Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Volume II, Issue III 2008A TYPICAL 74 FRENCHGUNSHIPUSING POLYMER CLAY FOR YOURSHIP MODEL ORNAMENTATIONTHE MATTHEW PROJECTPART IX:The Upperworks ContinuedTYPES OF HULL CON-STRUCTION PART III:Plank on Frame HullSPLICE THE MAIN-BRACE:Is it time for a roundof drinks?

The MSB Journal—Volume II Issue IIITypes of Hull ConstructionPart III:Plank-on-Frameby Gene BodnarMany people think that a scale modelbuilt plank-on-frame (POF) style is thehighest expression of the wood ship modeler’sart. It is the kind of model in whichthe builder starts with laying a keel, thenbuilds the stem and sternpost, and thenframes it as an accurate reproduction ofthe prototype ship. From this point, theexterior planking is trenailed onto eachframe, as precisely as can be accomplished,just like in the prototype. SomePOF modeler’s carry it a step further bybuilding much of its interior, includingdeck beams, knees, multiple decks, andall of its interior fittings, such as ladders,capstans, and whatever else may befound below-decks, ending up with a veryimpressive model that emulates the realship in almost every detail.This article will attempt to explain someof the mystery involved in building a POFmodel. Actually, this type of model is nomore difficult to build than a plank-onbulkheadmodel; it just has more pieces tomake.This article also assumes that you arefamiliar with lofting your own frames,meaning that you are capable of interpretingthe lines shown on a set of plans andthat you can draw frames from the givenlines. If you are not familiar with this process,a few good sources of such informationare given at the end of this article.Laying the KeelAs with the real ship, we begin buildingthe POF model by laying the keel. If themodel is built on a large scale, it may bemade of two or more pieces of straightwood jointed and glued together on a perfectlyflat surface. It should be made a fewinches longer at both ends than the lengthshown on the plans so that it will be held ina jig, which will be explained later.Add the SternpostThe sternpost is the piece of woodmounted at the aftermost end of the keeland is the place for holding the rudder.From the plans, determine the length ofthe sternpost, and use a piece the samethickness as the keel. It is a good idea todrill a couple of small holes up from thebottom of the keel into the sternpost, andthen dowel them together.Add the StemFrom the plans, lay out the shape of thestem (or cutwater), which is located at thefront of the vessel, usually rising in acurved shape just below the projection ofthe bowsprit. Cut out this piece of wood,which is the same thickness as the keel,and then glue and dowel it in place.Build the DeadwoodThe deadwood appears at the bow andstern area of the keel assembly. It pro-www.modelshipbuilder.com 4

The MSB Journal—Volume II Issue IIIvides an extension of the keel to whichother timbers, particularlyplanking, is attached. It should be made ofseveral pieces of wood the same thicknessas the keel and fitted snugly together andglued in place. Make a few scarf joints inthe pieces of wood to simulate the constructionfound in the actual ship. It is recommendedhere, too, that these pieces bedoweled inplace to the stem and sternpost and toeach other to give the entire assembly a lotof strength.Cut the RabbetThe exterior planking will be resting inthe keel, stem, sternpost, and deadwoodareas at varying angles. The first strake ofplanking, called the garboard strake, will fitdirectly into a groove cut into these areas.Theobject of cutting the rabbet is to allow thegarboard strake to fit snugly into thisgroove. The width of the rabbet that is cutwill depend on the thickness of the plankingmaterial and also on the angles atwhich the planking intersects the rabbet. Abearding line is usually found on mostplans; this line represents the innermostextension of the rabbet. Note that at thestern near the keel, the bearding line isquite wide and rounded. This distancerepresents the area upon which the exteriorplanking will rest, tapering smoothlytoward the sternpost. Using a steel rulerand an X-Acto knife, remove all the unwantedmaterial, remembering to adjustthe angle of the cut as you approach eitherend of the model. Use miniature files toclean out the rabbet as you cut.Mark the Frame LocationsOne method of determining where toplace your frames is called “room-andspace.”There are other methods, but thisis the one described here for illustrationpurposes. In the room-and-space method,it is assume that the width of one frame isequal to the distance between two frames.For example, if your frame width will be¼”, then the vacant space on either side ofthis frame will also be ¼”. In other words,there will be a frame, a ¼-inch space, aframe, a ¼-inch space, and so forth.Examine the profile view of the ship onyour plans. Note the sectionlines already drawn on the plans will correspondto the location of bulkheads, especiallyif you are using plans designed for aPOB model. Note also that there is a“center” section line located about amidshipsin the plan. Usually, the plans can beeasily converted to POF plans by addingadditional “bulkhead” lines. Measure thedistance between these sectionlines to determine how many additionallines should be drawn to make each ofthem equidistant from each other, startingfrom the center section line. For the purposesof illustration, it is assumed that ¼”intervals will work. Mark your additionalsection lines all across your plans, makingall of themparallel to each other and perpendicular tothe load waterline. It helps to color in theframes will a colored pencil for distinguishthem from the spaces. Then transfer thesesame lines precisely in the same locationsto your keel assembly, again distinguishingthe frame locations from the spaces.Cut Out Frame Spaces on KeelThe full frames (as opposed to cantframes) will be located between the twodeadwood areas of the keel. The fullframes will rest in notches cut out for eachof them, and they will be perfectly perpendicularto the keel assembly when placed inthe notches. Now cut out these notches tothe depth you have determined in loftingthe frames, which will end just above yourrabbet.www.modelshipbuilder.com 5

