the new wiring rules (pdf) - Energy Safe Victoria

the new wiring rules (pdf) - Energy Safe Victoria

the new wiring rules (pdf) - Energy Safe Victoria

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

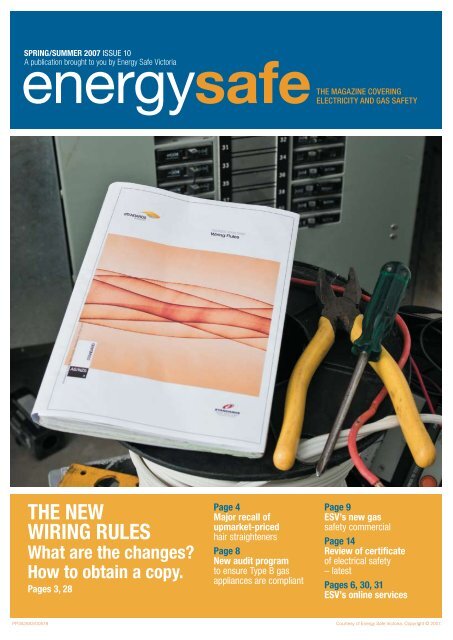

SPRING/SUMMER 2007 ISSUE 10energysafeA publication brought to you by <strong>Energy</strong> <strong>Safe</strong> <strong>Victoria</strong>THE MAGAZINE COVERINGELECTRICITY AND GAS SAFETYTHE NEWWIRING RULESWhat are <strong>the</strong> changes?How to obtain a copy.Pages 3, 28Page 4Major recall ofupmarket-pricedhair straightenersPage 8New audit programto ensure Type B gasappliances are compliantPage 9ESV’s <strong>new</strong> gassafety commercialPage 14Review of certificateof electrical safety– latestPages 6, 30, 31ESV’s online servicesPP352583/00578Courtesy of <strong>Energy</strong> <strong>Safe</strong> <strong>Victoria</strong>. Copyright © 2007.

FROM THE EDITORContentS2energysafeIt has been a busy few months as far as energysafety in <strong>Victoria</strong> is concerned and hopefullyIssue 10 of energysafe reflects a great dealof what is happening.Activities are wide ranging – <strong>new</strong> energy safetycommercials are being put to air, ESV’s rangeof online services is enhanced significantly and<strong>the</strong>re is a whole lot more happening to make<strong>Victoria</strong> a safer place as far as electricity, gasand pipelines are concerned. But, incidentsand injuries keep happening.Possibly <strong>the</strong> most significant event of recentweeks is <strong>the</strong> release of <strong>the</strong> long awaited <strong>new</strong>Wiring Rules – AS/NZS 3000:2007 – at <strong>the</strong> startof November, and by <strong>the</strong> time you read this <strong>the</strong>hard copies will be available.One could be humorous and suggest that<strong>the</strong> <strong>new</strong> Rules will make essential Christmasreading! But <strong>the</strong> reality is that <strong>the</strong>re is a lot totake in from <strong>the</strong> <strong>new</strong> Standard and while <strong>the</strong>provisions will not become mandatory in <strong>Victoria</strong>until <strong>the</strong> middle of next year or so, it is amazinghow time flies.Of course we have a report on <strong>the</strong> <strong>new</strong> WiringRules explaining briefly <strong>the</strong> changes and o<strong>the</strong>rimprovements made compared to <strong>the</strong> previousversion. We also have all <strong>the</strong> information onhow you can obtain your copy.An underlying <strong>the</strong>me of <strong>the</strong> revised Standard is<strong>the</strong> setting out of “specifications and proceduresto ensure electrical installations, services andsystems are safe and reliable”.Mention <strong>the</strong> word “safe” and this leads toano<strong>the</strong>r important issue – safety in <strong>the</strong> leadup to Christmas and <strong>the</strong> holiday period.Recently, Work<strong>Safe</strong> issued a media releasewith a stark, no-holds-barred heading:“<strong>Victoria</strong> moves into <strong>the</strong> pre-Christmasdeath zone”The release urges <strong>Victoria</strong>n employers,supervisors and workers to do all <strong>the</strong>y canto prevent serious injuries and deaths beforeChristmas.In November and December last year eightpeople died at work and this representedalmost a quarter of <strong>the</strong> year’s total of 29. With20 fatalities reported to Work<strong>Safe</strong> so far in 2007,<strong>the</strong> danger is that <strong>the</strong> figure could increasesignificantly in <strong>the</strong> remaining weeks of thisyear. Let’s hope it doesn’t happen.So what is <strong>the</strong> cause of <strong>the</strong> alarming “spike” ofincreased deaths in 2006 in <strong>the</strong> last months ofyear? Is it because everybody is working that bitharder and with less regard to safety becauseof <strong>the</strong> need to finish things off before <strong>the</strong> endof year?ESV and energysafe lends its support toWork<strong>Safe</strong> in appealing to everyone to take thatlittle bit more care in <strong>the</strong>se crucial final weeksof 2007 and not become a statistic that nobodywants. Fortunately <strong>the</strong>re were no electrical orgas tradespeople involved in <strong>the</strong> “pre-Christmasdeath zone” in 2006 and please make sure <strong>the</strong>reare none in 2007 ei<strong>the</strong>r.On a cheerier note, Issue 10 is packed wi<strong>the</strong>ssential information on electricity and gassafety. Once more we are confident <strong>the</strong>re issomething in it for everyone.And finally, as this is <strong>the</strong> last issue for 2007,<strong>the</strong> team at energysafe wishes to thankeveryone for <strong>the</strong>ir support during <strong>the</strong> year.We are certainly encouraged by <strong>the</strong> positivecomments received about <strong>the</strong> magazine andwe will be striving to at least maintain andhopefully improve <strong>the</strong> standard in 2008.Please have an enjoyable Christmas and NewYear. In particular make it a safe one.David Guthrie-Jonesdguthriejones@esv.vic.gov.auThe “industry bible” – <strong>new</strong> Wiring 3Rules releasedPotential electrocution from multiple 3errors on building siteWarning to ensure circuit breakers 3are not simply isolation switchesMajor recall on upmarket-priced hair 4straightenersClearing up interstate licensing 5confusionESV’s <strong>new</strong> online services 6BBQ burns couple plea for gas safety 7ESV audits to ensure Type B 8gas appliances are compliantESV’s <strong>new</strong> gas safety commercial 9Boy injured after contacting overhead 10train line conductorThe importance of apprentice 12supervisionESV’s <strong>new</strong> industry electrical incident 12committeeSt John Ambulance/ESV brochure 13on electric shock treatmentReview of Certificate of Electrical <strong>Safe</strong>ty 14Powerline detection device is a 15television “hit”Royal Childrens Hospital electrician 16,17celebrates 30 yearsDangerous gas installations at events 18New standard to cover energy efficiency 19performance of fridgesProsecutions, Infringement 22Notice updateYour electricity questions answered 24Gas technical articles 27ESV’s online services – what you 30,31can do to save time and moneyFRONT COVER: It is <strong>the</strong> industry “bible” and no one with a professional involvement with electricity in any capacitywhatsoever can afford to be without one - <strong>the</strong> <strong>new</strong> edition of <strong>the</strong> Australian/New Zealand Standard for Wiring Rules(AS/NZS 3000:2007). As our front cover depicts <strong>the</strong> <strong>new</strong> Wiring Rules should become a tool of <strong>the</strong> trade, after all<strong>the</strong> provisions will become mandatory within a few months. We have information on <strong>the</strong> <strong>new</strong> Rules and <strong>the</strong> detailson how to obtain a copy.The energysafe team for this issue:Editor David Guthrie-JonesContributors Charlotte Roseby, Norm Jackson, Allen Peacock,Darren Margerison, Trevor Hudson, Neil Fraser, Michael Leahy,Terry Clement, Stephen Brook, Bill te Wierik.Editorial assistant Taryn DrewettPhotography Mike Long, Noel Butcher, Michael Wearne,Tony Mott, ESV staff.Cartoonist/illustrator Paul HarveyDesign Aer DesignPrinting Energi PrintEditorial panel Management and staff of <strong>Energy</strong> <strong>Safe</strong> <strong>Victoria</strong>Authorised by: <strong>Energy</strong> <strong>Safe</strong> <strong>Victoria</strong>Building 2, 4 Riverside Quay, Southbank, <strong>Victoria</strong> 3006Ph: 03 9203 9700Printed by: Energi Print, 2-4 Emily Street, Murrumbeena, <strong>Victoria</strong> 3163Copyright. All material appearing in energysafe is copyright. Reproduction in whole or in part is notpermissible without <strong>the</strong> written permission of <strong>Energy</strong> <strong>Safe</strong> <strong>Victoria</strong>, depending on <strong>the</strong> source of <strong>the</strong> article.Liability. Howsoever arising as a consequence of use or reliance upon any advice, representations, statement,opinion or conclusion expressed herein is expressly denied by <strong>Energy</strong> <strong>Safe</strong> <strong>Victoria</strong> and all persons involvedin <strong>the</strong> preparation of this publication.TO ADVERTISE INenergysafeFor advertising information andbookings contact Barry Telfer ofBarry Telfer Media Services onPh: (03) 9579 7787, Fax: (03) 9579 7782or by email at btms@patash.com.auBookings are now being taken for <strong>the</strong> nextand subsequent issues of energysafe.Our attractive advertising rates are as follows:Full page $5000Half page $2500One third page $1700Quarter page $1500

