EN / ACS800-07/U7 Hardware Manual (45 to 560 ... - Simark Controls

EN / ACS800-07/U7 Hardware Manual (45 to 560 ... - Simark Controls

EN / ACS800-07/U7 Hardware Manual (45 to 560 ... - Simark Controls

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ACS800</strong> Single Drive <strong>Manual</strong>sHARDWARE MANUALS (appropriate manual is included in thedelivery)<strong>ACS800</strong>-01/U1 <strong>Hardware</strong> <strong>Manual</strong> 0.55 <strong>to</strong> 160 kW (0.75 <strong>to</strong> 200 HP)3AFE64382101 (English)<strong>ACS800</strong>-01/U1/04/U4 Marine Supplement 0.55 <strong>to</strong> 160 kW (0.75 <strong>to</strong>200 HP) 3AFE64291275 (English)<strong>ACS800</strong>-11/U11 <strong>Hardware</strong> <strong>Manual</strong> 5.5 <strong>to</strong> 110 kW (7.5 <strong>to</strong> 125 HP)3AFE68367883 (English)<strong>ACS800</strong>-31/U31 <strong>Hardware</strong> <strong>Manual</strong> 5.5 <strong>to</strong>110 kW (7.5 <strong>to</strong> 125 HP)3AFE68599954 (English)<strong>ACS800</strong>-02/U2 <strong>Hardware</strong> <strong>Manual</strong> 90 <strong>to</strong> 500 kW (125 <strong>to</strong> 600 HP)3AFE6<strong>45</strong>67373 (English)<strong>ACS800</strong>-04/U4 <strong>Hardware</strong> <strong>Manual</strong> 0.55 <strong>to</strong> 160 kW (0.75 <strong>to</strong> 200 HP)3AFE68372984 (English)<strong>ACS800</strong>-04/04M/U4 <strong>Hardware</strong> <strong>Manual</strong> <strong>45</strong> <strong>to</strong> <strong>560</strong> kW (60 <strong>to</strong>600 HP) 3AFE64671006 (English)<strong>ACS800</strong>-04/04M/U4 Cabinet Installation <strong>45</strong> <strong>to</strong> <strong>560</strong> kW (60 <strong>to</strong>600 HP) 3AFE68360323 (English)<strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong> <strong>Hardware</strong> <strong>Manual</strong> <strong>45</strong> <strong>to</strong> <strong>560</strong> kW (50 <strong>to</strong> 600 HP)3AFE64702165 (English)<strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong> Dimensional Drawings <strong>45</strong> <strong>to</strong> <strong>560</strong> kW (50 <strong>to</strong>600 HP) 3AFE64775421<strong>ACS800</strong>-<strong>07</strong> <strong>Hardware</strong> <strong>Manual</strong> 500 <strong>to</strong> 2800 kW3AFE64731165 (English)<strong>ACS800</strong>-17 <strong>Hardware</strong> <strong>Manual</strong> 55 <strong>to</strong> 2500 kW (75 <strong>to</strong> 2800 HP)3AFE68397260 (English)<strong>ACS800</strong>-37 <strong>Hardware</strong> <strong>Manual</strong> 55 <strong>to</strong> 2700 kW (75 <strong>to</strong> 3000 HP)3AFE68557925 (English)• Safety instructions• Electrical installation planning• Mechanical and electrical installation• Mo<strong>to</strong>r control and I/O board (RMIO)• Maintenance• Technical data• Dimensional drawings• Resis<strong>to</strong>r brakingFIRMWARE MANUALS, SUPPLEM<strong>EN</strong>TS AND GUIDES(appropriate documents are included in the delivery)Standard Control Program Firmware <strong>Manual</strong>3AFE6<strong>45</strong>27592 (English)System Control Program Firmware <strong>Manual</strong>3AFE64670646 (English)Control Program Template Firmware <strong>Manual</strong>3AFE64616340 (English)Master/Follower 3AFE6<strong>45</strong>90430 (English)Pump Control Program Firmware <strong>Manual</strong>3AFE68478952 (English)Extruder Control Program Supplement 3AFE64648543 (English)Centrifuge Control Program Supplement 3AFE64667246 (English)Traverse Control Program Supplement 3AFE64618334 (English)Crane Control Program Firmware <strong>Manual</strong> 3BSE11179 (English)Adaptive Programming Application Guide3AFE6<strong>45</strong>27274 (English)OPTION MANUALS (delivered with optional equipment)Fieldbus Adapters, I/O Extension Modules etc.

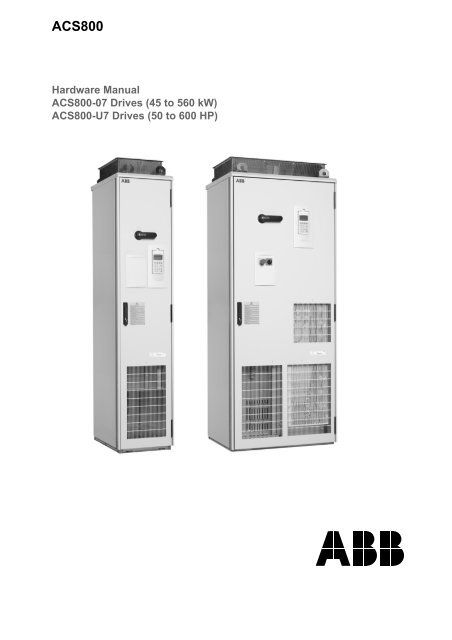

<strong>ACS800</strong>-<strong>07</strong> Drives<strong>45</strong> <strong>to</strong> <strong>560</strong> kW<strong>ACS800</strong>-<strong>U7</strong> Drives50 <strong>to</strong> 600 HP<strong>Hardware</strong> <strong>Manual</strong>3AFE64702165 Rev G <strong>EN</strong>EFFECTIVE: 19.1.2009© 2009 ABB Oy. All Rights Reserved.