The MSB Journal—Volume II Issue IIIMake the KeelsonThe keelson is the internal keel that is mounted immediately above the main keel onthe upper edges of the bases of the frames. It secures all the full frames in place and alsoprovides extra strength to the main keel.The Keel Assembly FinishedSo far, the keep assembly looks like this:Build a Framing JigFig.1To hold the keel assembly and the frames it is necessary to build a compound jig. Thebase of the jig, sometimes called the clamping jig, holds the keel assembly in place, ensuringthat it cannot move in any direction. It consists of a perfectly flat board a little longerthan the length of the keel assembly. Angle irons or other L-shaped material is attachedto the board at the stem and stern, and small piece of wood are placed along the edge ofthe keel to prevent the possibility of the keel warping out of shape. It is a good idea tomark the location of all frames on the base of this jig. This part of the jig is shown in Fig.2.Fig.2www.modelshipbuilder.com 6

The MSB Journal—Volume II Issue IIIA second part of the same jig is called the alignment jig. It consists of a piece of plywoodor Masonite cut out to the exact shape of the hull at the load waterline, with notches cutout for the precise location of every frame at the same load waterline. It is secured to theclamping jig below it with blocks of wood spaced so that it meets the load waterline precisely.Some builders use nuts and bolts for the spacing distance. The frame markings ofthis part of the jig should be directly aligned above the frame markings of the clamping jig.The final framing jig is shown below.Fig.3Make the FramesAs mentioned earlier, it is assumed that you have lofted all the required frames, andthat you are now ready to build them.There are several ways to build frames, some more sophisticated than others. Somemodelers will cut them from a solid piece of plywood; others will make them from severalpieces of wood glued and doweled together, as shown below, with the grain of each pieceof wood following the curve of the frame (see Fig. 4). Still others model them out of doublelayers of wood along with chock blocks between joints, just as they did in real ships.Fig.4www.modelshipbuilder.com 7

The MSB Journal—Volume II Issue IIIIf you have lofted your frames properly, you have also determined the bevel requiredfor each frame. Now is the time to form the bevel either by trimming with knives or bysanding it. It is critical that the bevel be made precisely. Just like in plank-on-bulkheadmodels, the bevel is the resting place for the exterior planking.Temporarily install each frame in its location on your framing jig, aligning it perfectlywithin all the notches in your jig. Using a long length ofyour exterior planking material, place it along several or you frames to check your beveljust as you did for POB models.The cant frames at the bow and stern deadwood areas are different from the rest inthat they are made in two pieces, with one half attached to each side of the deadwood atthe places you’ve marked. They, too, require a bevel; in fact, the bevels at these pointswill be more extreme than at other locations, so be careful that they are accurate.Install the KeelsonOnce all the center frames are completed – those frames not situated on deadwood –you may install the keelson, which rests directly atop those frames. It is recommendedthat you glue and dowel the keelson onto each frame.A Great Example of a POF in ProgressIf you have followed these instructions for building a POF, your model should look similarto the outstanding example shown below:Fig.5Fig.6What’s Next?After you have completed framing your POF model, the remainder of the build is handledjust like another other model. The exterior of the hull is now planked. A very big advantageof the POF model is that the planking will be much more accurate that any othermethod used, because the frames will be spaced much closer together than a POB hull,thus eliminating the need for a second layer of planking material. It is unlikely that therewill be bulges or inaccuracies you commonly find in POB models. Each plank, of course,can be trenailed precisely to each frame, just as the real ship waswww.modelshipbuilder.com 8

The MSB Journal—Volume II Issue IIItrenailed, and they have a solid backing to connect to as well. Your planking will be finishedin the exact same way as the real ship.Another big advantage to building the POF hull is that you can build as much of the interiorof the hull as you like. You are no longer hindered from doing so, because the entireinterior is still wide open. You can add other decks, if you like. You are only limited bydetails you see on your plans. Actually, if you do further research, you may be able tobuild the entire interior exactly like the original ship. If you do this, you may also want toleave several of the exterior planks off the ship to show your handiwork. There’s nothinglike the feeling you experience when you successfully complete a POF model with your ownhands.The Hahn Method of POFAn important addendum to this style of hull construction is the Hahn method, namedafter Harold Hahn, a prominent shipmodeler who developed the method. Briefly, hismethod lengthens and extends all frames to the same plane such that the tops edges of allframes are parallel to the keel. He then constructs a framing jig that connects all the topedges of these frames so that the frames correspond to the shape of the load waterline.Then, the frame is inverted so that it now becomes the base of the jig, and each frame isinserted into the base upside down and attached to the keel, which is now located at thetop.The biggest advantage of the Hahn method of POF construction is that it guaranteesthat the shape of hull will be perfectly symmetrical at all points. It also makes the modelmuch easier to plank, because the model is always upside down as the planking progresses.A couple of pictures of an outstanding model in progress will serve to illustratethe process:Fig.7Fig.8A disadvantage of the Hahn method is the fact that there is a considerable wastage ofwood. After all framing and planking is completed, the frames are sawn off at the raillevel, which means the portions of the wood frames between the rail and the edge of thejig are wasted material that is simply scrapped because it’s not much good for anythingelse.www.modelshipbuilder.com 9

