “General Motors is<br />

so impressed, they’re benchmarking<br />

this store.”<br />

As one tours the facility, a peek<br />

into LaFontaine’s office, located<br />

front and center near the showroom,<br />

will reveal a sign hanging proudly<br />

above Ryan’s desk: “Going <strong>green</strong><br />

isn’t only the best way to <strong>go</strong>. It’s the<br />

only way to <strong>go</strong>.”<br />

It’s a statement that’s aptly<br />

reflects the spirit and commitment<br />

that abounds throughout the<br />

dealership.<<br />

(Left) State-of-the art<br />

waterborne spray booth<br />

with air blower towers<br />

speed drying times of<br />

Envirobase HP basecoat.<br />

Recyclable drinking cup<br />

made from corn.<br />

(Below) LaFontaine’s<br />

Geothermal system<br />

provides up to 54% annual<br />

energy savings over<br />

conventional heating and<br />

cooling systems.<br />

9

Ridler Rambler<br />

AWARDinG-WinninG “FeRRAmBo” illUStRAteS thAt BeAUty iS moRe thAn Skin DeeP.<br />

10<br />

HOW DOES ONE GO ABOUT WINNING THE “RIDLER<br />

AWARD”—THE NATION’S MOST PRESTIGIOUS<br />

RECOGNITION FOR CUSTOM CAR ExCELLENCE?<br />

Answer. Meticulously customize<br />

a tiny station wa<strong>go</strong>n from a longdefunct<br />

nameplate, marry it with<br />

a full-on Ferrari power plant and<br />

components, then top it off with<br />

a flawless, shiny, bright red finish.<br />

<strong>PPG</strong> “Ferrari Rosso Corsa Red”<br />

to be specific. That’s the short<br />

story of “Ferrambo” and its<br />

capturing of the Don Ridler<br />

Memorial Award at the<br />

2008 Detroit Autorama.<br />

But the real beauty is in<br />

the details…<br />

“Ferrambo” is the product of<br />

a creative collaboration between<br />

builder Tim Divers of Divers Street<br />

Rods and owner Mike Warn from<br />

Wilsonville, Ore<strong>go</strong>n. As so many<br />

inspired projects do, this one began<br />

with more than a little speculative<br />

fantasizing over the availability of<br />

a clean 1960 Rambler American<br />

wa<strong>go</strong>n in Tim’s shop and Mike’s<br />

taste for exotic automobiles as the<br />

owner of Gran Prix Imports. After<br />

an initial start as a basic Rambler<br />

with a Ferrari engine project, the<br />

perfectionist overachievers at Divers<br />

ran off with the plot, and soon a fullblown<br />

attempt at winning the Ridler<br />

was underway.<br />

The flawless finish on<br />

“Ferrambo” aptly reflects the<br />

exceptional and unique vehicle<br />

beneath where you’ll find<br />

meticulous craftsmanship, attention<br />

to detail and exceptional creativity<br />

everywhere you look. Divers<br />

started by fabricating the chassis to<br />

incorporate a removable subframe<br />

for the engine and transaxle. A 2002<br />

Ferrari 360 Modena donated more<br />

than its powerplant, surrendering<br />

its suspension to complement the<br />

395 horsepower, 3.6-liter v8 and<br />

6-speed gearbox.<br />

Combining features of the two<br />

distinctly different vehicles, the<br />

wa<strong>go</strong>n was transformed to take<br />

on decidedly Italian styling cues<br />

reminiscent of the romance of ’50s<br />

and ’60s classic European design.<br />

The hand-formed aluminum<br />

bumpers and grille, the handmade<br />

headlamps, taillights and steering<br />

wheel are all products of the talent<br />

pool at Divers. Even the threaded<br />

hardware is a Divers design, evident<br />

in the elegant splined fasteners used<br />

throughout the car. Tim tapped<br />

his brother Scott for the wheel<br />

design. The custom center-lock 18”<br />

fronts and 20” rears were machined<br />

specifically for “Ferrambo.”<br />

Meshing the Ferrari components<br />

into the Rambler, Divers did<br />

away with some of the modern<br />

technology, such as the paddle<br />

shift, electronic throttle and<br />

indecipherable Italian electrics.<br />

Shifting is now through a gated lever<br />

and the butterfly-valved throttle<br />

provides a real connection with<br />

the driver’s right foot. The original<br />

wiring went in the bin and Brian<br />

Macy sorted out the Motec CPU<br />

that now directs the electrons.<br />

At the Divers shop in Startup,<br />

Washington, Shawn McNally and<br />

Jim Lykken executed a flawless <strong>PPG</strong><br />

finish using Deltron ®<br />

DBC75259 over<br />

red oxide DP74LF sealer and topping<br />

it with DCU2002 clear. Not only<br />

was the body covered in <strong>PPG</strong>—<br />

every single part on the car has been<br />

treated. Rather than plating or<br />

polishing, every component of the<br />

suspension is body finished and<br />

painted to present the cleanest,<br />

smoothest finish possible. k38<br />

primer surfacer was used throughout<br />

the build. The frame was treated to a<br />

chemical cleaning with Dx579<br />

followed by conditioning with<br />

Dx520 before applying DP90LF<br />

sealer and DCC9300 color. After<br />

prepping all the pieces with Dx533<br />

and conditioning with Dx503, the<br />

engine was fully detailed using<br />

DP48LF sealer, DBC33897<br />

Fine Silver Metallic and DCU2002.<br />

<strong>PPG</strong> custom painting<br />

instructor Paul<br />

Stoll was<br />

enthusiastically<br />

on board, providing support to the<br />

Divers crew. The phenomenal finish<br />

speaks for itself.<br />

“True to its promise, <strong>PPG</strong><br />

provided us with the most durable,<br />

reliable and beautiful finish products<br />

possible,” explained Divers. “The<br />

<strong>PPG</strong> Ferrari Rosso Corsa Red<br />

color chosen for “Ferrambo” really<br />

delivered.”<br />

Combining the talents of<br />

Divers Street Rods and the openmindedness<br />

of “Ferrambo”<br />

owner Mike Warn resulted in a<br />

stunning cross-platform creation.<br />

Contemporary Ferrari mechanicals<br />

wrapped in the much-modified<br />

skin of a diminutive Rambler<br />

wa<strong>go</strong>n—modern power and<br />

technology within an extensively<br />

reworked vintage envelope renders<br />

an incredible original construction.<br />

