924G - Eltrak

924G - Eltrak

924G - Eltrak

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

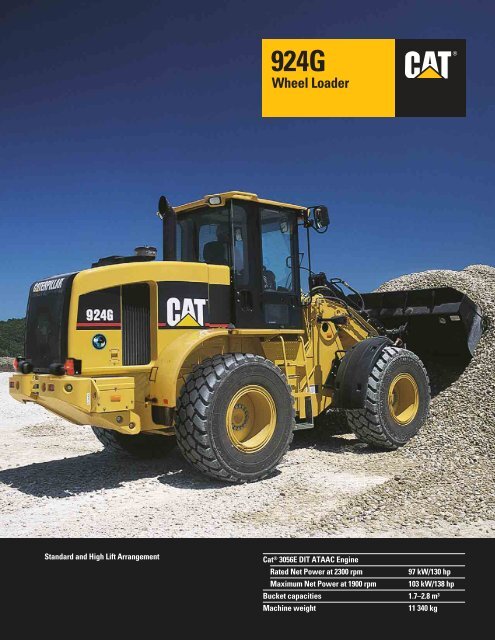

<strong>924G</strong>Wheel Loader®Standard and High Lift ArrangementCat ® 3056E DIT ATAAC EngineRated Net Power at 2300 rpm97 kW/130 hpMaximum Net Power at 1900 rpm 103 kW/138 hpBucket capacities 1.7–2.8 m 3Machine weight11 340 kg

✔Operator StationThe <strong>924G</strong> operator station isergonomically designed to create acomfortable work area. Easy-to-usemachine controls and a new gaugeconsole reduce operator fatigue andincrease efficiency and productivity.pg. 8ServiceabilityPerform daily maintenance with easyground-level access to all major servicepoints. Gull-wing doors provideexcellent engine access and a swing-outfan simplifies radiator service.pg. 11Complete Customer SupportCaterpillar dealers offer unmatchedcustomer support, with excellentwarranty and fast parts availability,resulting in maximum uptime andminimum repair costs.pg. 123

Caterpillar Power TrainRugged, dependable Cat components deliver maximum rimpull to the groundand full power to the loader hydraulics.Caterpillar Engine. The six-cylinder,3056E direct injection, turbocharged(DIT) engine with air-to-air after cooler(ATAAC) has a proven reputation forreliability, durability and performance.Fuel injection is electronicallycontrolled for precise timing.Torque Rise. The engine features a 48%torque rise for increased power duringheavy-duty use.Emission Standards. The 3056E DITATAAC engine meets worldwideemissions standards.Cylinders. Low cylinder pressure riseand low peak pressure provideoutstanding reliability and durability.Cooling System. Engine and coolingsystem are in separate compartments forclean, quiet operation and easy service.Air-to-Air After Cooling. Air-to-air aftercooling reduces engine emissions.Electronic Control Module.The Caterpillar engine control modulenot only controls the timing needs ofthe engine but also monitors criticalsystems to maintain optimum performanceand provide engineprotection.Service Intervals. The normal engineoil change requirement is every 500hours of operation.Axles. Heavy-duty design featuresstrong gears and bearings for durableperformance. Oscillating rear axle helpsassure four-wheel ground contact foroptimum traction and stability.Brakes. Oil-disc brakes are adjustmentfree and fully enclosed.Optional Heavy-Duty Brakes. Optionalheavy-duty brakes provide additionalbrake discs and oil cooler for severeapplications.Limited Slip Differentials. Optionalfront and rear Limited Slip differentialsprovide improved traction in poor oruneven underfoot conditions.Duo-Cone Seals. Duo-Cone Seals keepoil in and contaminants out.Transmission. Rugged, field-provenCaterpillar 4F/3R transmission usesheavy-duty components for durable andreliable operation. High-energy frictionmaterials allow for better heat tolerancewhile thick reaction plates allow forbetter heat dissipation. The transmissionis also designed for easy service andrebuild.Electronic Clutch Pressure Control.Electronic Clutch Pressure Control(ECPC) manages shift torque providingexceptional smoothness.Gears. High-contact ratio spur gears areprecision ground and heat treated forquiet, durable operation.Shifting Options. Operator can choosemanual shift or two autoshift modes(full throttle or variable shift control).Full throttle selection providesmaximum acceleration while variableselection increases fuel economy andimproves operator comfort.4

Hydraulic SystemModular system provides improved efficiency and greater control.Precise Control. Designed byCaterpillar, the modular hydraulicsystem provides low effort operation andsuperior control.Performance. Fast loader cycle timesresult in greater productivity.The hydraulic system is matchedto the power train for outstandingperformance.Joystick Control. Low effort, joystickimplement control improves efficiencywith simultaneous lift and tilt functions.Load-Sensing Steering. Load-sensingsteering provides low effort operatorcontrol, making more power availablefor rimpull, breakout and lift forces.Load-Sensing Implement Hydraulics.Load-sensing implement hydraulicsprovide exceptional second gearhydraulic-to-rimpull match for bettermaterial handling.Pumps. Separate steering and implementpumps improve machine response.Tilt Cylinder. A large tilt cylinderdelivers exceptional backdragperformance.Pressure Taps. Standard pressure tapsallow quick diagnosis of the entirehydraulic system.Hoses. Caterpillar XT hoses andcouplings provide rugged, reliableperformance with significantly reducedrisk of leaks and blown lines.Modular Hydraulic Control Valves.Modular hydraulic control valves add anew dimension of versatility that greatlysimplifies and lowers overall cost ofreconfiguring the machine foradditional functions.Two-Section Control Valve. The <strong>924G</strong>comes equipped with a two-sectioncontrol valve for lift and tilt functions.Up to two additional valve sections canbe stacked onto the existing ones.Ground Level Access. The controlvalves feature convenient ground levelaccess for easy modifications to thesystem.Diagnostics and Monitoring. The <strong>924G</strong>is equipped with Scheduled OilSampling (S•O•S SM ) ports for thehydraulic, transmission and engine oils.Optional Ride Control System. Theimproved Ride Control system providesa comfortable ride at all speeds andimproved hard bank digging. Threemodes are available: auto, on and off.Optional Joystick with Integrated ThirdFunction Controls. Low effort pilothydraulics operated lift and tilt functionsare combined with electrohydraulictransmission forward-neutral-reverse,transmission kick down and integratedthird function auxiliary hydrauliccontrols. Enables operator to maintaincontrol of loader linkage whilemanipulating hydromechanical toolssuch as top clamp buckets and forks,high dump buckets and hydraulicbrooms.Two modes of operation include: Standard Work Tool Mode – Providesintermittent flow to the work tool.Rolling the roller switch upwardpressurizes the left side of the auxiliarysystem, downward activation of theroller switch pressurizes the right side.This system is ideal for high or sidedump buckets. Continuous Flow Mode – Graduallyincreases auxiliary hydraulic flow tothe work tool when the roller switch isheld upward. A momentarydownward activation of the rollerswitch stops the flow. Adjust the flowrate with a control knob enablingbroom speed to be matched to vehicleground speed or maximum top clampactivation speed.5