The MSB Journal—Volume II Issue IIIThe Next ArticleThe next part to this series of articles will briefly cover Admiralty models.Further ReadingFor further information on reading and interpreting plans, lofting your own plans, andbuilding plank-on-frame models, the following books are highly recommended:1. Plank-on-Frame <strong>Model</strong>s, Volume 1 by Harold Underhill.2. <strong>Ship</strong> <strong>Model</strong>ing from Scratch by Edwin B. Leaf.3. Historic <strong>Ship</strong> <strong>Model</strong>s by Wolfram zu MondfeldCreditsFig. 1 -- from <strong>Ship</strong> <strong>Model</strong>ing from Scratch by Edwin B. Leaf, p. 51.Fig. 2 -- from <strong>Ship</strong> <strong>Model</strong>ing from Scratch by Edwin B. Leaf, p. 55.Figs. 3 & 4 -- courtesy of the author.Figs. 5 & 6 – Brigantine Leon, courtesy of Keith Harrison of www.modelshipworld.comFigs. 7 & 8 – Frigate Confederacy, courtesy of Eric Tilley of www.modelshipworld.comBooks on <strong>Model</strong>ingGet them today from The MSB StoreAlong with many other great publicationswww.modelshipbuilder.com 10

The MSB Journal—Volume II Issue IIIMSB Book NookCaptain Cook’sEndeavour(Revised Edition)By Karl MarquardtPrice: $36.95Eligible for Free <strong>Ship</strong>pingon orders over $25.00at our Amazon Book StoreThe Endeavour, made eternally famous by Captain Cook's first voyage in her in 1768-71, was originallythe collier Earl of Pembroke and was chosen by Cook for his voyage because of her strong construction.She was purchased by the Royal Navy at Whitby and then converted to an exploration shipat Deptford. After her voyage she was sold out of service in 1775, and finally condemned sometimein the 1790s.This revised edition features accurate, visually exciting and totally comprehensive drawings. In additionto these, a colour representation of Endeavour on the jacket provides a useful painting guide, onthe back of which is a beautifully folded large scale plan of the ship.The 'Anatomy of the <strong>Ship</strong>' series aims to provide the finest documentation of individual ships andship types ever published. What makes the series unique is a complete set of superbly executed linedrawings, both the conventional type of plan as well as explanatory views, with fully descriptive keys.These are supported by technical details and a record of the ship's service history.Karl Heinz Marquardt is an internationally known ship modeller and has spent a lifetime researchingthe era of the sailing ship. He is an accomplished draughtsmen and has illustrated a number of highlypraised maritime books.With over 200 perspective and 3-view drawings, accompanied by in-depth descriptive keys.Get your Copy HereIn the Anatomy of a <strong>Ship</strong> Sectionwww.modelshipbuilder.com 11

The MSB Journal—Volume II Issue IIIThe Matthew ProjectPart IXBulwark PlankingPlanking the bulwarks begins with thescuppers shown on the photo of the Matthew.The Matthew built inEngland simply left off the first plank abovethe wales at midship. We will begin bymarking out at plank at every stanchionand dividing the width of the plank in half.Using a drum sander each scupper issanded out leaving nice rounded corners.www.modelshipbuilder.com 12

The MSB Journal—Volume II Issue IIIOnce all the scuppers are sanded into theplank it is positioned on the hull at mid shipand the bulkwards are planked to the caprail.Looking at the deck layout we will need toinstall a few items before we can start layingdeck planking. Starting at the bow thefirst pieces will be the platform the capstansits on. The deck is not level, it has a sheerfrom the bow to the stern, if the capstanplatform were laid on the deck it wouldhave a slant as shown in the first drawing.In the second drawing the capstan platformis wedged shaped allowing the capstan tosit vertical. On the model a wedgedWith the planking complete to the cap railwe will stop at this point and move on tolaying out the main deck. There are variousmolding pieces, which fit at the quarter andforecastle where the deck meets the side ofthe hull. In order to install these decks themain deck has to be laid down first.shaped platform is used. Exactly how theplatform is made will be up to you as thebuilder. In the photo it appears the platformis higher in the middle then tapers tothe front and back. This platform wouldwww.modelshipbuilder.com 13

The MSB Journal—Volume II Issue IIIBuilding the rest of the capstan began withturning the spindle to the measurementshave been made of two or three heavy timbersrather than one piece.It’s a simple job to make the platform. Cuta piece from the ¼ thick sheet material tothe size indicated on the plans. Cut agrove along the two sides to the correctdepth then clamp the piece in a vice. Proceedto sand down the surface until itseven with the groves on either side.on the plans. Two circles were cut fromsheet stock and black paper was gluedaround the edges tosimulate the banding.Cutting the circlesfor the spindleand the head peacesis a simple job offinding an exact sizewasher and using itas a guide. Using adouble sided tape stick the washer to apiece of wood. With a single edge razorblade continue to nip away the wood untilyou have a nice circle.www.modelshipbuilder.com 14

