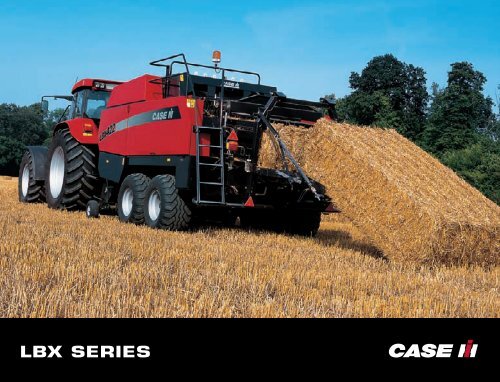

LBX SERIES

LBX SERIES

LBX SERIES

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>LBX</strong> <strong>SERIES</strong>

2Case IH performance monitorTotal control from the momentyou start to bale.Six gear driven knotters(<strong>LBX</strong>422 and <strong>LBX</strong>432)Extremely stable, higherdensity bales.Powerful debris fansKnotting area is keptfree of dust and straw.Automatically controlledbale chamberThree-way density controlsystem for optimum baledensity and shape.Massive PTO flywheelLower operating horsepowerrequirement; maximumworking efficiency.Wide pick-upYour crop is handledquickly and efficiently.Long stroke, smoothrunning plungerDriven directly from themain gearbox forreliable and consistentbale formation.Spacious twine boxesPlenty of twine readyfor a full day’s work.

3THE CONCEPTHeavy duty <strong>LBX</strong> chutesChoice of either plate or rollerbale chute to ensure that balesare laid flat on the field.THE <strong>LBX</strong> <strong>SERIES</strong> – CUSTOMER SATISFACTION IN EVERY BALETo meet the ever changing needs of farming, Case IH have launched a <strong>LBX</strong>422 – for the medium size farming operation orsuperb range of high output big balers with an appetite to match their size. contractor. Producing 120x70cm high density bales for straw andEach model is designed to get the maximum benefit from the crop so that all hay, available with a fine cut rotor option for grass silage.the goodness and value is retained for our customers... and their customers too! <strong>LBX</strong>432 – the ultimate choice. Designed for high volume harvestingof all crop types and capable of producing 120x90cm hay and straw bales<strong>LBX</strong>322 or <strong>LBX</strong>332 – ideal for the livestock farmer. Perfect for 2.5 metres in length, the most stable size for economic transportation.baling hay and grass silage, capable of forming a high quality, easilyCase IH Total harvesting solutions for a changing world.transportable 80x70cm or 80x90cm bale for long term storage.Hydraulic densitypressure releaseIn conjunction with thebale ejector, helps ensurethere is no time lost whenmoving between fields.The Case IH <strong>LBX</strong> Series. Fast and efficient harvesting, from loose swath to compact bale in under 60 seconds.

5OPERATOR CONTROLSADVANCED TECHNOLOGY AT ITS MOST PRODUCTIVEThe unique Case IH electronic performance monitor keeps you in totalcontrol from the moment you start to bale, with all essential set-up andoperating data at your fingertips. Fine tuning adjustments can be madeon-the-move without leaving the tractor seat and the self-diagnostic alarmsystem will keep you fully informed should any problem occur. A printer isalso available so a job summary can be printed out instantly for straightforwardand immediate customer invoicing.Transport mode: PTO speed, hours worked, number of bales pluslubrication and additional operational information can be displayed on-screen.With this mode selected the flashing warning beacon works automatically.Work mode: Above 600rpm PTO speed the screen changesautomatically; the beacon is switched off and the knotter fans andlubrication system switched on.Warning signals: A series of automatic alarms monitor twine conditionand knife position. They also warn of any misties or shearbolt failures.For additional safety a sensor fitted to the end bale chute roller signalsthe last bale drop.Logging: The performance monitor has ten memory storage locationsallowing daily work records to be stored for later analysis. A printer isavailable, which enables Contractors to hand a work record to the customeras soon as the job has been completed.

Oversized PTO flywheel and heavy-duty gearboxdeliver maximum working efficiency.6Adjustable windguard for smoother crop flow.Quick and easy setting of the fully adjustable pick-upflotation system for superior field performance.