No part of the vehicle was left<br />

untouched and every detail is<br />

prominently displayed for all to see.<br />

The flawless red finish covering it<br />

all is both the introduction to this<br />

marvel, and afterward, the indelible<br />

memory.<<br />

11

<strong>PPG</strong> hot Wheels ®<br />

12<br />

Spectraflame ®<br />

Paint your Ride Contest<br />

Winning Finishes<br />

IT WAS ONE OF THE MOST COMPETITIvE CUSTOM CAR<br />

BEAUTY CONTESTS IN THE COUNTRY AS THE <strong>PPG</strong> HOT<br />

WHEELS ®<br />

SPECTRAFLAME ®<br />

PAINT YOUR RIDE CONTEST<br />

LIvED UP TO ExPECTATIONS.<br />

the quality of the entries made selecting a winner<br />

very difficult. After whittling the preliminary field<br />

down to 12 finalists, the decision naturally <strong>go</strong>t<br />

even harder. but in the end, Jim and melinda<br />

Cooper’s 1956 Chevy Handyman 2-door wa<strong>go</strong>n<br />

was awarded the grand prize at a special reception<br />

held at the 11 th<br />

annual Goodguys <strong>PPG</strong> Nationals<br />

in Columbus, Ohio.<br />

Paint Your Ride contestants included custom<br />

painters, car builders and hot rod enthusiasts who<br />

created original paint schemes for their vehicles<br />

using any of the 12 vibrant colors of the popular<br />

<strong>PPG</strong> Vibrance Collection ®<br />

Hot Wheels ®<br />

Spectraflame ®<br />

paint. the co-branded line features colors found on<br />

the popular Hot Wheels ®<br />

line of die-cast toy vehicles<br />

from mattel, inc.<br />

the judging panel comprised a distinguished<br />

group well-known to street rod buffs: dave<br />

Perewitz of Perewitz Cycle Fabrication, <strong>PPG</strong><br />

custom painting trainer Paul Stoll, larry Wood,<br />

chief designer at Hot Wheels ®<br />

, brian brennan of<br />

Street Rodder magazine and Ed Capen of the<br />

Goodguys Rod & Custom Association.<br />

Faced with 12 jaw-dropping, wow-inspiring<br />

color schemes, the judges did not have an easy time.<br />

Wood said, “We were so impressed with the finalist<br />

cars. it was a difficult decision. Everyone has their<br />

own taste in cars and each judge had a favorite. but<br />

in the end, we all agreed on the Chevy Wa<strong>go</strong>n. it<br />

had everything—awesome paint, cool graphics, a<br />

great overall look.”<br />

As the grand prize winners, the Coopers, from<br />

laguna Hills, California, will receive an exclusive<br />

Hot Wheels ®<br />

1/18” scale model award trophy<br />

featuring their winning paint job. their car’s paint<br />

scheme—Hot Wheels ®<br />

Spectraflame ®<br />

medium sapphire<br />

with silver flames, from <strong>PPG</strong>’s Vibrance Collection—<br />

will also be reproduced on a future Hot Wheels ®<br />

toy<br />

car from mattel, inc. in addition, the car will be<br />

showcased in the <strong>PPG</strong> booth at the upcoming 2008<br />

SEmA show in las Vegas and featured in a 2009<br />

<strong>PPG</strong> calendar along with the other finalists.<br />

All the finalists attended the annual Goodguys<br />

<strong>PPG</strong> Nationals—the largest, most prestigious<br />

show the Goodguys organization sponsors. they<br />

displayed their vehicles in the special Paint Your<br />

Ride contest area, and were guests of honor at a<br />

ViP-style, <strong>PPG</strong> Paint Your Ride cocktail party and<br />

banquet where the winner was announced. When<br />

Jim Cooper’s name was read, his reaction came<br />

through loud and clear, “i was pretty excited. i was<br />

amazed to see all the wild and over-the-top finishes<br />

you can achieve with Spectraflame ®<br />

paint. All the<br />

entries were truly spectacular, so it’s a real honor to<br />

be named the winner.”<br />

“All of us at <strong>PPG</strong> were especially wowed by the<br />

entries” said Randy Cremeans, marketing director<br />

for <strong>PPG</strong> Refinish. “And the contest itself proved to<br />

be an excellent showcase for the awesome finishes<br />

that can be achieved with our hot line-up of Hot<br />

Wheels ®<br />

Spectraflame ®<br />

colors.” <<br />

13

The 12 Finalists of the<br />

<strong>PPG</strong> Hot Wheels ®<br />

Paint Your Ride Contest<br />

1956 Chevrolet Handyman<br />

2-door Wa<strong>go</strong>n<br />

Jim & Melinda Cooper,<br />

Laguna Hills, CA<br />

Medium Sapphire<br />

1960 Chevrolet El Camino<br />

Jerry Ford, New Braunfels, TX<br />

Bright Red & Orange<br />

1931 Chrysler 309 4-door Sedan<br />

Keith & Kathleen Bright,<br />

Salina, KS<br />

Anti-Freeze Green<br />

Spectraflame ®<br />

1969 Chevrolet El Camino<br />

David Giles, Arkport, NY<br />

Medium Sapphire &<br />

Anti-Freeze Green<br />

1951 Mercury Sport Sedan<br />

Zachary Hawthorne,<br />

Mineral City, OH<br />

Purple<br />

1950 Studebaker<br />

R-Series Pickup<br />

Rick & Kathy Adams,<br />

Backus, MN<br />

Orange<br />

1903 Custom-built Oldsmobile<br />

John F. Beecher III, Lafayette, IN<br />

Anti-Freeze Green<br />

1932 Ford High Boy Roadster<br />

Tom Paternoster &<br />

Brent Keener, Rochester, MI<br />

Anti-Freeze Green, Orange &<br />

Lime Gold<br />

1959 Ford Thunderbird<br />

2-door Convertible<br />

Clifford Nicholson, Dassel, MN<br />

Lime Gold<br />

1969 Chevrolet Camaro<br />

RS/SS Convertible<br />

Tim Doyon, Eagle, ID<br />

Hot Wheels ®<br />

Blue<br />

1953 Ford Panel Truck<br />

Kevin Young, Byesville, OH<br />

Rich Yellow Gold, Hot Wheels ®<br />

Blue, Hot Pink & Anti-Freeze<br />

Green<br />

1970 Chevrolet El Camino<br />

Custom<br />

John Joyce, Germantown, MD<br />

Hot Wheels ®<br />

Blue, Hot Pink,<br />

Purple & Medium Sapphire<br />

*Finalists shown in no particular order.<br />

14 15

First Class<br />

Big Rig<br />

A chromed and detailed<br />

Pittsburgh Power engine<br />

pours out 750 hp of brute<br />

strength, enough to haul<br />

monstrous loads.<br />

WHEN A COMPANY IS NAMED “FIRST CLASS SERvICES,<br />

INC.,” THERE’S A LOT OF PRESSURE ON IT TO DELIvER<br />

THE GOODS. AND THAT’S ExACTLY WHAT FIRST CLASS<br />

SERvICES DID AT THIS YEAR’S “BIG RIG BUILD-OFF.”<br />

Headquartered in Lewisport,<br />

kentucky, First Class Services is<br />