The MSB Journal—Volume II Issue IIIThe three head piece you just cut nowhave to be split for the bars. Using a pieceof two sided tape stick the end of a bar tothe center of the circle piece. With a sharprazor blade cut on both sides of the barproducing two semi circle pieces. Do thiswith all three circle pieces. Mark out thecenter of the spindle circle and place thebar in the center of the circle. Glue the twosemi circles on both sides of the bar. Beforethe glue sets remove the bar so itdoes not end up getting glued to the circles.Do the same thing with all three circlesbeing sure you rotate the location ofeach bar. The final piece is the drum cap.With everything glued in place sand thedrum smooth.You can glue the capstan together but atthis time do not glue it to its base. If youglue the capstan to its base it will be in theway of planking the deck.www.modelshipbuilder.com 15

The MSB Journal—Volume II Issue IIILooking at the capstan on the Matthewthere are thin boards called whelps attachedaround the spindle. You can eitherscribe lines in the spindle and cut a smallnotch at the base or add the thin boardsaround the spindle.planking. In actual construction the coamingsrest on the deck beams and carlingswith the ends of the deck planking buttingagainst the sides of the coamings.The next photo is standing on deck lookingat the hatch. The white arrow points to thecoaming, the yellow arrow is the deckbeam and the blue arrow is the carling.The next item is a hatch, which will take abit more work to create than the simpleplatform. Before building the hatch coaming,lets first examine a real hatch and seehow they are built.At the corners coamings have a lap jointwhich is fastened with a long spike whichgoes down through both coamings and intothe beam below. The white arrow points tothe head of this spike. The height of thecoamings will vary from ship to ship andfrom builder to builder. An average is 8 to14 inches.In this photo the view is from inside of thehold looking up through a hatch. A commonerror model builders will make is placethe hatch coamings on top of the deckThe Matthew hatch has a separate piece onthe top edge forming an inset for the hatchcovers. There is a piece fastened to theside of the coaming with a slit cut in onewww.modelshipbuilder.com 16

The MSB Journal—Volume II Issue IIIend where a board is slid through to holdthe hatch cover boards in place.Hatches on the Matthew appear to beabout 18 to 24 inches, which seems to be alittle high for a coaming, on the model thecoamings are 12 inches. There is no rightor wrong way, so if you want to make yourcoamings 12 inches or 20 inches the choiceis up to you. If you do decide to go with ahigher coaming you will not be able tooverlap the corners. Corners on the highercoamings will either have to fit at a 45-degree angle or butt together.The following steps are using a piece of ¼x 1/8 inch material. Each corner is cutwith an overlapping joint and then twosides are glued using a square block corner. After you have a set of two sideswww.modelshipbuilder.com 17

The MSB Journal—Volume II Issue IIIglued up, glue the two pieces together toglued in place. Making the mast partner isform a complete coaming. Once all thesides are glued together place a 1/16square frame around the top to form aledged for the hatch cover boards.a simple job of cutting a square to the sizeindicated on the plans and cutting a hole inits center for the mast. Position the partnerso the mast hole is tight to the forwardCarlings were added to between the bulkheadsfor the hatch coamings to sit on andadd a surface along the hatch for theplanking.Next in line are the mast partners. First thecenter profile piece is cut away so the mastcan drop below the deck. A piece of dowelis positioned and two side supports arebulkhead and not centered between thebulkheads.www.modelshipbuilder.com 18

The MSB Journal—Volume II Issue IIIThree pin rails are needed of slightly different sizes so we begin by cutting to length sixpieces of square stock and clamping them together. Draw a line for the center of thecurved section. The series of photos show how the rail is assembled and glued to the faceof the bulkhead.www.modelshipbuilder.com 19

The MSB Journal—Volume II Issue IIIAt the break of the quarter deck the Matthewleaves the middle section open with acabin on either side. It was a commonpractice to completely close off the break ofthe quarter deck with a bulkhead. As amodel shipwright you can choose either wayand either would be correct. My thoughtwas to close off the end of the quarter deckwith a bulkhead to make a dry cabin area.This was an exploration ship and was intendedto sail on the open ocean. A drycabin would be quite welcome by the crew.Bulkheads sat on what was called a sill. Thissill had the same purpose of coamingsaround hatches. They sealed the hatch or inthis case the bulkhead from water seepingin. In the B&W photo you can see the sillbeing pointed to by the blue arrows. If youintend on building a bulkhead start withadding a landing for the main deck planking,This was done by gluing two pieces ofwood to the outer face of the bulkheadshown by the white arrow. A sill sits directlyon the deck beam and the deck plankingbutts against the side of the sill andcaulked between the decking and sill. Lookingat the photo you can see how the use ofa sill would prevent water from getting intothe cabin area, as apposed to the bulkheadsitting directly on the deck.There are a few other items to add to the deck but they will be added after the planking isfinished.www.modelshipbuilder.com 20

The MSB Journal—Volume II Issue IIIA TYPICAL 74 FRENCH GUNSHIPThis article is divided in 3 parts:1. Use of exotic wood for their grain and color2. Getting over basic tooling3. Ultimate lightingPart I Use of exotics woods for their grains and colorThis scale model above is realised at 1/48 scale. It is ready for masting and rigging. Themodel follows a previous 74 gunship built at 1/192 scale. Third model will also be built ofthe same 74 gunship but this time at 1/24 scale. The figurehead represents a Minerva withan antique hat who is pulling the sword out of the scabbard. The greater the scale, theeasier it is to work, and you can render the details with much greater precision.Scale 1/192 Scale 1/48www.modelshipbuilder.com 21