1Update NoticeThe notice concerns the following <strong>ACS800</strong>-<strong>07</strong> Drives (<strong>45</strong><strong>to</strong> <strong>560</strong> kW) and <strong>ACS800</strong>-<strong>U7</strong> Drives (50 <strong>to</strong> 600 HP)<strong>Hardware</strong> <strong>Manual</strong>s:Code Revision Language3AFE64702165 G English <strong>EN</strong>3AFE64787292 G Danish DA3AFE64787306 G German DE3AFE64787314 G Spanish ES3AFE64787322 G Finnish FI3AFE64787331 G French FR3AFE64787373 G Italian IT3AFE64787403 G Dutch NL3AFE64787438 G Portuguese PT3AFE64787<strong>45</strong>4 G Russian RU3AFE64787462 G Swedish SVCode: 3AUA00000594<strong>45</strong> Rev AValid: from 01.02.2010 until the release of the next revision ofthe manualContents:The headings in this update notice refer <strong>to</strong> the modifiedsubsections in the original English manual. Each heading alsoincludes a page number and a classifier NEW, CHANGED, orDELETED. The page number refers <strong>to</strong> the page number in theoriginal English manual. The classifier describes the type ofthe modification.NEW (page 6): Safety / Installation and maintenance work• After maintaining or modifying a drive safety circuit or changing circuit boardsinside the module, retest the functioning of the safety circuit according <strong>to</strong> thestart-up instructions.• Do not change the electrical installations of the drive except for the essentialcontrol and power connections. Changes may affect the safety performance oroperation of the drive unexpectedly. All cus<strong>to</strong>mer-made changes are on thecus<strong>to</strong>mer's responsibility.[...]Note:• The Safe <strong>to</strong>rque off function (option +Q968) does not remove the voltage from themain and auxiliary circuits.CHANGED (page 10): Safety / Permanent magnet mo<strong>to</strong>r• Ensure that the mo<strong>to</strong>r cannot rotate during work. Prevent the start-up of anydrives in the same mechanical group by opening the Prevention of unexpectedstart switch (option +Q950) or Safe <strong>to</strong>rque off switch (option +Q968) andpadlocking it. Make sure that no other system, like hydraulic crawling drives, areable <strong>to</strong> rotate the mo<strong>to</strong>r directly or through any mechanical connection like felt,nip, rope, etc.Update Notice

2NEW (page 10): Safety / Permanent magnet mo<strong>to</strong>r• Note concerning permanent magnet mo<strong>to</strong>r drives in case of a multiple IGBTpower semiconduc<strong>to</strong>r failure: In spite of the activation of the Safe <strong>to</strong>rque offfunction (option +Q968), the drive system can produce an alignment <strong>to</strong>rque whichmaximally rotates the mo<strong>to</strong>r shaft by 180/p degrees. p denotes the pole pairnumber.NEW/CHANGED (page 24): Type codeThe table below contains the valid option code definitions for the emergency s<strong>to</strong>p.CodeDescription+Q951 Emergency s<strong>to</strong>p, s<strong>to</strong>p category 0 with opening the main contac<strong>to</strong>r/breaker+Q952 Emergency s<strong>to</strong>p, s<strong>to</strong>p category 1 with opening the main contac<strong>to</strong>r/breaker+Q963 Emergency s<strong>to</strong>p, s<strong>to</strong>p category 0 without opening the main contac<strong>to</strong>r/breaker+Q964 Emergency s<strong>to</strong>p, s<strong>to</strong>p category 1 without opening the main contac<strong>to</strong>r/breaker SS1NEW (page 24): Type codeThe table below contains the new option code definition for the Safe <strong>to</strong>rque offfunction.CodeDescription+Q968 Safe <strong>to</strong>rque off (STO) with a safety relayNEW (page 47): Emergency s<strong>to</strong>pNote: If you add or modify the wiring in the drive safety circuits, ensure that theappropriate standards (e.g. IEC 61800-5-1, <strong>EN</strong> 62061, <strong>EN</strong>/ISO 13849-1 and -2) andthe ABB guidelines are met. After making the changes, verify the operation of thesafety function by testing it.NEW (page 50): Safe <strong>to</strong>rque offThe drive supports the Safe <strong>to</strong>rque off (STO) function according <strong>to</strong> standards<strong>EN</strong> 61800-5-2:20<strong>07</strong>; <strong>EN</strong>/ISO 13849-1:2008, IEC 61508, and <strong>EN</strong> 62061:2005. Thefunction also corresponds <strong>to</strong> an uncontrolled s<strong>to</strong>p in accordance with category 0 of<strong>EN</strong> 60204-1 and prevention of unexpected start-up of <strong>EN</strong> 1037.The STO may be used where power removal is required <strong>to</strong> prevent an unexpectedstart. The function disables the control voltage of the power semiconduc<strong>to</strong>rs of thedrive output stage, thus preventing the inverter from generating the voltage required<strong>to</strong> rotate the mo<strong>to</strong>r (see the diagram below). By using this function, short-timeoperations (like cleaning) and/or maintenance work on non-electrical parts of themachinery can be performed without switching off the power supply <strong>to</strong> the drive.Update Notice

3Update Notice

4WARNING! The Safe <strong>to</strong>rque off function does not disconnect the voltage of the mainand auxiliary circuits from the drive. Therefore maintenance work on electrical partsof the drive or the mo<strong>to</strong>r can only be carried out after isolating the drive system fromthe main supply.Note: The Safe <strong>to</strong>rque off function can be used for s<strong>to</strong>pping the drive in emergencys<strong>to</strong>p situations. In the normal operating mode, use the S<strong>to</strong>p command instead. If arunning drive is s<strong>to</strong>pped by using the function, the drive will trip and s<strong>to</strong>p by coasting.If this is not acceptable, e.g. causes danger, the drive and machinery must bes<strong>to</strong>pped using the appropriate s<strong>to</strong>pping mode before using this function.Note concerning permanent magnet mo<strong>to</strong>r drives in case of a multiple IGBTpower semiconduc<strong>to</strong>r failure: In spite of the activation of the Safe <strong>to</strong>rque offfunction, the drive system can produce an alignment <strong>to</strong>rque which maximally rotatesthe mo<strong>to</strong>r shaft by 180/p degrees. p denotes the pole pair number.Note: If you add or modify the wiring in the drive safety circuits, ensure that theappropriate standards (e.g. IEC 61800-5-1, <strong>EN</strong> 62061, <strong>EN</strong>/ISO 13849-1 and -2) andthe ABB guidelines are met. After making the changes, verify the operation of thesafety function by testing it.CHANGED (pages 72-73): Layout drawing of fac<strong>to</strong>ry installed optionalequipmentFrame sizes R5 and R6:A21 *Relay for Prevention of unexpected start (option +Q950) or Safe <strong>to</strong>rque off(option +Q968)Additional terminal blocks:*X9 Prevention of unexpected start (option +Q950) or Safe <strong>to</strong>rque off (option +Q968)Frame size R7 and R8:*Relay for Prevention of unexpected start (option +Q950) or Safe <strong>to</strong>rque off (option+Q968)NEW (page 84): On-load checksThe following information has been added <strong>to</strong> the procedure:ActionAdditional informationCheck the correct operation of the emergency s<strong>to</strong>pcircuits from each operating location.If the drive is equipped with the category 1emergency s<strong>to</strong>p function (option +Q952 or +Q964),adjust the delay time of the emergency s<strong>to</strong>p relayand the deceleration time of the drive emergencys<strong>to</strong>p function. The fac<strong>to</strong>ry default settings do notnecessarily meet the application needs.Update Notice

