You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

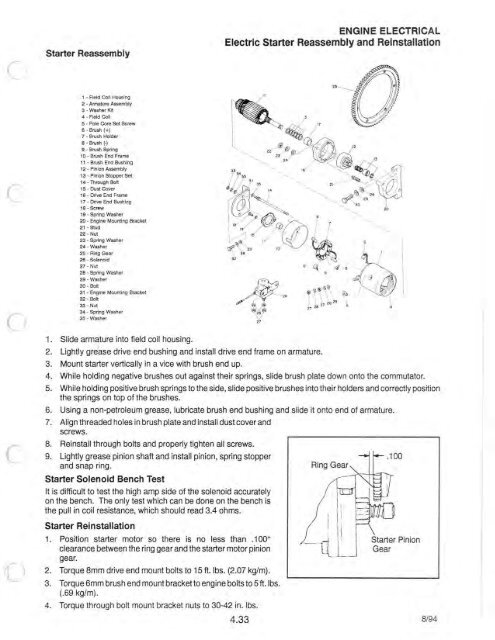

cStarter ReassemblyENGINE ELECTRICALElectric Starter Reassembly and Reinstallation25c()1 - Field Coil Housing2 - Armature Assembly3 - Washer Kit4 - Field Coil5 - Pole Core Set Screw6 - Brush (+)7 - Brush Holder8 - Brush H9 - Brush Spring10 - Brush End Frame11 - Brush End Bushing12 - Pinion Assembly13 - Pinion Stopper Set14 - Through Bolt15 - Dust Cover16 - Drive End Frame17 - Drive End Bushing18 - Screw19 - Spring Washer20 - Engine Mounting Bracket21 - Stud22 - Nut23 - Spring Washer24 - Washer25 - Ring Gear26 - Solenoid27 - Nut28 - Spring Washer29 - Washer30 - Bolt31 - Engine Mounting Bracket32 - Bolt33 - Nut34 - Spring Washer35 - Washer1. Slide armature into field coil housing.o• ~ I/' .( ~~~~V27. 2.i ~ ~\\\ \ 28 2927 28 272. Lightly gre'ase drive end bushing and install drive end frame on armature.3. Mount starter vertically in a vice with brush end up.4. While holding negative brushes out against their springs, slide brush plate down onto the commutator.5. While holding positive brush springs to the side, slide positive brushes into their holders and correctly positionthe springs on top of the brushes.6. Using a non-petroleum grease, lubricate brush end bushing and slide it onto end of armature.7. Align threaded holes in brush plate and install dust cover andscrews.8. Reinstall through bolts and properly tighten all screws.9. Lightly grease pinion shaft and install pinion, spring stopperand snap ring.Starter Solenoid Bench TestIt is difficult to test the high amp side of the solenoid accuratelyon the bench. The only test which can be done on the bench isthe pull in coil resistance, which should read 3.4 ohms.Starter Reinstallation1 . Position starter motor so there is no less than .1 00"clearance between the ring gear and the starter motor piniongear.2. Torque 8mm drive end mount bolts to 15 ft. Ibs. (2.07 kg/m).3. Torque 6mm brush end mount bracket to <strong>engine</strong> bolts to 5 ft.lbs.(.69 kg/m).4. Torque through bolt mount bracket nuts to 30-42 in. Ibs.4.33\Starter PinionGear8/94