The MSB Journal—Volume II Issue IIIThere will be three 74 gunship built, however, different woods and different techniques willbe used for their construction. The references used to build this model ship are 4 volumesof Jean Boudriot. These volumes are not a practicum, but do explains with great detail theconstruction of the 74 gunship. When you have so much information about the same ship,you can produce a high quality model many details and you can learn so much about theconstruction and the history of the French naval construction.I began this model 1½ year ago. I like to try different wood color combinations. Matchingcolors is not easy to get harmonious results. On the other end, I could not do a monochromemodel entirely realised in one kind of wood only. I do not want to use paint or dyeon the wood. For the finishing, Danish teck oil is applied. The use of exotics woods and oilhelps to give an overall appearance a look of a model ship built 100 years ago... and formy taste, this is the look I am trying to achieve.For the rigging, I have 1 kg roll of linen. With this roll I can turn all the necessary rigging IExample showing the composition of a cotton ropeneed. To increase the diameter of a line, I simply add more linen threads on the rope machine.To get the desired color effect on the standing rigging, I use a dye powder called“Acajoutine”. I mix brown and red dyes together to obtain a brown reddish color to imitatethe tar used in that period.Although pearwood is a fruit wood, it could be considered one of the less dense of the exoticswoods. It is exceptionally easy to work for this category of wood. Boxwood workswww.modelshipbuilder.com 22

The MSB Journal—Volume II Issue IIIgreat for sculpture and smalls turnings. Ebonyis excellent for the black parts, but it isnot easy to bend when it is too thick, itmust be laminated. Bubinga, when carefullychosen, works great for the framing, itlooks like wood grain at the good scale. Italso gives an older look to the scale model.Bocote imitates old oak at this scale. Forthe mast, goncalo alves gives a nice effect.I have also tried bloodwood for the redparts but it is hard to work.Part II Getting over basic toolingIn a first period, I built model ships for 15years. I believe that it is a normal progressionover the years to upgrade toolingwhen you want to save time and to work ina better and easier way.At the beginning, an Xacto knife was used.One day, I discovered scalpel blade. Thisblade is thinner than Xacto blade, it canbreak easily but it cuts so much better.When you working with a scalpel handle fora long period of time, you can get crampsin your hands. So, the next step was tobuy another scalpel handle covered withacrylic which makes it much easier to workwith.Here is another example with sanding. Atfirst, I bought a disk and belt benchsander. When you place a block of wood onthe table, you can sand it perpendicular tothe table. Then, one day I wanted to do thesame thing with a small steel block. Youcan achieve it, but it takes a long to do. Ifyou apply too much pressure, the block willnot have perpendiculars sides. The nextstep is to buy a better sander, or even better,you can build one as I did. The knifebelt sander works very fast and can bevery precise for wood and as well formetal.Let’s know see the use of a lathe. Watchmaker’slathe is not made for us. A minilathe is more appropriate and versatile.With this kind of lathe, you can turn a passof .001” at a time. Turning a big part withthis lathe can be a very long and tedioustask. The next step is a tool room lathe.This lathe is not expensive as you maythink at first. I bought it used and I paid$2000 about 5 years ago. This lathe caneasily take .01” by pass. This means, youcan produce a piece 10 times faster.www.modelshipbuilder.com 23

The MSB Journal—Volume II Issue IIIMetal lathe tools accessories can be veryexpensive. As an example, if you buy a 3jaws chuck with a precision of .001”, youcould pay $150 depending of the size. Ifyou buy one with a precision of .0001”, youwould have to add a 0 to the price. Again,another option is to build the tools youneed.When I had badly fractured my right indexfinger, I had stopped model ship buildingfor a while. I did not have enough dexterityto make knots for the rigging. Instead Ichanged to tools building. During this secondperiod, I wanted to be able to buildanything I wanted. To have a lathe was thefirst goal; to equip it is the second, becausethere is always a missing tool tobuild a more complex tool. For the metal, 3categories of tools and accessories areneeded: lathe, milling and grinding. I wentthrough that spiral for a period of 10 years.1½ year ago, I did not have any more toolsto build. I now had a options to do thework I wanted. I like to use my hands andmy brain to create something so, I turnedonce again to model ship building.Many tools we use already exist in otherprofessions. Dentistry can offer us a widevariety of dental burs perfectly suited forour needs. The jewellery world is a veryhelpful world. It is nice to say: “If you buya tool, buy a good one”. This is not as easyas it is sounds. When we begin to buildmodel ships, we are not aware of the widerange of tool availability on the market. Sowe buy the tool we know at this momentand we use it as long as wedo not need any better.The first rotary tool I boughtwas a Dremel. I had manyyears of satisfaction with it.But this tool is heavy, notvery strong and is very noisyto use. Foredoom shaft wasthe next step with differentheads through the times. TheForedom’s shaft decreases thedexterity of the user. To eliminatethis shaft, we can go onestep further; Gesswein electricrotary handpiece. The speedturns from 0to 50,000turns perminute. Themotor is veryquiet. Theprecision andthe dexterityoffered bythis tool areoutstanding.One lastpoint, when Iwork, thereis no othertool on thetable thanthose I needat this moment.I wantto have asless possible tools on the table. The cleaneris the place, the easier it is to work, andthe easier it is to find the tool when youneed it. The little tools that I use regularlyare placed in the tray system near by thetable.www.modelshipbuilder.com 24