THE “INDUSTRY BIBLE” - NEW WIRING RULES RELEASEDIt’s called <strong>the</strong> “industry bible” and a “musthave” document. There are 450 pagesand it comes in a two-part format. Yes,it’s <strong>the</strong> <strong>new</strong> edition of <strong>the</strong> Australian/NewZealand Standard for Wiring Rules (AS/NZS3000:2007).It was released in early November and copies canbe ordered by email, through <strong>the</strong> web or by phone.See details on how to obtain a copy on page 28.The <strong>new</strong> Wiring Rules are essential readingfor electricians, electrical contractors, designconsultants, inspectors, regulators, industrytraining bodies, as well as manufacturers,importers, wholesalers and retailers of electricalequipment and accessories. O<strong>the</strong>r tradespeople –including gasfitters who have “D” licences – shouldalso have <strong>the</strong>ir own copy.It is expected that <strong>the</strong> <strong>new</strong> Rules will be mandatoryin <strong>Victoria</strong> from <strong>the</strong> middle of next year.The <strong>new</strong> edition comprises:> Part One outlines fundamental safetyprinciples and provides an ‘outcomes oriented’approach to allow flexibility in design.> Part Two details ‘deemed to comply’solutions to satisfy <strong>the</strong> Part One fundamentalsafety principles for <strong>the</strong> majority of electricalinstallation work.Standards Australia says <strong>the</strong> <strong>new</strong> edition is moreflexible, user-friendly and easier to read, andincludes both revised and <strong>new</strong> definitionsincluding <strong>the</strong> following terminology:> electrical installation;> circuit;BEWARE:NOT ALL CIRCUITBREAKERS ARE EQUALAn ESV investigation of a recent switchboard firein <strong>the</strong> classroom of a Melbourne suburban primaryschool has revealed – not for <strong>the</strong> first time – thatsome electricians have inadvertently installedisolating switches in switchboards believing <strong>the</strong>mto be circuit breakers.It was only <strong>the</strong> quick reaction of <strong>the</strong> school staff,who turned off <strong>the</strong> main switch which preventedpossible serious injury to both <strong>the</strong> children and<strong>the</strong> teacher who were in <strong>the</strong> class room at <strong>the</strong> time.A worker recently suffered an electric shock ona building site in Melbourne’s CBD – and ESV’sinvestigations showed he was lucky not to havebeen electrocuted. A non compliant and unsafecord extension set, temporary <strong>wiring</strong> and poorwork practices were <strong>the</strong> ingredients of apotential disaster.During <strong>the</strong> investigation, an ESV EnforcementOfficer found a three-phase cord extension setplugged into a temporary supply box which was“dangling” unsupported down <strong>the</strong> outside of abuilding for six floors.As this still did not reach <strong>the</strong> ground, a four metrethree-phase cord extension set was added tosupply a wet saw which was being used to cutconcrete in a lift well.During use <strong>the</strong> saw stopped and when <strong>the</strong>intermediate plug and socket were “wiggled” <strong>the</strong>conductors within <strong>the</strong> plug fused, melted <strong>the</strong> plugcase and gave <strong>the</strong> worker an electric shock.> basic protection (protection against directcontact);> fault protection (protection against indirectcontact);> outbuilding;> isolation; and> competent person.O<strong>the</strong>r key changes to <strong>the</strong> Wiring RulesStandard include:> <strong>the</strong> extended application of Residual CurrentDevices (RCDs) and testing for correctoperation;> protection against arcing faults;> requirements for selectivity (discrimination)between circuits;> streng<strong>the</strong>ning of requirements for <strong>the</strong> preventionof <strong>the</strong> spread of fire;> enhanced requirements for recessedluminaries;> requirements for sanitisation areas in <strong>the</strong> foodprocessing industry;> inclusion of detailed guidance material removedfrom <strong>the</strong> 2000 edition; and> a more intuitive index, additional appendices,illustrations and background information.Standards also says <strong>the</strong> revised edition expandson issues relating to electrical installations,improves safeguards and, addresses <strong>the</strong> needsand expectations of stakeholders through what is aconcise and comprehensible two-part publication.Colin Blair, Deputy CEO of Standards Australia saidin a media release that <strong>the</strong> Wiring Rules StandardESV’s investigation found that a distributionboard suffered a catastrophic fault as a resultof a submain conductor failure to <strong>the</strong> incomingterminals of <strong>the</strong> board’s isolating switch, whereby<strong>the</strong> energised phase conductor contacted <strong>the</strong>ear<strong>the</strong>d metal frame of <strong>the</strong> board.Under normal circumstances, <strong>the</strong> protective deviceat <strong>the</strong> origin of <strong>the</strong> submain circuit, at <strong>the</strong> mainswitchboard, should have safely isolated supply.However, in this instance it was found that <strong>the</strong>device installed on <strong>the</strong> main switchboard was notan overcurrent protection device - but merely anisolation device.As a consequence <strong>the</strong> distribution board sufferedirreparable damage as well as substantial smokeMULTIPLE ERRORS COULD HAVE CAUSED BUILDING SITE ELECTROCUTIONThe investigations showed that one wire within <strong>the</strong>plug had come out of <strong>the</strong> terminal and shorted to anadjacent phase resulting in a phase to phase shortcircuit.Fur<strong>the</strong>r investigation found that although <strong>the</strong> fourmetre three-phase cord extension set had been‘Tagged’ it was not terminated or assembledcorrectly, was made from non-compliant 2.5mmPVC insulated / PVC shea<strong>the</strong>d lead (Orangecircular) and fitted with four-pin plug and five-pinsocket.ESV’s conclusionWorking in confined spaces on construction sites inwet areas using defective equipment is dangerous.If <strong>the</strong> equipment does not look safe DO NOT use it -even if it is tagged as compliant. IT’S YOUR LIFE.For information on <strong>the</strong> Standards which were notcomplied with in this instance, see page 29.plays an important role in setting out specificationsand procedures to ensure electrical installations,services and systems are safe and reliable.“Recognised as <strong>the</strong> benchmark for safe andefficient electrical installations, Wiring Rules isone of <strong>the</strong> most widely used Standards in Australiaand has played an important role in reducing <strong>the</strong>incidences of electrical mishaps and injuries,”he said.“Of note in <strong>the</strong> <strong>new</strong> edition is an increasedemphasis on common, practical, cost effectiveand flexible methods to achieve safety compliance,fitness for purpose and a level of good practice.“Changes in <strong>the</strong> <strong>new</strong> edition reflect <strong>the</strong> increasinguse of Residual Current Devices (RCDs) to allsocket outlets and lighting circuits rated up to 20amps and include restricting <strong>the</strong> number of circuitsthat can be connected to any one RCD and <strong>the</strong>required division of lighting circuits over RCDs.“Taking into consideration <strong>the</strong> experience gainedthrough <strong>the</strong> application of <strong>the</strong> former edition anda survey of <strong>the</strong> electrical industry, <strong>the</strong> <strong>new</strong> editionflows more logically, is easier to understand,reinstates much of <strong>the</strong> supporting informationomitted in <strong>the</strong> previous edition and contains morediagrammatic representations of concepts andmore real-life examples,” said Colin.The <strong>new</strong> 2007 edition of <strong>the</strong> Wiring Rules Standardwas produced by <strong>the</strong> joint Standards Australia/Standards New Zealand Committee EL-001. Itis available from SAI Global at www.saiglobal.com/shop or by ringing 131 242. Hard copies arescheduled to be available by <strong>the</strong> end of November.damage to <strong>the</strong> adjacent class room where <strong>the</strong>board was installed.The device used in this instance, commonly calleda non-auto circuit breaker, although similar inappearance to overload circuit breakers, did notprovide overcurrent protection.ESV’s adviceIf electricians have any doubt as to <strong>the</strong> capabilitiesof <strong>the</strong> device <strong>the</strong>y are installing, <strong>the</strong>y shouldcontact <strong>the</strong> manufacturer or distributor for advice.Remember – it is <strong>the</strong> responsibility of <strong>the</strong>installer to install <strong>the</strong> appropriate equipment!The damaged and non-compliant equipment retrievedfrom <strong>the</strong> building site.3springsummer