a highly-regarded, 140-person<br />

transport company that carries<br />

liquid and dry bulk loads across the<br />

country. Randy Stroup, its founder,<br />

president and CEO, is a thirdgeneration<br />

trucker who believes<br />

strongly in premium customer<br />

service and all-out fleet maintenance.<br />

He also loves big trucks. Even more,<br />

he loves making them look <strong>go</strong>od.<br />

It was that love of trucks that led<br />

Stroup to enter and subsequently win<br />

the 4 th<br />

annual Pride and Polish “Big<br />

Rig Build-Off” truck beauty contest<br />

at the Mid-America Trucking Show<br />

held this past March in Louisville at<br />

the kentucky Exposition Center.<br />

The contest, by invitation<br />

only, matched five prominent<br />

North American custom truck<br />

builders in a challenge to create<br />

the ultimate big rig working truck.<br />

Participants were supported by<br />

<strong>PPG</strong> and Jones Performance, Inc.<br />

with <strong>PPG</strong> supplying paints and<br />

Jones Performance offering design<br />

consulting and fabrication services.<br />

“First in Class” paint finish<br />

Stroup’s entry, a 1986 “359”<br />

Peterbilt 63’ Flat Top Sleeper<br />

plucked out of the company fleet and<br />

appropriately named “First in<br />

Class,” easily caught the judges’<br />

attention. (How could it not?) The<br />

truck was finished with <strong>PPG</strong>’s<br />

gleaming Vibrance Collection ®<br />

Liquid<br />

Crystal Candy Apple Red and<br />

Burnt Orange colors on<br />

top of Delfleet ®<br />

Evolution<br />

primers and sealers, and<br />

clearcoated with Delfleet<br />

Evolution F3905. The paint<br />

was supplied through <strong>PPG</strong><br />

distributor Gipe Autocolor<br />

of Owensboro, kentucky.<br />

The result is a huge custom<br />

truck sporting a “wow”<br />

finish usually associated<br />

with show-stopping<br />

street rods.<br />

For First Class Services, however,<br />

a striking paint job is really no<br />

surprise. The company has an<br />

in-house paint facility in nearby<br />

Owensboro and uses <strong>PPG</strong> paint<br />

exclusively. The company’s fleet is<br />

painted an eye-catching combination<br />

of flame red, high metallic burgundy<br />

and stardust <strong>go</strong>ld.<br />

“We have a great relationship<br />

with <strong>PPG</strong>,” Stroup says. “We love<br />

the product, love the support. We<br />

put four-and-a-half months of<br />

custom work into this truck inside<br />

and out. When it was time for<br />

painting, we wanted something that<br />

would really stand out in the<br />

crowd of beautiful trucks<br />

that would be at the show.<br />

So we decided to use <strong>PPG</strong>’s<br />

Vibrance candy colors.”<br />

“Putting these Vibrance<br />

colors together created<br />

an unbelievable finish,”<br />

adds Greg Boarman, paint<br />

shop manager. “They were<br />

beautiful in any kind of<br />

light, but simply amazing<br />

in sunlight. It’s a look that will last<br />

for years.”<br />

While the truck’s paint scheme<br />

makes the first impression, it is also<br />

a unique creation underneath, with<br />

all the radical modifications that<br />

Stroup and his crew came up with.<br />

The original CAT 3406B power<br />

plant was replaced by a Pittsburgh<br />

Power 750-hp engine. The frame<br />

was stretched from a 260” wheelbase<br />

to 305”. The cab and sleeper were<br />

converted to a unibilt<br />

format. The windshield<br />

was lowered by four<br />

inches, and the dash,<br />

header, door panels,<br />

floor boards and rear<br />

interior sleeper were all<br />

replaced. The stunning<br />

paint job was the<br />

finishing touch.<br />

Since winning the<br />

Big Rig award, “First<br />

in Class” has been on the 2008 truck<br />

show circuit strutting its colors<br />

across the country. When the tour<br />

is complete, “First in Class” will<br />

return to the ranks of the working<br />

trucks at First Class Services where<br />

undoubtedly the drivers will be<br />

lining up to take her on the road.<<br />

DAIMler TruckS<br />

expANDS ppG role AS A<br />

ToTAl Source SupplIer<br />

Coming Soon—the 2008 Big<br />

Rig Delfleet Evolution Poster<br />

featuring “First in Class.”<br />

See your <strong>PPG</strong> distributor or<br />

territory manager for more<br />

information.<br />

Daimler Trucks North America recently extended its partnership with<br />

<strong>PPG</strong> by selecting Delfleet as the OEM paint system at its Sterling<br />

truck manufacturing plant, located in St. Thomas, Ontario, Canada.<br />

Previously, in 2006, Daimler Trucks designated <strong>PPG</strong> as an OEM Total<br />

Source Supplier and awarded <strong>PPG</strong> all of the paint business at its<br />

Portland truck plant.<br />

As a Total Source Supplier, <strong>PPG</strong> provides a complete range of<br />

paint technologies enabling Daimler Trucks North America to<br />

meet customer demands and compete in the heavy-duty truck<br />

market. The line-up of products includes <strong>PPG</strong>’s industry-leading<br />

Powercron ® electrocoat and Delfleet topcoats for cabs and<br />

chassis.<br />

Approved worldwide for warranty work<br />

Daimler Trucks North America corporate<br />

engineering has ri<strong>go</strong>rously tested and<br />

approved the Delfleet Evolution system for<br />

all warranty and paint repairs on all Daimler<br />

Truck brands, including Sterling and Western<br />

Star models, in their business and repair<br />

centers worldwide. With the approval, the<br />

same quality paint system used on the<br />

OEM’s original truck finishes can be<br />

used in the aftermarket creating a<br />

unified <strong>PPG</strong> offering.<br />

16 17

T e C H T A l K<br />

Paint Manager’s<br />

Production screen<br />

allows multiple<br />

technicians to enter<br />

data on a repair order.<br />

TouchMix<br />

p A I N T M A N A G e r<br />

T H e l AT e S T T o o l f o r m A N A G I N G y o u r PA I N T o P e r AT I o N C o S T e f f e C T I V e ly<br />