VersaLink Loader LinkageLinkage design offers unparalleled versatility without compromise to performance.Linkage Design. Versatility is the keybenefit of the VersaLink loader linkage.The <strong>924G</strong> can be configured in manyways:with a Quick Coupler, work toolchanges are quick and easy. In thisconfiguration, the <strong>924G</strong> offers theversatility of an integrated toolcarrierand the performance of a wheelloader;equipped with pin-on tools, like abucket, the <strong>924G</strong> becomes adedicated wheel loader, withexceptional breakout force, tippingload and dump height;equipped with the High LiftVersaLink loader linkage option, the<strong>924G</strong> is ideal for special applicationsthat require more reach and liftheight.Reconfiguration. The VersaLink loaderlinkage can be reconfigured from pin-onto Quick Coupler or from standardlinkage to high lift linkage with aminimum of new parts required.Outstanding Performance. TheVersaLink loader linkage is designedfor exceptional loader performance in awide range of applications, offering: increased breakout force to shortencycle times and increase bucket fillfactors; higher dump clearance for working inhigh lift applications that ordinaryloaders cannot; more dig depth for better excavationperformance, even when equippedwith larger 20.5 x 25 tires; greater rackback angle for improvedmaterial retention, resulting in higherproductivity; greater dozing angle for improvedcontrol of material when fine grading.Visibility. The VersaLink loader linkagegeometry maximizes visibilitythroughout the entire production cycle.Parallel Lift. Parallel lift simplifiesworking with palletized or stackedmaterial. Operators can concentrate onmaterial placement while the loadautomatically remains parallelthroughout the lift range. And, like anintegrated toolcarrier, the <strong>924G</strong> caneasily manipulate loads.6

Work ToolsIncrease your productivity by performing a variety of jobs with one machine.Versatility. With a variety of work toolsoffered by Caterpillar, the <strong>924G</strong> is idealfor a wide range of applications.Quick Coupler. Work tools can bechanged quickly and easily with themachine’s integral quick couplersystem. A switch in the operatorcompartment activates a hydrauliccylinder for positive tool engagement ordisengagement.Buckets. With exceptional rimpull andhigh breakout and lift forces, the <strong>924G</strong>demonstrates strong performance as abucket loading machine. A wide rangeof Caterpillar buckets are availableincluding: general purpose penetration light material multi purpose side dump high dump material handlingMaterial Handling. Exceptionalvisibility and heavy-lift capabilitiesenable you to work quickly andefficiently with the <strong>924G</strong> as a materialhandler. A wide range of tools areavailable such as: pallet forks lumber and log forks, with or withouttop clamp, coupler-mounted or pin-on material handling arm tire loaders specialty clampsSpecial Applications. Some of thenumerous specialty tools availableinclude: dozer blades snow plows hydraulic brooms asphalt cutter loader rakesAuxiliary Hydraulics. Optional 3rdand 4th function hydraulics areavailable for use with work tools thatrequire hydraulic power, such as rotarybrooms, augers, high dump and sidedump buckets.7

Operator StationErgonomic design emphasizes comfort, visibility and easy operation.Cab. The ergonomic cab provides acomfortable work environment withlarge windows, spacious interior room,generous storage areas and low interiorsound levels.Access/Egress. Access/egress isthrough a two-door design. Both doorsopen fully and lock flush against thecab. Steps leading up to the cab arewide and angled out for secure footing.Windows. Large windows improvevisibility in all directions. The rearwindow features a standard electricdefroster. Sliding glass is availableas an option on the doors.Visibility. Visibility to critical areassuch as the bucket have been optimized.Optional Rear View Camera System.Work area visual enhancement systemutilizes a closed circuit videomonitoring system. One, two or threecameras can be mounted on the machineframe. Objects can be viewed in a7 inch color LCD monitor located inplace of the right cab rear view mirror.Rear view system is compatible withheavy duty radiator guarding and wastehandling packages.Instrument Panel. Redesignedinstrument panel is conveniently locatedwith easy-to-read gauges and expandedwarning/indicator and diagnosticfunctions.Electronic Engine Speed Control.A specific engine rpm can be set andmaintained with a switch in the cab.Steering System. The load-sensing,closed-center steering system with flowamplification matches steering responseto a wide variety of applications. Theadjustable steering console tilts easilyout of the way. Dual suspended brakepedals function as a brake and atransmission neutralizer so the operatorcan maintain high engine rpm for fullhydraulic flow and fast cycle times.8

