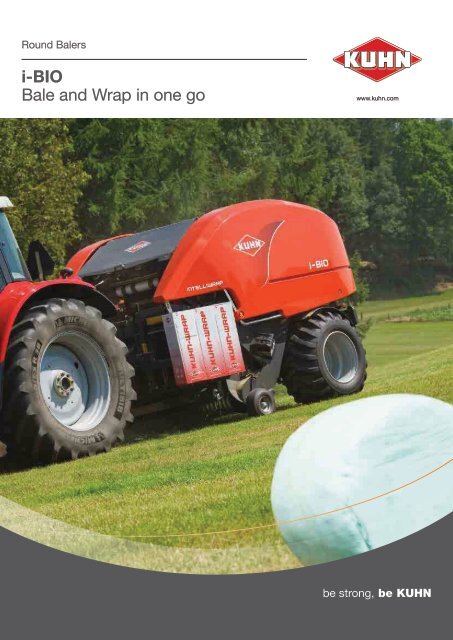

i-BIO Bale and Wrap in one go - Kuhn.com

i-BIO Bale and Wrap in one go - Kuhn.com

i-BIO Bale and Wrap in one go - Kuhn.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

i-<strong>BIO</strong><strong>Bale</strong> In OneKUHN BALERSPERFECT BALES UNDER ALL CONDITIONS!THE QUALITY YOU’RE LOOKING FORField performance, bale quality <strong>and</strong> bale density are fundamentalto the profitability of every bal<strong>in</strong>g operation. Every m<strong>in</strong>ute countswhen weather conditions are uncerta<strong>in</strong>. The unique <strong>in</strong>novations onthe KUHN balers make a real difference <strong>in</strong> field performance.UNMATCHED RELIABILITYKUHN offers the most efficient <strong>and</strong> versatile range of balersavailable on the market. KUHN balers are not only designed toproduce top quality bales but are also built for unmatched reliability<strong>and</strong> performance under all conditions.STAYING IN FRONT WITH NEW INNOVATIONSKUHN’s Research & Development department is constantlyimprov<strong>in</strong>g the i-<strong>BIO</strong> to stay <strong>in</strong> front with <strong>in</strong>novations like:INTEGRAL ROTOR Technology, INTELLIWRAP <strong>and</strong> DROP-FLOOR.Integral Rotor Opticut 14 Opticut 23Knives 14 23Cutt<strong>in</strong>g length 70 mm 45 mmGroup selection No Yes, 0-7-11-12-233

INTELLIWRAPHIGH-SPEED WRAPPINGKUHN has been a pi<strong>one</strong>er <strong>in</strong> the wrapp<strong>in</strong>g <strong>and</strong> bal<strong>in</strong>g technology, lead<strong>in</strong>g the way for over 25 years. The latest result of this cont<strong>in</strong>ued vision isa revolutionary new wrapp<strong>in</strong>g technique called INTELLIWRAP. This is a unique, <strong>in</strong>telligent <strong>and</strong> sophisticated way of wrapp<strong>in</strong>g bales.12341. Selection of 5 film layers -2. The bale is covered with 3 layers <strong>and</strong>67% overlap -3. Increas<strong>in</strong>g of the bale rotation speed -4. F<strong>in</strong>al 2 layers with 50% overlapExcellent wrapp<strong>in</strong>g; by <strong>in</strong>troduc<strong>in</strong>g INTELLIWRAP on the i-<strong>BIO</strong>, greater management <strong>and</strong> control is achieved. INTELLIWRAP uses sophisticatedelectronics <strong>and</strong> hydraulics to monitor the wrapp<strong>in</strong>g process <strong>and</strong> cont<strong>in</strong>uously controls the film overlap, allow<strong>in</strong>g total flexibility. Depend<strong>in</strong>g onlocal circumstances, crop conditions <strong>and</strong> storage periods the operator simply adjusts the amount of requested film layers (4, 5, 6, 7, 8, 9…)<strong>in</strong>to the term<strong>in</strong>al by a push on a button.18 second film wrap!*After rais<strong>in</strong>g the upper part of the bale chamber, the bale is ready for immediate wrapp<strong>in</strong>g. No bale transfer is needed. The bottompart of the bale chamber is now function<strong>in</strong>g as wrapp<strong>in</strong>g table. Synchroniz<strong>in</strong>g with the pre-stretchers INTELLIWRAP assures a correctoverlap. The two <strong>in</strong>tegrated pre-stretchers, mounted on a r<strong>in</strong>g, wrap the bale with a magnificent speed up to 50 m<strong>in</strong>-¹.Proportional valves ensure smooth speed<strong>in</strong>g up <strong>and</strong> slow<strong>in</strong>g down of the wrapp<strong>in</strong>g cycle <strong>and</strong> so gentle h<strong>and</strong>l<strong>in</strong>g of the film.After wrapp<strong>in</strong>g, the wrapper r<strong>in</strong>g <strong>go</strong>es up <strong>and</strong> the lower part of the bale chamber is lowered allow<strong>in</strong>g the bale to roll gently onto theground.*Apply<strong>in</strong>g 6 layers 5

