Rotary Press - Waste 'n WaterTech Ltd.

Rotary Press - Waste 'n WaterTech Ltd.

Rotary Press - Waste 'n WaterTech Ltd.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

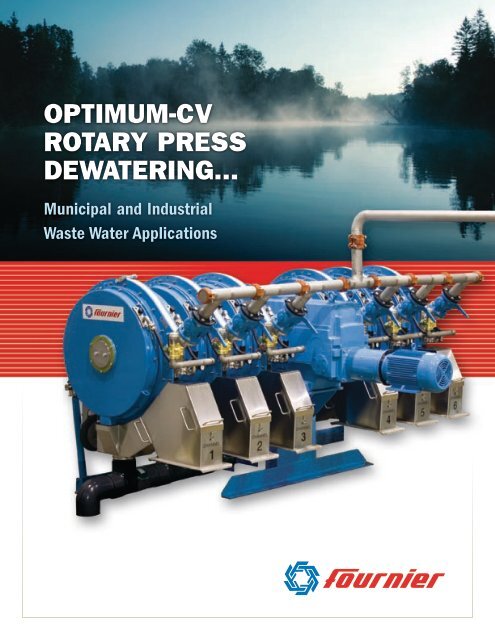

OPTIMUM-CVROTARY PRESSDEWATERING...Municipal and Industrial<strong>Waste</strong> Water Applications

THE FOURNIERPRESS TECHNOLOGYThe FOURNIER PRESS is in the forefront of municipaland industrial sludge dewatering technology.The principle of operation is simple. Sludge is fed intoa rectangular channel, and rotates between two parallelrevolving stainless steel chrome plated screens. Thefiltrate passes through the screens as the flocculatedsludge advances within the channel. The sludge continuesto dewater as it travels around the channel, eventuallyforming a cake near the outlet side of the press.The frictional force of the slow moving screens, coupledwith the controlled outlet restriction, results in theextrusion of a very dry cake.The benefits derived from using the FOURNIER ROTARYPRESS have been well documented and are translatedinto huge savings for the customer by meansof performance, operation and maintenance.

HOWIT WORKS...Sludge is fed at low pressure into a space betweentwo parallel filtering elements.As the free water comes away from the sludge,solids accumulate in the channel until enough pressureis generated against the outlet gate.The filtering element’s slow speed rotation generatesenough back pressure to dewater the remainingsolids and extrude a dry cake.Low maintenance, low power consumption and reducedpolymer usage translate into lower operating costs.Principle of operationSLUDGESEALCOVERSTATIC MECHANICAL COMPONENTROTATING MECHANICAL COMPONENTDEWATERING SLUDGE (CAKE)FILTRATE FLOWSCREENCAKE FORMATIONINTERIOR OFCHANNELOUTLET FORFILTRATEASLUDGEFEEDFILTRATE FILTRATE RESTRICTION ZONEACAKEEXTRUSION

ADVANTAGES> Totally enclosed> Low odor levels> Low speed> Little maintenance> Low power consumption> Small footprint> New Optimized 36" dia. channelsurpasses previous modelsPerformanceOperationMaintenanceEconomy■ Consistently high cake dryness■ Continuous process■ Robust construction■Savings on final disposal costs■ Competitive throughput■ Equipment totally enclosed■ Small number of■Minimal space requirements■ High capture rateswith reduced odor concernsmechanical parts■Low maintenance costs■ Reduced airborne contaminants■ Easy start-up and shut-downprocedures■ Very simple to operate■ Requires very little supervision■ Slow rotation speed■ Reduced corrosive exposureto nearby equipment■ Automated 5 minutes/day■■■Reduced labor costsLow energy consumptionLow potable water usage■ Can be completely automatedself-cleaning cycle (optional)and remotely controlledTHE NEW CV-OPTIMUM PRESSThe Fournier CV-Optimum <strong>Rotary</strong>Dewatering <strong>Press</strong> is the latest developmentin the 20-year history of the technology.Winner of the 2002 WEF InnovativeTechnology Award, this Canadianinvention has undergone severalupgrades over the years.From the first version, involving a largeshaft-mounted gear unit, large supportbearings and base, the units are nowmanufactured with a 36” diameterdewatering channel that far surpassesearlier versions.A single-width channel has now provenitself able to dewater all varieties of sludge,allowing a single machine to be usedanywhere, without physical modification.With more than 140 units installedand running in over a dozen countries,the Fournier <strong>Rotary</strong> <strong>Press</strong> is the marketleader in its category.A dedicated team of more than160 employees approaches each newyear as a challenge, charged with findingnew ways to improve the current modelwithout increasing costs.A large parts inventory is maintained forall previous models of the <strong>Rotary</strong> <strong>Press</strong>,ensuring that customers who enjoy theirown model year can rest assuredthey will always be able to obtainreplacement parts.Retro-fit kits are available for thosecustomers wishing to upgrade their unitto the newest technology available.ExpandabilityAnother unique feature of the <strong>Rotary</strong> <strong>Press</strong> is the abilityto order units that can be expanded at a future date.This allows customers to benefit from lower capital costat time of purchase and flexible expansion as the need arises.Common configurations are 1 to 2 channel(s), 2 to 4 channel(s)and 4 to 6 channel(s); however any combination of channelscan be obtained, up to the maximum of 6 channels per machine.