Seat. The standard seat is available incloth or vinyl with fully adjustablefore/aft position, seatback angle, bottomcushion height, armrest angle andsuspension stiffness. Other seat optionsinclude: Cat Contour Seat which addsadjustable backrest and adjustablelumbar support Cat Contour Series Seat with addedair suspension, electrically adjustable KAB fabric seat heated with an alarmfeature for operatorSeat Belt. All seats include acomfortable 51 mm or 75 mm wideretractable seat belt.Storage. Generous storage spaceincludes a lockable compartment, coathook and special molded compartmentsdesigned to hold a lunchbox/cooler,cup or can. A tool box is also provided.Customize the Cab. The cab can becustomized with: 12V converter for poweringelectronics such as cellular phones,two-way radios and music systems Radio installation package Sun visor for windshield Roll-down sun screen for rearwindow External mirror packages Auxiliary lighting packages Low Effort Operation. Joystick hydrauliccontrols provide ease of lift and tiltfunctions. A single joystick is standard.An Integrated directional control switchon the joystick provides easy operationand enhanced productivity.9

Owning and Operating CostsCost saving features help improve your bottom line.Low Fuel Consumption. The 3056E DITATAAC engine features low fuelconsumption for more economicaloperation.Increased Power, Faster Cycle Times.Higher horsepower and increasedtorque rise results in more power andfaster cycle times, allowing the operatorto get more work done in a day.Extended Service Intervals. Serviceintervals have been extended to reducemachine service time and increasemachine availability: 4000 hour hydraulic oil change 1000 hour hydraulic filter change 500 hour engine oil changeSmoother Transmission for IncreasedProductivity. A smoother shiftingtransmission provides a morecomfortable work environment,allowing the operator to be moreproductive throughout the entire workshift.Demand Fan. Demand fan changesspeed to meet load requirements andsave fuel.Engine Derate Feature. Auto Deratemonitors vital engine systems and will,if necessary, derate the enginehorsepower up to 50% to protect theengine.Product Link Option. Caterpillar’s assetmanagement or equipment managementsystem called Product Link, enablesdealers and their customers to trackequipment for hours and location, andin some cases monitor machine health.This easy to use system providesinformation flow between a machineand the user through the internet basedDealer Storefront. This informationhelps lower operating costs throughtimely service/repairs and optimizedmachine use.Machine Security System Option.The Machine Security System (MSS)inhibits unauthorized machine use byimmobilizing vital electrical circuits.Critical machine circuits are inhibitedunless a valid key is used to start themachine.10

ServiceabilityImproved access and fewer maintenance requirements add up to unparalleledease of service.Easy Access. Gull-wing engineenclosure doors with gas struts lift forexceptional access to filters and servicepoints. Radiator and oil coolers areeasily accessible for cleaning.Simplified Routine Service. All servicepoints are accessible from the groundlevel. It is easy to check radiatorcoolant, hydraulic oil and transmissionoil levels with sight gauges.Swing-out Cooling Fan. A swing-outcooling fan allows quick, easy cleaningand service of the radiator. The fan ishydraulically driven and separate fromthe engine compartment for exceptionallow noise operation.Optional Reversing Fan. Optionalreversing capability of the fan cleansscreens without interrupting machineoperation.S•O•S Ports. Scheduled Oil Sampling(S•O•S) ports are factory installed forimproved access to engine, transmissionand hydraulic oils. S•O•S ports make oilsampling quicker, cleaner and providethe best oil sample for analysis.Oil Filters. Spin-on filters for engine oil,transmission oil and hydraulic oil arevertically mounted for easier servicing.Self-Diagnostics. Built in selfdiagnostics allow quick and easytroubleshooting by service personnel.Service codes are easily accessedthrough the gauge console.Extended Life Coolant/Antifreeze.Cat Extended Life Coolant/Antifreezeallows extended operation (up to6000 hours) between changes.Other Service Features. Other servicefeatures include: Maintenance-free driveshaft Stationary radiator and coolant hoses Standard hydraulic oil cooler Adjustment-free brakes Adjustment-free engine fuel system Grouped grease fittings Positive torque hose clamps Braided, color coded wiring11

Environmentally Responsible DesignCaterpillar machines not only help you build a better world, they help maintain and preservethe fragile environment.Low Fuel Consumption. The <strong>924G</strong> isthe top performer in its size class.The result is more work done in a day,less fuel consumed and minimal impacton the environment.Low Exhaust Emissions. The Cat 3056EDIT ATAAC is a low emission enginedesigned to meet current worldwideemission regulations and is Stage IIcompliant.Quiet Operation. The engine coolingsystem allows the engine to be fullyenclosed, allowing less engine noiseto escape. With the optional soundsuppression package, the <strong>924G</strong> iseven quieter.Ozone Protection. To help protectthe earth’s ozone layer, the airconditioning unit uses only R-134arefrigerant which does not containharmful chlorofluorocarbons (CFC’s).Fewer Leaks and Spills. Engine oil,transmission and hydraulic filters arepositioned vertically and are easilyremoved without spillage. Cat O-ringface seals, XT hose and hydrauliccylinders are all designed to helpprevent fluid leaks that can weakenthe machine’s performance and causeharm to the environment.Rebuildable Components.All major components are designedfor rebuildability.Biodegradable Hydraulic Oil.Caterpillar biodegradable hydraulic oilcan be used in the <strong>924G</strong>, providing anenvironmentally-sound alternative tomineral-based oils.Complete Customer SupportCaterpillar dealer services ensure a longer machine operating life with lower costs.Selection. Make detailed comparisonsof machines before purchasing.What are the job requirements?What production is needed?What is the true cost of lost production?Your Cat dealer can give you preciseanswers to these questions.Purchase. Look at the value the <strong>924G</strong>offers. Consider the financing optionsyour Cat dealer offers as well as daytodayoperating costs. Dealer supportservices can be included in the cost ofthe machine to yield lower equipmentowning and operating costs over the lifeof the machine.Operation. For the best operatingtechniques to increase productivityand your profit, turn to your Cat dealerfor the latest training literature andknowledgeable staff.Maintenance. Choose from a widerange of maintenance services at thetime of machine purchase. Repairoption programs guarantee the cost ofrepairs up front. Diagnostic programssuch as S•O•S Oil Analysis andTechnical Analysis help avoidunscheduled repairs that can costunnecessary time and money.Replacement. Repair, rebuild orreplace? Your Cat dealer can help youevaluate the cost involved to makethe right choice.Product Support. You will find nearlyall parts at our dealer parts counter.Cat dealers utilize a worldwidecomputer network to find in-stock partsto minimize machine downtime.Additionally, Caterpillar offers a lineof genuine remanufactured componentswhich can help lower repair costs.12