7PICK-UP AND TRANSFERNO FIELD TOO LARGE; NO SWATH TOO WIDEWhen there is no time to waste Case IH <strong>LBX</strong> balers go to work with a speedand efficiency that is hard to beat, operating at the cutting edge of technologyto form the perfect bale.A wide mouth with a gentle pick-up. It’s amazing how the <strong>LBX</strong>pick-up takes the hard work out of baling, always working at the optimumheight for crop collection with the minimum risk of crop damage. At headlandturns the large gauge wheels limit soil damage.To handle the changing field conditions the hydraulic pick-up lift features anadjustable flotation spring designed to stop the gauge wheels bouncing.The windguard can be adjusted manually when required to smooth outan uneven swath.Nothing lost or wasted. Depending on model, <strong>LBX</strong> big balersoffer robust pick-ups with widths between 1.98 and 2.4 metres that feature steelor rubber mounted spring tines, designed to make sure all the crop is collectedfrom the windrow and delivered to the pre-compression chamberin a smooth and continuous flow via two centring augers.This will ensure that the bales are uniformly filled so that silage bales retainall their nutritional qualities and straw bales retain their storage characteristics.Wide pick-up for efficient, clean crop collection.

Smooth and efficient rotor for maximum efficiency.8Knife drawer slides out giving instant accessfor replacement and sharpening.Bale segments are of a firm consistency for easydistribution.

9BALE FORMATIONTHE PERFECT BALE IN UNDER 60 SECONDSWhatever the crop- light hay, dry straw or wilted fodder with long,short or fragile stems, <strong>LBX</strong> big balers will form precisely the right balein perfect condition for bedding or feeding. And with four models inthe range offering a series of cutting options there will always be theright model available to suit your farming or contract operation.Rotor/cutter. A massive rotor, available in two widths, uses a seriesof alternating long and short tines that help prevent rotor blockage. Up to33 knives (depending on model) can be fitted for a short 39mm theoretical choplength, designed to create tight and compact segments for easy distribution tothe feeding stalls.A clean sweep means a tight bale. As soon as a segment isformed to the required density the stuffer fork pushes the material upward intothe bale chamber, this cycle is repeated until the correct bale length is achieved.During the forming process the bale chamber’s three-way density system keepsthe bale in shape. Each bale can take only 45 to 60 seconds to complete and istied using a double knotting system for maximum binding security.Better handling and storage. Case IH big balers deliver –seefor yourself. Neat and tidy fields and well stacked trailers and barns arethe result of superb quality high density bales that are very easy to handle.Easy to handle and fast to stack.A perfect bale every time.

Up to six knotters (<strong>LBX</strong>422 and 432)for compact and sturdy bales.10Adjustable double knotter system toensure maximum bale protection and quality.Powerful fans keep the knotting area freeof dust and straw.

11BINDINGRELIABILITY – THE REWARD FOR YEARS OF HARVESTING EXPERIENCEBale density can be easily adjusted from the tractor seat using the electronicperformance monitor, or manually using the control mounted on the left sideof the baler.To ensure a full day’s work in the field, the side cabinets are spaciousenough to hold 30 balls of twine and a toolbox.Safe and sure. As the crop enters the bale chamber twine is fed fromtwo separate balls to both the top and bottom of the bale. This system has beendesigned to keep twine tension minimal when working with heavy, resilientcrops. Each bale has two knots on each twine, the first, which ties the two twineballs together in readiness to form the bale, and the second, which completesthe bale once the desired length has been reached. Depending on the model,up to six heavy duty knotters are fitted, with sensors on the twine tension rollersto detect any break or mistie. Powerful debris fans keep the knotters clear ofdust and straw to ensure uninterrupted high performance.Staying in great shape. <strong>LBX</strong> models can be specified with flat platetype or roller type bale chutes that can be folded away for safe and easytransportation. The bale ejector functions by releasing the bale tensioningpressure, then operating the hydraulically controlled ejecting fingers, which pushout the bale, so there is no time or bales lost changing fields.Both types of bale chute fold awayautomatically for safe transportation.Huge side cabinets with a 30 ballcapacity and large storage boxes.

Tandem axle with Auto-Steer rear axle protectsthe sward on tight headland turns.12SAFETY AND SOIL PROTECTIONFor maximum soil protection and road safety Case IH big balers offer a wide choice of tyres pluseither single axle or tandem axle (available on <strong>LBX</strong>422 and <strong>LBX</strong>432), or even an auto-steered rearaxle feature to offer the best protection for grassland.Air brakes are available to offer improvedsafety on the road.Auto-Steer Tandem axle. This industry-leading design offers safe handling on the road pluspositive control in the field for increased sward protection, operating with a 6° turning angle that actsautomatically during baling. Heavy-duty leaf springs help to give a comfortable ride on rough fieldtracks or on the road and the steering locks automatically when reversing or during transportation.Lighting the way. The standard lighting package on all <strong>LBX</strong> balers features powerful workinglights on both sides for those early starts!A series of drawbars are available to suit your specifications.Night operation is easy with the baler’s powerfulworking lights.

