Poly-vinyl chloride sheet lining system

Poly-vinyl chloride sheet lining system

Poly-vinyl chloride sheet lining system

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Protective Lining Products<br />

Description<br />

A high polymer <strong>vinyl</strong> <strong>chloride</strong><br />

<strong>sheet</strong> <strong>lining</strong><br />

Resists strong acidic, alkaline<br />

and salt solutions<br />

Dense extrusion allows outstanding<br />

abrasion resistance and imperability<br />

Mechanical lock to new concrete<br />

Typical Uses<br />

Ameron T-Lock, on the market since<br />

1947 with well over 175,000,000 square<br />

feet (nearly 16,000,000 square meters)<br />

installed, is now entering a period of resurgence<br />

as design engineers all over the<br />

world are rediscovering its broad range<br />

of physical and chemical properties.<br />

Ameron T-Lock is often used to line tanks,<br />

sumps, neutralization basins, clarifiers,<br />

thickeners and other structures. Ameron<br />

T-Lock has long been recognized for the<br />

outstanding corrosion protection it provides<br />

in sewage treatment plants and as<br />

a liner for thousands of miles of concrete<br />

sewer pipe, along with large diameter<br />

concrete waste effluent piping in many<br />

different industrial facilities.<br />

For Steel and Certain<br />

Concrete Surfaces<br />

Ameron T-Lock-Plain Sheet is installed<br />

in existing tanks and structures, and<br />

also makes a superior membrane under<br />

acid-proof brick. Sheets are applied with<br />

Ameron T-Lock adhesive and joined together<br />

by fusing Ameron T-Lock welding<br />

strip over the joints with a hot air welding<br />

gun. This results in a continuous and<br />

highly impermeable membrane.<br />

For New Concrete Structures<br />

Where new concrete tanks are to be built,<br />

T-Lock Ameron T-Lock may be cast into<br />

the walls and made an integral part of<br />

the structure without the use of adhesive,<br />

thereby, providing a long-term mechanical<br />

lock, with hydrostatic back pressure<br />

resistance of 100 feet (30.5M) of head.<br />

Ameron T-Lock<br />

®<br />

95Y<br />

<strong>Poly</strong>-<strong>vinyl</strong> <strong>chloride</strong> <strong>sheet</strong> <strong>lining</strong> <strong>system</strong><br />