Engine TorqueNm600500400300200EngineCaterpillar four-stroke cycle, six cylinder3056E DIT ATAAC diesel engine.Rated Net Power2300 rpmISO 924997 kW/130 hpEEC 80/1269 97 kW/130 hpMaximum Net Power 1900 rpmISO 9249103 kW/138 hpEEC 80/1269 103 kW/138 hpBore100 mmStroke127 mmDisplacement6 liters Net Power ratings are tested at thereference conditions for the specifiedstandard. Net power advertised is the poweravailable at the flywheel when the engineis equipped with alternator, aircleaner, muffler and fan at minimumspeed. No derating required up to 3000 maltitude. Auto Derate protects hydraulicand transmission systems. When the fan is at maximum speed ratednet power is 86 kW (115 hp) andMaximum Net Power is 96 kW (129 hp)at the flywheel per the SAE referenceconditions. The Caterpillar 3056E DIT ATAACengine meets Stage II off highwayemission regulations.Features Electronically controlled rotary fuel pump Three-ring, controlled-expansion,lubricated pistons Gear-driven water and oil pumps One-piece cast iron cylinder heads withtwo valves per cylinder Fuel priming pump and fuel/waterseparator S•O•S sampling port for engine oil Replaceable dry liners Cast aluminum valve cover Radiator can be easily accessed forcleaningEngine TorqueEngine PowerNetNetkW120100806040TransmissionStandard Transmission and OptionalLow Speed Transmission. Maximumtravel speeds (550/65 R25 tires)Standard Low SpeedForward km/h km/h1 7 42 12 83 22 204 39 39Reverse1 7 42 12 83 22 21Engine PowerElectronically-controlled Caterpillarcountershaft transmission with fullon-the-go directional and speedchange capability.High-energy friction materials andthick reaction plates for bettertolerance of heat.High-contact ratio spur gears areprecision ground and heat treated forquiet, reliable operation.Electronic autoshift is standard.Button on implement control leverallows downshifting on demand.Computer controlled modulationprovides smoother transitions.Optional low speed transmissionavailable for better match withattachments requiring high hydraulicflow.Tires 17.5 - 25 17.5 R25 550/65 R25 20.5 - 25 20.5 R25Loader Hydraulic SystemOutput at 2300 engine rpmand 6900 kPa withSAE 10W oil at 65°CMaximum working pressureHydraulic cycle timeRaiseDumpLower, empty,float downTotalLift cylinders, double actingBoreStrokeTilt cylinders, double actingBoreStroke152 L/min25 900 kPa5.1 Seconds1.4 Seconds2.4 Seconds8.9 Seconds101.6 mm810 mm133.4 mm945 mmLoad-sensing system provides onlythe flow and pressure needed to movethe load.Variable-displacement axial pistonimplement pump.Low effort, hydraulic joystickcontrols.Electronic pilot shut-off switchdisables implement functions foradded safety.Hydraulic couplings with O-ring faceseals.Space around radiator for easycleaning.Improved Ride Control systemavailable to provide improved ridewith less spillage from bucket duringload & carry operations and betterhard bank capability.Other tire choices are available, contact your Cat Dealerfor details.In certain applications, the loader’s productivecapabilities may exceed the tire’s tonnes-km/hcapabilities. Caterpillar recommends that you consulta tire supplier to evaluate all conditions before selectinga tire model.100201000 1200 1400 1600 1800 2000 2200Engine Speedrpm<strong>924G</strong> Wheel Loader specifications 13

SteeringAxlesWeightsMinimum turning radius(over tire)5070 mmSteering angle, each direction 40ºSteering cylinders, two, bore 70 mmHydraulic output at2300 engine rpm and6900 kPa 106 L/minMaximum workingpressure20 685 kPaCenter-point frame articulation.Front and rear wheels track.Variable displacement piston pumpprovides steering power at all engineand ground speeds.Tilt steering console.High-impact rubber steering stops.Secondary steering system availableto meet roading regulations in variouscountries and ISO 5010. Fixed front, oscillating rear (±12°with 17.5 - 25 L-2 tires). Caterpillar axle with fully-enclosedbrakes and final drives. Patented Duo-Cone Seals betweenaxle and housing. Rear wheel can raise or drop a totalof: 423 mm with 17.5 tires,or 326 mm with 20.5 tires. Limited Slip differentials are optionalon front, rear or both axles. Rear axle trunnion has remotelubrication fitting. Planetary final drives are lubricatedfrom the main oil sump. High contact gearset reduces noiselevels during meshing.Operating Weight11 340 kgSpecifications are for <strong>924G</strong> with optionalcounterweight, standard lubricants, full fuel tank,cab with A/C, sliding glass, Cat contour seat, limitedslip axles with dual disc rear, 4L 4V hydraulics, heavyduty cooler, supplemental steering, roading fenders,reversing fan, back-up alarm, guards, ride control,radio, 1.8 m 3 bucket with bolt-on cutting edge, 80 kgoperator and 20.5 R25 radial (L-3) XHA tires.Service Refill CapacitiesLitersFuel tank 225Cooling system 40Crankcase 20Transmission 23Front axle 21Rear axle 21Hydraulic system (including tank) 125Hydraulic tank 70Bucket ControlsBrakesROPS/FOPSLift circuit Four positions: raise, hold, lowerand float. Adjustable automatic kickout fromhorizontal to full tilt.Tilt circuit Three positions: tilt back, holdand dump. Two speed dump for quick dumpingwith bucket and precise load controlwith forks or other work tools. Adjustable automatic bucketpositioner to desired loading angle. Does not require visual spotting.Controls Choice of two low effort controlsystems: a joystick or a two-levercontrol of lift and tilt circuits. Optional third and fourth functionhydraulic circuits available withindividual lever controls for remotehydraulic functions. Controls can be disabled for roading.14 <strong>924G</strong> Wheel Loader specificationsService brake Inboard oil-immersed disc brakeson front and rear axles are standard. Completely enclosed and sealed. Adjustment-free. Separate circuits for front and rear. Dual pedal braking system. Fully integrated with hydraulicsystem, no air system required.Secondary brake Indicator light alerts operator if brakepressure drops. Continually-charged nitrogenaccumulators provide stopping powerafter loss of engine power.Parking brake Mechanical, shoe-type brake. Mounted on drive line for positivemanual operation. Application of parking brakeneutralizes the transmission.Heavy-duty brake Optional heavy-duty brakes withintegrated oil cooler. Caterpillar cab with integratedRollover Protective Structure(ROPS/FOPS) are standard. ROPS meets ISO 3471:1994. FOPS meets ISO 3449:1992 Level II.SoundOperator Sound The operator sound level measuredaccording to the procedures specifiedin ISO 6394:1992 is 74 dB(A), forcab offered by Caterpillar, with doorsand windows closed.Exterior Sound As manufactured by Caterpillar, thismachine's exterior sound power levelmeets the criteria spelled out in theEuropean Directives noted on thecertificate of conformance and theaccompanying labeling.– standard version 104 dB(A)– low sound or Blue Angelversion 101 dB(A)