4energysafeHAIR STRAIGHTENERRECALLThe hunt is on through a major national recall alert for morethan 60 000 upmarket hair straighteners imported intoAustralia from Korea. According to one major importerof <strong>the</strong> product, some 30 000 have been sold in <strong>Victoria</strong>.Three models of hair straightener are now <strong>the</strong> subject of <strong>the</strong> recall across all states andterritories after it was discovered that <strong>the</strong> heating plates in <strong>the</strong> product may become “live”to 240 volts and cause electric shock.Although <strong>the</strong> models were approved and approval numbers issued for <strong>the</strong>m, <strong>the</strong> problemarose after <strong>the</strong> manufacturer changed <strong>the</strong> specification and did not inform <strong>the</strong> safetyregulator involved – <strong>the</strong> Queensland Electrical <strong>Safe</strong>ty Office (ESO) – or <strong>the</strong> importer.The importer, Dateline Imports P/L, is managing <strong>the</strong> recall. O<strong>the</strong>r safety regulators includingESV are monitoring <strong>the</strong> recall process. The recall notice was published in 28 <strong>new</strong>spapersacross Australia including <strong>the</strong> Herald Sun and The Age in <strong>Victoria</strong>.O<strong>the</strong>r hair straightener products from <strong>the</strong> same manufacturer brought to Australia by differentimporters are also being checked, primarily by <strong>the</strong> ESO to ensure compliance and safety.O<strong>the</strong>r models may be recalled following <strong>the</strong> checks.Information provided by Dateline Imports P/L show sales of <strong>the</strong> hair straightener totalling61 256 – 29 514 of <strong>the</strong>m in <strong>Victoria</strong>.The recall noticeContinued opposite page.Handy safety hint. Tell your customers:Because water conducts electricity DO NOT touch electrical appliances or switches with wet hands.You could receive a fatal shock.energysafe advertorial – an article supplied by NECAEcoSmart ElectriciansTHE GROWING DEMAND FOR SUSTAINABILITYConnecting you to a more sustainable futureThe demand among Australia’s electricians toget a better understanding of <strong>the</strong> technologiesand products used in providing energy efficientsolutions for <strong>the</strong>ir customers is growingdramatically.According to NECA’s CEO Philip Green <strong>the</strong>“recently released EcoSmart ElectriciansProgram has seen an unprecedented demandfrom contractors wanting to get a head startin this fast growing market”.The program, developed in <strong>Victoria</strong>, andnow being offered Australia wide, providestraining and certification for electricians andaccreditation for <strong>the</strong> contracting business toenable <strong>the</strong>m to brand <strong>the</strong>mselves as EcoSmartElectricians.The program provides <strong>the</strong> contractor witha range of marketing and support materialsand training which are designed to providea recognisable market differential for <strong>the</strong>customer. Market research conducted byNECA as part of <strong>the</strong> program shows that it isnot always clear to home-owners how to makeenergy savings in <strong>the</strong> electrical field, because<strong>the</strong>y are not as obvious as in water conservationor recycling materials.The opportunity exists for electricians to havean effect by providing advice on <strong>the</strong> optionsavailable. This applies across <strong>the</strong> market,whe<strong>the</strong>r it is in <strong>the</strong> domestic, commercialor industrial sectors.The EcoSmart Electricians program has arole to play in equipping electricians with <strong>the</strong>knowledge to help customers make <strong>the</strong> rightdecisions on energy-efficient installations andproducts, and educate <strong>the</strong>m on <strong>the</strong> savings<strong>the</strong>y can make.Since August NECA has run 9 courses in<strong>Victoria</strong> in both metropolitan and regional areas,with additional courses being run in Sydney,Brisbane and Perth. The training schedule for<strong>the</strong> 2008 up until June has been finalised and isshown inset.Response from attendees has been mostpositive according to <strong>the</strong> program managerRod Lovett. “The feedback across <strong>the</strong> boardhas been excellent,” he says. “The trainingmaterial has been developed in associationwith industry so <strong>the</strong> information is of <strong>the</strong> highestorder and we use industry based trainers topresent <strong>the</strong> material, so <strong>the</strong> guys get <strong>the</strong> bestof both worlds”.McKnights Electrical Ballarat contract managerCasey Moran who recently completed <strong>the</strong>training is typical of <strong>the</strong> attendees. He saidthat <strong>the</strong> course provided him with invaluableinformation.“It showed me which systems use a lotof energy and ways of reducing powerconsumption across a range of areas such aslighting and motors. I believe it’s really importantfor electricians to get on <strong>the</strong> bandwagon andknow more about <strong>new</strong> technology. Savingenergy means saving money so that is a winwin.” The course also provides participantswith an introduction into <strong>the</strong> area of solar gridconnect systems, an area that Rod believeswill become a growing market.“The need in <strong>the</strong> market for ‘clean andre<strong>new</strong>able energy’ is growing rapidly and manyhome owners see this as a viable option.”For more information visitwww.ecosmartelectricians.com.auor call 03 9645 5533Training commencement datesand locations for 2008ManninghamSaleMoorabbinSunshineWodongaMilduraBerwickWarrnamboolSouth Melbourne5 February4 March5 March1 April2 April6 May7 May20 May4 June

Silver Bullet Centurion and Platinum hairstraightening irons with approval numberN20360 and Extreme, Extreme Wet to Dry,Extreme Ionic and Extreme Titanium hairstraightening irons with approval numberQ04093 or Q041236 are <strong>the</strong> subject of <strong>the</strong>recall.The Recall Notice says <strong>the</strong> affected productscan be identified by <strong>the</strong> approval numberlocated on <strong>the</strong> name plate.One of <strong>the</strong> recalled hair straightenersCLARIFICATIONON INTERSTATEREGISTRATIONAND LICENSINGESV is receiving a number of queries followingrecent statements in <strong>the</strong> media that electriciansand contractors can now work interstate under<strong>the</strong> provisions of <strong>the</strong>ir state based licences orregistrations.While <strong>the</strong>re is now mutual recognition ofelectricians’ licences and contractor registrationsacross all states and territories, ESV wishes topoint out that <strong>the</strong>se statements are notcompletely correct.5springsummer“This measure has been taken because <strong>the</strong>manufacturer of <strong>the</strong>se appliances has changed<strong>the</strong> specifications of <strong>the</strong>se appliances with <strong>the</strong>result that <strong>the</strong> heating plates may become live to240 Volts with <strong>the</strong> risk of electric shock.” It says.The notice urges consumers to discontinue <strong>the</strong>use of <strong>the</strong> hair straighteners immediately.Customers are advised to visit <strong>the</strong> datelineImports website at www.datelinecity.com orcall 1800 251 215 between 10 am and 4 pmMonday to Friday to arrange a replacementat no cost.Name platesUnder mutual recognition a person holding alicence or registration in one state or territorymust apply for a comparable licence in ano<strong>the</strong>rstate or territory.Recent changes means it is now much easierfor electricians and contractors to move acrossborders and start work, but <strong>the</strong>y can only doso after <strong>the</strong>y have applied and received <strong>the</strong>comparable licence from <strong>the</strong> responsibleregulator in <strong>the</strong> state or territory concerned.There is more information under “licensingand registration” on <strong>the</strong> ESV website. Thereis a link from this section to ano<strong>the</strong>r site –www.licencerecgnition.gov.au – whichhas extensive information about <strong>the</strong> mutualrecognition provisions.