Typical<br />

Properties<br />

Thermoplastic—Ameron T-Lock remains<br />

flexible for handling and installation<br />

purposes throughout a normal working<br />

temperature range down to as low as 40°F<br />

(4°C). The average brittleness temperature<br />

per ASTM D746 test method is 5° F<br />

(-15°C).<br />

Welding—A continuous membrane is<br />

formed by heat fusing Ameron T-Lock<br />

weld strip over butted or lapped edges<br />

of the <strong>sheet</strong>. The same weld strip may be<br />

used to repair damage at any time during<br />

the life of the <strong>sheet</strong>.<br />

In-service temperature resistance<br />

in solutions—Withstands continuous<br />

immersion up to l50°F (66°C), although<br />

specific temperature limits depend upon<br />

the nature and concentration of the solution.<br />

Dielectric strength—Ameron T-Lock is<br />

a nonconductor of electricity and resists<br />

electrolysis. Dielectric strength of the<br />

<strong>sheet</strong> <strong>lining</strong> using ASTM Dl49 test method<br />

short time test is 500 volts per mil of<br />

thickness.<br />

Water absorption—Absorbs 0.1 to 0.4<br />

percent during the first 24 hours, then<br />

the rate drops rapidly using ASTM D149<br />

D570 test method. Total absorbed amount<br />

is not significantly increased during any<br />

prolonged period.<br />

Water vapor transmission—Using ASTM<br />

E96 test method, the transmission rate is<br />

less than 0.1 gram per l00 square inches<br />

in 24 hours at 77°F (25°C) and 23.5 mm of<br />

mercury.<br />

Gas transmission rate—Using 40-mil<br />

<strong>sheet</strong> and ASTM test method D1434<br />

Procedure V, the rate of transmission with<br />

a l6-inch water column pressure was 0.0<br />

cc/100 sq in./24 hours. At 3 atmospheres,<br />

the rate was l6.8 cc/100 sq in./24 hr<br />

average. Great care must be exercised in<br />

making the fusion welds and in repairing<br />

nail holes, snap-tie holes, etc., so that the<br />

installed <strong>system</strong> will pass a reasonable<br />

gas tightness test if required in certain<br />

applications.<br />

1<br />

Physical Data<br />

Color Black or White<br />

Packaging<br />

Ameron T-Lock<br />

Plain Sheet 200 sq. ft. rolls<br />

(18.58 sq. m. rolls)<br />

48 in. wide x 50 ft. long<br />

(1.22m wide x 15.24 m long)<br />

Plain Sheet<br />

thickness and<br />

shipping weight 1/16 in. (1.6mm) —105 lbs.<br />

(48kb) per roll<br />

3/32 in. (2.4mm)—145lbs.<br />

(66 kg.) per roll<br />

1/8 in. (3.2mm)—190 lbs.<br />

(86 kg) per roll<br />

3/16 in. (4.8mm)—135 lbs.<br />

(61 kg) per roll in 25 ft.<br />

(7.62 m.) length<br />

T-Lock 4 ft. x 8 ft. <strong>sheet</strong>s or metric<br />

<strong>sheet</strong>s 1.25m. x 2.25m. or<br />

special prefabricated sizes<br />

T-Lock thickness 69 mils ± 4 mils<br />

(Standard) (1.75 mm ± 0.10 mm)<br />

T-Lock weight 0.7lbs/sq. ft. or<br />

3.42 kg./sq. m.<br />

Ameron T-Lock adhesive<br />

<strong>system</strong> material 19Y primer<br />

19Y adhesive<br />

19Y thinner/cleaner<br />

Shelf life of primer and adhesive is 6 months from<br />

date of shipment<br />

Coverage/gallon/coat<br />

Primer 200 sq. ft. (18.58 sq. m.)<br />

Adhesive 150 sq. ft. (13.94 sq. m.)<br />

Coverage varies with roughness and porosity<br />

of the substrate.<br />

Packaging 1 gallon and 5 gallon<br />

(3.79 L and 18.93 L)<br />

containers<br />

Shipping weight<br />

Primer<br />

1 gallon 9 lbs. (4kg.)<br />

5 gallon 43 lbs. (20 kg.)<br />

Adhesive<br />

1 gallon 8 lbs. (3.6 kg.)<br />

5 gallon 41 lbs. (18.6 kg.)<br />

Thinner/cleaner<br />

1 gallon 8 lbs. (3.6 kg.)<br />

5 gallon 37 lbs. (16.8kg.)

Coefficient of thermal expansion—Using<br />

ASTM D696 test method, the coefficient<br />

is 0.0001 in./in./°F. T-Lock, when<br />

cast into concrete pipe or structures,<br />

does not expand or contract to any<br />

greater or lesser extent than the concrete.<br />

Plain Sheet moves with the steel<br />

substrate.<br />

Hardness—Shore Durometer “D” is<br />

approximately 54 at ambient temperature<br />

per ASTM D2240 test method. This<br />

equates to approximately 95 on the “A”<br />

scale.<br />

Tensile strength of parent material—<br />

2200 psi minimum per ASTM D412 test<br />

method. Factory welds are a minimum<br />

2000 psi test.<br />

Elongation of parent material—200<br />

percent minimum per ASTM D412 test<br />

method.<br />

Abrasion resistance—Using ASTM<br />

D1044 test method with a CS-17<br />

Calibrase Wheel loaded to 1000 g, the<br />

weight loss is 35 mg per 1000 cycles.<br />

This is substantially better than bare<br />

concrete or vitrified clay.<br />

Coefficient of friction—Using ASTM<br />

D1894 test method, the static coefficient<br />

is 0.75 and the kinetic coefficient<br />

is 0.54.<br />

Specific Gravity—Using ASTM D792<br />

test method, the specific gravity is 1.28.<br />

Tear Resistance—Using ASTM D1004<br />

test method, the tear resistance is<br />

220g/mil.<br />

Brittleness Temperature—Using ASTM<br />

D746 test method, the low brittleness<br />

temperature is 5°F.<br />

Volume Resistivity—Using ASTM D257<br />

test method, the value is 5.8 x 10 12<br />

OHM - CM.<br />

Surface Resistivity—Using ASTM D257<br />

test method, the value is 1.1 x 10 14<br />

OHMS.<br />

Pull-Out Resistance—100 pounds per<br />

lineal inch of Tee at 75°F (24°C) from<br />

cured concrete.<br />

Chemical<br />

Resistance<br />

Chart<br />

Acid resistance—Ameron T-Lock performs<br />

well in continuous exposure to<br />

most mineral acids. Ameron T-Lock is<br />

also resistant to immersion in specific<br />

organic acids.<br />

Salt resistance—Resistance to many<br />

highly corrosive salts, including sodium<br />

<strong>chloride</strong>, copper sulfate, calcium <strong>chloride</strong><br />