Supplemental SpecificationsAir conditionerCanopy, ROPS (less cab)Counterweight, 175 kg (removal)Guard, crankcaseGuard, driveshaftGuard, power trainRide Control SystemSecondary steering (removal)Fenders, roadingLow sound packageLighting AR, roadingTires, 1 piece rims17.5-25, 12PR (L-2)17.5-25, 12PR (L-3)17.5-R25, radial (L-2)17.5 R25, radial (L-3)Tires, 3 piece rims17.5-25, 12PR (L-2)17.5-25, 12PR (L-3)17.5-25, radial (L-2)17.5 R25, radial (L-3)550/65 R25, radial (L-2)550/65 R25, radial (L-3)20.5-25, 12PR (L-2)20.5-25, 12PR (L-3)20.5-25, radial (L-2)20.5-25, radial (L-3)Bucket Size SelectorMaterial DensityBucket1.7 m 31.8 m 32.0 m 3High LiftHigh LiftHigh LiftStandardStandardStandardChange inOperating Weight2.1 m 3 StandardHigh Lift1000 1200 1400 1600 1800 2000 kg/m 3Change in ArticulatedStatic Tipping Loadwith Hook-On Bucketkgkg-32 -27-199 -166-175 -273-15 -19-17 -5-52 -47-40 -27-37 -31-39 -50104 11612 11-652 -371-580 -330-612 -348-512 -292-528 -301-456 -260-488 -278-388 -221-196 -112-136 -78-240 -137-36 -21-172 -980 02.8 m 3 700 800 900 1000 1100 kg/m 35.0 m 3 400 450 500 550 600 kg/m 3% – Bucket Fill Factor115% 100% 95%Typical MaterialDensities – Loosekg/m 3Basalt 1960Bauxite, Kaolin 1420Claynatural bed 1660dry 1480wet 1660Clay and graveldry 1420wet 1540Decomposed rock75% rock, 25% earth 196050% rock, 50% earth 172025% rock, 75% earth 1570Earthdry, packed 1510wet, excavated 1600Granitebroken 1660Gravelpitrun 1930dry 1510dry, 6-50 mm 1690wet, 6-50 mm 2020Gypsumbroken 1810crushed 1600Limestonebroken 1540crushed 1540Sanddry, loose 1420damp 1690wet 1840Sand and clayloose 1600Sand and graveldry 1720wet 2020Sandstone 1510Shale 1250Slagbroken 1750Stonecrushed 1600<strong>924G</strong> Wheel Loader specifications 15

➤➤➤➤➤➤➤➤➤➤➤➤➤➤Dimensions with BucketAll dimensions are approximate. Dimensions may vary with bucket.➤15➤➤➤➤1➤2➤310111213➤➤➤➤14➤➤16➤➤1817➤➤➤2524234➤5➤19➤➤7➤➤9➤68➤➤➤20➤78°➤➤2122➤➤Standard VersaLink High Lift VersaLink1 Height to top of ROPS/FOPS 3227 mm 3226 mm2 Height to top of exhaust stack 3211 mm 3210 mm3 Height to top of hood 2219 mm 2218 mm4 Height to centre of axle 692 mm 692 mm5 Ground clearance 436 mm 435 mm6 Overall length 7168 mm 7659 mm7 Length - rear axle to bumper 1923 mm 1923 mm8 Centre line of front axle to hitch 1400 mm 1400 mm9 Wheel base length 2800 mm 2800 mm10 Dump clearance at maximum lift and 45˚ dump 2828 mm 3335 mm11 Bucket clearance at maximum lift and carry 3556 mm 4063 mm12 Bucket pin height at maximum lift 3881 mm 4387 mm13 Overall height - bucket raised 5178 mm 5684 mm14 Reach at maximum lift and 45˚ dump 992 mm 993 mm15 Rack back angle at maximum lift and level 58˚ 62˚16 Dump angle at maximum lift 45˚ 45˚17 Rack back angle at ground 50˚ 50˚18 Rack back angle at carry 51˚ 54˚19 Carry height 435 mm 592 mm20 Digging depth 64 mm 75 mm21 Width over tread center22 Overall width over tires23 Minimum turning radius over tires17.5-25 Tires 20.5-25 Tires1880 mm 1880 mm2356 mm 2466 mm5070 mm 5135 mm24 Loader clearance radius with bucket in carry position See Operation Specifications on pg 20+2125 Steering angle - left/right40˚40˚Change in vertical dimension-68 mm 0Dimensions listed are for <strong>924G</strong> with optional counterweight, standard lubricants, full fuel tank, cab with A/C, sliding glass, Cat contour seat, limited slip axleswith dual disc rear, 4L 4V hydraulics, heavy duty cooler, supplemental steering, roading fenders, reversing fan, back-up alarm, guards, ride control, radio,1.8 m 3 bucket with bolt-on cutting edge, 80 kg operator and 20.5 R25 radial (L-3) XHA tires. Refer to Operating Specifications for bucket variations.16