IN A COMPETITIvE ENvIRONMENT WHERE MANAGING<br />

INSURANCE CAPS AND kEEPING COSTS TO A MINIMUM<br />

ARE CRITICAL TO MAINTAINING PROFITABILITY OF<br />

YOUR PAINT REFINISH OPERATION, IT IS ESSENTIAL THAT<br />

A PRODUCTION MANAGER TAkE ADvANTAGE OF THE<br />

LATEST COLOR MANAGEMENT TOOLS.<br />

With its full-featured paint mixing<br />

tracking features, TouchMix ®<br />

Paint<br />

Manager <br />

provides instant access to<br />

all the information required to make<br />

informed decisions on job costs,<br />

material usage, mixing efficiency,<br />

inventory and much more. In fact,<br />

Paint Manager can generate over<br />

30 reports for the collision shop<br />

manager to work with, including<br />

such essential information as:<br />

• Paint and Material Gross Profit<br />

• Repair Order Cost per Refinish Hour<br />

• Average Employee Cost per Refinish Hour<br />

• Painter Mix Accuracy<br />

• Product Usage<br />

• VOC and HAPS reports<br />

For users without touch-screen<br />

hardware, TouchMix software is<br />

flexible enough that it can run<br />

as a mouse-driven Windows ®<br />

application for use by the<br />

production manager. For example,<br />

with a networked system in place,<br />

Paint Manager information can be<br />

viewed on a computer in the front<br />

office, while the technician in the<br />

mixing room uses the compliant,<br />

touch-screen version connected<br />

to a computerized scale. For shops<br />

currently using TouchMix Basic<br />

Mixing in the mixing room, Paint<br />

Manager is an simple software<br />

upgrade and will integrate<br />

seamlessly with the current system.<br />

managing costs with<br />

Paint manager<br />

There are a myriad of ways Paint<br />

Manager works to monitor and<br />

control costs in the paint booth,<br />

giving the production manager the<br />

enhanced ability to:<br />

• Customize pricing<br />

• Optimize color control<br />

• Minimize paint usage<br />

• Control volume required per color<br />

• Benchmark technicians product usage<br />

• Track product usage over time<br />

Many of the cost-managing<br />

reports draw from information<br />

entered on a Repair Order Entry<br />

screen, which can be accessed<br />

via the Production screen. At a<br />

minimum, the repair order number<br />

should be entered to enable any<br />

real job tracking capability. The<br />

Production screen can be ‘switched<br />

on’ as the default screen. This<br />

allows multiple painters to select<br />

their particular “RO” and assign<br />

the color mixing, reducing and final<br />

clear application to one repair order.<br />

Paint Manager offers a variety of<br />

options for customization, so the<br />

system can be tailored to track and<br />

control as much or little as you need<br />

for your collision repairs.<br />

Volume Estimator enables the painter to visually select the area(s) to be<br />

repainted and automatically calculates the appropriate volume of intermix.<br />

Controlling paint usage<br />

Paint Manager’s instant access to<br />

reports—such as Paint & Material<br />

Gross Profit, Product Usage, Repair<br />

Order Cost per Refinish Hour and<br />

Painter Mix Accuracy—gives<br />

managers a true picture of how well<br />

the shop is controlling paint usage.<br />

But there are also many features<br />

available to paint technicians to help<br />

manage paint usage on their end.<br />

For example, there is a Minimum<br />

Mix button that calculates the<br />

smallest amount to mix without<br />

jeopardizing color match—and<br />

there’s a Recalculate feature that<br />

can automatically adjust for “over<br />

pours” to avoid waste.<br />

One cost-saving<br />

feature for<br />

paint usage in<br />

the mix room<br />

is the Volume<br />

Estimator. This<br />

helps the painter<br />

select the right<br />

amount of product<br />

to cover per panel<br />

on the vehicle.<br />

To illustrate how<br />

Volume Estimator<br />

works, let’s say 4<br />

ounces is the default<br />

volume for painting a panel. First,<br />

the technician selects a panel<br />

to repair. One tap on his touch<br />

screen will indicate full coverage.<br />

TouchMix will respond by showing<br />

the formula for a 4-ounce volume<br />

of the intermix color. Two taps on<br />

the screen will indicate a blended<br />

area. This would indicate a 2-ounce<br />

volume to mix. If the two adjacent<br />

panels are selected, the volumes<br />

for a panel and blend repair are<br />

added together and TouchMix will<br />

compute the formula for a 6-ounce<br />

intermix.<br />

With all its features, numerous<br />

functions and flexibility, there is<br />

not enough space here to detail all<br />

Sample of a 6-ounce formula for a two-panel repair, automatically<br />

calculated by Volume Estimator.<br />

the benefits of using TouchMix Paint<br />

Manager. If your shop isn’t already<br />

taking advantage of this powerful<br />

tool, you may be missing out on<br />

many opportunities to save time,<br />

money and increase profitability in<br />

the paint operation. To learn more,<br />

contact your local <strong>PPG</strong> territory<br />

manager or distributor.<<br />

18 19

Demystifying<br />

oe Color<br />

Variation<br />

I N l I V I N G C o l o r<br />

by mIKe HeNry, <strong>PPG</strong> mANAGer, Color PrINT ToolS<br />

CRASH! That awful sound that comes from screeching<br />

tires, and then, bumper meeting fender. The vehicle<br />

owner’s expectations for the repair are high—they want<br />

their car’s finish to be just like the factory, the way it<br />