13TRANSPORT/SERVICEAutomatic oil distribution to drive chains is standard.SIMPLE, EASY AND VIRTUALLYMAINTENANCE FREE<strong>LBX</strong> Series big balers have been designed to give trouble free operation and apart from routinelubrication and servicing they are maintenance free. Direct access to the twine cabinets, tool storageand all major components is made easy by the wide-opening panels that lift upwards supported bygas assisted cylinders - everything designed to make access easier and give you more time in thefield. For more information on the <strong>LBX</strong> Series balers and other farm equipment contact your nearestCase IH dealer today.Manual centralised greasing system,automatic system also available.Fast and easy access to all major components.

14BALE DIMENSIONS<strong>LBX</strong>322 <strong>LBX</strong>322 <strong>LBX</strong>332 <strong>LBX</strong>332 <strong>LBX</strong>422 <strong>LBX</strong>422 <strong>LBX</strong>432 <strong>LBX</strong>432STANDARD* ROTOR/CUTTER** STANDARD* ROTOR/CUTTER STANDARD ROTOR/CUTTER STANDARD ROTOR/CUTTERWidth x Height (cm) 80 x 70 80 x 70 80 x 90 80 x 90 120 x 70 120 x 70 120 x 90 120 x 90Maximum length (cm) 250 250 250 250 250 250 250 250TRACTOR REQUIREMENTSMinimum PTO power (kW/hp(CV)) 75/102 95/130 75/102 95/130 85/114 105/141 90/122 110/150Hydraulic distributors (single) 1 1 1 1 1 1 1 1(double) 1 2 1 2 1 2 1 2PICK-UPWidth, effective (DIN 11220) (m) 1.98 2.00 1.98 2.00 2.25 2.40 2.25 2.40Flotation Adjustable spring Adjustable spring Adjustable spring Adjustable spring Adjustable spring Adjustable spring Adjustable spring Adjustable springGauge wheels 2 2 2 2 2 2 2 2ROTOR / CUTTERMaximum number of knives - 23 - 23 - 33 - 33Knife spacing (mm) - 39 - 39 - 39 - 39Knife removal - knife drawer - knife drawer - knife drawer - knife drawerKnife activation, in - out - hydraulic - hydraulic - hydraulic - hydraulicKnife protection - individual springs - individual springs - individual springs - individual springsFEEDING SYSTEMSFeeder two sets of two tines rotor width 972mm two sets of two tines rotor width 972mm three sets of two tines rotor width 1356 mm three sets of two tines rotor width 1356 mmStuffer fork type, 4 tines fork type, 4 tines fork type, 4 tines fork type, 4 tines fork type, 6 tines fork type, 6 tines fork type, 6 tines fork type, 6 tinesPLUNGERSpeed (strokes/min) 42 42 42 42 42 42 42 42Length of stroke (mm) 710 710 710 710 710 710 710 710TYING SYSTEMType double knot double knot double knot double knot double knot double knot double knot double knotTwine type 110-150 M/kg plastic 110-150 M/kg plastic 110-150 M/kg plastic 110-150 M/kg plastic 110-150 M/kg plastic 110-150 M/kg plastic 110-150 M/kg plastic 110-150 M/kg plasticNumber of knotters 4 4 4 4 6 6 6 6Knotter fans 2 2 2 2 3 3 3 3Knotter function alert performance performance performance performance performance performance performance performancemonitor and visual monitor and visual monitor and visual monitor and visual monitor and visual monitor and visual monitor and visual monitor and visualTwine ball capacity 30 30 30 30 30 30 30 30BALE DENSITY CONTROLProportional 3-way control performance monitor performance monitor performance monitor performance monitor performance monitor performance monitor performance monitor performance monitorManual override ● ● ● ● ● ● ● ●TYRESWith single axle 600/55 - 22.5 - 12PR 600/55 - 22.5 - 12PR 600/55 - 22.5 - 12PR 600/55 - 22.5 - 12PR 600/55 - 22.5 - 12PR 600/55 - 22.5 - 12PR 600/55 - 22.5 - 12PR 600/55 - 22.5 - 12PR700/45 - 22.5 - 12PR 700/45 - 22.5 - 12PR 700/45 - 22.5 - 12PR 700/45 - 22.5 - 12PR 700/45 - 22.5 - 12PR 700/45 - 22.5 - 12PR 700/45 - 22.5 - 12PR 700/45 - 22.5 - 12PRWith tandem axles 1) 500/50 - 17 - 14PR 500/50 - 17 - 14PR 500/50 - 17 - 14PR 500/50 - 17 - 14PR 500/50 - 17 - 14PR 500/50 - 17 - 14PR 500/50 - 17 - 14PR 500/50 - 17 - 14PR500/50 - R17 - 146D 500/50 - R17 - 146D 500/50 - R17 - 146D 500/50 - R17 - 146D 500/50 - R17 - 146D 500/50 - R17 - 146D 500/50 - R17 - 146D 500/50 - R17 - 146D

