Progressive Cavity Pump, C-series - Flowrox

Progressive Cavity Pump, C-series - Flowrox

Progressive Cavity Pump, C-series - Flowrox

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

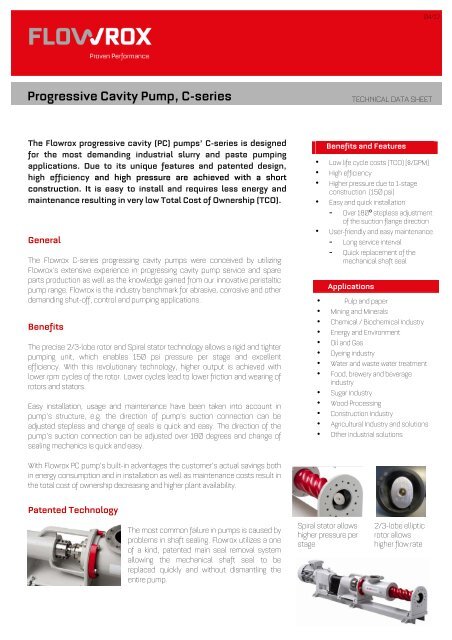

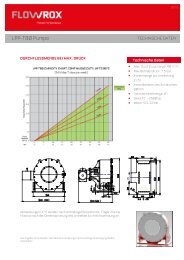

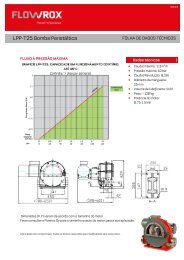

04/12<strong>Progressive</strong> <strong>Cavity</strong> <strong>Pump</strong>, C-<strong>series</strong>TECHNICAL DATA SHEETThe <strong>Flowrox</strong> progressive cavity (PC) pumps’ C-<strong>series</strong> is designedfor the most demanding industrial slurry and paste pumpingapplications. Due to its unique features and patented design,high efficiency and high pressure are achieved with a shortconstruction. It is easy to install and requires less energy andmaintenance resulting in very low Total Cost of Ownership (TCO).GeneralThe <strong>Flowrox</strong> C-<strong>series</strong> progressing cavity pumps were conceived by utilizing<strong>Flowrox</strong>’s extensive experience in progressing cavity pump service and spareparts production as well as the knowledge gained from our innovative peristalticpump range. <strong>Flowrox</strong> is the industry benchmark for abrasive, corrosive and otherdemanding shut-off, control and pumping applications.BenefitsThe precise 2/3-lobe rotor and Spiral stator technology allows a rigid and tighterpumping unit, which enables 150 psi pressure per stage and excellentefficiency. With this revolutionary technology, higher output is achieved withlower rpm cycles of the rotor. Lower cycles lead to lower friction and wearing ofrotors and stators.Easy installation, usage and maintenance have been taken into account inpump’s structure, e.g. the direction of pump’s suction connection can beadjusted stepless and change of seals is quick and easy. The direction of thepump’s suction connection can be adjusted over 180 degrees and change ofsealing mechanics is quick and easy.Benefits and Features• Low life cycle costs (TCO) [$/GPM]• High efficiency• Higher pressure due to 1-stageconstruction (150 psi)• Easy and quick installation- Over 180º stepless adjustmentof the suction flange direction• User-friendly and easy maintenance- Long service interval- Quick replacement of themechanical shaft sealApplications• Pulp and paper• Mining and Minerals• Chemical / Biochemical Industry• Energy and Environment• Oil and Gas• Dyeing industry• Water and waste water treatment• Food, brewery and beverageindustry• Sugar Industry• Wood Processing• Construction Industry• Agricultural Industry and solutions• Other industrial solutionsWith <strong>Flowrox</strong> PC pump’s built-in advantages the customer’s actual savings bothin energy consumption and in installation as well as maintenance costs result inthe total cost of ownership decreasing and higher plant availability.Patented TechnologyThe most common failure in pumps is caused byproblems in shaft sealing. <strong>Flowrox</strong> utilizes a oneof a kind, patented main seal removal systemallowing the mechanical shaft seal to bereplaced quickly and without dismantling theentire pump.Spiral stator allowshigher pressure perstage2/3-lobe ellipticrotor allowshigher flow rate

Product specificationMaterial alternatives: Drive: Shaft sealing:Bearing unit:• Cast IronSuction Pipe:• Stainless steelRotor:• Stainless steel hard coated• Stainless steel• Carbon steel hard coatedStator• NBRBase Plate• Carbon steel• Gear motor drivewith coupling• Single Mechanical Shaft Seal• Double Mechanical Shaft Seal• Gland PackingMain DimensionsModel A B C D E F G* H* I J K L* M NWeight(lb)Suctionflange (D1), Pressureflange (D2)C2/10 17.32 9.16 27.2 16.4 118 50 60.2 11.48 13.52 80 8.4 11.92 6.4 5.2 299 DN50C4/10 17.32 9.16 29 16.8 118 52 63.36 12.36 13.52 80 8.4 12.28 6.4 5.2 330 DN65C10/10 20.76 12.6 32 20 118 58 69.88 12.76 14 80 8.4 12.76 6.4 5.2 418 DN80C20/10 27.92 15.8 36.8 28.4 118 72 86.2 14.52 16.8 100 10.4 15.56 8 5.2 661 DN100C35/10 30.96 18.84 43.2 30 138 81.2 93.08 12.8 19 100 12.6 21.08 8 6 917 DN125C70/10 34.48 22.76 43.2 43.2 123 93.2 108.64 12.8 20.6 280 14.2 23.84 14.4 5.2 1426 DN150C150/10 39.72 24.6 52.4 52.4 179 114.4 132.12 16 25.88 400 18.4 28.88 20 7.16 3300 DN200C250/10 45.12 27 59.6 59.6 189 129.2 151.88 20 30.4 400 21.6 36.16 22.4 7.6 5163 DN250*=Normative dimensions. Dimensions are in inches.Information without engagement. All rights to changes without prior notice reserved.<strong>Flowrox</strong> Inc808 Barkwood CourtSuite NLinthicum, MD 21090Tel. 410-636-2250Fax 410-636-9062info@flowrox.comwww.flowrox.us