6energysafeUSE ESV’S ONLINE SERVICES TO RENEWLICENCES AND REGISTRATIONS ELECTRONICALLYESV’s expanded and enhanced range ofonline services is now available, enabling inparticular registered electrical contractors,licensed electricians and licensed electricalinspectors to re<strong>new</strong> <strong>the</strong>ir registrations andlicences electronically – and undertake o<strong>the</strong>rbusiness processes online.Under <strong>the</strong> changes, <strong>the</strong> branch offices ofagencies distributing certificates of electricalsafety on behalf of ESV can now conduct moreof <strong>the</strong>ir business with <strong>the</strong> organisations online.Internal business processes within <strong>the</strong> branchescan also be enhanced through using <strong>the</strong> ESVsystem.Director of <strong>Energy</strong> <strong>Safe</strong>ty, Ken Gardner, said:“There are winners and no losers to emergefrom <strong>the</strong> introduction of <strong>the</strong> <strong>new</strong> services.On <strong>the</strong> one hand, ESV is a winner because of<strong>the</strong> improvement in <strong>the</strong> way it can do businesswith customers, while registration and licenceholders – and o<strong>the</strong>rs – are also winners becauseof <strong>the</strong> savings in time and money <strong>the</strong>y can makeby conducting <strong>the</strong>ir business transactions withESV online.“Conducting business online, such as banking,paying bills, ordering services and equipment– <strong>the</strong> list goes on – is now a natural part of lifefor many of us. At ESV we regarded it as veryimportant to take due regard of requirementsand stay abreast or even slightly ahead ofdevelopments in <strong>the</strong> world of online services.”ESV conducted some research earlier thisyear to gauge <strong>the</strong> demand of its customersfor more online business opportunities andwhat encouragement might be required before<strong>the</strong>y would use <strong>the</strong> <strong>new</strong> on-line licensing andcertification services. Registration and licenceholders in particular indicated very strongly that<strong>the</strong>y wanted to do more of <strong>the</strong>ir business withESV online and that <strong>the</strong>y did not needany encouragement to do so.Ken said: “Delivering <strong>the</strong> <strong>new</strong> service is proofthat ESV is a progressive organisation willingto embrace <strong>the</strong> best and latest technologyto improve <strong>the</strong> way it does business – for <strong>the</strong>benefit of customers as well as itself.”Promotional leaflets explaining <strong>the</strong> <strong>new</strong> serviceswill be distributed to certificate of electricalsafety agency branch offices shortly, and toregistration and licence holders well ahead ofre<strong>new</strong>al times. The full range of online businessopportunities will be explained in <strong>the</strong> leaflets.(For more information see pages 30, 31).To access <strong>the</strong> ESV online services, registrationand licence holders will use <strong>the</strong> same USERID and PIN required to access <strong>the</strong> IVR system.They will <strong>the</strong>n be asked to create a <strong>new</strong>password to be used when logging into<strong>the</strong> online services.Briefly, <strong>the</strong> expanded and enhanced online ESVsystem will enable:> Registered Electrical Contractors tore<strong>new</strong> registrations, change business detailsand improve <strong>the</strong> ordering and managementof certificates of electrical safety.> Licensed Electrical Workers to re<strong>new</strong>licences and use <strong>the</strong> system to view reportsof business activities.> Licensed Electrical Inspectors to re<strong>new</strong>licences, add inspection classes and viewreports of business activities.> Agency branch offices to view stock levelsof certificates of electrical safety, view salehistory and transfer or re-stock incorrectlysold certificates.During ESV’s research earlier this year acommon question asked by respondents was:Once licence holders provide credit card details,will ESV automatically debit <strong>the</strong> card each time<strong>the</strong> licence needed to be re<strong>new</strong>ed withouttelling <strong>the</strong> holder?All customers can be assured this will nothappen. Every time a licence or registrationcomes up for re<strong>new</strong>al, <strong>the</strong> holder will receivea re<strong>new</strong>al notice and have <strong>the</strong> option of payingonline, by mail or in person. Even if <strong>the</strong>y payonline on one occasion, it does not mean <strong>the</strong>yhave to use this service <strong>the</strong> next time if <strong>the</strong>ywant to pay by ano<strong>the</strong>r method. And ESVwill not use <strong>the</strong> credit card details under anycircumstances.ESV proposes to progressively increase itsrange of online services.Because some registration and licence holdersdo not wish to wish to avail <strong>the</strong>mselves of<strong>the</strong> online services, traditional processes forconducting business with ESV will remain inplace for as long as <strong>the</strong>re is a need.MAN RECEIVES BURNS TO ARMS,FACE AND CHEST IN TRENCH EXPLOSIONESV is assisting investigations intoa trench explosion in which a manreceived burns to his arms, faceand chest when <strong>the</strong> bucket of anexcavator struck an undergroundpowerline.The incident occurred in Lorimer Street, PortMelbourne, in late October when contractorswere laying a <strong>new</strong> fire service ring main pipe.The victim was taken to The Alfred for treatmentand is reportedly recovering from his injuries.A statement provided by <strong>the</strong> operator of <strong>the</strong>excavator said workers at <strong>the</strong> site had beenmade aware of a sewer and live powerline in<strong>the</strong> vicinity of <strong>the</strong> trench <strong>the</strong>y were digging.The victim was in <strong>the</strong> trench.The operator said <strong>the</strong> sewer was exposedmostly by hand and he <strong>the</strong>n used <strong>the</strong> excavatorto dig slowly – just between 30 mm and 50 mmof earth at a time. The victim was keeping watchon <strong>the</strong> teeth of <strong>the</strong> excavator’s bucket while <strong>the</strong>digging was underway.According to <strong>the</strong> statement it was when <strong>the</strong>bucket was being slowly lifted that <strong>the</strong>re wasan explosion – with flames coming out of <strong>the</strong>trench.The operator said he immediately went to<strong>the</strong> assistance of <strong>the</strong> victim.The work shirt worn by <strong>the</strong> victimBurn mark on <strong>the</strong> excavator bucket

GAS BBQVICTIMS’PLEA FORGAS SAFETYJennyESV’s <strong>new</strong> television commercialwarning of <strong>the</strong> need for care whenusing outdoor gas appliances– barbecues, gas lights and heaters– is aimed at preventing deaths,fires and <strong>the</strong> sort of terrible incidentin which Melbourne couple JennySpencer and Con Kondovasisreceived serious burns.Jenny and Con remember enjoying <strong>the</strong>barbecue at <strong>the</strong>ir friend’s house last summer– that is until someone disconnected <strong>the</strong>gas cylinder while <strong>the</strong> gas was still on, and<strong>the</strong> barbeque was still sizzling, creating anexplosion that blew Jenny across <strong>the</strong> backyardand burned 30% of her body.It was a typical summer backyard scene. Theadults standing around with drinks and nibbles,<strong>the</strong> kids playing in <strong>the</strong> pool. The blokes fired up<strong>the</strong> barbie and started cooking.Then <strong>the</strong>re was a big debate whe<strong>the</strong>r <strong>the</strong>re wasenough gas in <strong>the</strong> cylinder to finish cooking <strong>the</strong>meat. One of <strong>the</strong> blokes offered to take <strong>the</strong> gascylinder and exchange it for a full one.Con said: “He undid it without turning off <strong>the</strong>gas first. I can remember shouting: No don’t.Spencer and Con KondovasisIt ignited so quickly. We couldn’t smell it.We heard it first.”Jenny, standing three or four metres away,caught <strong>the</strong> full force of <strong>the</strong> explosion. The gascylinder rolled onto its side, creating a fireballwith a force “like a blow torch”, directed straightat her. Jenny was thrown back against <strong>the</strong>awning, dislocating her knee.“I was trying to move out of <strong>the</strong> way of <strong>the</strong> fireand I didn’t know why I couldn’t.”Con ran over and put his hands into <strong>the</strong> fire,grabbing her and pulling her out, receivingserious burns to his hands and arms in <strong>the</strong>process.Jenny had <strong>the</strong> presence of mind to run straightinto <strong>the</strong> house and under <strong>the</strong> shower, dislocatedknee and all. It was a piece of quick-thinkingthat probably reduced <strong>the</strong> severity of her burnsand aided her eventual recovery.“The worst thing was that <strong>the</strong> bathroom was fullof mirrors, all around me. I could see every inchof my burns.”Jenny was taken by ambulance to <strong>the</strong> <strong>Victoria</strong>nAdult Burns Service at The Alfred.“The burns unit was fantastic. I can’t speakhighly enough of all of <strong>the</strong>m,” she says.Jenny benefited from some ground-breakingburns treatment at The Alfred which meant thatshe didn’t have to have skin grafts. Ten monthslater, everything is healing beautifully.“Now it’s just a matter of time. They told me ittakes up to two years for nerves and tendonsto return to normal.”The psychological effects are harder to heal.A few months down <strong>the</strong> track Jenny wasdiagnosed with post-traumatic stress disorder(PTSD), a condition common to many burnsand accident victims.Jenny and Con are keen to spread <strong>the</strong> gassafety message. “When we were in <strong>the</strong> burnsunit, we were told that <strong>the</strong>re had been four o<strong>the</strong>rbarbecue accidents in <strong>the</strong> weeks before me,”says Jenny.“People don’t even think <strong>the</strong>y need to knowhow to operate a gas barbecue properly …You wouldn’t get in a car and drive it withoutlearning exactly how to use it and what risksyou are taking.”Con says: “Alcohol and gas bottles don’t mix.You should breathalyse people before <strong>the</strong>y use<strong>the</strong> barbie.”You can read about <strong>the</strong> <strong>new</strong> commercialon page nine.7springsummerDon’t forget.To tell us what you would like to particularly see in energysafeContact us by fax at (03) 9686 2197, or by email at info@esv.vic.gov.au