The MSB Journal—Volume II Issue IIIPart III Ultimate LightingLighting is an under-estimated subject. To clearly see an object, 2 things must be considered;accurate vision and lighting. When I need to work on small objects, I use a headmagnifier with interchangeable lens. It can be use with or without eye glasses. For thesculptures and smalls detailed works, I use a surgical loupe. If I need to check a very smalldetail, or if I want to check a first part of a series, I use a gemmology microscope.A well adapted lighting greatly facilitates the work and reduces the ocular tiredness. Basiclighting is done with neon fixtures on the ceiling. Incandescent light must be avoided. Agood neon quality produces a good color rendition. For the close range work, a Dazor jeweller’sbench top light with 3 neons is the best. Finally, for the small details, I bought surgerylights on eBay. With this type of lamp, there will be no hidden details and the colorrendition will be very close to the reality. Dentist’s lights are not as powerful. Their colorrendition is much less accurate. I do not use anymore halogen lamp because it radiates toomuch heat and color rendition is too yellow. These types of lamps are fixed to the ceilingand it is possible to adjust it in almost any position. From all these previous lamps, if I hadonly one to choose, I would pick the one I use the most often; the Dazor’s jewellery lamp.You’ll soon be able to see more pictures of these models at the <strong>Model</strong> <strong>Ship</strong> <strong>Builder</strong> website in themodel builders section.www.modelshipbuilder.com 25

The MSB Journal—Volume II Issue IIIWhat <strong>Ship</strong> Is This?Last IssueHMS Ark RoyalThis is the fifth vessel to bear theproud name. Ark Royal was builtby Swan Hunters <strong>Ship</strong> <strong>Builder</strong>s'yard at Wallsend in December1978 and launched by Her MajestyQueen Elizabeth the QueenMother. HMS Ark Royal was acceptedinto service on 1 July1985.www.modelshipbuilder.com 26

The MSB Journal—Volume II Issue IIISPLICE THE MAINBRACE!by Gene BodnarIn pirate movies, in books, in bars, in today’s popular culture, you hear it frequently:“Splice the mainbrace!” It’s time for a round of drinks. The term originates, of course,from the days of the wooden sailing ships. It was an order to perform a difficult and dangerousrepair job aboard a sailing warship, frequently right during the engagement thatcaused its loss.As every ship modeler knows, braces are the lines that control the angle of the yards.The mainbrace, especially on a first-rater, was the heaviest rope of the running rigging, upto five inches in diameter. It was common practice during a naval battle to aim for themainbrace; if it was shot away, the ship would stayon the same tack, could not be steered at all, andbecame a much easier target of destruction for theadversary. Therefore, if the main- brace was severed,it had to be repaired immediately if the vesselexpected to survive. Splicing in a large run ofrope required strenuous effort by the ship’s bestAble Seamen under the supervision of the Bosun,and it was a task upon which the ship’s safety depended.Indeed, splicing the mainbrace was so difficultthat, when the task was completed successfully, itwarranted the issue of an additional ration of rumto the <strong>Ship</strong>’s Company. It was customary for theBosun to always get a sip from the ration of eachof the men he had selected for the task.Pulling up the Port Main BraceEventually, the order to “Splice the mainbrace!” came to mean that the crew would receivean extra ration of rum on special occasions, especially after victory in battle or thechange of a monarch or a royal birth.In recent times, the issue to splice the mainbrace was heavily restricted. For example,the Royal Navy allowed only the Queen or the Admiralty Board to issue such an order. TheCanadian Navy allowed the Queen, the Governor General, or the Chief of the Defense Staffto issue the order.Nowadays, the order is somewhat more freely given than it once was. As recently as2002, the Queen issued the order after merely reviewing the fleet off Portsmouth.In common usage, the phrase refers to an invitation to have a drink after a hard day,or even not so hard a day.www.modelshipbuilder.com 27

The MSB Journal—Volume II Issue IIIOnline Discussion ForumsIn this issue we continue on with our list of discussion forums. These are online forumswhere model builders can connect to discuss all aspects of model building. They are listedin no particular order of importance as all have something unique to offer you the modeler.If you know of a good discussion forum you think others would like to know about, by allmeans let us know by sending us an email at msbjournal@modelshipbuilder.com. Eventually,we’ll get them listed in this section.Admiralty Boardhttp://admiraltyboard.imsaw.com/index.phpThe Admiralty Board is a discussion forum which only recently started up. I’m not surewhat direction it’s going to go in, but from my discussions with the owner Andrew Gilmourit certainly has some promise. What direction do you think modeling is heading? Join in thediscussion.<strong>Model</strong> <strong>Ship</strong> Worldhttp://www.modelshipworld.comA very active and friendly discussion forum. There are also a few online projects that maybe of interest to those of you who either scratch build or want to learn how to scratchbuild. At present: The USS Syren (POB), The HMS Triton (section build and full build)(POF) and the 100 Gun Royal Albert (POF, POB and Admiralty).Warriorgrouphttp://groups.yahoo.com/group/WarriorgroupThis discussion group is primarily focused on scratch building 17th and 18th centurywooden ship models using plank on frame methodology. The membership is composed ofmodelers at all levels of expertise. Discussion of all topics related to ship modeling are encouraged,and everyone is welcome to comment.www.modelshipbuilder.com 28

