Intralox Helps Naarmann Increase Flexibility and Reduce ...

Intralox Helps Naarmann Increase Flexibility and Reduce ...

Intralox Helps Naarmann Increase Flexibility and Reduce ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

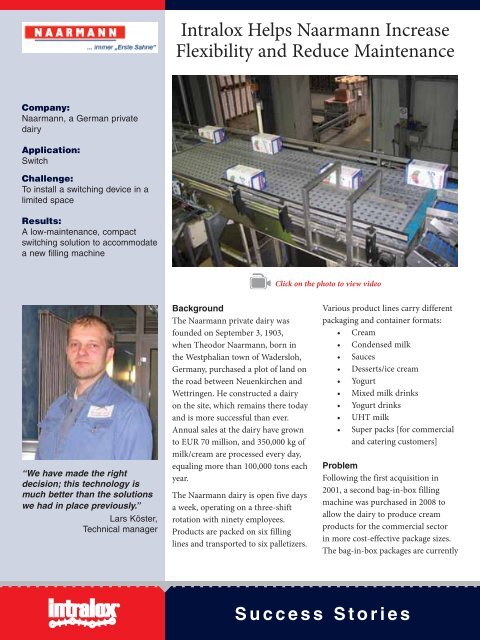

<strong>Intralox</strong> <strong>Helps</strong> <strong>Naarmann</strong> <strong>Increase</strong><strong>Flexibility</strong> <strong>and</strong> <strong>Reduce</strong> MaintenanceCompany:<strong>Naarmann</strong>, a German privatedairyApplication:SwitchChallenge:To install a switching device in alimited spaceResults:A low-maintenance, compactswitching solution to accommodatea new filling machineClick on the photo to view video“We have made the rightdecision; this technology ismuch better than the solutionswe had in place previously.”Lars Köster,Technical managerBackgroundThe <strong>Naarmann</strong> private dairy wasfounded on September 3, 1903,when Theodor <strong>Naarmann</strong>, born inthe Westphalian town of Wadersloh,Germany, purchased a plot of l<strong>and</strong> onthe road between Neuenkirchen <strong>and</strong>Wettringen. He constructed a dairyon the site, which remains there today<strong>and</strong> is more successful than ever.Annual sales at the dairy have grownto EUR 70 million, <strong>and</strong> 350,000 kg ofmilk/cream are processed every day,equaling more than 100,000 tons eachyear.The <strong>Naarmann</strong> dairy is open five daysa week, operating on a three-shiftrotation with ninety employees.Products are packed on six fillinglines <strong>and</strong> transported to six palletizers.Various product lines carry differentpackaging <strong>and</strong> container formats:• Cream• Condensed milk• Sauces• Desserts/ice cream• Yogurt• Mixed milk drinks• Yogurt drinks• UHT milk• Super packs [for commercial<strong>and</strong> catering customers]ProblemFollowing the first acquisition in2001, a second bag-in-box fillingmachine was purchased in 2008 toallow the dairy to produce creamproducts for the commercial sectorin more cost-effective package sizes.The bag-in-box packages are currentlySuccess Stories

available in five-liter <strong>and</strong> ten-litersizes. These new container formats<strong>and</strong> the capacity utilization of thepalletizers required the dairy to usea switch to help sort products. Theswitch system provided the flexibilitythat was required to transport productsto various palletizers dependingupon capacity. The switch alsoenabled packages without a barcodeor with an illegible barcode to bedischarged for post-processing.<strong>Naarmann</strong> had previously gainedoperating experience with two differentswitch solutions—pusherarm <strong>and</strong> roller transfer systems. Thepusher arm system required a verycostly safety enclosure, while theroller transfer system proved to bevery high-maintenance <strong>and</strong> also hadperformance limitations. The entiremechanism had to be replaced <strong>and</strong>fitted with new pneumatic cylinders,valves, <strong>and</strong> rollers, etc., every fourmonths. Another key issue was spacerestrictions. As the packaging <strong>and</strong>delivery division has grown over theyears, there was no room to housethe additional conveyance technology<strong>and</strong> switch.SolutionThe company charged with planning<strong>and</strong> implementation of the bag-inboxfilling machine had to employ allof its expertise to meet these toughrequirements. An <strong>Intralox</strong> switchturned out to be the perfect solutionfor the lack of floor space; the systemwas installed from overhead at aheight of 2.5 meters. This low-maintenance<strong>and</strong> simple technology ensureseven difficult installation sites canbe accessed.Result<strong>Naarmann</strong> is very pleased with thedecision to use this new technology.Technical manager, Lars Köster, says:“We have had no problems whatsoeverwith this new technology. Wehave made the right decision; thistechnology is much better than thesolutions we had in place previously.”INTRALOX, L.L.C. JAPAN0120-779-040Additional country- <strong>and</strong> industry-specific free phone numbers available at intralox.comINTRALOX, L.L.C. USANew Orleans, LA1-888-419-2358+504-733-0463INTRALOX LTD. (UK)0800-894392INTRALOX, L.L.C. EUROPEAmsterdam, The Netherl<strong>and</strong>s+800-5445-5445+31-(0)20-540 36 00INTRALOX AUSTRALIA PTY. LTD.1800-128742INTRALOX SHANGHAI LTD.Shanghai, ChinaNorthern: 10800-711-0100Southern: 10800-110-0100INTRALOX BRASIL LTDA.0800-771-4325© 2009 <strong>Intralox</strong>, L.L.C. 50513_ENGLISHSuccess Stories