8energysafeOWNING AND OPERATING TYPE BGAS APPLIANCES – AUDITS TO ENSURECOMPLIANCEBefore a Type B gas appliance can be operated in <strong>Victoria</strong>, it mustbe “accepted” by ESV. This means an application has been made inaccordance with <strong>the</strong> Gas <strong>Safe</strong>ty Act and following a safety assessment,ESV has indicated that it has accepted <strong>the</strong> appliance. An acceptancelabel will <strong>the</strong>n be attached to <strong>the</strong> appliance.ESV acceptance remains current as long as <strong>the</strong>re are no changes to <strong>the</strong>appliance specification or installation. This means <strong>the</strong> appliance may notbe modified, changed or moved without a <strong>new</strong> application being madeto ESV.Once an appliance has been accepted, <strong>the</strong> Gas <strong>Safe</strong>ty (Gas Installation)Regulations (R35) require <strong>the</strong> owner to keep that appliance in a“proper state of repair”.Type B appliances embrace many differing types and various energyinputs. A “proper state of repair” may range from simple servicing andmaintenance to detailed scheduled maintenance and inspection regimesassociated with process plant and equipment of great complexity. Inmaking judgements on compliance with R35, ESV inspectors seek toverify that owners have-> considered <strong>the</strong>ir obligations and have service maintenance systemsin place that demonstrate compliance; and> directly or through o<strong>the</strong>r facility maintenance or asset managementarrangements, employed competent Type B appliance persons toundertake work.Examples of Type B gas appliances.By Steve Brook, ESV’s Executive Manager, Gas Installation and Appliance <strong>Safe</strong>ty.R35 Compliance audit - 2008What will this mean to Type B appliance workers?In 2008 ESV will consult with Type B appliance owners and commence<strong>the</strong> roll-out of an audit program to confirm compliance with Regulation 35.ESV will be looking to audit maintenance strategies and outcomesby reference to service records. These audits will include serviceorganisations and appliance workers.Your client may provide a service schedule or you may be asked, asa competent Type B person, to establish a schedule by reference tomanufacturers’ service requirements. Ei<strong>the</strong>r way you may wish toconsider your servicing/maintenance report and ask yourself-> does it record <strong>the</strong> work performed?> does it include sufficient information on <strong>the</strong> appliance condition,settings and combustion performance?> does it provide a means to clearly identify any safety issues orconcerns?ESV will ask Type B appliance owners to provide evidence that competentpersons are undertaking work. If you are a Licensed Type B person and/or operate a business that includes <strong>the</strong> servicing of Type B appliances,you must ensure competent persons do <strong>the</strong> work.ESV will seek assurance from appliance owners that any change to <strong>the</strong>accepted specification of a Type B appliance has been managed with<strong>the</strong> involvement of ESV.As a competent person you are expected to understand your obligationsin applying to ESV to accept changes from an appliance’s originalspecification.For fur<strong>the</strong>r details, please contact <strong>the</strong> ESV Gas <strong>Safe</strong>ty TechnicalInformation Line on 1800 652 563.LANDLORD RECEIVES BIG FINE FOR UNLICENSED GAS INSTALLATION.A landlord who installed a second hand cooker in a rentalproperty should be regretting his actions after receiving asubstantial fine and costs for carrying out <strong>the</strong> work whileunlicensed.The tenant of <strong>the</strong> property told ESV that <strong>the</strong> cooker had tilted forwardcausing a pan of hot water to fall and scald a young childIn its investigations, ESV found that <strong>the</strong> upright cooker was not stabilisedas required by Australian Standard Gas Installations AS 5601.The landlord was prosecuted in a magistrate’s court and was fined $3500and ordered to pay a fur<strong>the</strong>r $1585 in costs for carrying out plumbing /gasfitting work while not registered or licensed to do so.There is no doubt that if <strong>the</strong> work had been carried out by a licensedgasfitter, <strong>the</strong> stove would have been stabilised as required under <strong>the</strong>regulations – and <strong>the</strong> incident would not have happened.A reminder for gasfitters:Australian Standard Gas Installations AS 5601, section 5.12.1.7 states;Stabilisation of a freestanding cooking appliance.The method recommended by <strong>the</strong> manufacturer to prevent <strong>the</strong> tiltingof a freestanding cooking appliance, when in <strong>the</strong> installed position,shall be used.All licensed or registered plumbers / gasfitters should ensure that,> When installing a <strong>new</strong> gas appliance this installation must conformwith <strong>the</strong> manufactures installation instructions.> When servicing or repairing an existing gas appliance, check <strong>the</strong>safety of that appliance, and <strong>the</strong> appliance installation.Handy safety hint. Tell your customers:Statistics show that <strong>the</strong> most frequent of gas related incidents within <strong>the</strong> home involve cooktops and heaters. Never leavecooking unattended. Make sure <strong>the</strong>re are no flammable materials near appliances. Always have appliances installed andregularly serviced by a licensed gasfitter.

ESV’s NEW GAS SAFETY COMMERCIALWARNS OF DANGERS FROM OUTDOORAPPLIANCESIt’s a blissful scene – families and friends having a good time around <strong>the</strong> camp fire gazing at <strong>the</strong> starsabove. A serene and peaceful time with lots of laughter, chatter and banter for some while o<strong>the</strong>rs busy<strong>the</strong>mselves with such activities as preparing food and fixing little things around tents and caravans.Suddenly <strong>the</strong>re’s a reality check. Flames areseen escaping from <strong>the</strong> valve of a LiquifiedPetroleum Gas cylinder. Thanks to <strong>the</strong> quickaction of one of <strong>the</strong> campers, <strong>the</strong> flame isextinguished . There are no injuries just shockand amazement at such a thing happening. Theconsequences could have been a lot worse.This is <strong>the</strong> scenario in ESV’s <strong>new</strong> gas safetycommercial which started showing onmetropolitan and regional television – along with<strong>the</strong> <strong>new</strong> electricity safety commercial featured in<strong>the</strong> last issue of energysafe – from <strong>the</strong> middleof October.Scenes from <strong>the</strong> “shooting” of ESV’s<strong>new</strong> gas safety commercialThe actual commercial was shot over manyhours at a park in a Melbourne suburb on awet and chilly afternoon and evening in August.Just <strong>the</strong> right wea<strong>the</strong>r for camping, some of youwould say!The message of this commercial is:Whenever you use gas appliancesat home or on holidayAlways check <strong>the</strong> fittings are tightAnd <strong>the</strong> hoses are in good working order.Never use appliances inside tents or nearanything flammable.Always treat gas with respect.Click on to <strong>Energy</strong> <strong>Safe</strong> <strong>Victoria</strong>.ESV selected this commercial because of twodeaths in 2006/07 caused by fires resultingfrom gas escaping due to insecure fittingsbetween appliances and LPG cylinders. Twogirls received serious burns in a tent fire alsoresulting from gas escaping from a cylinder.These incidents have been reported inenergysafe.The <strong>new</strong> commercial also features <strong>the</strong> logos of<strong>the</strong> Metropolitan Fire Brigade, <strong>the</strong> Country FireAuthority and <strong>the</strong> <strong>Victoria</strong>n Adult Burns Serviceat The Alfred.9springsummerSTAY SAFE THIS SUMMER WITH GASAND ELECTRICITY, SAYS MINISTERESV’s <strong>new</strong> television commercials were formally introduced to <strong>the</strong>community on Sunday, 14 October, through a media release from<strong>the</strong> Minister for <strong>Energy</strong> and Resources, Peter Batchelor, who urged<strong>Victoria</strong>ns to take extreme care with electricity and gas.Mr Batchelor said as summer approaches <strong>Victoria</strong>ns should performsome simple checks to ensure <strong>the</strong>y stay safe.He said <strong>the</strong> commercials were about reminding <strong>Victoria</strong>ns to take extremecare when dealing with gas and electricity. By doing <strong>the</strong> right thing <strong>the</strong>ycan make sure <strong>the</strong>y enjoy a safe summer and beyond.Barbecue safety“Before people use <strong>the</strong>ir barbecues it is essential <strong>the</strong>y’re checked toensure <strong>the</strong>y are safe for <strong>the</strong> users, <strong>the</strong>ir families and any friends whomay be attending Cup Day parties or o<strong>the</strong>r events.”Mr Batchelor said that people needed to make sure:> The appliances and gas cylinders are in good condition;> Connecting hoses between <strong>the</strong> cylinder and appliance arenot damaged or leaking gas;> Hand-tightened cylinder connections are as tight as <strong>the</strong>y cango – in <strong>the</strong> case of o<strong>the</strong>r fittings use a spanner if possible.Electrical safetyMr Batchelor also reminded <strong>Victoria</strong>ns that it is illegal and dangerous forhouseholders to undertake <strong>the</strong>ir own electrical work around <strong>the</strong> home.“The message is clear, always use a licensed electrician, ask to see <strong>the</strong>irlicence before <strong>the</strong>y start work and demand a Certificate of Electrical<strong>Safe</strong>ty when <strong>the</strong> job is completed,” he said.“Electrical work done by unqualified people can be a recipe for disaster.While shoddy and dangerous work may not be immediately apparent,<strong>the</strong> risks caused will be <strong>the</strong>re for any current and future occupants ina property.”

