CA NO : CE (P) VIJAYAK/ /2012-13 Serial Page No : 01 ... - Bro.nic.in

CA NO : CE (P) VIJAYAK/ /2012-13 Serial Page No : 01 ... - Bro.nic.in

CA NO : CE (P) VIJAYAK/ /2012-13 Serial Page No : 01 ... - Bro.nic.in

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

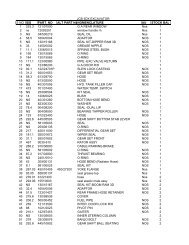

<strong>CA</strong> <strong>NO</strong>: <strong>CE</strong> (P) <strong>VIJAYAK</strong>/ /<strong>2<strong>01</strong>2</strong>-<strong>13</strong> <strong>Serial</strong> <strong>Page</strong> <strong>No</strong> :66TENDER <strong>NO</strong>: <strong>CE</strong> (P) <strong>VIJAYAK</strong>/46/ 2<strong>01</strong>1-<strong>2<strong>01</strong>2</strong>(PARTICULAR SPECIFI<strong>CA</strong>TIONS CONTD…)3.1.6 Every supply of cont<strong>in</strong>uous sandwich panel (Wall and Roof) should accompany with the orig<strong>in</strong>al<strong>in</strong>voice of the manufactur<strong>in</strong>g company along with orig<strong>in</strong>al EXCISE GATE PASS for verify<strong>in</strong>g thepayment of central excise for confirmation of orig<strong>in</strong>al supply.3.1.7 Pre-<strong>in</strong>spection of the sandwich panels (Wall and Roof) at the factory site of the manufacturer willbe carried out by a Board Of Officers to be detailed by Commander Contract before delivery of theconsignment for scrut<strong>in</strong>iz<strong>in</strong>g the quality of these sandwich panels. The board of officers will verifythe follow<strong>in</strong>g aspects:-(i)(ii)(iii)(iv)(v)Whether the sandwich panel is cont<strong>in</strong>uous or not.Thickness of Panel for wall panel.Thickness of Panel for Roof panel.Density of PUF Insulation.Verification of Orig<strong>in</strong>al Certificates for the above seven properties / specifications.3.2. Wall Panels (Internal/External):- All walls shall be made of <strong>in</strong>ner white colour coated GI metalsk<strong>in</strong> PUF panels. The thickness of PUF panels shall be 60 mm. The PUF <strong>in</strong>sulation material <strong>in</strong> thepanel shall have fire retard<strong>in</strong>g and self ext<strong>in</strong>guish<strong>in</strong>g properties as per <strong>in</strong>ternational standard.There should not be any gap between PUF wall and roof and this should be done with suitableflush<strong>in</strong>g of all jo<strong>in</strong>ts.(a)(b)(c)All material required for the manufacture of shelter shall be new and shall comply withrelevant Bureau of Indian Standard Specification.The PUF panels are to be manufactured us<strong>in</strong>g high pressure dispens<strong>in</strong>g mach<strong>in</strong>e ofrequired capacity to <strong>in</strong>ject specified amount of PUF chemical <strong>in</strong>to the cavity of a full panel<strong>in</strong> one shot not exceed<strong>in</strong>g 25 sec duration. This is to ensure that the liquid PUF mixture issprayed <strong>in</strong>to the cavity before the foam<strong>in</strong>g reaction starts so that the <strong>in</strong>sulation core of thepanel is formed <strong>in</strong> one piece and provides desired structural and physical properties. Thebulk density of <strong>in</strong>sulation panel should be 40 Kg ±2Kg/Cum and the dispens<strong>in</strong>g mach<strong>in</strong>eryshould be kept with a PLC controlled panel for monitor<strong>in</strong>g and controll<strong>in</strong>g the <strong>in</strong>jection rateto assure specified uniform density requirements. The total thickness of the f<strong>in</strong>ishedcomposite panel should be 60 mm. The tolerance <strong>in</strong> the panel can only be on the plus side.The outer colour coated GI sk<strong>in</strong> (RAL-10<strong>01</strong>) of the panels should be 0.55 mm thick TCT(Total coated thickness) with 50 micron thick PVC guard film on the f<strong>in</strong>ished surfaced onlyfor protection aga<strong>in</strong>st scratches dur<strong>in</strong>g handl<strong>in</strong>g and galvanization as per GR-120 IS-277.(d) The pre coated GI sheet sk<strong>in</strong> should have m<strong>in</strong> coat<strong>in</strong>g of 4.5 micron epoxy primer and 25micron polyester top coat on the f<strong>in</strong>ished surface and 7-8 micron Primer Alkyd Backer onbackside which is bounded to the polyurethane foam. The pre coated GI sheet shouldconform to IS 14246-1995 with manufacturer test certificates conform<strong>in</strong>g to specification.(e)The PUF <strong>in</strong>sulated core of these composite panels should have the follow<strong>in</strong>g properties:-(i) Density : 40 kg/cum (± 2 kg/cum)(ii) Compressive strength at 10% deformation: 2.10kg/cm2(iii) Tensile Strength : 4.0 kg/cm2(iv) Bend<strong>in</strong>g Strength : 4.2 kg/cm2(v) Adhesion Strength : 3. 0 kg/cm2(vi) Dimensional Stability (48 Hours)(aa) (-) 25 degree C : 0.1%(ab) +38 degree C & 90% RH : 0.1%(ac) +100 degree C : 0.4%Signature of ContractorDated : _________________<strong>2<strong>01</strong>2</strong>For Accept<strong>in</strong>g Officer