5NEW (page 84): On-load checksThe following information has been added <strong>to</strong> the procedure:ActionCheck that the Safe <strong>to</strong>rque off function (option+Q968, if installed) works:Additional informationOptional function. See deliveryspecific circuit diagrams.• Ensure that the drive can be run and s<strong>to</strong>ppedfreely during the commissioning.• S<strong>to</strong>p the drive (if running), switch the input poweroff and isolate the drive from the power line by adisconnec<strong>to</strong>r.• Check the STO circuit connections against thecircuit diagram.• Close the disconnec<strong>to</strong>r and switch the power on.• Test the operation of the STO function when themo<strong>to</strong>r is s<strong>to</strong>pped:- Give a s<strong>to</strong>p command for the drive (if running)and wait until the mo<strong>to</strong>r shaft is at standstill.- Activate the STO circuit and give a startcommand for the drive.- Ensure that the mo<strong>to</strong>r stays at standstill.- Deactivate the STO circuit.• Restart the drive and check that the mo<strong>to</strong>r runsnormally.• Test the operation of the STO function when themo<strong>to</strong>r is running:- Start the drive and ensure that the mo<strong>to</strong>r isrunning.- Activate the STO circuit.- Ensure that the mo<strong>to</strong>r s<strong>to</strong>ps and the drive trips.- Reset the fault and try <strong>to</strong> start the drive.- Ensure that the mo<strong>to</strong>r stays at standstill.- Deactivate the STO circuit.• Restart the drive and check that the mo<strong>to</strong>r runsnormally.Update Notice

6CHANGED (page 109): LEDsLEDV309 (red)When the led is litPrevention of unexpected start (option +Q950) or Safe <strong>to</strong>rque off (option +Q968) isON.NEW (page 132): Ambient conditionsCabinets with option +Q968: the installation site altitude in operation is 0 <strong>to</strong> 2000 m.Operationinstalled for stationary useInstallation site altitude [...]Cabinets with option +Q968:0 <strong>to</strong> 2000 mUpdate Notice

5Safety instructionsWhat this chapter containsThis chapter contains the safety instructions which you must follow when installing,operating and servicing the drive. If ignored, physical injury or death may follow, ordamage may occur <strong>to</strong> the drive, the mo<strong>to</strong>r or driven equipment. Read the safetyinstructions before you work on the unit.Use of warnings and notesThere are two types of safety instructions throughout this manual: warnings andnotes. Warnings caution you about conditions which can result in serious injury ordeath and/or damage <strong>to</strong> the equipment. They also tell you how <strong>to</strong> avoid the danger.Notes draw attention <strong>to</strong> a particular condition or fact, or give information on asubject. The warning symbols are used as follows:Dangerous voltage warning warns of high voltage which can causephysical injury and/or damage <strong>to</strong> the equipment.General warning warns about conditions, other than those caused byelectricity, which can result in physical injury and/or damage <strong>to</strong> theequipment.Electrostatic discharge warning warns of electrostatic discharge whichcan damage the equipment.Hot surface warning warns of hot surfaces which can cause physicalinjury.Safety instructions

6Installation and maintenance workThese warnings are intended for all who work on the drive, mo<strong>to</strong>r cable or mo<strong>to</strong>r.WARNING! Ignoring the following instructions can cause physical injury or death, ordamage <strong>to</strong> the equipment:.• Only qualified electricians are allowed <strong>to</strong> install and maintain the drive.• Never work on the drive, mo<strong>to</strong>r cable or mo<strong>to</strong>r when main power is applied.After switching off the power, always wait for 5 minutes <strong>to</strong> let the intermediatecircuit capaci<strong>to</strong>rs discharge before you start working on the drive, the mo<strong>to</strong>r orthe mo<strong>to</strong>r cable.Always ensure by measuring with a multimeter (impedance at least 1 Mohm)that:1. Voltage between drive input phases L1, L2 and L3 and the frame is close <strong>to</strong>0V.2. Voltage between terminals UDC+ and UDC- and the frame is close <strong>to</strong> 0 V.• Do not work on the control cables when power is applied <strong>to</strong> the drive or <strong>to</strong> theexternal control circuits. Externally supplied control circuits may causedangerous voltages inside the drive even when the main power on the drive isswitched off.• Do not make any insulation or voltage withstand tests on the drive or drivemodules.• When reconnecting the mo<strong>to</strong>r cable, always check that the phase order iscorrect.Note:• The disconnecting device (means) of the drive does not isolate the input cablesand busbars from the main AC supply. Before working inside the cabinet,isolate the input cables and busbars from the main supply with thedisconnecting device at the distribution board or with the disconnec<strong>to</strong>r of thesupply transformer.• The mo<strong>to</strong>r cable terminals on the drive are at a dangerously high voltage whenthe input power is on, regardless of whether the mo<strong>to</strong>r is running or not.• The brake control terminals (UDC+, UDC-, R+ and R- terminals) carry adangerous DC voltage (over 500 V).• Depending on the external wiring, dangerous voltages [115 V, 220 V or 230 V]may be present on the terminals of relay outputs RO1 <strong>to</strong> RO3 or on the optionalAGPS board (Prevention of Unexpected Start).• The Prevention of Unexpected Start function does not remove the voltage fromthe main and auxiliary circuits.Safety instructions

7• At installation sites above 2000 m (6562 ft), the terminals of the RMIO boardand optional modules attached <strong>to</strong> the board do not fulfil the Protective ExtraLow Voltage (PELV) requirements stated in <strong>EN</strong> 50178.GroundingThese instructions are intended for all who are responsible for the grounding of thedrive.WARNING! Ignoring the following instructions can cause physical injury, death orequipment malfunction and increase electromagnetic interference.• Ground the drive, the mo<strong>to</strong>r and adjoining equipment <strong>to</strong> ensure personnelsafety in all circumstances, and <strong>to</strong> reduce electromagnetic emission andinterference.• Make sure that grounding conduc<strong>to</strong>rs are adequately sized as required bysafety regulations.• In a multiple-drive installation, connect each drive separately <strong>to</strong> protectiveearth (PE).• Do not install a drive with EMC filter option +E202 on an ungrounded powersystem or a high resistance-grounded (over 30 ohms) power system.Note:• Power cable shields are suitable for equipment grounding conduc<strong>to</strong>rs onlywhen adequately sized <strong>to</strong> meet safety regulations.• As the normal leakage current of the drive is higher than 3.5 mA AC or 10 mADC (stated by <strong>EN</strong> 50178, 5.2.11.1), a fixed protective earth connection isrequired.Safety instructions