10energysafeESV ASSISTS INVESTIGATIONS AFTER BOY CONTACTSOVERHEAD CONDUCTOR ON RAILWAY LINEESV is recommending that authorities accelerate <strong>the</strong> placing of barrierson <strong>the</strong> overhead electric line structures across Melbourne’s suburban railnetwork to prevent people climbing onto <strong>the</strong>m.The recommendation follows an incident in late September involving a 14-year-old boy who received an electric shock and burns, and fell more than10 metres to <strong>the</strong> ground after climbing a structure on <strong>the</strong> Melbourne toFrankston line near Seaford.ESV assisted <strong>Victoria</strong> Police and rail authorities, including <strong>the</strong> track ownersand <strong>the</strong> operators of <strong>the</strong> system, with inquiries into <strong>the</strong> incident.It was ascertained that <strong>the</strong> boy had climbed <strong>the</strong> steel structure and hadbeen standing on <strong>the</strong> lower steel cross arm when he contacted <strong>the</strong> middlephase of <strong>the</strong> 22 kV conductor with his right hand, his left hand appearedto have been on <strong>the</strong> vertical section of <strong>the</strong> structure. He <strong>the</strong>n fell to <strong>the</strong>ground sustaining serious injuries.Following <strong>the</strong> incident <strong>the</strong> boy was placed on life support at <strong>the</strong> RoyalChildren’s Hospital with burns to 40% of his body, toge<strong>the</strong>r with a brokenpelvis and femur. He also received serious injuries to his left foot and righthand. His condition was not known when energysafe went to press.ESV’s Investigations Officer, Michael Leahy, conducted an on siteinvestigation including using an elevated work platform to examine<strong>the</strong> area of <strong>the</strong> structure from where <strong>the</strong> boy is thought to have fallen.He found that on <strong>the</strong> bottom cross arm – 10.7 metres above <strong>the</strong> ground– was a burn mark and what appeared to be white rubber from <strong>the</strong> soleof a shoe. Splatters of copper could be seen along <strong>the</strong> conductor.On <strong>the</strong> top cross arm were two rubber rings on <strong>the</strong> bolt that held <strong>the</strong>insulator. It is hard to see how <strong>the</strong>se rubber rings could have got <strong>the</strong>reby any o<strong>the</strong>r means o<strong>the</strong>r than being placed by someone, said <strong>the</strong> ESVreport into <strong>the</strong> incident.Preventative measuresAs a result of a similar incident some two years ago, ESV in conjunctionwith <strong>the</strong> network operators, MainCo, developed a program to installbarriers on <strong>the</strong> structures some three metres above <strong>the</strong> ground <strong>the</strong>reforemaking <strong>the</strong>m more difficult to climb.MainCo has advised ESV that <strong>the</strong> work installing <strong>the</strong> barriers will becompleted by November 2009.A typical barrier to prevent unauthorised climbing on overhead electric line structures.The structure from where <strong>the</strong> boy received <strong>the</strong> electric shock and fell to <strong>the</strong> ground.ANNUAL REPORT –A LISTING OF ESV ACHIEVEMENTS IN 2006/07ESV’s Annual Report for <strong>the</strong> financial year 2006/07 was tabled in State Parliamentat <strong>the</strong> end of October and is now a public document. It is available on <strong>the</strong> ESV websiteat www.esv.vic.gov.auIn a letter to stakeholders accompanying copies of <strong>the</strong> report, Director of <strong>Energy</strong> <strong>Safe</strong>ty Ken Gardnersaid: “As stated in <strong>the</strong> report, 2006/07 has been a busy and challenging year for ESV and its people.We continued to develop what is still a relatively <strong>new</strong> organisation to leverage off <strong>the</strong> benefits ofcombining electricity and gas safety expertise.“Our responsibilities have also increased. Late in <strong>the</strong> year, responsibility for <strong>the</strong> safety of <strong>Victoria</strong>’slicensed pipelines was transferred to ESV from <strong>the</strong> Department of Primary Industries. The transferprovides us with <strong>new</strong> responsibilities and challenges, and we welcome <strong>the</strong>m.“Our achievements over <strong>the</strong> year are many and <strong>the</strong>y are covered fully in <strong>the</strong> Annual Report. Much of <strong>the</strong>credit for our achievements is due to <strong>the</strong> professionalism and commitment of ESV’s management andstaff. We have worked hard to develop <strong>new</strong> energy safety initiatives and enhance existing programs.“I also wish to acknowledge <strong>the</strong> support we receive each year from our safety partners as we jointlypursue electricity, gas and pipeline safety. We have even streng<strong>the</strong>ned our working partnerships witha number of agencies in recent times and this is very encouraging and satisfying.“Despite <strong>the</strong> work of ourselves and our partners, incidents causing a range of injuries – and evendeath in extreme circumstances – continue to occur. We will always do everything possible toreduce incidents, and I trust that <strong>the</strong> electricity, gas and pipeline industries will demonstrate a similarcommitment in <strong>the</strong> years ahead,“ said Ken.ESV’s 2006/07 Annual ReportHandy safety hint. Tell your customers:Transport LP Gas cylinders securely fastened and in an upright position.