looked on the showroom floor.<br />

But for the painter, any vehicle color can be a<br />

challenge, and with the increasing use of metallic and<br />

pearlescent pigments, that WOW effect must be restored.<br />

In our example, the color of the customer’s fender may<br />

be a little bluer and a little darker than a car of the same<br />

color that was repaired a week a<strong>go</strong>. If both customers<br />

were to compare their vehicle colors, they most likely<br />

would say they are the same exact color. A professional<br />

painter however can easily perceive the difference.<br />

There are several reasons for color variation. One is<br />

the fact that OEMs might source their paint from more<br />

than one supplier and they often use different paint<br />

chemistries. Depending on the source, pigments can<br />

also vary in their material makeup, and this can often<br />

contribute to a color shift.<br />

Another cause occurs at the assembly plants where<br />

variation in line speed, application equipment calibration,<br />

robotic pathing and spray-line environmental conditions<br />

can all contribute to color disparity. Bottom line—no<br />

OEM can match a color standard 100% on every vehicle<br />

and eliminate process variation completely.<br />

These subtle variances—and sometimes not so<br />

subtle—present a challenge for the paint technician<br />

who must determine the right color formulation that<br />

accurately matches the actual color of the customer’s<br />

vehicle should it vary from the OEM standard.<br />

The Color variance Program at <strong>PPG</strong> identifies<br />

variances when they occur, with the <strong>go</strong>al of providing<br />

refinishers with an extensive formula database to cover<br />

all the colors they are likely to encounter. The <strong>PPG</strong><br />

Refinish team proactively seeks out new color variants at<br />

import centers as new model year vehicles arrive at our<br />

North American ports of entry.<br />

<strong>PPG</strong> territory managers, distributors and painters play<br />

a critical role in partnering together to identify potential<br />

variances in the field at the point of vehicle repair. When<br />

an unfamiliar color comes into a collision shop, a car<br />

part—typically a gas cap or a body panel—is sent directly<br />

to <strong>PPG</strong>’s Cleveland Refinish laboratory where it is<br />

analyzed and a determination is made to create a special<br />

variant. The <strong>PPG</strong> Car Parts program targets new and<br />

difficult carryover colors and has been largely responsible<br />

for our success in developing hundreds of variant<br />

formulas each year.<br />

Getting accurate, up-to-date variant color<br />

information quickly to the end user is a high priority<br />

of the Color variance Program. When a new variant<br />

is approved, the formula is entered into <strong>PPG</strong>’s Global<br />

Reflective Intermix Database and immediately uploaded<br />

to the <strong>PPG</strong> Online Color database. Online Color can be<br />

accessed in the Color Tools section of the <strong>PPG</strong> Refinish<br />

website (ppgrefinish.com). Within 24 hours of a variant<br />

creation, a shop technician, painter or distributor can<br />

easily search and find the variant formula.<br />

The new variant formulas are also added to the<br />

next quarterly updates of <strong>PPG</strong>’s e-Fiche, TouchMix ®<br />

Basic Mixing and Paint Manager <br />

color retrieval software.<br />

To verify the correct variant for the vehicle repair, a<br />

visual representation of the color is the recommended<br />

next step. The <strong>PPG</strong> color retrieval software provides<br />

a link to the correct visual color tool for confident<br />

identification and accurate color matching. The <strong>PPG</strong><br />

Color variant System is available for both our solventbased<br />

and waterborne paint lines and is easy to use at the<br />

car. Each system contains hundreds of large color chip<br />

decks covering exterior body and underhood colors for<br />

all major vehicle manufacturers. To assure accuracy, the<br />

chips are sprayed using <strong>PPG</strong> Refinish paint so the match<br />

from the vehicle color to color chip to color formula is a<br />

reliable and dependable color solution.<br />

If you’d like to learn more about OEM color<br />

variation and are attending the NACE Expo, be sure to<br />

attend our presentation on “Demystifying OE Color<br />

variation” on Wednesday, November 5 at 8:00 a.m.<<br />

True<br />

®<br />

With Envirobase<br />

High Performance.<br />

Color matching today’s<br />

sophisticated OEM colors is<br />

easier than ever, once you’ve<br />

made the move to Envirobase<br />

High Performance. The<br />

Envirobase system of advanced<br />

non-stir, high opacity toners is<br />

well-proven to offer true matches<br />

to even the most difficult<br />

colors—a definite breakthrough<br />

in color-matching accuracy.<br />

Experience color matching<br />

with the industry’s most<br />

advanced waterborne basecoat.<br />

• Unparalleled color match<br />

• High-opacity pigments<br />

• Easy to apply and blend<br />

• Anti-settle toner technology<br />

• Spray-applied variant chips<br />

World Leaders In Automotive Finishes<br />

20 ©2008 <strong>PPG</strong> <strong>Industries</strong> www.ppgrefinish.com<br />

Envirobase is the OEM original finish on many of today’s high-performance, exotic sports cars

T r A I N I N G u P D A T e<br />

22<br />

PD-0100 Light Body Repair and Surface Prep Process Learning Module ( 00:31 / 06:54 )<br />