➤➤Dimensions with Pallet ForksAll dimensions are approximate. Dimensions may vary with bucket.Standard VersaLinkFork Tine Length1200 mm 1350 mm1 7607 mm 7772 mm2 32 mm 32 mm3 932 mm 947 mm4 1561 mm 1576 mm5 1790 mm 1790 mm6 3637 mm 3652 mm7 762 mm 762 mm➤➤7➤4➤➤High Lift VersaLink1 8104 mm 8269 mm2 42 mm 42 mm3 1468 mm 1443 mm4 1952 mm 1967 mm5 4144 mm 4159 mm6 1790 mm 1790 mm7 762 mm 762 mm➤1➤3➤➤➤➤➤652Operating Specifications with Pallet ForksFork Tine LengthFork Tine LengthStandard VersaLink: 1200 mm 1350 mmOperating load:Per EN 474-3, rough terrain (60% of FTSTL) 3263 kg 3128 kgPer EN 474-3, firm and level ground (80% of FTSTL) 4350 kg 4170 kgLoad center 600 mm 675 mmStatic tipping load with level arms and forks, straight* 6209 kg 5960 kgStatic tipping load with level arms and forks, full 40˚ turn* 5438 kg 5213 kgOperating weight* 11 042 kg 11 102 kgHigh Lift VersaLink:Operating load:Per EN 474-3, rough terrain (60% of FTSTL) 2789 kg 2678 kgPer EN 474-3, firm & level ground (80% of FTSTL) 3719 kg 3571 kgLoad center 600 mm 675 mmStatic tipping load with level arms and forks, straight* 5330 kg 5108 kgStatic tipping load with level arms and forks, full 40˚ turn* 4649 kg 4464 kgOperating weight* 11 128 kg 11 188 kg* Static tipping and operating weights are for a <strong>924G</strong> with optional counterweight, lubricants, full fuel tank, standard lubricants, cab with A/C, sliding glass,Cat contour seat, limited slip axles with dual disc rear, 4L 4V hydraulics, heavy duty cooler, supplemental steering, roading fenders, reversing fan, back-upalarm, guards, ride control, radio, 1.8 m 3 bucket with bolt-on cutting edge, 80 kg operator and 20.5 R25 radial (L-3) XHA tires. Tipping load is defined by SAEJ732 JUN92.<strong>924G</strong> Wheel Loader specifications 17

➤➤➤➤➤Dimensions with Standard VersaLink and Millyard ForksAll dimensions are approximate. Dimensions may vary with bucket.➤Hook-on Fork Pin-On Fork1 7670 mm 7556 mm2 969 mm 865 mm3 1597 mm 1436 mm4 798 mm 637 mm5 1220 mm 1220 mm6 1802 mm 1736 mm7 2141 mm 2491 mm8 2462 mm 2533 mm9 3650 mm 3583 mm10 69˚ 48˚11 2705 mm 2705 mm12 1195 mm 1195 mm13 1651 mm 1651 mm14 1779 mm 1779 mm➤➤➤➤121314➤➤➤1➤➤➤432➤➤45°➤➤105➤➤➤➤➤➤76811➤9Operating Specifications with Standard VersaLink and Millyard ForksFork Type Hook-On Fork Pin-on ForkOperating load:Per EN 474-3, log handling, rough terrain (75% of FTSTL) 3521 kg 3870.75 kgPer EN 474-3, log handling, firm and level ground (85% of FTSTL) 3990 kg 4386.85 kgLoad center 616 mm 592 mmStatic tipping load with level arm and forks, straight* 5449 kg 5961 kgStatic tipping load with level arm and forks, full 40˚ turn 4694 kg 5161 kgOperating weight* 11 742 kg 11 630 kg* Static tipping and operating weights are for a <strong>924G</strong> with optional counterweight, lubricants, full fuel tank, standard lubricants, cab with A/C, sliding glass,Cat contour seat, limited slip axles with dual disc rear, 4L 4V hydraulics, heavy duty cooler, supplemental steering, roading fenders, reversing fan, back-upalarm, guards, ride control, radio, 1.8 m3 bucket with bolt-on cutting edge, 80 kg operator and 20.5 R25 radial (L-3) XHA tires. Tipping load is defined by SAEJ732 JUN92.18 <strong>924G</strong> Wheel Loader specifications

➤➤➤➤➤➤➤Dimensions with Material Handling ArmAll dimensions are approximate.StandardVersaLinkHigh LiftVersaLink1 2355 mm 2077 mm2 1881 mm 1670 mm3 1407 mm 1264 mm4 7197 mm 7853 mm5 6317 mm 6940 mm6 5438 mm 6027 mm7 3221 mm 3612 mm8 4220 mm 4610 mm9 5220 mm 5611 mm10 1602 mm 1601 mm11 2138 mm 2063 mm12 3088 mm 2967 mm13 4039 mm 3871 mm14 858 mm 1631 mm15 1166 mm 2058 mm16 1475 mm 2485 mm➤➤➤➤➤➤231➤➤➤789➤➤➤➤➤➤➤10➤➤➤45614 13➤➤111215➤➤16➤➤Operating Specifications with Material Handling ArmStandard VersaLink: Retracted Mid-Position ExtendedOperating load 1965 kg 1557.5 kg 1277.5 kgStatic tipping load, straight* 4505 kg 3571 kg 2948 kgStatic tipping load, full 40° full turn* 3930 kg 3115 kg 2555 kgOperating weight* 11 000 kg 11 000 kg 11 000 kgEquipped with High Lift VersaLink:Operating load 1717.5 kg 1386.5 kg 1164 kgStatic tipping load, straight* 3967 kg 3205 kg 2692 kgStatic tipping load, full 40° full turn* 3435 kg 2773 kg 2328 kgOperating weight* 11 086 kg 11 086 kg 11 086 kg* Static tipping and operating weights are for a <strong>924G</strong> with optional counterweight, lubricants, full fuel tank, standard lubricants, cab with A/C, sliding glass,Cat contour seat, limited slip axles with dual disc rear, 4L 4V hydraulics, heavy duty cooler, supplemental steering, roading fenders, reversing fan, back-upalarm, guards, ride control, radio, 1.8 m 3 bucket with bolt-on cutting edge, 80 kg operator and 20.5 R25 radial (L-3) XHA tires. Tipping load is defined by SAEJ732 JUN92.Machine stability and operating weights are affected by tire size, tire ballast and other work tools.<strong>924G</strong> Wheel Loader specifications19