8Mechanical installation and maintenanceThese instructions are intended for all who install and service the drive.WARNING! Ignoring the following instructions can cause physical injury or death,or damage <strong>to</strong> the equipment:• Cover the drive when installing <strong>to</strong> ensure that dust from borings and grindingsor foreign objects do not enter the drive. Electrically conductive dust inside theunit may cause damage or lead <strong>to</strong> malfunction.• Ensure sufficient cooling.• Welding of the cabinet frame is not recommended. However, if electric weldingis the only way <strong>to</strong> mount the cabinet, follow the instructions given in chapterMechanical installation. Ensure that welding fumes are not inhaled. If thewelding return wire is connected improperly, the welding circuit may damageelectronic circuits in the cabinet.• When removing the module from the cabinet and manoeuvring it outside thecabinet, prevent it from <strong>to</strong>ppling over by securing it. The drive module is heavyand has a high centre of gravity.• Beware of hot surfaces. Some parts, such as heatsinks of powersemiconduc<strong>to</strong>rs, remain hot for a while after disconnection of the electricalsupply.Printed circuit boardsWARNING! Ignoring the following instructions can cause damage <strong>to</strong> the printedcircuit boards:• The printed circuit boards contain components sensitive <strong>to</strong> electrostaticdischarge. Wear a grounding wrist band when handling the boards. Do not<strong>to</strong>uch the boards unnecessarily.Fibre optic cablesWARNING! Ignoring the following instructions can cause equipment malfunctionand damage <strong>to</strong> the fibre optic cables:• Handle the fibre optic cables with care. When unplugging optic cables, alwaysgrab the connec<strong>to</strong>r, not the cable itself. Do not <strong>to</strong>uch the ends of the fibres withbare hands as the fibre is extremely sensitive <strong>to</strong> dirt. The minimum allowedbend radius is 35 mm (1.4 in.).Safety instructions

9OperationThese warnings are intended for all who plan the operation of the drive or operatethe drive.WARNING! Ignoring the instructions can cause physical injury or death or damage<strong>to</strong> the equipment.• Before adjusting the drive and putting it in<strong>to</strong> service, make sure that the mo<strong>to</strong>rand all driven equipment are suitable for operation throughout the speed rangeprovided by the drive. The drive can be adjusted <strong>to</strong> operate the mo<strong>to</strong>r atspeeds above and below the speed provided by connecting the mo<strong>to</strong>r directly<strong>to</strong> the power line.• Do not activate au<strong>to</strong>matic fault reset functions of the Standard ControlProgram if dangerous situations can occur. When activated, these functionswill reset the drive and resume operation after a fault.• Do not control the mo<strong>to</strong>r with the disconnecting device (disconnecting means);instead, use the control panel keys and , or commands via the I/Oboard of the drive. The maximum allowed number of charging cycles of the DCcapaci<strong>to</strong>rs (i.e. power-ups by applying power) is five in ten minutes.Note:• If an external source for start command is selected and it is ON, the drive (withStandard Control Program) will start immediately after fault reset unless thedrive is configured for 3-wire (a pulse) start/s<strong>to</strong>p.• When the control location is not set <strong>to</strong> Local (L not shown in the status row ofthe display), the s<strong>to</strong>p key on the control panel will not s<strong>to</strong>p the drive. To s<strong>to</strong>pthe drive using the control panel, press the LOC/REM key and then the s<strong>to</strong>pkey .Safety instructions

10Permanent magnet mo<strong>to</strong>rThese are additional warnings concerning permanent magnet mo<strong>to</strong>r drives. Ignoringthe instructions can cause physical injury or death, or damage <strong>to</strong> the equipment.Installation and maintenance workWARNING! Do not work on the drive when the permanent magnet mo<strong>to</strong>r is rotating.Also, when the supply power is switched off and the inverter is s<strong>to</strong>pped, a rotatingpermanent magnet mo<strong>to</strong>r feeds power <strong>to</strong> the intermediate circuit of the drive and thesupply connections become live.Before installation and maintenance work on the drive:• S<strong>to</strong>p the mo<strong>to</strong>r.• Ensure that the mo<strong>to</strong>r cannot rotate during work. Prevent the start-up of anydrives in the same mechanical group by opening the “prevention of unexpectedstart” switch and padlocking it. Make sure that no other system, like hydrauliccrawling drives, are able <strong>to</strong> rotate the mo<strong>to</strong>r directly or through any mechanicalconnection like felt, nip, rope, etc.• Ensure that there is no voltage on the drive power terminals:Alternative 1) Disconnect the mo<strong>to</strong>r from the drive with a safety switch or by othermeans. Measure that there is no voltage present on the drive input or outputterminals (L1, L2, L3, U2, V2, W2, UDC+, UDC-).Alternative 2) Measure that there is no voltage present on the drive input or outputterminals (L1, L2, L3, U2, V2, W2, UDC+, UDC-). Ground the drive outputterminals temporarily by connecting them <strong>to</strong>gether as well as <strong>to</strong> the PE.Alternative 3) If possible, both of the above.Start-up and operationWARNING! Do not run the mo<strong>to</strong>r over the rated speed. Mo<strong>to</strong>r overspeed leads <strong>to</strong>overvoltage which may damage or explode the capaci<strong>to</strong>rs in the intermediate circui<strong>to</strong>f the drive.Controlling a permanent magnet mo<strong>to</strong>r is only allowed using the control program forPermanent Magnet Synchronous Machine Drive, or other control programs in scalarcontrol mode.Safety instructions

11Table of contents<strong>ACS800</strong> Single Drive <strong>Manual</strong>s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Safety instructionsWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Installation and maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Mechanical installation and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Printed circuit boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Fibre optic cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Permanent magnet mo<strong>to</strong>r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Installation and maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Start-up and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Table of contentsAbout this manualWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Common chapter for four products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Categorization according <strong>to</strong> the frame size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Categorization according <strong>to</strong> the + code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Installation and commissioning flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21Type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23Main circuit and control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25Door switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26Printed circuit boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27Mo<strong>to</strong>r control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27Table of contents