Outline Notes<br />

1. Introduction<br />

2. Benefits<br />

3. Video<br />

4. Review<br />

5. Clean area<br />

6. Sand Damaged Area and Feather<br />

7. Sand Low Spots<br />

8. Use Mixing Techniques Outlined<br />

9. Rough shape Filler<br />

10. Apply 3M Dry Guide Coat<br />

11. Block Sand<br />

12. Rough Featheredge<br />

13. Apply Finishing Putty<br />

14 Block Sand<br />

15. Apply 3M Dry Guide Coat<br />

16. Block Sand<br />

17. Fine Featheredge Around Repair<br />

18. Problem Prevention<br />

19. Quiz<br />

20. End<br />

divided into modules, so the user<br />

can more readily absorb the content.<br />

Following the video, there’s a<br />

step-by-step review to reinforce key<br />

practices and tips.<br />

After the content is presented and<br />

reviewed, the student is prompted<br />

to take a quiz. All questions must<br />

be answered correctly to pass. The<br />

student can review the course<br />

content and re-take the quiz as many<br />

times as needed. Upon passing the<br />

quiz, the student can download a<br />

“Certificate of Completion.”<br />

Registering for a course<br />

Signing up and taking one of the<br />

online courses is easy. Simply <strong>go</strong> to<br />

the Training & Support section of<br />

the <strong>PPG</strong> Refinish website, and select<br />

the “Online Training” link.<br />

00:21 / 02:28 00:40 / 02:28<br />

00:54 / 02:28 01:15 / 02:28<br />

Ready online. Anytime.<br />

<strong>PPG</strong> REFINISH WEBSITE OFFERS TECHNICAL TRAINING<br />

COURSES FOR TECHNICIANS, APPRENTICES AND STUDENTS.<br />

The industry today demands<br />

consistency from its collision repair<br />

centers. Critical to productivity<br />

and profitability, shops require<br />

technicians to maintain a high level<br />

of technical knowledge and skills.<br />

Collision centers now have another<br />

option for continued learning.<br />

It’s <strong>PPG</strong>’s new Online Technical<br />

Training video courses, available at<br />

ppgrefinish.com.<br />

“It’s always been our <strong>go</strong>al to<br />

extend our training reach; providing<br />

technicians with another resource<br />

PD-0100 Light Body Repair and Surface Prep Process<br />

SlidE 3 Of 20 PAUSEd 00:00 / 02:28<br />

Drag seekbar to navigate video<br />

on best practices for refinishing a<br />

vehicle.” Bill Troyer, director of<br />

training, <strong>PPG</strong>, continues, “Offering<br />

online training complements our<br />

instructor-led classes. This new<br />

instruction, now available at the<br />

technician’s convenience, will<br />

become a strategic segment of our<br />

training solution. We’re continuing<br />

to build tools for collision centers<br />

looking to standardize their repair<br />

operations.”<br />

Developing course content<br />

Developed through a partnership<br />

between <strong>PPG</strong> Refinish and 3M’s<br />

Automotive Aftermarket team, each<br />

00:00 / 02:28<br />

ATTACHMENTS EXIT<br />

online course is designed to teach an<br />

established standard technical repair<br />

process.<br />

The video courses teach standard<br />

processes from light body repair<br />

to polishing and detailing. Eleven<br />

courses are currently available with<br />

additional ones to be uploaded in the<br />

near future.<br />

According to Troyer, the training<br />

courses were developed using a<br />

proven methodology for teaching<br />

students of varying skills and ability.<br />

As a result, each video course is<br />

Technicians who have already<br />

attended a <strong>PPG</strong> training course<br />

and are currently registered in the<br />

<strong>PPG</strong> database can use their existing<br />

<strong>PPG</strong> User ID to access the available<br />

courses. They do not have to reregister<br />

to take an online course.<br />

However, since the training is only<br />

available to <strong>PPG</strong> customers, students<br />

without an existing <strong>PPG</strong> User ID<br />

must submit an application for<br />

registration and approval.<br />

After entering their <strong>PPG</strong> User<br />

ID and password, students can select<br />

from the listing of available courses.<br />

“We believe these online courses<br />

will benefit technicians looking for<br />

additional training. They supplement<br />

our instructor-led offering and<br />

reinforce what technicians learn in<br />

NeW TrAINING<br />

ceNTer IN<br />

NorTHerN<br />

cAlIForNIA<br />

San Francisco •<br />

★<br />

Concord<br />

Rancho Cucamonga<br />

★<br />

Los Angeles •<br />

San Die<strong>go</strong> •<br />

<strong>PPG</strong> Refinish recently opened a<br />

state-of-the-art Business Development<br />

Center in Concord, California<br />

serving collision repair facilities in<br />

San Francisco, Sacramento, and the<br />

Northern California region.<br />

As the only fixed location training<br />

facility operated by a paint supplier<br />

in Northern California, the new BDC<br />

will focus primarily on training and<br />

support for <strong>PPG</strong>’s Envirobase<br />

our classrooms around<br />

the country,” added<br />

Troyer. “They also offer<br />

a perfect opportunity for<br />

vocational instructors and<br />

their students to study best<br />

practices for paint repair.”<br />

Another new feature<br />

under the Training &<br />

Support tab allows users<br />

to view their current<br />

instructor-led, <strong>PPG</strong><br />

training transcript. Go<br />

to the “My Training” tab; enter<br />

your <strong>PPG</strong> User ID and password for<br />

access. Students can also update their<br />

personal profile with new addresses<br />

or employer changes.<<br />

®<br />

High<br />

Performance and Nexa Autocolor <br />

Aquabase ®<br />

Plus waterborne basecoat<br />

systems, in response to the new VOC<br />

regulations taking effect for Northern<br />

California. The new center will also<br />

offer training for <strong>PPG</strong>’s fleet and<br />

industrial coatings.<br />

The facility replicates the paint<br />

shop of a collision center including<br />

the latest equipment for optimizing the<br />

process time of waterborne basecoat.<br />

Now <strong>PPG</strong> customers will have the<br />

opportunity to learn about this newly<br />

mandated technology in a hands-on,<br />

“real world” environment.<br />

The Concord center is <strong>PPG</strong>’s<br />

second such facility in California. A<br />

training center in Rancho Cucamonga<br />

(Los Angeles area) has been in<br />

operation for several years.<br />

23

TAKING CAre of buSINeSS<br />

Surviving the<br />

“Perfect Storm”Facing<br />

Collision Repair<br />

B y Jim Be r k e y , Di r e c t o r , mVP Bu s i n e s s so l u t i o n s , J B e r k e y @ P P g . c o m<br />