The MSB Journal—Volume II Issue IIIUsing Polymer Clay for Your <strong>Ship</strong> <strong>Model</strong> Ornamentationby Chuck Passarocpassaro@mindspring.netYou have probably marvelled at the carvingskills of 18th century masters when visitinga naval museum. I am sure you have admiredthe intricately carved details of a figurehead.Some ship models have anabundance of finely carved and elegantscroll work. Sometimes these elementsare gilded or painted or left in their naturalstate. One of the most intimidating aspectsof ship modeling is how to approachcarving these details.One alternative mightbe to sculpt these detailsrather than carvethem. Sculpting a figureheadfrom polymerclay affords you theopportunity to continuallytweak your workbefore curing it. Whencarving out of wood, amistake can be much more difficult to fix.It usually requires that you start overrather than remedy the situation. Woodcan easily split and crack and adding additionalwood material to correct a deepgauge or misplaced cut would certainlyshow up on an unpainted figurehead.I recommend experimenting with somePolymer clay like SCULPEY or FIMO. Theseclays come in a variety of colors that canbe mixed. Sculpey also comes in metalliccolors like gold and bronze and after beingbaked the ornamentation would not needto be painted. The gilded effect is quitenice and the most intricate details are notlost by painting them. In the case ofSculpey there are several grades of claythat have a different sculpting texture andconsistency. You should choose the rightclay for your application on the ship model.I regularly use Super Sculpey or SculpeyIII. Super Sculpey comes in a limited colorpalette but is great to use when very finedetailing is required. This clay is baked inthe oven until it hardens. After it coolswww.modelshipbuilder.com 29

The MSB Journal—Volume II Issue IIIdown the clay can be sanded, drilled andcarved. It can be painted and acceptsstain as well.SculpeyIII – Comes in dozens of colorsincluding metallic. Is less brittle after baking.However it captures less fine detail.Remains somewhat flexible after baking.Super Sculpey and Super Sculpey Firm- Much better for fine detailing. More brittleafter baking. Only comes in Flesh tone.But easily stained. The firm type onlycomes in dark green and is also brittle ifbaked to long or very thin pieces are made.Can be mixed with SculpeyIII to make itmore flexible and easier to work with.The tools needed to sculpt the ornamentationand figureheads for a model are nodifferent than any other sculpting tools youmight find in an art store. They just needto be smaller. Some folks will use dentaltools to good effect on small miniaturesculptures. Dentil picks with varying sizedtips can be bought on EBAY very cheaply.Overall the tools are very inexpensive andmany can be home made. Wooden dowelscan be tapered and shaped to suit. Shownbelow are some typical tools. Those withthe different shaped open loops are used toremove clay from your piece rather thanpush it around and texture the clay’s surface.Some people prefer softer clay to workwith and there is a clay softener availablefrom Sculpey. Just a drop or twoon the clay while kneading itwith your fingers will soften it upconsiderably. Softer clay will nothold details as well as firmerclay. If the clay begins to getsticky and difficult to work withsimply dipping your tools into water willtake care of it. Some sculpter’s prefer touse corn starch much like a baker woulduse to prevent the clay from sticking toyour tools. This will be important shouldyou decide to create a push mold. You canquickly duplicate your carved pieces isingone. Gun port wreaths and scrollwork canbe precisely molded and dozens of copiesproduced.To produce the push mold just prepare apiece of SculpeyIII a little larger andthicker than the piece to be duplicated.Coat the original with corn starch or brushit down with water to prevent sticking. Thesame should be done with the surface ofthe Sculpey you will be pressing the originalinto. Press the original into the clayfirmly and then remove it. Be careful notwww.modelshipbuilder.com 30

The MSB Journal—Volume II Issue IIIto distort the unbaked mold while removing the master. Bake the mold to cure it. Justlike anything else Sculpey can burn if baked for too long so adjust the temperature andtime according to the directions given by the manufacturer. With the mold completed it isa snap to create multiple copies of your original. Coat the mold as mentioned above withcorn starch or water and then push some uncured Sculpey into it. Remove the Sculpeycarefully and you have a perfectly formed duplicate. Trim off any excess clay and bake it.This is the technique I used to create thequarter badges for my model of the US BrigSyren 1803. It was easier to fabricate theoriginal with mixed media. Wood, wire,clay and whatever else I could find lyingaround was used to make the mastershown in the photo provided. It doesn’tlook pretty because of the colors and textureson the original piece. So I took thatmaster and created a push mold. The photographon the right side shows the moldedbadge after it was stained several times. Iused the same wood stain that was used onthe hull planking. Super Sculpey was used. Its pink, fleshy color was a great undercoatand it took the stain pretty well. You will probably need to use many coats of stain to getthe deeper shades you desire. The window panes were painted black afterwards. You cansee the color does match the surrounding planking and the surface of the badge differentthan if you painted itIt would also be good to point out that polymer clay can be baked more than once. Whencreating larger or more complex pieces it is best to complete it a portion at a time. Forexample, if you were creating a figurehead you could sculpt the torso first and then bakeit. This will prevent the torso from being damaged or altered. Then you can add the headand arms to the piece afterwards because the torso will now act as a strong foundation tobuild upon. Then bake it again. Then add some more details and bake it yet again. Thisstepped approach will give you some flexibility. The completed sections can still be sandedand carved if they need to be worked on. Preparing the figurehead in increments this waywill alleviate the need for any wire framing to make it structurally stronger before bakingit.I have included some pictures of the Syren figurehead for my model illustrating this technique.The torso was actually rough shaped on the stem of the model. It was removedfrom the stem and then baked. I repositioned it back on the stem and the head wasadded. I used some clay softener on the joint between the cured torso and the uncuredwww.modelshipbuilder.com 31