12Mechanical installationWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29Moving the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30Delivery check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30Requirements for the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30Cooling air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31Cable channel in the floor below the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31Fastening the cabinet <strong>to</strong> the floor and wall (non-marine units) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32Fastening the cabinet with the outside brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33Fastening the cabinet through the holes inside the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . .34Fastening the cabinet <strong>to</strong> the floor and roof/wall (marine units) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35Electric welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36Planning the electrical installationWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37To which products this chapter applies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37Mo<strong>to</strong>r selection and compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37Protecting the mo<strong>to</strong>r insulation and bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39Requirements table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40Permanent magnet synchronous mo<strong>to</strong>r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43Supply connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44Disconnecting device (disconnecting means) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44<strong>ACS800</strong>-01, <strong>ACS800</strong>-U1, <strong>ACS800</strong>-11, <strong>ACS800</strong>-U11, <strong>ACS800</strong>-31, <strong>ACS800</strong>-U31,<strong>ACS800</strong>-02 and <strong>ACS800</strong>-U2 without enclosure extension, <strong>ACS800</strong>-04, <strong>ACS800</strong>-U4 .44<strong>ACS800</strong>-02 and <strong>ACS800</strong>-U2 with enclosure extension, <strong>ACS800</strong>-<strong>07</strong> and <strong>ACS800</strong>-<strong>U7</strong> .44EU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44US . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44Main contac<strong>to</strong>r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44Thermal overload and short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<strong>45</strong>Thermal overload protection of the drive and the input and mo<strong>to</strong>r cables . . . . . . . . . . . . . . .<strong>45</strong>Thermal overload protection of the mo<strong>to</strong>r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<strong>45</strong>Protection against short-circuit in the mo<strong>to</strong>r cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<strong>45</strong>Protection against short-circuit inside the drive or in the supply cable . . . . . . . . . . . . . . . . . .46Ground fault protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47Emergency s<strong>to</strong>p devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47<strong>ACS800</strong>-02/U2 with enclosure extension and <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong> . . . . . . . . . . . . . . . . . . . . . . . .47Restarting after an emergency s<strong>to</strong>p . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47Power-loss ride-through function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48<strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong> units with line contac<strong>to</strong>r (+F250) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48Prevention of Unexpected Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49Table of contents

13Selecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50General rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50Alternative power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51Mo<strong>to</strong>r cable shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51Additional US requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52Armored cable / shielded power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52Power fac<strong>to</strong>r compensation capaci<strong>to</strong>rs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52Equipment connected <strong>to</strong> the mo<strong>to</strong>r cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53Installation of safety switches, contac<strong>to</strong>rs, connection boxes, etc. . . . . . . . . . . . . . . . . . . . . 53Bypass connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53Before opening a contac<strong>to</strong>r (DTC control mode selected) . . . . . . . . . . . . . . . . . . . . . . . . . . . 53Protecting the relay output contacts and attenuating disturbances in case of inductive loads . . . . 54Selecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55Relay cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55Control panel cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55Connection of a mo<strong>to</strong>r temperature sensor <strong>to</strong> the drive I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56Installation sites above 2000 metres (6562 feet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56Control cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57Electrical installationWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59IT (ungrounded) systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Input cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Mo<strong>to</strong>r and mo<strong>to</strong>r cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Brake resis<strong>to</strong>r assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60Warning sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60Example wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61Power cable connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62Connecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63Additional instructions for frame size R6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64Cable terminals R+ and R- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64Cable lug installations <strong>to</strong> R+ and R- screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64Connecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65Routing the cables (frame sizes R5 and R6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65Routing the cables (frame sizes R7 and R8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66360 degrees EMC grounding at the cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67Special for <strong>to</strong>p entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68Connecting the cables <strong>to</strong> the I/O terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69Settings of the cooling fan transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70Installation of optional modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70Cabling of I/O and fieldbus modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70Pulse encoder module cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71Fibre optic link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71Table of contents

14Layout drawing of fac<strong>to</strong>ry installed optional equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72Frame sizes R5 and R6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72Additional terminal blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72Frame size R7 and R8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73Installation of brake resis<strong>to</strong>rs (units with brake chopper option) . . . . . . . . . . . . . . . . . . . . . . . . . . .73Mo<strong>to</strong>r control and I/O board (RMIO)What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75Note for the <strong>ACS800</strong>-02 with enclosure extension and the <strong>ACS800</strong>-<strong>07</strong> . . . . . . . . . . . . . . . . . . . . .75Note on terminal labelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75Note on external power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76External control connections (non-US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77External control connections (US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78RMIO board specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79Analogue inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79Constant voltage output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79Auxiliary power output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79Analogue outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79Relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80DDCS fibre optic link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8024 V DC power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80Installation checklist and start-upChecklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84Checks with no voltage connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84Starting the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84Control program set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84On-load checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84MaintenanceWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85Required <strong>to</strong>ols for maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86Cabinet layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87Frame sizes R5 and R6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87Frame sizes R7 and R8 without du/dt filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88Frame sizes R7 and R8 with du/dt filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90Layout of the drive module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91Checking and replacing the air filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92Heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92Table of contents

15Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92Replacing the drive module fan (R5 and R6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93Replacing the drive module fan (R7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94Replacing the drive module fan (R8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95Replacing the cabinet fans (R5 and R6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96Replacing the fans at upper part of the cubicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96Replacing the additional fan at the lower part of the cubicle (R6 with du/dtfilter, +E205) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96Replacing the cabinet fans (frame size R8 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97Replacing the additional cabinet fan (frame sizes R7 and R8 only with IP 22 and IP 42when cabling: bot<strong>to</strong>m entry/exit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98Replacing the additional cabinet fan (frame sizes R7 and R8 only with IP 22 and IP 42when cabling: <strong>to</strong>p entry and bot<strong>to</strong>m exit, bot<strong>to</strong>m entry and <strong>to</strong>p exit or <strong>to</strong>p entry/exit) . . . . . . 99Replacing the IP 54 (UL type 12) fan in frame size R6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100Replacing the IP 54 (UL type 12) fan in frame sizes R7 and R8 . . . . . . . . . . . . . . . . . . . . . 101Capaci<strong>to</strong>rs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102Reforming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102Replacing the capaci<strong>to</strong>r pack (R7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102Replacing the capaci<strong>to</strong>r pack (R8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103Replacing the drive module (R5 and R6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104Replacing the drive module (R7 and R8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109Technical dataWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111IEC data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113Temperature derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114Altitude derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114Calculation example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114Notes concerning the fuse tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115Ultrarapid (aR) fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116Optional gG fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118Quick guide for selecting between gG and aR fuses . . . . . . . . . . . . . . . . . . . . . . . . . 120Cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123Dimensions, weights and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123Table of contents

