KI62101_Piretti 2000 Task Tech Specs.pdf - KI.com

KI62101_Piretti 2000 Task Tech Specs.pdf - KI.com

KI62101_Piretti 2000 Task Tech Specs.pdf - KI.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

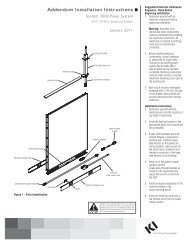

<strong>Tech</strong>nical Specifications ■accept the molded back foam. Wood board to provide anchoring for staples when C-Gex fabricattached.Back Foam:To be molded polyurethane foam 2" thick (38 I.L.D.) is contoured to fit the wooden back board.Back foam is to be adhered to the back board. Foam is to accept adhesive to secure the back fabric.Back Fabric:Die-cut fabric is to be sewn for a C-Gex press. Fabric along with foam and board assembly to beplaced in a C-Gex press where the fabric is to be fitted to the foam and secured to the board withfive staples. Adhesive is to be applied to secure fabric to foamBack Liner:Is to be injection molded of polypropylene. Is to be used as a protective shroud to cover the backandheight-adjustment mechanism. Is to be attached to the back board via four #6 x ¾” type ABPhillips head screws.Adjustable Back Inclination Mechanism:To attach to the back to the J-Bar. To allow user to infinitely adjust angle of backrest from 87º to100º.Adjustable Back Height:To allow 2" of vertical travel in five incremental steps. To be activated by lifting the backrest up todesired height. Locks in automatically (no levers).J-Bar:To connect the back to the seat mechanism. To be 2.75" wide x .315" thick and made of die-formedsteel.Main Weighing Mechanism:Steel <strong>com</strong>ponents to be stamped out of 11-, 14-, and 16-gauge steel. Plastic <strong>com</strong>ponents areinjection molded of polypropylene, Delrin and nylon. Two weighing mechanisms are to be attachedto the seat board (one left side, and one right side) with two ¼-20 x 1" Phillips pan head cap screwseach.Main Tilt Forward Mechanism:To be made of a die cast aluminum center hub. Steel <strong>com</strong>ponents are to be stamped out of 11-gauge steel. Plastic <strong>com</strong>ponents are to be injection molded of polypropylene, Delrin, and nylonmaterial. Tilt forward of 6 degrees can be locked in by pushing the optional lever underneath theseat while applying weight forward. The height adjustment is to also be activated through the maintilt mechanism by pulling the lever up on the left side underneath the seat. To be attached to themain weighing mechanism with eight M4 x 8 Phillips pan head thread cutting screws.Fixed Arms:The arm is to be available in a self-skinning urethane molded arm cap. The arm is to be supportedby a ¾” x 1½” x 14-gauge steel oval tube. The steel support arm is to be attached to the seat boardvia four ¼-20 x 1" Phillips pan head cap screws. Arm caps are to be attached using two 6mm x30mm Allen head machine screws. Both the arm caps and the steel support arms are to be<strong>com</strong>pletely field replaceable and field addable.Height- and Width-Adjustable Arm:Available with self-skinning urethane top cap. Armrests to offer 2½” of vertical adjustment and 1”of horizontal adjustment per arm. Both the arm caps and the steel support arms are to be<strong>com</strong>pletely field replaceable and field addable.