and alum.<br />

Alkali resistance—Good resistance<br />

to alkalies. Withstands dilute caustic<br />

soda at ambient temperature.<br />

Solvent resistance—T-Lock resists<br />

dilute solutions of alcohols that normally<br />

occur in sewage wastes; it is not<br />

resistant to chlorinated hydrocarbons,<br />

esters, ketones and similar solvents.<br />

Petroleum resistance—T-Lock withstands<br />

exposure to petroleum products<br />

that normally occur in municipal waste<br />

disposal <strong>system</strong>s; it is not designed for<br />

continuous exposure to high concentrations<br />

of petroleum products.<br />

Vegetable and animal oil resistance—<br />

T-Lock resists repeated exposure to<br />

liquid vegetable and animal oils that<br />

occur as components of municipal or<br />

industrial wastes.<br />

Fungi and bacteria resistance—Continuous<br />

exposure to actions of fungi<br />

and bacteria have no effect since T-<br />

Lock provides no sustenance for such<br />

growths.<br />

Plating Solutions<br />

Plating tank operators must test<br />

Ameron T-Lock to determine its suitability<br />

and expected performance life<br />

for their particular mixtures, including<br />

proprietary additives and temperature<br />

range. Extra layers may be appropriate<br />

in some applications, especially at<br />

liquid/atmosphere interface and above.<br />

Chemical Testing<br />

Ameron T-Lock has been tested in<br />

continuous immersion of the following<br />

chemicals at the temperatures shown<br />

for a period of one year. It is the nature<br />

of this material that it may show discoloration<br />

in some solutions, and in some<br />

of the most severe applications, it may<br />

gradually begin to swell or harden. Such<br />

observations do not mean the <strong>lining</strong><br />

<strong>system</strong> has failed, and if left alone, it<br />

may perform well for many years.<br />

2<br />

Any recommendation or suggestion relating<br />

to the use of the products made<br />

by Ameron, whether in its technical<br />

literature, or in response to specific<br />

inquiry, or otherwise, is based on data<br />

believed to be reliable; however, the<br />

products and information are intended<br />

for use by Buyers having requisite skill<br />

and know-how in the industry, and<br />

therefore it is for Buyer to satisfy itself<br />

of the suitability of the products for<br />

its own particular use and it shall be<br />

deemed that Buyer has done so, at its<br />

sole discretion and risk. Variation in<br />

environment, changes in procedures of<br />

use, or extrapolation of data may cause<br />

unsatisfactory results.<br />

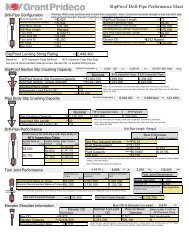

Solutions of Inorganic Acids<br />

Maximum<br />

Concentration<br />

by Weight<br />

Maximum<br />

Temperature<br />

°F (°C)<br />

Boric Acid any 150(66)<br />

Carbon Dioxide any 90(32)<br />

Chlorine Water<br />

sat at atmos. press. 90(32)<br />

Hydrofluoric<br />

Acid 1% 140(60)<br />

Hydrogen<br />

Sulfide<br />

sat at atmos. press. 90(32)<br />

Hydrochloric<br />

Acid (Muriatic) 19% 100 (38)<br />

Nitric Acid 1% 120 (49)<br />

Sulfuric Acid 20% 150 (66)<br />

Solutions of Inorganic Salts<br />

and Alkalies<br />

Aluminum<br />

Chloride any 150 (66)<br />

Aluminum<br />

Fluoride any 150 (66)<br />

Aluminum<br />

Nitrate 25% 150 (66)<br />

Aluminum<br />

Sulfate any 150 (66)<br />

Alum any 150 (66)<br />

Ammonium<br />

Alum any 150 (66)<br />

Ammonium<br />

Chloride any 150 (66)<br />

Ammonium<br />

Fluoride any 150 (66)<br />

Ammonium<br />

Nitrate any 150 (66)<br />

Ammonium<br />

Phosphate any 150 (66)<br />

Ammonium<br />

Sulfate any 150 (66)