16NEMA data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126UL class T or L fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127Cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129Dimensions, weights and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129Free space around the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130Input power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131Mo<strong>to</strong>r connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132Degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133US patents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135Compliance with the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135Compliance with <strong>EN</strong> 61800-3 (2004) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135First environment (drive of category C2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135Second environment (drive of category C3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136Second environment (drive of category C4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136Machinery Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136“C-tick” marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137Compliance with IEC 61800-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137First environment (drive of category C2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137Second environment (drive of category C3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138Second environment (drive of category C4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138UL/CSA markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139Equipment warranty and liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139Dimensional drawingsFrame sizes R5 and R6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142Frame sizes R7 and R8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143IP 54 and IP 54R units of frame sizes R7 and R8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144Resis<strong>to</strong>r brakingWhat this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1<strong>45</strong>Availability of brake choppers and resis<strong>to</strong>rs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1<strong>45</strong>How <strong>to</strong> select the correct drive/chopper/resis<strong>to</strong>r combination . . . . . . . . . . . . . . . . . . . . . . . . . . . .1<strong>45</strong>Optional brake chopper and resis<strong>to</strong>r(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146Resis<strong>to</strong>r installation and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149Table of contents

17Protection of frame size R5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149Protection of frame sizes R6, R7 and R8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150Brake circuit commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150Table of contents

18Table of contents

17About this manualWhat this chapter containsTarget audienceThis chapter describes the intended audience and contents of the manual. Itcontains a flowchart of steps in checking the delivery, installing and commissioningthe drive. The flowchart refers <strong>to</strong> chapters/sections in this manual and othermanuals.This manual is intended for people who plan the installation, install, commission, useand service the drive. Read the manual before working on the drive. The reader isexpected <strong>to</strong> know the fundamentals of electricity, wiring, electrical components andelectrical schematic symbols.The manual is written for readers worldwide. Both SI and imperial units are shown.Special US instructions for installations within the United States that must beperformed per the National Electrical Code and local codes are marked with (US).Common chapter for four productsChapter Planning the electrical installation applies <strong>to</strong> the <strong>ACS800</strong>-01/U1, <strong>ACS800</strong>-02/U2, <strong>ACS800</strong>-04/U4, and <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>.Categorization according <strong>to</strong> the frame sizeSome instructions, technical data and dimensional drawings which concern onlycertain frame sizes are marked with the symbol of the frame size R2, R3... or R8.The frame size is not marked on the drive designation label. To identify the framesize of your drive, see the rating tables in chapter Technical data.Categorization according <strong>to</strong> the + codeThe instructions, technical data and dimensional drawings which concern onlycertain optional selections are marked with + codes, e.g. +E205. The optionsincluded in the drive can be identified from the + codes visible on the typedesignation label of the drive. The + code selections are listed in chapter The<strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong> under Type code.About this manual

18ContentsThe chapters of this manual are briefly described below.Safety instructions give safety instructions for the installation, commissioning,operation and maintenance of the drive.About this manual introduces this manual.The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong> describes the drive.Mechanical installation shows how <strong>to</strong> move and unpack the delivery and how <strong>to</strong>fasten the cabinet <strong>to</strong> the floor.Planning the electrical installation instructs on the mo<strong>to</strong>r and cable selection, theprotections and the cable routing.Electrical installation instructs how <strong>to</strong> wire the drive.Mo<strong>to</strong>r control and I/O board (RMIO) shows external control connections <strong>to</strong> the mo<strong>to</strong>rcontrol and I/O board and its specifications.Installation checklist and start-up helps in checking the mechanical and electricalinstallation of the drive.Maintenance contains preventive maintenance instructions.Technical data contains the technical specifications of the drive, e.g. the ratings,sizes and technical requirements, provisions for fulfilling the requirements for CEand other markings and warranty policy.Dimensional drawings contains the dimensional drawings of the drive.Resis<strong>to</strong>r braking describes how <strong>to</strong> select, protect and wire optional brake choppersand resis<strong>to</strong>rs. The chapter also contains technical data.Installation and commissioning flowchartTaskIdentify the frame size of your drive: R6, R7 or R8.SeeTechnical data / IEC data or NEMA dataPlan the installation.Check the ambient conditions, ratings, requiredcooling air flow, input power connection, compatibilityof the mo<strong>to</strong>r, mo<strong>to</strong>r connection, and other technicaldata.Select the cables.Technical dataPlanning the electrical installationOption manual (if optional equipment isincluded)About this manual

19TaskUnpack and check the units.Check that all necessary optional modules andequipment are present and correct.Only intact units may be started up.SeeMechanical installation: Moving the unit, BeforeinstallationIf the converter has been non-operational formore than one year, the converter DC linkcapaci<strong>to</strong>rs need <strong>to</strong> be reformed. Ask ABB forinstructions.Check the installation site.Mechanical installation: Before installationTechnical dataIf the drive is about <strong>to</strong> be connected <strong>to</strong> an IT(ungrounded) system, check that the drive is notequipped with EMC filter +E202.The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>: Type code. Forinstructions on how <strong>to</strong> disconnect the EMCfiltering, contact ABB.Route the cables.Planning the electrical installation: Routing thecablesCheck the insulation of the mo<strong>to</strong>r and the mo<strong>to</strong>rcable.Electrical installation: Checking the insulation ofthe assemblyInstall the drive. Connect the power cables. Connectthe control and the auxiliary control cables.Mechanical installation, Electrical installation,Resis<strong>to</strong>r braking (optional)Check the installation.Installation checklist and start-upCommission the drive.Installation checklist and start-up, appropriatefirmware manualCommission the optional brake chopper (if present).Resis<strong>to</strong>r brakingProduct and service inquiriesAddress any inquiries about the product <strong>to</strong> your local ABB representative, quotingthe type code and serial number of the unit in question. A listing of ABB sales,support and service contacts can be found by navigating <strong>to</strong> www.abb.com/drives andselecting Sales, Support and Service network.About this manual

20Product trainingFor information on ABB product training, navigate <strong>to</strong> www.abb.com/drives and selectTraining courses.Providing feedback on ABB Drives manualsYour comments on our manuals are welcome. Go <strong>to</strong> www.abb.com/drivesand selectDocument Library – <strong>Manual</strong>s feedback form (LV AC drives).Document library on the InternetYou can find manuals and other product documents in PDF format on the Internet.Go <strong>to</strong> www.abb.com/drives and select Document Library. You can browse the libraryor enter selection criteria, for example a document code, in the search field.About this manual