15TECHNICAL DATABALER DIMENSIONS<strong>LBX</strong>322 <strong>LBX</strong>322 <strong>LBX</strong>332 <strong>LBX</strong>332 <strong>LBX</strong>422 <strong>LBX</strong>422 <strong>LBX</strong>432 <strong>LBX</strong>432STANDARD* ROTOR/CUTTER** STANDARD* ROTOR/CUTTER STANDARD ROTOR/CUTTER STANDARD ROTOR/CUTTERA Length with chute raised (mm) 7230 7600 7230 7600 7230 7600 7230 7600B Height, single axle (mm) 3000 3100 3100 3200 3000 3100 3100 3200Width (600/55-22,5PR tyres) (mm) 2580 2580 2580 2580 2960 2960 2960 2960Width (700/45-22,5PR tyres) (mm) 2820 2820 2820 2820 3200 3200 3200 3200Width with tandem axle (mm) 2520 2520 2520 2520 2900 2900 2900 2900Weight, single axle (kg) 1) 6650 7700 6650 7700 7500 8750 7500 8750BA<strong>LBX</strong>322 STANDARD* <strong>LBX</strong>322 ROTOR/CUTTER**<strong>LBX</strong>332 STANDARD* <strong>LBX</strong>332 ROTOR/CUTTER <strong>LBX</strong>422 STANDARD <strong>LBX</strong>422 ROTOR/CUTTER <strong>LBX</strong>432 STANDARD <strong>LBX</strong>432 ROTOR/CUTTEROTHER STANDARD ANDOPTIONAL EQUIPMENTCentral greasing system ● ● ● ● ● ●Automatic greasing system ● ● ● ● ● ●Bale release system ● ● ● ● ● ●Working lights ● ● ● ● ● ●Mud guard ● ● ● ● ● ●Hydraulic folding roller bale chute 2) ● ● ● ● ● ●Printer O O O O O O● Standard O Optional at extra cost * Also available in feeder cutter version with three sets of two tines and six knives ** Not available in UK/ROI 1) Tandem axles not available on <strong>LBX</strong>322 models in UK/ROI2) Optional at extra cost on <strong>LBX</strong>322 Standard in UK/ROI

Powering agriculture for more than 160 yearsIt was back in 1842 that we started creating powerful machines for the farming sector, and we have never stopped. Over theselong years we have gathered, preserved and made good use of all the tradition, experience and prestige of those who, like us,have the present and future of the people who work the land at heart. The superb range of tractors, balers, Axial-Flow andconventional combines that Case IH offers reflects the heritage of Case, International Harvester and David Brown,three great agricultural equipment producers and brands, and all the power, productivity, reliability and performance essentialto improving your farm’s profitability in today’s market.Walk into any Case IH dealership with high expectations and you will not leave disappointed: you will find powerful, tough, efficientmachines with an array of top-range features, unrivalled after sales service, ready access to all the guaranteed Case IH genuine parts,and customised financial packages from CNH Capital created especially for agricultural businesses.In short, you will find the world of Case IH: for those who demand more.STX STEIGER321 hectares ploughedin 24 hoursSafety never hurts! Always read the Operator’s Manual before working with any equipment. Inspect equipment before using it, and be sure it is operating properly.Follow the product safety signs, and use any safety features provided.This literature has been published for worldwide circulation. The standard and optional equipment and the availability of individual models may vary from one country to the next. Case IH reserves theright to undertake modifications without prior notice to the design and technical equipment at all times without this resulting in any obligation whatsoever to make such modifications to units alreadysold. Whilst every effort is made to ensure that the specifications, descriptions and illustrations in this brochure are correct at the time of going to press, these are also subject to change without priornotice. Illustrations may show optional equipment or may not show all standard equipment.Case IH recommends lubricantsCNH UK Ltd - Cranes Farm Road - Basildon - Essex - SS14 3AD© 2007 CASE IH - www.caseih.com - <strong>LBX</strong>-UK-BR - Free phone 0800 015 1953 (UK) or 1 800 523 128 (ROI) - Printed in Italy - 01/07 - TP01 - Cod. N. 5C3000/INB