Standard VersaLink and BucketOperating specificationsHook-on Bucketsusing Quick CouplerPin-on Buckets(values in brackets)General Purpose BucketsPenetrationWaste/AgBolt-OnCutting EdgeBolt-OnTeeth and Segments*Bolt-OnTeeth*Flush MountedTeethBolt-OnCutting EdgeRated bucket capacitym 31.8 2.1 1.8 2.1 1.7 2.0 1.7 2.8Struck capacitym 31.5 1.7 1.5 1.7 1.4 1.6 1.4 2.3Bucket widthDump clearance at full liftand 45° dischargeReach at full liftand 45° dischargeReach at 45° dischargeand 2130 mm clearanceReach with lift arms horizontaland bucket levelDigging depthOverall lengthOverall height with bucketat full raiseLoader clearance radius withbucket in carry positionStatic tipping load, straightStatic tipping load,full 40° turnBreakout forceOperating weightmmmmmmmmmmmmmmmmmmkgkgkNkg2550 2550 2585 2585 2585 2585 2594 25502828 2759 2724 2655 2724 2655 2744 2623(2918) (2849) (2814) (2745) (2814) (2745) (2834) (2713)992 1060 1095 1163 1095 1163 1110 1198(885) (953) (988) (1056) (988) (1056) (1053) (1091)1515 1545 1558 1583 1558 1583 1586 1596(1451) (1484) (1500) (1529) (1500) (1529) (1530) (1544)2295 2392 2441 2538 2441 2538 2439 2585(2155) (2252) (2301) (2398) (2301) (2398) (2299) (2441)64 72 64 72 39 47 37 89(64) (72) (64) (72) (39) (47) (37) (89)7168 7272 7168 7418 7291 7397 7287 7479(7028) (7132) (7094) (7278) (7154) (7257) (7147) (7339)5178 5288 5178 5288 5178 5288 5178 5410(5088) (5200) (5088) (5200) (5088) (5200) (5088) (5322)5603 5631 5662 5690 5662 5690 5653 5689(5568) (5595) (5625) (5653) (5625) (5653) (5618) (5651)8286 8195 8120 7969 8299 8134 8355 7946(8720) (8647) (8554) (8419) (8740) (8585) (8801) (8382)7232 7144 7065 6919 7234 7083 7295 6910(7626) (7557) (7459) (7330) (7635) (7495) (7702) (7309)97 89 96 88 103 112 104 76(112) (102) (111) (101) (120) (108) (121) (86)11 335 11 383 11 470 11 567 11 384 11 433 11 326 11 497(11 213) (11 241) (11 349) (11 423) (11 263) (11 291) (11 182) (11 357)Specifications are for <strong>924G</strong> with optional counterweight, standard lubricants, full fuel tank, cab with A/C, sliding glass, Cat contour seat,limited slip axles with dual disc rear, 4L 4V hydraulics, heavy duty cooler, supplemental steering, roading fenders, reversing fan, back-up alarm,guards, ride control, radio, 1.8 m 3 bucket with bolt-on cutting edge, 80 kg operator and 20.5 R25 radial (L-3) XHA tires.* Dimensions are measured to the tip of the bucket teeth to provide accurate clearance data. SAE standards specifies the cutting edge.20 <strong>924G</strong> Wheel Loader specifications

High Lift VersaLink and BucketOperating specificationsHook-on Bucketsusing Quick CouplerPin-on Buckets(values in brackets)General Purpose BucketsPenetrationWaste/AgBolt-OnCutting EdgeBolt-OnTeeth and Segments*Bolt-OnTeeth*Flush MountedTeethBolt-OnCutting EdgeRated bucket capacitym 31.8 2.1 1.8 2.1 1.7 2.0 1.7 2.8Struck capacitym 31.5 1.7 1.5 1.7 1.4 1.6 1.4 2.3Bucket widthDump clearance at full liftand 45° dischargeReach at full liftand 45° dischargeReach at 45° dischargeand 2130 mm clearanceReach with lift arms horizontaland bucket levelDigging depthOverall lengthOverall height with bucketat full raiseLoader clearance radius withbucket in carry positionStatic tipping load, straightStatic tipping load,full 40° turnBreakout forceOperating weightmmmmmmmmmmmmmmmmmmkgkgkNkg2550 2550 2585 2585 2585 2585 2594 25503335 3266 3231 3162 3231 3162 3251 3130(3426) (3358) (3322) (3253) (3322) (3253) (3341) (3170)993 1061 1096 1165 1096 1165 1111 1199(886) (954) (989) (1057) (989) (1057) (1004) (1144)1946 1981 1999 2031 1999 2031 2024 2048(1876) (1914) (1933) (1968) (1933) (1968) (1960) (2020)2686 2783 2832 2929 2832 2929 2830 2976(2546) (2643) (2692) (2789) (2692) (2789) (2794) (2888)75 83 75 83 50 58 50 100(74) (82) (74) (82) (49) (57) (50) (150)7659 7761 7805 7907 7787 7890 7784 7965(7518) (7620) (7664) (7766) (7649) (7749) (7644) (7824)5684 5794 5684 5794 5684 5794 5684 5917(5595) (5707) (5595) (5707) (5595) (5707) (5595) (5778)5840 5870 5902 5933 5902 5933 5873 5934(5801) (5831) (5862) (5892) (5862) (5892) (5854) (11 781)6717 6638 6556 6475 6708 6578 6769 6428(7107) (7048) (6946) (6884) (7103) (6988) (7120) (6827)5880 5803 5718 5640 5863 5743 5928 5605(6188) (6131) (6026) (5968) (6176) (6071) (6251) (5923)97 89 96 88 103 112 104 76(112) (102) (111) (101) (120) (108) (121) (86)11 421 11 470 11 556 11 602 11 471 11 520 11 434 11 583(11 300) (11 328) (11 435) (11 463) (11 349) (11 377) (11 289) (11 446)Specifications are for <strong>924G</strong> with optional counterweight, standard lubricants, full fuel tank, cab with A/C, sliding glass, Cat contour seat,limited slip axles with dual disc rear, 4L 4V hydraulics, heavy duty cooler, supplemental steering, roading fenders, reversing fan, back-up alarm,guards, ride control, radio, 1.8 m 3 bucket with bolt-on cutting edge, 80 kg operator and 20.5 R25 radial (L-3) XHA tires.* Dimensions are measured to the tip of the bucket teeth to provide accurate clearance data. SAE standards specifies the cutting edge.<strong>924G</strong> Wheel Loader specifications 21