INTAKEDifferent Intake SystemsPick-UpThe new designed Pick-Up gathers the densest of swaths even at highforward speeds. The PENDULUM system <strong>and</strong> 2.30 m wide <strong>in</strong>take withheight adjustable guide wheels accurately carry the Pick-Up over everyground contour. The Pick-Up roller helps to even out the flow of material<strong>in</strong>to the <strong>in</strong>tegral rotor, regardless of the crop conditions.OPTICUT 14The Integral Rotor with the 14-knife OPTICUT system is designedto even out the swath <strong>and</strong> force-feed the crop <strong>in</strong>to the baler formaximum throughput. The 14-knife OPTICUT cutt<strong>in</strong>g system providesa theoretical cutt<strong>in</strong>g length of 70 mm. Each s<strong>in</strong>gle knife is spr<strong>in</strong>gprotected aga<strong>in</strong>st damage from foreign objects.OPTICUT 23The Integral Rotor with the 23-knife OPTICUT system from KUHN has the benefitsof <strong>in</strong>tensive cutt<strong>in</strong>g <strong>and</strong> the mechanical protection. The 23-knife OPTICUT systemprovides a theoretical cutt<strong>in</strong>g length of 45 mm. Each s<strong>in</strong>gle knife is spr<strong>in</strong>gprotected aga<strong>in</strong>st damage from foreign objects. With group selection the operatorcan choose to have 0, 7, 11, 12, or 23 knives <strong>in</strong> operation.The OPTICUT systems from KUHN are acknowledged by users as <strong>one</strong> of the bestcutt<strong>in</strong>g systems on the market.WORK QUALITYIntegral Rotor TechnologyA ma<strong>in</strong>tenance-free <strong>and</strong> short distance <strong>in</strong>take system which ensures even feed<strong>in</strong>g regardlessof variations of the crop. With this system, even the heaviest crops are forced through the<strong>in</strong>take, result<strong>in</strong>g <strong>in</strong> higher forward speeds for outst<strong>and</strong><strong>in</strong>g productivity.The silage is guided <strong>and</strong> drawn to the knives <strong>in</strong> an early stage which improves the flow <strong>and</strong> cutt<strong>in</strong>g performance <strong>and</strong> is also prevent<strong>in</strong>gunwanted blockages. As a result of the redesigned <strong>in</strong>take unit the power requirement of the i-<strong>BIO</strong> has decreased.DROP-FLOORThe <strong>in</strong>take unit is protected by the ma<strong>in</strong> PTO clutch. If a blockage occurs the PTO clutch is automatically activated. In addition the <strong>com</strong>pletecutt<strong>in</strong>g floor <strong>in</strong>clud<strong>in</strong>g the knives can be lowered with a push on a button on the term<strong>in</strong>al. After the blockage is cleared the cutt<strong>in</strong>g floor <strong>in</strong>clud<strong>in</strong>gthe knives can be brought back <strong>in</strong>to the work<strong>in</strong>g position via the term<strong>in</strong>al. In extreme circumstances KUHN provides double security by rotordisengagement clutch which separates the rotor drive so the bale can be f<strong>in</strong>ished.6

