VERSAMID® 125 - ChemCenters

VERSAMID® 125 - ChemCenters

VERSAMID® 125 - ChemCenters

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

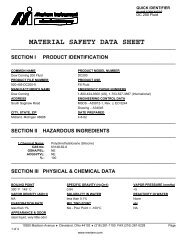

<strong>VERSAMID®</strong> <strong>125</strong>UseVersamid® <strong>125</strong> is a medium viscosity, reactivepolyamide resin based on dimerized fatty acid andpolyamines. This product is designed for use withsolid or liquid epoxy resins to give tough, chemicalresistance, thermoset coatings using roomtemperature cure.Versamid® <strong>125</strong> gives coatings which are generallyharder than Versamid® 140/epoxy formulations andcure more rapidly than Versamid® 140/epoxysystems. It is often blended with fatty amidoamineresin such as Genamid® 250 to give a range ofviscosities, cure speeds and resistance properties.Versamid® <strong>125</strong>/epoxy resin systems are used inmaintenance coatings, primers and enamel paintformulation because of their excellent resistanceproperties and adhesion. Versamid® <strong>125</strong> is alsouseful in adhesive applications.Specification Amine Value - mg KOH/gram resin 340 - 370Thermosel Viscosity at 75 °C -poise 6.5 - 9.5Color, Gardner- maximum 8Additional data Amine Value- mg KOH/gram resin 345Viscosity at 75 °C - poise 8Viscosity at 25 °C - poise 400Color, Gardner 6Theoretical Amine HydrogenEquivalent Weight 103Mix Ratio with 190 EEW liquid Epoxy 54 phrDensity8.1 lb/galSeta Flash Point > 200 °F09.03.2009 VERSAMID_r_<strong>125</strong>_E 1

Properties Typical Properties in a Cured Coating 1Tack Free Time 5 hoursThrough Cure Time12 hoursPot Life 2 hoursGel Time129 minutes1With 190 EEW EpoxyTypical Cured Resin Properties 2DSC max Tg °C 84Tensile Strength6100 psiElongation 5 %Flexural Modulus239,000 psiCompressive Strength8,500 psi2With 190 EEW Epoxy Cured 7 days 25 °CTypical Chemical Resistance Properties ofUnfilled Castings 310 % Acetic Acid 6.9310 % Hydrochloric Acid 0.8010 % Sulfuric Acid 1.2410 % Sodium Hydroxide 0.57Methyl Ethyl KetoneDESXylene 15.47Ethanol 6.713Percent weight gain after a 7 day 25 °C curefollowed by 21 day immersion at 25 °C09.03.2009 VERSAMID_r_<strong>125</strong>_E 2

Application Formulation General Purpose White GlossEnamel Room Temperature CurePart APounds GallonsDER 671-XM75 360.0 40.0Xylene 36.0 5.0Dowanol PMA 40.2 5.0436.2 50.0Part BVersamid® <strong>125</strong> 121.5 15.0Calcium Carbonate 150.0 6.6Titanium Dioxide 175.0 4.9Bentone 34 8.0 0.5Xylene 108.0 15.0Dowanol PM 62.0 8.0624.5 50.0Composite Blend Total 1060.7 100.0Thoroughly mix Part A and Part B prior to use. Allow½ - 1 hour induction time before application. Reduceviscosity as needed for application after inductionperiod using the following solvent blend.Thinners Brush SprayMIBK 33 % 45 %Xylene 33 % ---Toluene --- 50 %Dowanol PM 34 % 3 %Dowanol DPM --- 2 %100 % 100 %Formulation InformationWeight per Gallon10.6 lbs(combined components)Combined viscosity71 KUPVC 21.8 %Pigment/Binder Ratio 1/1.2Solids by Weight 68.2 %Typical Tack Free4 - 6 hoursTypical Hard DryOvernightTypical Full Resistance Properties 7 Days09.03.2009 VERSAMID_r_<strong>125</strong>_E 3

ApprovalsSection175.105(c)(5)175.300(b)(3)(viii)(c)176.170(b)(1)175.300(b)(3)(xxxii)FDA InformationVersamid® <strong>125</strong> polyamide resin complies with FDAregulations listed under the following sections of Title21 of the Code of Federal Regulations.AdhesivesCoatings- adjunct for epoxy resins.Components of paper and paperboard in contactwith aqueous and fatty foodsSide seam cementsAdhesives, coatings and cements formulated withVersamid® <strong>125</strong> resin will comply with theseregulations provided they are used only inconjunction with other approved materials, inkeeping with good manufacturing practices, and thefinished product conforms to extractives limitationsfor the use-situation as specified in that regulation.MiscellaneousPACKAGING, STORAGE AND HANDLINGVersamid® <strong>125</strong> may absorb moisture and carbondioxide if left in open containers. This may result inan increased viscosity and some foaming whencuring epoxy resins. Therefore, it should be kept intightly closed containers when not in use and storedin a cool, dry place. Properly protected frommoisture, the product has a minimum shelf life ofone year.Versamid® <strong>125</strong> and epoxy resins should not bemixed until just prior to use because a chemicalreaction will take place.Read SAFETY INFORMATION before handling orusing product.Safety InformationBased on toxicological studies with animals,Versamid® <strong>125</strong> causes eye and skin irritation andmay be harmful if swallowed.09.03.2009 VERSAMID_r_<strong>125</strong>_E 4

Do not get product in eyes, on skin or on clothing.Do not inhale product. Use only with adequateventilation. Wear recommended protectiveequipment.In case of skin or eye contact, immediately flush withplenty of clean running water for at least 15 minuteswhile removing contaminated clothing. Call aphysician.If swallowed, do not induce vomiting until afterconsulting a physician. Immediately drink largequantities of milk or water and call a physician.Recommended protective equipment includeschemical goggles, rubber gloves and work clothingplus splash apron and respirator with organic vaporfilter unless used with local exhaust. Use an air hoodplus other protective equipment if used in a confinedarea.AvailabilityVersamid® <strong>125</strong> is supplied in 55-gallon drumscontaining 420 pounds net. Shipments are madefrom Kankakee, Illinois and conveniently locatedwarehouses. Additional information and samples areavailable from COGNIS Corporation, Coatings &Inks Division, 300 Brookside Avenue, Ambler, PA19002.Versamid® <strong>125</strong> is available from the followingCOGNIS subsidiariesLocationTrade NameCognis (Japan) Ltd. Osaka, Japan Versamid®Chem-Plast S.P.A. Milan, Italy Reamide®Indusquima, S.A. Sao Paulo, Brazil Versamid®Gemisa, S.A. de C.V. Mexico, D.F. Versamid®09.03.2009 VERSAMID_r_<strong>125</strong>_E 5

Revision-No. 1-05.2008 Effective May 6, 2008Subject to appropriate storage under the usual storage and temperature conditions, our productsare durable for at least 1 year.Suggestions of processing and using our products are given with best knowledge and information but withoutobligation. COGNIS does not accept any guarantee to the suitability of a product for the user's specificpurpose. Furtheron the user himself assumes a liability to follow all legal regulations by using our products.The user can only pass on our sample to third parties with previous assent of COGNIS.09.03.2009 VERSAMID_r_<strong>125</strong>_E 6