Maximum<br />

Concentration<br />

by Weight<br />

Maximum<br />

Temperature<br />

°F (°C)<br />

Ammonium<br />

Thiocyanate any 150 (66)<br />

Barium<br />

Carbonate any 150 (66)<br />

Barium Chloride any 150 (66)<br />

Barium<br />

Hydroxide any 150 (66)<br />

Barium Nitrate any 150 (66)<br />

Barium Sulfate any 150 (66)<br />

Barium Sulfide any 150 (66)<br />

Borax any 150 (66)<br />

Brine Solution any 150 (66)<br />

Calcium Acetate any 150 (66)<br />

Calcium<br />

Bilsulfite any 90 (32)<br />

Calcium<br />

Carbonate any 150 (66)<br />

Calcium<br />

Chloride any 150 (66)<br />

Calcium<br />

Fluophosphate any 150 (66)<br />

Calcium<br />

Hydroxide any 150 (66)<br />

Calcium Nitrate any 150 (66)<br />

Calcium Sulfate any 150 (66)<br />

Caustic Potash<br />

(Potassium<br />

Hydroxide) 10% 70(21)<br />

Caustic Soda<br />

(Sodium<br />

Hydroxide) 10% 70 (21)<br />

Chrome Alum any 150 (66)<br />

Copper Chloride<br />

(Cupric) any 150 (66)<br />

Copper Nitrate any 150 (66)<br />

Copper Sulfate<br />

(Cupric) any 150 (66)<br />

Cupric Nitrate any 150 (66)<br />

Cupric Sulfate any 150 (66)<br />

Disodium<br />

Phosphate any 150 (66)<br />

Ferric Chloride any 150 (66)<br />

Ferric Nitrate 10% 150 (66)<br />

Ferric Sulfate 10% 150 (66)<br />

Ferrous<br />

Ammonium<br />

Chloride any 150 (66)<br />

Ferrous<br />

Ammonium<br />

Sulfate any 150 (66)<br />

Maximum<br />

Concentration<br />

by Weight<br />

Ferrous<br />

Sulfate<br />

(Copperas) any 150 (66)<br />

Iron Chloride any 150 (66)<br />

Iron Sulfate any 150 (66)<br />

Lead Chloride any 150 (66)<br />

Lead Nitrate any 150 (66)<br />

Lead Sulfate any 150 (66)<br />

Lead Sulfamate any 150 (66)<br />

Lithium<br />

Chloride any 150 (66)<br />

Magnesium<br />

Carbonate any 150 (66)<br />

Magnesium<br />

Chloride any 150 (66)<br />

Magnesium<br />

Hydroxide any 150 (66)<br />

Magnesium<br />

Nitrate any 150 (66)<br />

Magnesium<br />

Oxide any 150 (66)<br />

Magnesium<br />

Sulfate any 150 (66)<br />

Manganese<br />

Ammonium<br />

Sulfate any 150 (66)<br />

Manganese<br />

Chloride any 150 (66)<br />

Manganese<br />

Sulfate any 150 (66)<br />

Manganese<br />

Nitrate any 150 (66)<br />

Nickel Acetate any 150 (66)<br />

Nickel Nitrate any 150 (66)<br />

Potassium<br />

Acid<br />

Sulfate any 150 (66)<br />

Potassium<br />

Aluminum<br />

Sulfate any 150 (66)<br />

Potassium<br />

Alum any 150 (66)<br />

Potassium<br />

Antimonate any 150 (66)<br />

Potassium<br />

Bicarbonate any 150 (66)<br />

Potassium<br />

Bichromate any 150 (66)<br />

Potassium<br />

Bisulfite any 90 (32)<br />

Potassium<br />

Carbonate any 150 (66)<br />

3<br />

Maximum<br />

Temperature<br />

°F (°C)<br />

Maximum<br />

Concentration<br />

by Weight<br />

Maximum<br />

Temperature<br />

°F (°C)<br />

Potassium<br />

Chlorate any 150 (66)<br />

Potassium<br />

Chloride any 150 (66)<br />

Potassium<br />

Chromate any 150 (66)<br />

Potassium<br />

Cupro Cyanide any 150 (66)<br />

Potassium<br />

Cyanide any 120 (49)<br />

Potassium<br />

Dichromate any 150 (66)<br />

Potassium<br />

Iodide any 150 (66)<br />

Potassium<br />

Nitrate any 150 (66)<br />

Potassium<br />

Phosphate any 120 (49)<br />

Potassium<br />

Sulfide any 150 (66)<br />

Potassium<br />

Thiosulfate any 150 (66)<br />

Sodium Acid<br />

Sulfate any 150 (66)<br />

Sodium Alum any 150 (66)<br />

Sodium<br />

Aluminum<br />

Sulfate any 150 (66)<br />

Sodium<br />

Antimonate any 150 (66)<br />

Sodium<br />

Bicarbonate any 150 (66)<br />

Sodium<br />

Bichromate any 150 (66)<br />

Sodium<br />

Bisulfate any 150 (66)<br />

Sodium<br />

Bisulfite any 90 (32)<br />

Sodium<br />

Carbonate any 150 (66)<br />

Sodium<br />

Chlorate any 150 (66)<br />

Sodium<br />

Chloride any 150 (66)<br />

Sodium<br />

Chromate any 150 (66)<br />

Sodium<br />

Cyanide any 120 (49)<br />

Sodium<br />

Dichromate any 150 (66)<br />

Sodium<br />

Fluoride any 150 (66)

