Download - Nivelco Process Control Co., Inc.

Download - Nivelco Process Control Co., Inc.

Download - Nivelco Process Control Co., Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

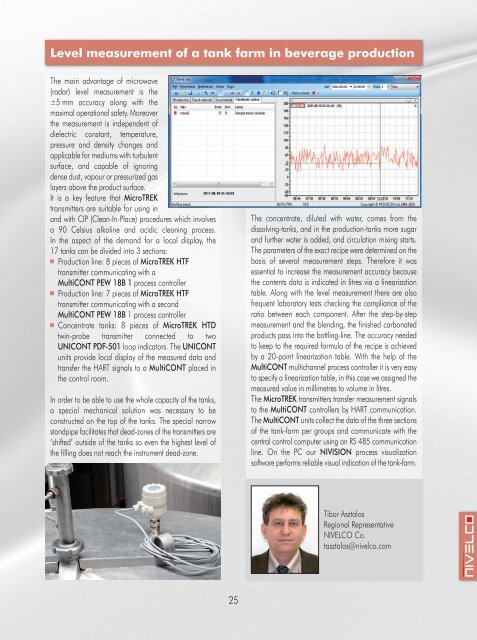

Level measurement of a tank farm in beverage productionThe main advantage of microwave(radar) level measurement is the±5 mm accuracy along with themaximal operational safety. Moreoverthe measurement is independent ofdielectric constant, temperature,pressure and density changes andapplicable for mediums with turbulentsurface, and capable of ignoringdense dust, vapour or pressurized gaslayers above the product surface.It is a key feature that MicroTREKtransmitters are suitable for using inand with CIP (Clean-In-Place) procedures which involvesa 90 Celsius alkaline and acidic cleaning process.In the aspect of the demand for a local display, the17 tanks can be divided into 3 sections:Production line: 8 pieces of MicroTREK HTFtransmitter communicating with aMultiCONT PEW 18B 1 process controllerProduction line: 7 pieces of MicroTREK HTFtransmitter communicating with a secondMultiCONT PEW 18B 1 process controller<strong>Co</strong>ncentrate tanks: 8 pieces of MicroTREK HTDtwin-probe transmitter connected to twoUNICONT PDF-501 loop indicators. The UNICONTunits provide local display of the measured data andtransfer the HART signals to a MultiCONT placed inthe control room.In order to be able to use the whole capacity of the tanks,a special mechanical solution was necessary to beconstructed on the top of the tanks. The special narrowstandpipe facilitates that dead-zones of the transmitters are‘shifted’ outside of the tanks so even the highest level ofthe filling does not reach the instrument dead-zone.The concentrate, diluted with water, comes from thedissolving-tanks, and in the production-tanks more sugarand further water is added, and circulation mixing starts.The parameters of the exact recipe were determined on thebasis of several measurement steps. Therefore it wasessential to increase the measurement accuracy becausethe contents data is indicated in litres via a linearizationtable. Along with the level measurement there are alsofrequent laboratory tests checking the compliance of theratio between each component. After the step-by-stepmeasurement and the blending, the finished carbonatedproducts pass into the bottling-line. The accuracy neededto keep to the required formula of the recipe is achievedby a 20-point linearization table. With the help of theMultiCONT multichannel process controller it is very easyto specify a linearization table, in this case we assigned themeasured value in millimetres to volume in litres.The MicroTREK transmitters transfer measurement signalsto the MultiCONT controllers by HART communication.The MultiCONT units collect the data of the three sectionsof the tank-farm per groups and communicate with thecentral control computer using an RS 485 communicationline. On the PC our NIVISION process visualizationsoftware performs reliable visual indication of the tank-farm.Tibor AsztalosRegional RepresentativeNIVELCO <strong>Co</strong>.tasztalos@nivelco.com25