Standard EquipmentStandard equipment may vary. Consult your Caterpillar dealer for specifics.ElectricalAlternator, 80-ampAlarm, back-upBatteries, maintenance-free, 12V,950 CCA (2)Directional signals, (front and rear)Electrical system, 24VHalogen working lights (front and rear)Ignition key start/stop switchRoading lightsStarting aid, thermalOperator environmentCab, ROPS (sound suppressed andpressurized)Gauges:Engine coolant temperatureHydraulic oil temperatureTorque converter oil temperatureFuel level gaugeSpeedometerDigital tachometerDigital hour meter/odometerWarning indicators:Primary steering malfunctionElectrical system voltage lowCoolant temperatureEngine oil pressure lowParking brake appliedBrake charge pressure lowTransmission oil temperatureTransmission oil filter bypassHydraulic oil filter bypassAdjustable tilt steering columnCoat HookGround level door releaseHeater/defrosterHorn, steering wheel mounted (electric)Interior lightInterior and exterior auxiliary powersocketsLighterLunch box storage with cup holderPilot hydraulic implement controlsRear window defroster, electricRear view mirrors (2 inside)Seat, adjustable suspension, backrest,armrest (fabric or vinyl)Seatbelt, 51 mm or 75 mm, retractableTinted safety glassTwo door cab, fixed glassWet arm wiper/washer, intermittent,front and rearPower TrainEngine, Caterpillar 3056E DIT ATAACLow emission diesel engineTurbochargedAftercooledElectronically controlledAir cleaner, dry typeAxle seal guardsBrakes, enclosed wet-disc full hydraulicDifferentials, conventional (front/rear)Driveshaft, lubed for lifeEngine fuel priming pumpEngine speed controlFuel/water separatorMufflerRadiator, unit serviceableRadiator, wide fin spacingS•O•S oil sampling port:engine oiltransmission oilTorque converterTransmission, 4F/3R, autoshift, singlelever control and kickdown buttonTransmission neutralizerHydraulicsHydraulic control, 2-valve, 1-lever,with F/N/RHydraulic control lever lockoutHydraulic diagnostic connectorsHydraulic oil coolerLoad-sensing steering systemS•O•S oil sampling port, hydraulic oilOther standard equipmentAntenna, for radioAntifreeze/coolant, extended-lifeprotects to -36˚CAutomatic bucket positioner/forkpositionerBrakes, secondary and parkingCounterweightEngine enclosure, lockableFenders, frontHitch, recoveryImplement control lever locksLoader linkage, VersaLinkLift kickout, automaticMachine Security System readyProduct Link readyRemote grease linesSteering stops, cushionedSwing-out, hydraulically drivendemand fanVandalism protection,lockable service pointsVisual indicators:air cleaner servicecoolant levelhydraulic oiltransmission oil22 <strong>924G</strong> Wheel Loader specifications

Optional EquipmentOptional equipment may vary. Consult your Caterpillar dealer for specifics.ElectricalAlternator, 95-ampElectrical accessories package(12V converter, accessoryplug outlet, wiring)Working lights, auxiliary, cab-mountedOperator environmentAir conditioner (R-134a refrigerant)Canopy, ROPSMirrors, external (2 sizes)Radio prep packages:12V installation, includes speakers,cable, mounting bracket, hardware,converter and accessory plug.Radio not included.24V installation, same as above,but without converter oraccessory plug.Rear veiw camera systemSeats:Caterpillar Contour Series, fabricCaterpillar Contour Series, fabric,with air suspensionKAB fabric seat heated with an alarmfeature for operator presenceSliding door windows (left and right)Sun screen, rearVisor, sun (front)Power TrainDifferential, limited slip, front axleand/or rear axleBrakes, heavy dutyFan, reversingLow speed transmissionRide control systemStarting aid, engine coolant heater,120V or 240VHydraulicsHydraulic control, 3rd and 4th valveHydraulic oil cooler, heavy-dutyOther optional equipmentAntifreeze/coolant, extended-life,protects to -50°CBeacon light, rotating, magnetic-mountBuckets/ground engaging toolsCounterweightDust bowl precleanerFenders, roading, rearGuards:CrankcasePower trainWaste guarding packageLinkage, high liftMachine Security SystemMaterial handling armPallet forks, carriageProduct LinkQuick CouplerSound suppression packageSteering, secondaryTires:Bias ply, 17.5 - 25 and 20.5 - 25Radial, 17.5 - 25, 550/65 R25and 20.5 - 25<strong>924G</strong> Wheel Loader specifications23

<strong>924G</strong> Wheel LoaderHEHL2833-3 (06/2006) hrFeatured photos of machines may not always include standard equipment.See your Caterpillar Dealer for available options.Materials and specifications are subject to change without notice.www.CAT.com© 2006 CaterpillarAll Rights Reserved®24