COMFORT<strong>Bale</strong> chamberThe KUHN i-<strong>BIO</strong> is a fixed chamber round baler with a chamber diameter of 125 cm.For <strong>com</strong>press<strong>in</strong>g the crop <strong>in</strong>to consistent size <strong>and</strong> dense bales, the bal<strong>in</strong>g process has to beas effective as possible, while be<strong>in</strong>g gentle on the crop. The 18 steel rollers equipped with aribbed profile ensure maximum traction <strong>and</strong> <strong>com</strong>pression, <strong>and</strong> create an ideal wrapp<strong>in</strong>g tablewhich is friendly for the film. The rollers are produced from high-grade steel constructed fromtwo fully seam-welded sections. Radial support r<strong>in</strong>gs are located <strong>in</strong>side each roller, creat<strong>in</strong>gadditional strength. The end plate <strong>and</strong> roller stub shafts are forged <strong>in</strong> <strong>one</strong> piece.OverviewWhile work<strong>in</strong>g with the KUHN i-<strong>BIO</strong> you have an excellent view on the process of bal<strong>in</strong>g,apply<strong>in</strong>g net, wrapp<strong>in</strong>g <strong>and</strong> unload<strong>in</strong>g the bale without the need of an additional camera.Also on the term<strong>in</strong>al with big color screen you are able to monitor the <strong>com</strong>plete bal<strong>in</strong>g <strong>and</strong>wrapp<strong>in</strong>g process.Netb<strong>in</strong>d<strong>in</strong>g without <strong>com</strong>promiseThe b<strong>in</strong>d<strong>in</strong>g cycle is a critical step <strong>in</strong> the bal<strong>in</strong>g process. Less time spent net wrapp<strong>in</strong>g meanshigher efficiency <strong>and</strong> productivity. To optimize this process, adjustments are conveniently madevia the term<strong>in</strong>al. On the KUHN i-<strong>BIO</strong>, the b<strong>in</strong>d<strong>in</strong>g system is located at the front of the mach<strong>in</strong>e,provid<strong>in</strong>g a perfect view of the b<strong>in</strong>d<strong>in</strong>g process from the tractor seat.7

Pre-stretchersWORK QUALITYPre-stretchersThe st<strong>and</strong>ard pre-stretchers hold 750 mm film rolls <strong>and</strong> are made of alum<strong>in</strong>um to avoid build-up of tack from the film. The bottomend of the alum<strong>in</strong>ium rollers are c<strong>one</strong>-shaped, to ma<strong>in</strong>ta<strong>in</strong> the optimum width of the film <strong>and</strong> reduce the risk of film tear. The specialribbed profile of the alum<strong>in</strong>um rollers keeps air <strong>and</strong> water away from the film. The st<strong>and</strong>ard pre-stretch of 70% is reached by alow-ma<strong>in</strong>tenance <strong>and</strong> low noise gear transmission.If <strong>one</strong> of the film rolls is empty or torn theoperator can switch to half speed with <strong>one</strong>push on a button <strong>in</strong> order to f<strong>in</strong>ish the balewith <strong>one</strong> roll of film. Optionally a film end/break sensor is available, which warns theoperator automatically for an empty film roll or abreakage.SAVINGSOptimum Silage qualityWhen wrapp<strong>in</strong>g with the KUHN i-<strong>BIO</strong> the bale rema<strong>in</strong>s <strong>in</strong> the bale chamber.Us<strong>in</strong>g a conventional bale wrap <strong>com</strong>b<strong>in</strong>ation the bale tends to exp<strong>and</strong> while be<strong>in</strong>g transferred from bale chamber to wrapp<strong>in</strong>g table.Immediate wrapp<strong>in</strong>g of the bale limits the use of netwrap, limits unwanted expansion <strong>and</strong> optimizes fermentation of the crop.As the bale is lay<strong>in</strong>g onto the lower part of the bale chamber wrapp<strong>in</strong>g on hilly slopes is no issue. The bale is held firmly <strong>in</strong>position supported by side rollers.Film cuttersTwo vertical film cutters hydraulically rise from the lower part of the bale chamber to hold <strong>and</strong> cut the film. Due to its design, the film is caught onits full width. The film is held with a clamp, stretched <strong>in</strong>to a solid str<strong>in</strong>g, <strong>and</strong> then cut before the bale is unloaded. The hydraulic clamp cont<strong>in</strong>ues tofirmly hold the film for the next bale.8

