Tank Bottom Scanners Magnetic Flux Leakage (MFL) - HMT

Tank Bottom Scanners Magnetic Flux Leakage (MFL) - HMT

Tank Bottom Scanners Magnetic Flux Leakage (MFL) - HMT

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

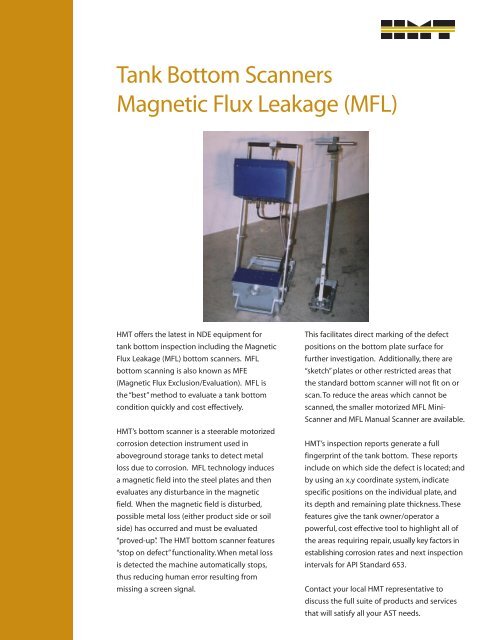

<strong>Tank</strong> <strong>Bottom</strong> <strong>Scanners</strong><strong>Magnetic</strong> <strong>Flux</strong> <strong>Leakage</strong> (<strong>MFL</strong>)<strong>HMT</strong> offers the latest in NDE equipment fortank bottom inspection including the <strong>Magnetic</strong><strong>Flux</strong> <strong>Leakage</strong> (<strong>MFL</strong>) bottom scanners. <strong>MFL</strong>bottom scanning is also known as MFE(<strong>Magnetic</strong> <strong>Flux</strong> Exclusion/Evaluation). <strong>MFL</strong> isthe “best” method to evaluate a tank bottomcondition quickly and cost effectively.<strong>HMT</strong>’s bottom scanner is a steerable motorizedcorrosion detection instrument used inaboveground storage tanks to detect metalloss due to corrosion. <strong>MFL</strong> technology inducesa magnetic field into the steel plates and thenevaluates any disturbance in the magneticfield. When the magnetic field is disturbed,possible metal loss (either product side or soilside) has occurred and must be evaluated“proved-up”. The <strong>HMT</strong> bottom scanner features“stop on defect” functionality. When metal lossis detected the machine automatically stops,thus reducing human error resulting frommissing a screen signal.This facilitates direct marking of the defectpositions on the bottom plate surface forfurther investigation. Additionally, there are“sketch” plates or other restricted areas thatthe standard bottom scanner will not fit on orscan. To reduce the areas which cannot bescanned, the smaller motorized <strong>MFL</strong> Mini-Scanner and <strong>MFL</strong> Manual Scanner are available.<strong>HMT</strong>’s inspection reports generate a fullfingerprint of the tank bottom. These reportsinclude on which side the defect is located; andby using an x,y coordinate system, indicatespecific positions on the individual plate, andits depth and remaining plate thickness. Thesefeatures give the tank owner/operator apowerful, cost effective tool to highlight all ofthe areas requiring repair, usually key factors inestablishing corrosion rates and next inspectionintervals for API Standard 653.Contact your local <strong>HMT</strong> representative todiscuss the full suite of products and servicesthat will satisfy all your AST needs.

Key Benefits Provided by<strong>HMT</strong>’s Inspection Serviceswith the <strong>Magnetic</strong> <strong>Flux</strong><strong>Leakage</strong> (<strong>MFL</strong>) Include:• Evaluates <strong>Tank</strong> <strong>Bottom</strong> Condition on <strong>Bottom</strong>Plates of Ferrous Material• Quick and Cost Effective and Requires noCouplant thus is a “Dry Application”• Steerable Fast Motor Driven Scanner• Features “Stop on Defect” Functionality• Ruggedized Touch Screen Technology forEase of Use Within the Storage <strong>Tank</strong>Environment• Available with the Full Sized <strong>MFL</strong> Scannerand/or with the Smaller Motorized <strong>MFL</strong>Mini-Scanner and <strong>MFL</strong> Manual Scanner<strong>HMT</strong> Inc.24 Waterway Avenue, Suite 400The Woodlands, Texas 77380Ph: +1.281.681.7000Fax: +1.281.419.7689Locations worldwide to serviceall your AST needs.3/09Visit us at www.hmttank.com