There’s a “perfect storm” prevailing over today’s<br />

collision repair industry—and there can be no<br />

doubt that new thinking and new approaches<br />

will be required for any collision shop wishing<br />

to weather the storm, compete successfully and<br />

operate a sustainable, profitable business.<br />

In the meteorological sense a<br />

“perfect storm” is the simultaneous<br />

occurrence of weather events that<br />

combine to create a significantly<br />

more powerful storm than the effect<br />

of the events taken individually. In<br />

collision repair, there are significant<br />

trends (events) underway that added<br />

together are creating the “perfect<br />

storm” in our industry.<br />

Prevailing trends<br />

Pressures on maintaining shop<br />

profitability has never been greater.<br />

The total collision market is getting<br />

smaller—primarily due to the<br />

increased introduction of accident<br />

avoidance technology, rising gas<br />

prices (resulting in fewer miles<br />

driven) as well as the increase in<br />

total loss rates. At the same time<br />

the market is shrinking, there is an<br />

overabundance of shops competing<br />

for the same business. And today’s<br />

consumer is more demanding than<br />

ever with high expectations for<br />

quality and fast service.<br />

knowing they are a mouse click<br />

away from a policyholder changing<br />

carriers, insurance companies are<br />

under more pressure, as they fight<br />

to grow and maintain policyholder<br />

loyalty. As a result, nearly all insurers<br />

have developed a much more<br />

competitive set of performancebased<br />

DRP programs that present<br />

new challenges for shops to improve<br />

the quality, speed and cost of<br />

operations of their repair process.<br />

This trend is of critical importance<br />

to collision centers given that the<br />

top ten insurers (who influence 65%<br />

of collision repair opportunities) are<br />

downsizing their DRP networks and<br />

thus, further reducing access to work<br />

for those collision repairers not part<br />

of their respective networks.<br />

the challenge of improving<br />

cycle time performance<br />

Since insurers now consider fast<br />

repair turnaround as a key factor<br />

in maintaining their customers’<br />

loyalty—and a key differentiating<br />

factor in determining which shops<br />

get their business—improving “cycle<br />

time performance” is the critical<br />

challenge facing collision shops as<br />

they navigate this perfect storm.<br />

When you think about it,<br />

fast cycle time was often talked<br />

about, but rarely considered a key<br />

consideration in selecting one shop<br />

over another. But now that the game<br />

has changed. Some businesses may<br />

require reducing cycle time in half to<br />

meet increasing expectations.<br />

Maintaining production<br />

efficiency remains important, but<br />

the most significant opportunities<br />

for improving cycle time center on<br />

the reasons why vehicles sit idle. It’s<br />

not about working harder or longer.<br />

It’s about eliminating the reasons<br />

why technicians are not touching<br />

the customer’s vehicle more<br />

continuously.<br />

Increasing “touch time”<br />

efficiency requires re-examination of<br />

every aspect of the repair process—<br />

from estimating and production<br />

scheduling to parts ordering and<br />

getting the right parts at the right<br />

time to the right technician. It<br />

requires better communication<br />

to assure that everyone is on the<br />

same page. And most critically,<br />

it requires the ability to attract<br />

and retain the right talent—and<br />

effective leadership—to implement<br />

the required changes in the repair<br />

process and develop a culture<br />

of continuous improvement<br />

throughout the organization.<br />

This is where our MvP Business<br />

Solutions team comes into play.<br />

knowing the challenges that our<br />

collision center customers face,<br />

we have been hard at work for the<br />

last several years upgrading and<br />

developing our program offerings<br />

to help our customers gain a<br />

competitive advantage in quality,<br />

speed and cost of operations.<br />

A <strong>green</strong> belt in lean<br />

One of our newest and most<br />

comprehensive programs designed to<br />

help collision shops improve virtually<br />

any aspect of their repair process<br />

is the MvP Green Belt Training<br />

program. This 4-day course,<br />

conducted both in the classroom and<br />

on the shop floor of an exemplary<br />

collision center, focuses on the<br />

proven process improvement science<br />

of Lean Six Sigma and how these<br />

principles can be practically applied<br />

to the collision repair process. Green<br />

Belt Training offers an effective<br />

balance between teaching enough<br />