ELECTRONICSCCI 100The ISOBUS <strong>com</strong>patible CCI 100 term<strong>in</strong>al has a large 21,6 cm (8.5”) color screen withoutst<strong>and</strong><strong>in</strong>g clarity. Bal<strong>in</strong>g adjustments can be easily made via the touch screen or by useof the <strong>in</strong>tuitive, large, soft-touch keys. The CCI 100 term<strong>in</strong>al can also be used with manyother ISOBUS <strong>com</strong>patible mach<strong>in</strong>es on the market.VT 50The KUHN ISOBUS VT 50 term<strong>in</strong>al has a14,5 cm (5.7”) color screen with outst<strong>and</strong><strong>in</strong>gclarity. Adjustments can easily be d<strong>one</strong> by thetouch screen <strong>and</strong> the large soft-touch keys onthe sides. The VT 50 term<strong>in</strong>al can be usedspecifically with the KUHN ISOBUS mach<strong>in</strong>es.9

OPTIONSDifferent wheel sizesAutomatic roller bear<strong>in</strong>g greas<strong>in</strong>g<strong>Bale</strong> turner, unload<strong>in</strong>g the bale on its flat endSeveral hitch options <strong>in</strong>clud<strong>in</strong>g a ball-hitchcoupl<strong>in</strong>gPivot<strong>in</strong>g Pick-Up wheelsHydraulic or pneumatic brakesHydraulic operation of rotor clutch10Rubber drop mat

SpecificationsOPTICUT 14 OPTICUT 23DimensionsWidth 2.80 m 2.80 mHeight / open balechamber 2.30 m / 3.75 m 2.30 m / 3.75 mLength 4.50 m 4.50 mWeight 3495 kg 3600 kgPick-UpPick-Up width 2.30 m 2.30 mNumber of t<strong>in</strong>e rows 5 5Crop roller St<strong>and</strong>ard St<strong>and</strong>ardPneumatic gauge wheels / pivot<strong>in</strong>g St<strong>and</strong>ard / Optional St<strong>and</strong>ard / OptionalIntakeIntegral Rotor OptiCut 14 OptiCut 23Knives 14 23 ( 0-7-11-12-23)Cutt<strong>in</strong>g length 70 mm 45 mmKnife protection S<strong>in</strong>gle / Spr<strong>in</strong>g S<strong>in</strong>gle / Spr<strong>in</strong>g<strong>Bale</strong> chamber<strong>Bale</strong> formation 18 rollers 18 rollersRoller diameter 190 mm 190 mmDiameter 1.25 m 1.25 mWidth 1.22 m 1.22 mLow friction plates St<strong>and</strong>ard St<strong>and</strong>ardCentral roller bear<strong>in</strong>g greas<strong>in</strong>g St<strong>and</strong>ard St<strong>and</strong>ardAutomatic central greas<strong>in</strong>g system Optional OptionalAutomatic cha<strong>in</strong> oiler St<strong>and</strong>ard St<strong>and</strong>ardNet b<strong>in</strong>d<strong>in</strong>g / storage St<strong>and</strong>ard / 1 roll St<strong>and</strong>ard / 1 rollOperationControl system ISOBUS ISOBUS<strong>Wrap</strong>p<strong>in</strong>g unitFilm width / storage 750 mm / up to 6 rolls 750 mm / up to 6 rolls½ table speed by end of film / tear St<strong>and</strong>ard St<strong>and</strong>ardFilm break sensor Optional OptionalWheelsS<strong>in</strong>gle axle 520/50-17 St<strong>and</strong>ard St<strong>and</strong>ardS<strong>in</strong>gle axle 500/45-22.5 Optional OptionalS<strong>in</strong>gle axle 600/40-22.5 Optional OptionalBrake system (optional) Air / Hydraulic Air / HydraulicOthersLong service <strong>in</strong>terval PTO 540 with st<strong>and</strong>ard free wheel clutch 540 with st<strong>and</strong>ard free wheel clutchOil consumption 35 l/m<strong>in</strong> at 180 bar 35 l/m<strong>in</strong> at 180 barNecessary hydraulic tractor equipment 1 s<strong>in</strong>gle act<strong>in</strong>g with 3/4” free return 1 s<strong>in</strong>gle act<strong>in</strong>g with 3/4” free returnM<strong>in</strong> power requirement* 80 kW (110 hp) 80 kW (110 hp)11* = Horsepower requirement may vary with different crops, conditions, <strong>and</strong> options used. Consult operators manual for proper tractor siz<strong>in</strong>g.