21The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>What this chapter containsThe <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>This chapter describes the construction and operating principle of the drive in short.The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong> is a cabinet-installed drive for controlling AC mo<strong>to</strong>rs.IP 21/22 (UL type 1)*Line contac<strong>to</strong>rControl panelSwitch fuse (mainswitch / disconnec<strong>to</strong>r)Switch fuse handleAuxiliary circuit fuses*Emergency S<strong>to</strong>p and Start/S<strong>to</strong>pswitches*Brake resis<strong>to</strong>r cubicle with +D151Drive control unit(RDCU, RMIO)DrivemoduleInputU1,V1,W1InputOutputSwing-out frameFor layout of optionalequipment on theswing-out frame, seeElectrical installation /Layout drawing offac<strong>to</strong>ry installed optionalequipmentPEOutputU2,V2,W2*du/dt filter (+E205)behind the swing-outframeBrakeresis<strong>to</strong>r(R-, R+)*EMC filter cubicle with +E202* Denotes optional equipment not present onall units.View of frame size R8Cableentries+E205Power and signal cable terminals, and du/dtfilter (+E205), behind the swing-out frameNote: The input terminals are located in theEMC filter cubicle with +E202.The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>

22IP 21/22See page72.DrivemoduleRMIOAdditionalfan (not inall types)View of frame size R6 without shroudsPower cable terminalsSee page72.DrivemoduleRMIOView of frame size R5 without shroudsPower cable terminalsThe <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>

23Type codeThe type code contains information on the specifications and configuration of thedrive. The first digits from left express the basic configuration (e.g. <strong>ACS800</strong>-<strong>07</strong>-0170-5). The optional selections are given thereafter, separated by + signs (e.g.+E202). The main selections are described below. Not all selections are available forall types. For more information, refer <strong>to</strong> <strong>ACS800</strong> Ordering Information (<strong>EN</strong> code:6<strong>45</strong>56568, available on request).SelectionAlternativesProduct series<strong>ACS800</strong> product seriesType <strong>07</strong> cabinet built. When no options are selected: 6-pulse diode inputbridge, IP 21, switch fuse with aR fuses, control panel CDP312R,no EMC filter, Standard Control Program, bot<strong>to</strong>m entry and exit ofcables, boards without coating, one set of manuals.<strong>U7</strong> cabinet built (USA). When no options are selected: 6-pulse diodebridge, UL type 1, switch fuse with class T or L fuses, controlpanel CDP312R, no EMC filter, US version of the StandardControl Program (three-wire start/s<strong>to</strong>p as default setting), cableconduit entry, common mode filter in frame size R8, boardswithout coating, one set of manuals.SizeSee Technical data: IEC data or NEMA data.Voltage range(nominal rating in bold)3 380/400/415 VAC5 380/400/415/440/460/480/500 VAC7 525/575/600/690 VAC+ optionsDegree of protection B053 IP 22 (UL type 1)B054 IP 42 (UL type 2)B055 IP 54 (UL type 12)B059 IP 54R with connection <strong>to</strong> air outlet ductConstruction C121 marine construction (reinforced mechanics and fastening,marking of conduc<strong>to</strong>rs according <strong>to</strong> class A1, door handles, selfextinctivematerials)C129 UL listed (for <strong>ACS800</strong>-<strong>07</strong> units only): US type main switch fuse,115 VAC control voltage, US cable conduit entry, all componentsUL listed/recognized, max. supply voltage 600 V.C134 CSA marked. US/CSA type main switch fuse, bot<strong>to</strong>m entry andexit, 115 VAC control voltage, all components UL/CSA listed/recognized, max. supply voltage 600 V.Resis<strong>to</strong>r braking D150 brake chopper (external resis<strong>to</strong>r)D151 brake chopper and resis<strong>to</strong>rFilter E200 EMC/RFI filter for second environment TN (grounded) systemE202 EMC/RFI filter for first environment TN (grounded) system,restricted (A limits)E210 EMC/RFI filter for second environment TN/IT (grounded/ungrounded) systemE205 du/dt filterE206 sine filterE208 common mode filterLine options F250 line contac<strong>to</strong>rF251 gG line fusesThe <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>

24SelectionAlternativesCabinet options G300 cabinet heater (external supply)G304 115 VAC control voltageG3<strong>07</strong> terminals for external control voltage (UPS)G313 output for mo<strong>to</strong>r heater (external supply)G330 halogen-free materials and control wiringCabling H351 <strong>to</strong>p entryH353 <strong>to</strong>p exitH358 cable conduit entry (US and UK version)Fieldbus K... Refer <strong>to</strong> <strong>ACS800</strong> Ordering Information (<strong>EN</strong> code: 6<strong>45</strong>56568).I/O L504 additional terminal block X2L505 thermis<strong>to</strong>r relay (1 or 2 pcs)L506 Pt100 relay (3, 5 or 8 pcs)L... Refer <strong>to</strong> <strong>ACS800</strong> Ordering Information (<strong>EN</strong> code: 6<strong>45</strong>56568).Starter for auxiliary mo<strong>to</strong>rfanM600 1...1.6 AM601 1.6...2.5 AM602 2.5...4 AM603 4...6.3 AM604 6.3...10 AM605 10...16 AControl program N... Refer <strong>to</strong> <strong>ACS800</strong> Ordering Information (<strong>EN</strong> code: 6<strong>45</strong>56568).Language of manual R...Specialities P901 coated boardsP902 cus<strong>to</strong>mizedP904 extended warrantyP913 special colourSafety features Q950 prevention of unexpected startQ951 emergency s<strong>to</strong>p of category 0 (+F250 required)Q952 emergency s<strong>to</strong>p of category 1 (+F250 required)Q954 earth fault moni<strong>to</strong>ring for IT (ungrounded) systemsThe <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>

25Main circuit and controlDoor switchesThe following switches are mounted on the cabinet door:Operating switch (units with maincontac<strong>to</strong>r only)“START” position closes the maincontac<strong>to</strong>r; “ON” position keeps the maincontac<strong>to</strong>r closed; “OFF” position opensthe main contac<strong>to</strong>r.Emergency s<strong>to</strong>p but<strong>to</strong>n(optional)The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>

26DiagramThis diagram shows the control interfaces and the main circuit of the drive.External control viaanalogue/digitalinputs and outputsMo<strong>to</strong>rcontrol andI/O board(RMIO)Optional module 1: RMBA, RAIO,RDIO, RDNA, RLON, RIBA, RPBA,RCAN, RCNA, RMBP, RETA, RRIA orRTACOptional module 2: RTAC, RAIO, RRIAor RDIODDCS communication option module:RDCO-01, RDCO-02 or RDCO-03Input power~ = ~ =Output powerBrake chopper (optional)R- UDC+ UDC-R+OperationThis table describes the operation of the main circuit in short.Componentsix-pulse rectifiercapaci<strong>to</strong>r banksix-pulse IGBT inverterDescriptionconverts the three-phase AC voltage <strong>to</strong> DC voltageenergy s<strong>to</strong>rage which stabilizes the intermediate circuit DC voltageconverts the DC voltage <strong>to</strong> AC voltage and vice versa. The mo<strong>to</strong>roperation is controlled by switching the IGBTs.The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>