The MSB Journal—Volume II Issue IIIhead. I applied it with a paint brush which made iteasier to blend the two pieces together. Then Ibaked it again. The same methods were used toadd the arms and then finally the mermaid’s tail.I hope after reading this introduction to polymerclay you might give it a try on your own shipmodel. There are a large number of websites andforums devoted to sculpting with polymer clay. Asimple search on Google for the keywords“polymer clay tips and techniques” or “sculptingminiatures with Polymer clay” will yield hundredsof advanced techniques. Polymer clay is a veryversatile and acceptable material for many of ourship modeling needs.www.modelshipbuilder.com 32

The MSB Journal—Volume II Issue IIIBadges:Heraldry of Canadian Naval <strong>Ship</strong>sHMCS BRANDONDescriptionVert a seahorse Argent gorged of a ducal coronet and holding a trident Or.SignificanceThe horse from the unofficial symbol for the City of Brandon appears as a seahorse in the ship's badge.Around its neck is a ducal coronet recalling the Duke of Brandon for whom the city was named. The seahorsealso holds a trident recalling the ship's defensive capability.MottoVires acquires eundo (She acquires strength through progress)ColorsGreen and WhiteBATTLE HONORSThe Second World WarATLANTIC, 1941-45Gulf of St. Lawrence, 1944.Source: readyayeready.comwww.modelshipbuilder.com 33

The MSB Journal—Volume II Issue IIIContributors PicturesHere’s an update from Mike Pendlebury on his current project. Looks like he’s about towrap things up soon.The next major items to be built were the deck air boxes that are under the side benches.These were beech blocks covered with lime sheeting and then had the slats for the seatsfitted on top and incorporated the anchor cable locker at the front on the Port side. Themast tabernacle was also fabricated and pinned to the deck. The other deck fitting is thecover over the drop keel for when it's raised out of the way on the slipway in the boathouse.The rigging for the sails was next, all the rigging was made to work in the correct mannerto allow the mast to be folded down .The working shackles shown are only 6mm long asare the working brass pulleys.www.modelshipbuilder.com 34

The MSB Journal—Volume II Issue IIIwww.modelshipbuilder.com 35

The MSB Journal—Volume II Issue IIIThe above picture was sent in by Chip Reahard. This was Chip’s first modeling projectand it included the display case. Very nice job Chip! I only wish my Phantom hadmade it that far! You certainly have more patience that I do! :-) Currently he’s workingon the HMS Bounty Launch. I look forward to seeing that one as well!www.modelshipbuilder.com 36

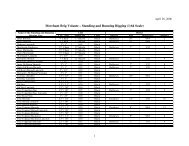

The MSB Journal—Volume II Issue IIIParts of a Sail by Gene Bodnar1 2 34 521 Curve of the edge of a sail, either inwardsor outwards22 Canvas made from flax or cotton67 824 Reinforcing strip of canvas running horizontallyacross a square sail, halfwaybetween the close reef and the foot910 1125 Strip of canvas reinforcing the belly of asail12 1314 15Down16 1718 19 202122 23 24251 Overlapping edges of two pieces of canvassewn together2 Small strengthening stripes of canvas atthe corners of a gaff sail3 Additional piece of canvas laced to thebottom of a sail in moderate weather togive it more area5 Lower corner of a square sail8 Rope sewn all the way around the edgeof a sail to prevent the canvas fromtearingAcross4 Lee edge of a fore-and-aft sail6 Uppermost corner of a gaff sail7 Small bulge in a furled sail8 Middle part of a sail9 Addition piece of canvas laced onto the lower edge of abonnet11 Small piece of canvas sewn into the middle of a sail,near the head, with an eyelet in it to take a line12 Sliding ring of wood or metal which attaches the edge ofa fore-and-aft sail to the mast14 Any sail that widens towards its foot16 Area of a sail between the head and any of the reefbands10 Small lines, like hoops, sewn to bonnetsand drablers in order to secure them tothe sail above13 Extra line sewn on the seam of a sailgiving addition strength15 Rope hanging from the mast-headpassed around the truss supporting ayard to keep it up19 Short length of rope used to lash theupper corners of a square sail to theyard-arm20 Broad hem on the edge of a sail, tostrengthen the part sewn to the boltrope22 Slack part of a sail which hangs downwhen leech lines are hauled up23 The upper part of a sail17 Forward upper end of a sail set on a boom18 Fitting consisting of three or four metal rings, used atthe clew of a sail to take the bolt-ropes, sheets andother ropeswww.modelshipbuilder.com 37

The MSB Journal—Volume II Issue IIIParts of a Sail AnswersF C BL A F T E R L E E C H OP E A K I L NT W R I N K L E B U N TS K W O EE D R A B L E R L TL A R G L U TA M A S T H O O P RS I I G O R I N GK D E P AE R E E F N O C K E VR S E AS P E C T A C L E S T LA I R O A C H LR T B IS A I L C L O T H B E L L Y B A N DL N H E I EA G S T R A I N B A N DB D Gwww.modelshipbuilder.com 38