i-<strong>BIO</strong><strong>Bale</strong> In OneFIND THE KUHN BALER,WHICH IS PERFECTLY ADAPTED TO YOUR NEEDS!i-<strong>BIO</strong>Integral Rotor OPTICUT 14 OPTICUT 23Knives 14 23Cutt<strong>in</strong>g length 70 mm 45 mmGroup selection No Yes, 0-7-11-12-23CHECK OUT THE WHOLE KUHN BALER AND WRAPPER RANGE14561.1Variable <strong>Bale</strong>rs - 2. Variable <strong>Bale</strong>Packs - 3. Fixed <strong>Bale</strong>rs - 4. Fixed <strong>Bale</strong>Packs - 5. Large Square <strong>Bale</strong>rs - 6. Round <strong>and</strong> Square bale <strong>Wrap</strong>persTo f<strong>in</strong>d your nearest Authorized Partner visitwww.kuhn.<strong>com</strong>Visit uson our YouTube channels.2Your <strong>Kuhn</strong> Dealer:3KUHN NORTH AMERICA, INC.Corporate Headquarters - 1501 West Seventh Avenue -P.O. Box 167 - Brodhead, WI 53520-0167 USA -Ph<strong>one</strong> : (608) 897-2131 - Fax : (608) 897-2561 -www.kuhnnorthamerica.<strong>com</strong>KUHN FARM MACHINERY PTY. LTD7 Manorwood PI. - MITCHAM, 3132 VIC - Fax : 039874 3462 -www.kuhn.<strong>com</strong>United K<strong>in</strong>gdom KUHN FARM MACHINERY (U.K.) LTDStafford Park 7 - TELFORD - SHROPSHIRE TF 3 3 BQ -Ph<strong>one</strong> : TELFORD (01952) 239300/1/2 - Fax : (01952) 290091 -www.kuhn.co.ukOur material is produced <strong>in</strong> accordance with the European Mach<strong>in</strong>ery Directive <strong>in</strong> the member states of the EuropeanUnion. In countries outside the E.U., our mach<strong>in</strong>ery <strong>com</strong>plies with the safety regulations set by the country concerned.Some safety devices may have been removed from our leaflets <strong>in</strong> order to clarify the illustration. Under no circumstancesshould the mach<strong>in</strong>e be operated without the necessary safety devices <strong>in</strong> place (as specified by the assembly <strong>in</strong>structions<strong>and</strong> operators manual). We reserve the right to change any designs, specifications or materials listed without furthernotice. Our models <strong>and</strong> trademarks are patented <strong>in</strong> more than <strong>one</strong> country. Mach<strong>in</strong>es <strong>and</strong> equipment <strong>in</strong> this documentcan be covered by at least <strong>one</strong> patent <strong>and</strong>/or registered design. Trademarks cited <strong>in</strong> this document may be registered<strong>in</strong> <strong>one</strong> or several countries.To protect the environment, this leaflet is pr<strong>in</strong>ted on chlor<strong>in</strong>e-free paper / Pr<strong>in</strong>ted the Netherl<strong>and</strong>s - ZPAF35GB A 09 -13 - Copyright 2013 KUHNwww.kuhn.<strong>com</strong>Also f<strong>in</strong>d KUHN on