theory to understand the challenges<br />

and providing practical solutions<br />

within collision to insure that shops<br />

can leave class and actually start<br />

down the path of implementation.<br />

MvP Green Belt covers all<br />

the basic fundamentals of Lean<br />

Six Sigma, such as workflow and<br />

workplace organization, variation,<br />

visual control, problem solving<br />

and continuous improvement.<br />

Attendees also study best practices<br />

for eliminating waste and how to use<br />

repair order data for process design<br />

and resource planning.<br />

Green Belt training is relevant<br />

for any collision center business,<br />

regardless of the size or structure of<br />

their operation. Customers who have<br />

<strong>go</strong>ne through Green Belt training<br />

come from shops ranging in size<br />

from doing $750,000 in business, on<br />

up to $10 million annually.<br />

Since it takes more than an<br />

understanding of the processes<br />

to implement Lean Six Sigma<br />

principles successfully, the Green<br />

Belt curriculum offers guidance on<br />

how to devise an implementation<br />

roadmap and how to develop and<br />

lead a work culture committed<br />

to change and continuous<br />

improvement.<br />

Green Belt Training offers a<br />

path toward continuous process<br />

improvement. For those shops<br />

wishing to focus on business<br />

fundamentals like estimating,<br />

production management, and<br />

administrative management to name<br />

a few, there’s the MvP Business<br />

Development Series of 1- and<br />

2-day courses. Each focuses on best<br />

practices related to a specific business<br />

fundamental.<br />

Whichever path you choose that<br />

best fits your needs, your partnership<br />

with <strong>PPG</strong> Refinish can provide<br />

you with solutions for weathering<br />

the “perfect storm” in our industry<br />

and providing your shop with a<br />

competitive advantage in quality,<br />

speed and cost.<<br />

24 25

The Hottest Colors<br />

<strong>PPG</strong>’S ViBRAnCe ColleCtion ®<br />

<strong>go</strong> <strong>green</strong><br />

line oFFeRS ComPliAnt<br />

WAteRBoRne SolUtion FoR<br />

CUStom FiniSheS<br />

As new, more stringent VoC<br />

regulAtions tAke effeCt in<br />

CAliforniA And CAnAdA, it<br />

is rAising ConCerns with<br />

professionAls who mAke their<br />

liVing CreAting hot pAint<br />

sChemes for Custom VehiCles,<br />

motorCyCles, helmets And<br />

other “one-off” CreAtions:<br />

how will we be Able to<br />

CreAte speCiAl effeCts And<br />

Custom pAint jobs And still<br />

meet VoC mAndAtes?”<br />

not to worry.<br />

<strong>PPG</strong>’s technology and color teams<br />

have developed a compliant solution<br />

that ensures all the colors and special<br />

effects currently offered with the<br />

Vibrance Collection will be available for<br />

use with <strong>PPG</strong>’s premium Envirobase ®<br />

High Performance waterborne basecoat.<br />

“Our customers in California<br />

and Canada love working with our<br />

Vibrance Collection custom color line<br />

and they’re very important to us,”<br />

says Randy Cremeans, marketing<br />

director for <strong>PPG</strong> Automotive<br />

Refinish. “So we challenged our<br />

team early on to make sure that<br />

the custom painter would not be<br />

hindered in the least bit when it<br />

becomes necessary to convert to a<br />

waterborne system.<br />

“Our <strong>go</strong>al was to take all the<br />

custom colors now available in<br />

solvent-based systems and offer those<br />

same colors in waterborne. And I’m<br />

proud to say we’re accomplishing<br />

our mission.”<br />

For the large majority of Vibrance<br />

colors, developing a compliant<br />

solution was pretty straightforward.<br />

<strong>PPG</strong>’s expert color-matchers<br />

matched the solvent-based custom<br />

colors with Envirobase HP waterborne<br />

basecoat. The result is a full lineup<br />

of “waterborne” formulas<br />

available for those who want to<br />

create special finishes using Crystal<br />

Pearl <br />

, Luminescence<br />

II ®<br />

, xirallics,<br />

Harlequin ®<br />

, Liquid<br />

Metal or<br />

StarFire.<br />

new VWm5555 Vibrance<br />

Collection midcoat<br />

Some special effect pigments<br />

available in the Vibrance Collection<br />

required a new technological solution<br />

to achieve waterborne compatibility.<br />

<strong>PPG</strong> developed the answer with<br />

its new and innovative Vibrance<br />

Collection midcoat. vWM5555 is<br />

designed to create a midcoat layer<br />

on top of the waterborne basecoat<br />

and allows painters to use Vibrance<br />

Collection special effect pigments such<br />

as Radiance ®<br />

II dyes, Flamboyance ®<br />

,<br />

Prizmatique ®<br />

, Liquid Crystals and<br />

Ditzler ®<br />

Big Flake <br />

.<br />

The new vWM5555 midcoat will<br />