SPECIFICATIONSMODEL NO.1-900/1000CV2-900/2000CVCHANNEL1MODELWHEEL Ø In. (mm)36 (900)2 36 (900)DEWATERING AREAFt 2 (m 2 )10,8 (1,00)21,5 (2,00)DIMENSIONS In. (mm)A B C70,3 (1785)77,5 (1969)72,0 (1830)72,0 (1830)40,5 (1028)64,8 (1646)WEIGHTLb (kg)4559 (2068)7967 (3614)MOTORHP (kW)5,0 (3,7)7,5 (5,6)3-900/3000CV 3 36 (900)32,3 (3,00) 79,0 (2007) 72,0 (1830) 85,8 (2180) 10128 (4594) 10,0 (7,5)MODEL NO.4-900/4000CV5-900/5000CVCHANNEL4MODELWHEEL Ø In. (mm)36 (900)5 36 (900)DEWATERING AREAFt 2 (m 2 )43,1 (4,00)53,8 (5,00)DIMENSIONS In. (mm)A B C91,3 (2320)92,8 (2358)75,4 (1915)75,4 (1915)101,6 (2580)123,0 (3124)WEIGHTLb (kg)12377 (5614)14581 (6614)MOTORHP (kW)15,0 (11,1)20,0 (15,0)6-900/6000CV 6 36 (900)64,6 (6,00) 92,8 (2358) 75,4 (1915) 144,4 (3668) 16676 (7564) 20,0 (15,0)

3/4"1/2"Process schematicCUTTING EDGE TECHNOLOGYSLUDGEFournier Industries inc. specializes in the manufacturingPOLYMERof mechanical equipment and has done so since1960. The company's technical abilities and expertise5131 1/2"involve design, lab and pilot testing, commissioningand training. The FOURNIER PRESS' performance canbe demonstrated through the use of our mobile units.4Resulting from many years of research and development,the technical advances implemented in the FOURNIER2PRESS are well demonstrated in numerous applicationsWASH WATERINTERMITTENTthroughout the world. Due to its reliability, the FOURNIERROTARY PRESS requires very little supervision. It is theFILTRATECAKEonly dewatering technology that is safe for stand-aloneautomatic operation and can be monitoredand operated by remote control.1 Polymer Storage Tank2 Polymer Metering Pump3 Sludge Feed Pump4 Flocculator5 <strong>Rotary</strong> <strong>Press</strong>Full-size Pilot MachineOur utilization of a full-scale pilot eliminates theneed for uncertain scale-up values in the finalinstallation. What you see is what you get!ISO-9001 : 2000Fournier Industries inc. is an ISO-registered manufacturer,assuring the highest level of quality-control.All parts are subjected to rigorous verificationbefore they are installed in your machine.

ACCESSORIES & MOREPolymerfeed systemsA wide variety of manual and fullyautomatic liquid and dry-feed polymersystems are available.Off-the-shelf units as well as customsystems respond to every customer’sindividual needs.From the smallest flow to clarifier-feedsystems, any size can be quickly assembledand shipped to your site or included fordelivery with your dewatering system.Shaftlessscrew conveyorsCustom-engineered for your application,hollow-flight (or shaftless) screw conveyorscan be fitted with any accessory for totalplant automation.Standard screw sizes from 8” to 16”allow a variety of feed rates for differentsize systems.Lengths from 10 ft to over 100 ft canbe combined for virtually any layout.Sludge blendersand otheraccessoriesHaving many years of custom-fabricationexperience, our engineering staffcan tackle any project and providea complete package solution to yourbiosolids handling application.Truck bodies and customizedmobile containers can be equippedwith a host of features particularto your requirements, allowing youto optimize your operation for themost beneficial use.Spare Parts InventoryFournier Industries inc. maintains a fullinventory of spare parts for all modelsof our <strong>Rotary</strong> <strong>Press</strong>. Our parts departmentcan ship orders for next day deliverywithin much of continental North America.Machining CapabilityMany large multi-functionmachining centres are usedin the manufacturing of<strong>Rotary</strong> <strong>Press</strong> components.Production CapabilitiesParts for <strong>Rotary</strong> <strong>Press</strong>es are produced in series.This allows us to reduce production costs andimprove quality of the individual components.

Expertise since 1960Fournier Industries Inc. has beenmanufacturing machinery since 1960.At our head office and factory,located in the Quebec mining area,we continue to provide qualityproducts and service to a wide rangeof international customers.Your local representativePrinted in Canada G R A P H I S S I M OFOURNIER INDUSTRIES INC.3787 West Frontenac blvd, Thetford MinesQuebec, Canada G6H 2B5Phone: (418) 423-4241Fax: (418) 423-7366general@fournierindustries.comwww.rotar y-press.com