27Printed circuit boardsThe drive contains the following printed circuit boards as standard:• main circuit board (AINT)• mo<strong>to</strong>r control and I/O board (RMIO) with a fibre optic link <strong>to</strong> the AINT board• input bridge control board (AINP)• input bridge protection board (AIBP) which includes varis<strong>to</strong>rs and snubbers forthe thyris<strong>to</strong>rs• power supply board (APOW)• gate driver control board (AGDR)• diagnostics and panel interface board (ADPI)• EMC filter boards (NRFC) with option +E202• brake chopper control board (ABRC) with option +D150Mo<strong>to</strong>r controlThe mo<strong>to</strong>r control is based on the Direct Torque Control (DTC) method. Two phasecurrents and DC link voltage are measured and used for the control. The third phasecurrent is measured for earth fault protection.The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>

28The <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>

29Mechanical installationWhat this chapter containsMoving the unitThis chapter describes the mechanical installation procedure of the drive.Move the transport package by truck and pallet truck <strong>to</strong> the installation site.Max 30°Cabinet back panelSupportView of cabinet laid on its backIt is allowed <strong>to</strong> tilt the drive if required, or move it on its backwhen supported properly from below. Note: It is not allowed<strong>to</strong> move a unit with sine filter (+E206) on its back.WARNING! Lift the drive by the upper part only using the lifting lugs/bars attached <strong>to</strong>the <strong>to</strong>p of the unit.Mechanical installation

30Before installationDelivery checkThe drive delivery contains:• drive cabinet including fac<strong>to</strong>ry installed options such as optional modules(inserted on<strong>to</strong> the RMIO board in the RDCU unit)• residual voltage warning stickers• hardware manual• appropriate firmware manuals and guides• appropriate optional module manuals• delivery documents.Check that there are no signs of damage. Before attempting installation andoperation, check the information on the type designation label of the drive <strong>to</strong> verifythat the unit is of the correct type. The label includes an IEC and NEMA rating, C-ULUS, and CSA markings, a type code and a serial number, which allow individualrecognition of each unit. The first digit of the serial number refers <strong>to</strong> themanufacturing plant. The next four digits refer <strong>to</strong> the unit’s manufacturing year andweek respectively. The remaining digits complete the serial number so that there areno two units with the same serial number.The type designation label is located on the front cover and the serial number labelinside the unit. Example labels are shown below.Type designation labelSerial number labelRequirements for the installation siteCheck the installation site according <strong>to</strong> the requirements below. See <strong>ACS800</strong>-<strong>07</strong>/<strong>U7</strong>Dimensional Drawings [3AFE64775421 (English)] for frame details. See Technicaldata for the allowed operation conditions of the drive.Mechanical installation

31Cooling air flowProvide the drive with the amount of clean cooling air given in Technical data / IECdata or NEMA data.Cable channel in the floor below the cabinetA cable channel can be constructed below the 400 mm wide middle part of thecabinet. The cabinet weight lies on the two 100 mm wide transverse sections whichthe floor must carry.Viewed from aboveSide viewWith heavycabinets,support thestructural C-sections fromThis area can be used for acable channelPrevent the cooling air flow from the cable channel <strong>to</strong>the cabinet by bot<strong>to</strong>m plates. To ensure the degree ofprotection for the cabinet use the original bot<strong>to</strong>m platesdelivered with the unit. With user-defined cable entriestake care of the degree of protection, fire protection andEMC compliance.CablesMechanical installation

32Fastening the cabinet <strong>to</strong> the floor and wall (non-marine units)Fasten the cabinet <strong>to</strong> the floor either with the outside fastening brackets from frontand back, or by the fastening holes inside the cabinet. When fastening at the back isnot possible, fasten the cabinet at the <strong>to</strong>p using L-brackets bolted <strong>to</strong> the holes of thelifting lugs (M16 bolt). The cabinet can be fastened against a wall or back <strong>to</strong> backwith another cabinet. See chapter Dimensional drawings for the horizontal andvertical fastening points. Height adjustment can be done by using metal shimsbetween the bot<strong>to</strong>m frame and floor.Fastening points when installedback against wallFastening points when installedback against back320 mm (12.28 in.) for fan replacementin frame sizes R7 and R8> 400 mm(15.75 in.)IP 21/22/42> 400 mm(15.75 in.)IP54Top clearanceL-bracketM16 boltCabinet <strong>to</strong>pFastening the cabinet at the <strong>to</strong>pby using L-brackets (side view)Mechanical installation

33Fastening the cabinet with the outside bracketsInsert the bracket in<strong>to</strong> the longitudinal hole in the edge of the cabinet frame body andfasten it with a bolt <strong>to</strong> the floor.Dimensions of the fastening bracket:Cabinet frame bodyCubiclewidthmm [in.]200 [7.87]Fastening hole distance in mm [in.]a b aCabinet frame body46 [1.81]400 [15.75] a: 250 [9.84]600 [23.62] a: <strong>45</strong>0 [17.71]800 [31.50] a: 650 [25.29]1000 [39.37] a: 350 [13.78], b: 150 [5.91], a: 350 [13.78]1200 [47.24] a: <strong>45</strong>0 [17.71], b: 150 [5.91], a: <strong>45</strong>0 [17.71]Fastening bolt: M10 <strong>to</strong> M12 (3/8” <strong>to</strong> 1/2”).Mechanical installation

34Fastening the cabinet through the holes inside the cabinetThe cabinet can be fastened <strong>to</strong> the floor using the fastening holes inside the cabinet,if they are available and accessible. The maximum allowed distance between thefastening points is 800 mm (31.50 in.).Side plates of the cabinet: 15 mmBack plate of the cabinet: 10 mmGap between the 200 mm, 400 mm, 600 mm,800 mm, 1000 mm and 1500 mm cubicles:25 [0.98]IP 20...42≈ 0.5IP 54≈ 1aCubicle width Fastening hole distance in mm [in.]∅ 31 mm [1.22]a b amm [in.]200 [7.87] a: 50 [1.97]400 [15.75] a: 250 [9.84]600 [23.62] a: <strong>45</strong>0 [17.71]800 [31.50] a: 650 [25.29]1000 [39.37] a: 350 [13.78], b: 150 [5.91], a: 350 [13.78]1200 [47.24] a: <strong>45</strong>0 [17.71], b: 150 [5.91], a: <strong>45</strong>0 [17.71]Fastening bolt: M10 <strong>to</strong> M12 (3/8” <strong>to</strong> 1/2”).Mechanical installation