11springsummer

THE IMPORTANCE OF RESPONSIBLE AND EFFECTIVE SUPERVISIONOF APPRENTICE ELECTRICIANS AT ALL TIMES12energysafeDirector of <strong>Energy</strong> <strong>Safe</strong>ty Ken Gardnerrecently covered <strong>the</strong> issue of responsibleand effective supervision of apprenticesin his monthly column in <strong>the</strong> NECA<strong>Victoria</strong>n Chapter <strong>new</strong>sletter. Becauseof its importance his comments arereproduced here.ESV is becoming increasingly concernedthat some electrical apprentices are not beingadequately supervised when working. Thismay be due to supervisors not being aware of<strong>the</strong>ir responsibilities or choosing to ignore <strong>the</strong>mfor reasons best known to <strong>the</strong>mselves – andplacing <strong>the</strong> apprentice at some risk.Employers, contractors and electricians must beaware that under <strong>the</strong> Electricity <strong>Safe</strong>ty Act 1998any electrical work undertaken by an apprenticeis in fact deemed to have been performed by<strong>the</strong> supervisor who is <strong>the</strong>refore responsible forensuring <strong>the</strong> work is safe and up to <strong>the</strong> requiredstandard.Recently an electrical apprentice was involvedin an incident which resulted in a warning letterbeing sent to <strong>the</strong> supervisor by ESV. Under<strong>the</strong> Electricity <strong>Safe</strong>ty (Installations) Regulations1999, we could have issued an infringementnotice with its accompanying fine or prosecuted<strong>the</strong> breach of <strong>the</strong> law in <strong>the</strong> magistrates court.On this occasion, however, ESV decided toapply discretion and issue <strong>the</strong> warning letter.But, as <strong>the</strong> letter makes quite clear, if <strong>the</strong>re areany fur<strong>the</strong>r breaches of <strong>the</strong> Act or Regulationsby <strong>the</strong> supervisor concerned, <strong>the</strong> individualwill not be so lucky next time.Hopefully this particular episode places<strong>the</strong> electricity industry on notice that whenresponsible and effective supervision is requiredto ensure that apprentices are not placed in anydanger and receive proper on <strong>the</strong> job training,it means that <strong>the</strong>y receive just that – responsibleand effective supervision.I urge everyone who is called upon to superviseapprentices to consult <strong>the</strong> “SupervisionGuidelines for Apprentices Working on ElectricalInstallations” which can be accessed anddownloaded from our website at www.esv.vic.gov.auThe guidelines are reproduced on page 25.The guidelines provide very useful definitionsof <strong>the</strong> levels of supervision normally requiredfor apprentices during each year of <strong>the</strong>irapprenticeship. For instance, first yearapprentices require “direct” supervision at alltimes when performing <strong>the</strong> work which <strong>the</strong>y arepermitted to carry out. “Direct” means that <strong>the</strong>supervisor must review <strong>the</strong> apprentice’s workconstantly, be within earshot at all times andwhere possible be within visual contact.O<strong>the</strong>r categories of supervision include <strong>the</strong>terms “general” and “broad”. Under a generalsupervision <strong>the</strong> apprentice does not require<strong>the</strong> constant attendance of <strong>the</strong> supervisingelectrician but <strong>the</strong> work needs to be regularlychecked and tested. With broad supervision,again <strong>the</strong> apprentices do not need constantattention but proper checks and tests must becarried out before <strong>the</strong>ir work is commissionedand circuits energised.It must also be noted under <strong>the</strong> guidelines thatsome work such as fault finding cannot beundertaken by first and second year apprenticeswhe<strong>the</strong>r <strong>the</strong>y are being supervised or not. Andthird and fourth year apprentices can only carryout such work when under “direct” supervisionof <strong>the</strong> supervising electrician.These guidelines have been developed to assistelectricians and electrical contractors whensupervising apprentices. Apart from ensuringresponsible and effective supervision, <strong>the</strong>yalso assist supervisors in ensuring <strong>the</strong>y donot breach <strong>the</strong> Electricity <strong>Safe</strong>ty Act.ESV ESTABLISHES COMMITTEE TO REVIEWAND PREVENT ELECTRICAL INCIDENTSESV has established a <strong>new</strong> industry committee with its major purpose beingto review electrical incidents and identify what can be done to make sure <strong>the</strong>ydon’t happen again.Charter of <strong>the</strong> committeeThe full charter of <strong>the</strong> committee reads:> To review electrical incidents to identify actions to enhance safetyprocedures and outcomes.> To analyse statistical information and identify trends in electrical safety,including providing reports to industry.> To make recommendations to <strong>the</strong> Director of <strong>Energy</strong> <strong>Safe</strong>ty to addressidentified trends in electrical safety.> To propose amendments to Codes, Guidelines, Standards and IndustryPractices.The committee has already held one of its quarterly meetings. The nextmeeting is scheduled for February. Special meetings can also be called fromtime to time.Who’s on <strong>the</strong> committee?The current membership of <strong>the</strong> committee is:> Darren Margerison - Chairperson appointed by ESV.> Loc Vuong from ESV representing three areas: Infrastructure <strong>Safe</strong>ty,Installation <strong>Safe</strong>ty, and Equipment <strong>Safe</strong>ty.> Terry Dyke, (CitiPower) representing <strong>the</strong> electricity distribution companies.> David Just, (SP Ausnet) representing <strong>the</strong> electricity transmission company.> Steve Lawlor, (NECA) representing <strong>the</strong> Employer Associations.> Alan Mulvena, (ETU) representing <strong>the</strong> Unions.> Stephen Darnley representing <strong>Victoria</strong>n WorkCover Authority.> One representative of electrical customers who is yet to be appointed.Subject matter experts and o<strong>the</strong>rs may be asked to attend meetings to act asobservers or provide specialist input.Proper protocols will apply to <strong>the</strong> conduct of <strong>the</strong> meetings. For instance <strong>new</strong>issues affecting policy cannot be raised at meetings unless all <strong>the</strong> appropriatepaperwork has been provided to members at least five days before <strong>the</strong>meeting.The committee’s charter sets <strong>the</strong> roles of <strong>the</strong> chairperson, deputy chairperson,committee members and <strong>the</strong> secretariat.energysafe looks forward to providing reports from <strong>the</strong> committee’s work.

NEW BROCHURE:FIRST AID FOR ELECTRICSHOCK VICTIMSA <strong>new</strong> brochure detailing how to provideFirst Aid for victims of electric shock has beenproduced jointly by St John Ambulance and ESV.It replaces <strong>the</strong> brochure “First Aid for Electric ShockVictims” produced by <strong>the</strong> former Office of <strong>the</strong> ChiefElectrical Inspector.The <strong>new</strong> brochure is entitled “Minutes Matter” and coversFirst Aid for electric shock, rescue, burns and how to savea life.Photos in <strong>the</strong> brochure provide useful advice and guidanceon how to treat victims.Copies of <strong>the</strong> brochure can be obtained from ESV.13springsummerHandy safety hint. Tell your customers:Always treat a tingle or slight shock as a warning – adviseyour electricity authority or a registered electrical contractorimmediately. Never touch an appliance which caused ashock until it has been disconnected from <strong>the</strong> power source.Label it clearly to prevent anyone else from using it until ithas been repaired and tested or replace it immediately.The <strong>new</strong> brochureDON’T PUT LIVES AT RISKUse 250 micron copper coated/cladded earth rodsAllearth rods have a minimum coating/cladding of 250 micronsand comply to all relevant Australian standardsEarth Rod Range● OER1440 13mm dia. x 1440mm long● OER1800 13mm dia. x 1800mm long● OER2440 13mm dia. x 2440mm long● OER1200X16B 16mm dia. x 1200mm long (extendible)● OER1800X16B 16mm dia. x 1800mm long (extendible)● OER3000X16B 16mm dia. x 3000mm long (extendible)● OER1800X19 19mm dia. x 1800mm long (non extendible)● OER3000X19 19mm dia. x 3000mm long (nonextendible)Clamps & AccessoriesCompliant toBS6651& Australian requirements250 MicronsCopper Coated/Cladded● EC130Earth Clamp for 13mm● CL602Earth Clamp for 16mm● EC19Earth Clamp for 19mm● CP502Copper Alloy CouplingAvailable through all reputable Electrical Wholesalers● DS81Driving Stud● DH2 / DH6Driving Headomegapower.com.ausales@omegapower.com.auVIC(03) 9793 6111NSW(02) 9734 9944QLD(07) 3216 2799SA(08) 8340 9200WA(08) 9475 0777