Maximum<br />

Concentration<br />

by Weight<br />

Maximum<br />

Temperature<br />

°F (°C)<br />

Sodium<br />

Hypochlorite 1% 80 (27)<br />

Sodium Iodide any 150 (66)<br />

Sodium Nitrate any 150 (66)<br />

Sodium Nitrite any 150 (66)<br />

Sodium<br />

Phosphate any 120 (49)<br />

Sodium Sulfide any 120 (49)<br />

Sodium<br />

Thiosulfate any 150 (66)<br />

Sulfite Liquors any 90 (32)<br />

Trisodium<br />

Phosphate 10% 120 (49)<br />

Water—Fresh any 150 (66)<br />

Water—Mine any 150 (66)<br />

Water—Salt any 150 (66)<br />

Water—Sea any 150 (66)<br />

Zeolite any 150 (66)<br />

Zinc Chloride 30% 150 (66)<br />

Zinc Sulfate any 150 (66)<br />

Maximum<br />

Concentration<br />

by Weight<br />

Organic Materials<br />

Citric Acid any 150 (66)<br />

Gallic Acid any 150 (66)<br />

Glucose any 150 (66)<br />

Glycerine any 90 (32)<br />

Lactic Acid any 90 (32)<br />

Malic Acid any 90 (32)<br />

Oxalic Acid any 90 (32)<br />

Soaps any 90 (32)<br />

Tannic Acid any 90 (32)<br />

Tartaric<br />

Acid any 90 (32)<br />

Urea any 150 (66)<br />

Uric Acid any 150 (66)<br />

Organic Acids and Salts<br />

AMERON<br />

I N T E R N A T I O N A L<br />

Ameron Protective Lining Products<br />

201 North Berry Street • P.O. Box 1629 • Brea, California 92822 • (714)256-7755 • Fax: (714)256-7750<br />

Email: t-lock@ameron.com • www.amerontlock.com<br />

© 2003 Ameron International • R8/03 • AB-3 • PDF<br />

4<br />

Maximum<br />

Temperature<br />

°F (°C)<br />

Ammonium<br />

Acetate 10% 150 (66)<br />

Maleic Acid 10% 150 (66)<br />

Picric Acid 25% 150 (66)<br />

Potassium Sodium<br />

Acetate any 150 (66)<br />

Sodium Acetate any 150 (66)<br />

Zinc Acetate any 150 (66)<br />

Warranty<br />

Ameron warrants its products to be<br />

free from defects in material and<br />

workmanship. Ameron’s sole obligation<br />

and Buyer’s exclusive remedy in<br />

connection with the products shall be<br />

limited, at Ameron’s option, to either<br />

replacement of products not conforming<br />

to this Warranty or credit to Buyer’s<br />

account in the invoiced amount of the<br />

non-conforming products. Any claim under<br />

this Warranty must be made by Buyer<br />

to Ameron in writing within five<br />

(5) days of Buyer’s discovery of the<br />

claimed defect, but in no event later than<br />

the expiration of the applicable shelf<br />

life, or one year from the delivery date,<br />

whichever is earlier. Buyer’s failure to<br />

notify Ameron of such nonconformance<br />

as required herein shall bar Buyer from<br />

recovery under this Warranty.<br />

Ameron makes no other warranties<br />

concerning the product. No other warranties,<br />

whether express, implied, or statutory, such<br />

as warranties of merchantability or fitness<br />

for a particular purpose, shall apply.<br />

In no event shall Ameron be liable for<br />

consequential or incidental damages.<br />

Any recommendation or suggestion<br />

relating to the use of the products made<br />

by Ameron, whether in its technical<br />

literature, or in response to specific<br />

inquiry, or otherwise, is based on data<br />

believed to be reliable; however, the<br />

products and information are intended<br />

for use by Buyers having requisite skill<br />

and know-how in the industry, and<br />

therefore it is for Buyer to satisfy itself<br />

of the suitability of the products for<br />

its own particular use and it shall be<br />

deemed that Buyer has done so, at its<br />

sole discretion and risk. Variation in<br />

environment, changes in procedures of<br />

use, or extrapolation of data may cause<br />

unsatisfactory results.