14energysafeMANDATING ELECTRICITYSAFETY MANAGEMENTSCHEMESIt will be mandatory for <strong>Victoria</strong>’s electricitytransmission and distribution networkoperators to submit electricity safetymanagement schemes (ESMS) every fiveyears to ESV under <strong>the</strong> Electricity <strong>Safe</strong>tyAmendment Bill which is likely to becomelaw soon.The main provisions of <strong>the</strong> Bill are to amend<strong>the</strong> Electricity <strong>Safe</strong>ty Act 1998 to:> mandate submission of and, onceapproved, compliance with electricity safetymanagement schemes by major electricitycompanies, namely electricity transmissionand distribution owners or operators;> harmonise <strong>the</strong> safety management schemeregime in <strong>the</strong> Electricity <strong>Safe</strong>ty Act 1998 with<strong>the</strong> gas safety case regime in <strong>the</strong> Gas <strong>Safe</strong>tyAct 1997;> require registered electrical contractorsand licensed electrical workers to rectify<strong>the</strong>ir defective electrical work that is unsafe(see separate article on this page):> improve <strong>the</strong> representation of <strong>the</strong> railwayand tramway industries on <strong>the</strong> <strong>Victoria</strong>nElectrolysis Committee.Introducing <strong>the</strong> Bill into State Parliament,Minister for <strong>Energy</strong> and Resources PeterBatchelor said it would secure improvedsafety and reliability of electricity assets.The Electricity <strong>Safe</strong>ty Amendment Bill 2007which is likely to become law soon will requireregistered electrical contractors and licensedelectrical workers to rectify any work which isconsidered to be defective and unsafe.Introducing <strong>the</strong> Bill into <strong>the</strong> <strong>Victoria</strong>n Parliamentrecently, Minister for <strong>Energy</strong> and ResourcesPeter Batchelor said: “Electricity is inherentlydangerous and unsafe electrical work createssignificant risks to life and property, for example,from house fires caused by faulty <strong>wiring</strong>.”He said <strong>the</strong> Bill provides that <strong>Energy</strong> <strong>Safe</strong><strong>Victoria</strong> may, by written notice, require aregistered electrical contractor or licensedelectrical worker that carried out unsafe workto rectify it at no additional expense to <strong>the</strong>customer. Penalties apply for non-compliancewith a rectification notice.“A registered electrical contractor or licensedelectrical worker can avoid a notice under<strong>the</strong> bill, and <strong>the</strong> risk of a penalty forHe said that an ESMS specifies <strong>the</strong> assetsor operations to which it applies, <strong>the</strong> hazardsand risks to persons and property arisingfrom those assets or operations, and <strong>the</strong> safetymanagement system to be followed to minimiseas far as practicable those hazards and risks.“This proposal will adopt best practice safetymanagement regulation that facilitates betterhazard identification and risk-managementactivities aimed at preventing incidents and atmitigating <strong>the</strong> consequences if <strong>the</strong>y do occur.“Most <strong>Victoria</strong>n transmission and distributioncompanies have seen <strong>the</strong> benefits associatedwith voluntarily submitting and complying withan approved ESMS under <strong>the</strong> existing Electricity<strong>Safe</strong>ty Act 1998. The bill will ensure that <strong>the</strong>sebenefits are locked in.“The benefits include lower compliancecosts under <strong>the</strong> ESMS regime compared toprescriptive regulations and improved safetyperformance.”The Minister said that by aligning, whereappropriate, <strong>the</strong> gas and electricity safetyregimes <strong>the</strong> Bill will reduce <strong>the</strong> regulatoryburden for those entities operating in both<strong>the</strong> electricity and gas industries.It also introduces a <strong>new</strong> section to clarify that<strong>Energy</strong> <strong>Safe</strong> <strong>Victoria</strong> may conduct audits todetermine compliance with an ESMS.NEW LAW TO ENSURE UNSAFEWORK IS RECTIFIEDnon-compliance, by rectifying unsafe workpromptly, as he or she would be contractuallybound to do anyway.“By providing for <strong>the</strong> issue of rectificationnotices, <strong>the</strong> Bill will ensure that defective workthat is unsafe is made safe as soon as possibleand regardless of whe<strong>the</strong>r <strong>the</strong> consumerchooses to enforce his or her contractualrights.”When <strong>the</strong> Bill was read for <strong>the</strong> second time,<strong>the</strong> Minister said compliance with a notice fromESV to rectify unsafe and defective work issubject to <strong>the</strong> right of review by <strong>the</strong> <strong>Victoria</strong>nCivil and Administrative Tribunal.“The rectification work is to be at no additionalexpense to <strong>the</strong> customer. Rectification ofunsafe defective electrical work may include<strong>the</strong> labelling of switchboards, <strong>the</strong> securing andprotection in position of cables and <strong>the</strong> secureinstallation of equipment.”Handy safety hint. Tell your customers:Never leave frying unattended, <strong>the</strong> oil may boil over and start a fire.CERTIFICATE OFELECTRICAL SAFETYREVIEW – LATESTESV’s extensive review of <strong>the</strong> Certificate ofElectrical <strong>Safe</strong>ty and <strong>the</strong> electrical inspectionand auditig systems has recommended that <strong>the</strong>certificate should be retained for all prescribed,non-prescribed and periodic work - but withsome refinements.As reported in <strong>the</strong> last issue of energysafe,ESV conducted 32 industry forums earlierthis year as part of <strong>the</strong> review process witha number of businesses and organisationsinvolved.Many refinements to improve <strong>the</strong> certificatesystem have been agreed to by all <strong>the</strong> partiesconsulted during <strong>the</strong> review, with only onedifficult but important issue of principle to beresolved before <strong>the</strong> review is concluded anda final recommendation made.The method of allocating inspections ofprescribed electrical work is still to be resolved.During consultations so far and from commentsreceived, any change in this area raises anumber of difficult issues impacting on existingbusinesses. These issues will require fur<strong>the</strong>rwork and analysis to decide whe<strong>the</strong>r a detailedproposal can be developed for a fur<strong>the</strong>r roundof consultations.Refinements include:> Data capture on <strong>the</strong> certificates should berelevant only to ESV’s needs and confinedto information on full location details, <strong>the</strong>identity of <strong>the</strong> electrical worker involved,<strong>the</strong> work performed and its level of risk.> The introduction of online purchasing,lodgement and reporting of certificates.A paper Certificate of Electrical <strong>Safe</strong>ty will,however, remain available to users who donot use computers.> Conducting a feasibility study aimed atreducing <strong>the</strong> number of forms required forcompletion as part of <strong>the</strong> inspection process.> Redefining prescribed inspections toconcentrate on such components as allsub-mains, earthing systems and distributionboards related to <strong>the</strong> control of an individualoccupier’s portions of multiple installations.> Reviewing <strong>the</strong> type of electrical work that isdeemed to be prescribed inspection workfor such components as standby generators,electric fences and remote area supplies.> An annual review of <strong>the</strong> cost of <strong>the</strong> certificateof electrical safety to ensure it reflects <strong>the</strong>CPI.> Amending legislation to require registeredelectrical contractors to retain paper copiesof certificates for three years. Electroniccopies will be retained by ESV.> Improving <strong>the</strong> electrical inspection processto include rationalising <strong>the</strong> listing of defectsto reflect <strong>the</strong> remedial work required, with <strong>the</strong>recording of <strong>the</strong> defects to be limited to <strong>the</strong>ESV, LEI and REC copies only.> The introduction of regular auditing oflicensed electrical inspectors who will alsohave to undertake additional on-goingtraining as a condition of licence re<strong>new</strong>al.> The introduction of <strong>new</strong> auditing processesto address work standards and workerperformance, and setting minimum timeframes between audits of LEIs, RECs, andLEWs. Also information collected from <strong>the</strong>audit process should be used to assisteducation and training.

KEEN INTEREST IN POWERLINE DETECTORAFTER ITS APPEARANCE ON TELEVISIONAn innovative device to shut off truck engines if <strong>the</strong> traysof vehicles come too close to overhead powerlines hasreceived national exposure after it was featured on ABCTV’s The New Inventors program on 26 September.The inspiration for <strong>the</strong> Wilsave Powerline Detector followed <strong>the</strong> threedeaths in <strong>Victoria</strong> in 2006 resulting from trucks accidently contactingoverhead powerlines.Truck operator Peter Wilson of Holbrook in NSW asked his bro<strong>the</strong>r Ken,a semi-retired electrician from Corryong, if it was feasible to invent adevice to overcome this danger.Ken and Peter came up with <strong>the</strong> Wilsave device. The product comprisesfrom 1 to 9 independent sensors fitted to <strong>the</strong> extremities of <strong>the</strong> trucktray for <strong>the</strong> detection of <strong>the</strong> electric field. Each sensor includes a radiotransmitter/receiver module, which communicates continuously with <strong>the</strong>central processor unit (CPU) located in <strong>the</strong> cab of <strong>the</strong> truck.The radio communication is held secure by scanning <strong>the</strong> radio channel todetect any interference. The CPU has an antenna mounted on <strong>the</strong> vehicleroof and an internal clock to enable time-stamping of all <strong>the</strong> memorisedinformation.In o<strong>the</strong>r words, when <strong>the</strong> truck tray comes within <strong>the</strong> safe operatingdistance of an overhead powerline, <strong>the</strong> Wilsave will halt <strong>the</strong> lifting processand shut off <strong>the</strong> truck’s engine. The tray will <strong>the</strong>n need to be lowered and<strong>the</strong> control unit re-set before <strong>the</strong> engine can be re-started.No input from <strong>the</strong> driver or operator is required and <strong>the</strong>re is no overridefunction on <strong>the</strong> truck powerline detector to eliminate human error. Thereare no wires to become entangled in truck components.On The New Inventors, <strong>the</strong> product was up against a stubby cooler anda form of concrete panelling. While one of <strong>the</strong> judges on <strong>the</strong> show felt <strong>the</strong>Wilsave should be a winner on <strong>the</strong> night because of its ability to save lives,after some lively discussions <strong>the</strong> panel eventually opted for <strong>the</strong> panelling.OperationHow does it operate? The Wilsave measures <strong>the</strong> electric field around amedium or high-voltage line and <strong>the</strong>n by <strong>the</strong> analysis of this measurementindicates <strong>the</strong> no-go zone.Sensors are continuously interrogated by <strong>the</strong> processing unit in order toverify <strong>the</strong>ir operational state. The battery charge level and <strong>the</strong> operationof <strong>the</strong> various radio channels are checked, so avoiding any failure andensuring redundant safety checks for <strong>the</strong> whole system.Ken Wilson told energysafe <strong>the</strong>re had been keen interest in <strong>the</strong>product since <strong>the</strong> program. Apart from truck operators, <strong>the</strong>re was alsointerest from operators of such equipment as cranes, concrete pumpingapparatus and mobile skips.The inventors propose a major advertising campaign shortly to helpmarket <strong>the</strong> product. It will involve <strong>the</strong> production of a video explaining<strong>the</strong> operation of <strong>the</strong> detector.The Wilsave is one of small number of products being developed toprevent trucks contacting powerlines. These are being assessed by ESV.15springsummerHandy safety hint. Tell your customers:It is safe practice to wear rubber or plastic soled shoes when using electrical appliances in laundries, on concretefloors or out of doors. Many victims of serious and fatal electrical accidents are barefooted.