SDI Annual Report '05 - Steel Dynamics, Inc.

SDI Annual Report '05 - Steel Dynamics, Inc.

SDI Annual Report '05 - Steel Dynamics, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

STEEL DYNAMICS

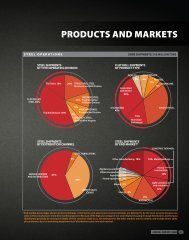

350Cash Flow from Operations3503003002503502502003002001502501501002001005015050001005002525 2020 1515 1025105 2050150105150 0150 1201209090 6015060 30120300 90060300Profit MarginOperating <strong>Inc</strong>ome per Ton Shipped2.52.52.52.02.02.01.51.51.51.01.01.0.5.50 .500A DECADE OF GROWTHTen years of vigorous growth—utilizing production capacity and diversifying product offeringsOPERATING HIGHLIGHTSFINANCIAL HIGHLIGHTS (Dollars in millions, except per-share amounts)1 Weighted averageSELECTED FINANCIAL DATA2005 2004 2003 2002 2001SELECTED OPERATING INFORMATIONNet Sales $2,185 $2,145 $987 $864 $607Operating <strong>Inc</strong>ome 393 507 97 158 26Net <strong>Inc</strong>ome 222 295 47 78 3Cash Flow from Operations 311 248 128 115 67EARNINGS PER SHARE2005 2004 2003 2002 2001Net <strong>Inc</strong>ome per Share—Basic $4.97 $5.99 $.99 $1.65 $.07Shares Outstanding 1 44,621 49,287 47,829 47,144 45,655Net <strong>Inc</strong>ome per Share—Diluted $4.35 $5.27 $.91 $1.64 $.07Shares & Share Equivalents Outstanding 1 51,642 56,527 54,890 47,592 45,8532005 2004 2003 2002 2001Operating Margin 18% 24% 10% 18% 4%Operating <strong>Inc</strong>ome per Ton Shipped $109 $148 $34 $66 $13Return on Sales 10% 14% 5% 9% 1%Net Sales per Employee 2 $1,270,000 $1,410,000 $871,000 $1,118,000 $914,000Consolidated Shipments (thousands of tons) 3,594 3,432 2,817 2,390 1,964Employees at Year-end 1,795 1,645 1,397 869 676Average Selling Price per Ton Shipped $608 $625 $350 $361 $3092 Calculated as year’s sales divided by year’s average number of employeesForward-looking statementThis publication contains predictive statements about future events. These statements are intended to be made as “forward-looking”within the safe-harbor protections of the Private Securities Litigation Reform Act of 1995. Reference is made to the “risk factors”section in <strong>SDI</strong>’s most recent <strong>Annual</strong> <strong>Report</strong> on Form 10-K, which describes the many factors and risks that may cause such predictivestatements to turn out differently. A copy of the 2005 Form 10-K is included with this <strong>Annual</strong> <strong>Report</strong>.

$600600$300300$200500400500400250200250200200015001504.54.03.53.02.52.01.51.00.50.0300200100steel shipments grew to 3.6 million tons in 2005. Our goal is to2002500 100double that volume of annual steel shipments in the near future.At the end of 1996, there were 0 293 <strong>Steel</strong> <strong>Dynamics</strong>employees. At the end of 2005, there were 1,795employees. In 1996, we shipped4794,000 tons ofhot-rolled steel, versus the 3.6 million tons in 2005.The mix of products shifted from 3 100-percent basichot-rolled bands in 1996 to a variety of steels that2include higher-priced, value-added finished products700as well as structural steels, rails, $600 SBQ bars, and1600fabricated products.5000500Our continued 400 emphasis on process improvement300and cost 700 300 control—as well as $600 our focus on an operatingculture 600 200 that stresses initiative200and offers strong200500financial 500 100 incentives for productivity 100 and quality—175400have 400 allowed 0 us to achieve profit150 0 margins among300the highest 300 in our industry. 1252002005100Financial Overview0100200751000Net sales for 2005 were $2.2 25 billion, two percenthigher than 2004, on shipments 0 of 3.6 million tonsof steel, an increase of five percent. Our averageconsolidated selling price for 2005 was $608 perton, compared to $625 in 2004.We earned $4.35 per diluted share, compared to250$5.27 per diluted share in 2004. Our 2005 net200income of $222 million was lower than the $2954.5million achieved in 4.0 2004, but 150remained very strong3.5by historical standards. Operating income per ton1003.0shipped was $109, compared to a record $148 per2.550ton in 2004. Our revenues 4.5 2.0 per employee remainedvery high at $1.3 million. 4.0 1.503.5 1.0300100400 0502000 50015002500100062000500 51500401000 3600 25003.0 0.5Domestic steel markets in 2005 were weak1252.5 0.00100initially but rebounded during the second half of2.075the year. During the 1.5early part of the year, demand50for flat-rolled steels 1.0weakened due to inventory250.5overhang and substantial import activity. As a result,0.00selling prices softened for these products. In the250second half of the year, demand rebounded and200prices improved, but did not return to the high levels in the secondhalf of 2004. Demand for wide-flange beams picked up gradually 150through the first half and became much stronger in the second half18001575135011259006754502250150500 10400 0300600200500100400030020041002000324130211750150125100200751755015025250100of the year as non-residential construction 1000 gained a significant100head of steam. Structural-steel pricing declined early in the year,50050but rebounded sharply in the second half of the year and has00remained strong.1751501251007550250In 2005, prices for ferrous resources fluctuated with1600$50steelmaker demand, but weakened somewhat toward 14001200year-end. 40 For the year, steel scrap and pig iron was10000somewhat less costly than in 2004, when scrap prices30800went through the roof. Ferrous resources accounted20 $300300for about 56 percent of our total manufacturing costs 400200in 2005. 250 Natural gas costs increased 25010significantly in02005, 200 although the impact of the cost 200 of natural gas0on mini-mill steel operations such as ours is much150150$300300less than on integrated steel producers. Electrical100100energy250costs also increased for those2502000 operations that100 5050are not 200covered by long-term contracts. 2009080015070<strong>SDI</strong> generated cash flow from1200operations of60 100100$311 million in 2005, versus $248 million in 2004.50Capital 40 5050expenditures were $63 million in 200530and $102 0 million in 2004. As 400 a result 40 0of our strong20 4cash 10 flows and aggressive management of working00 330capital, 6we had no outstanding borrowings under220our revolving 5 credit facilities at December 31, 2005,and we1increased our cash position 40 to $65 million410at December 0 31, 2005, from $16 million at3300December 31, 2004. <strong>SDI</strong> repurchased a total of2207.5 million shares of common stock in late 20041and 1800early 2005.101575 00In 1350 2005, we also replaced our four-year 80 $230-millionrevolving 112570credit facility with a new $350-million900revolving credit facility in response to our growth180050675100and the attractive credit markets.401575We have the ability9045030under 1350 certain circumstances to expand 80 the new22520112570facility to $450 million to facilitate 10 the company’s0609000continued growth.50675450225Flat Roll Division01506501500<strong>SDI</strong>’s Flat Roll Division, based175in Butler, Indiana,continued to be <strong>SDI</strong>’s major 150source of revenues andprofit in 2005. Flat Roll shipments reached 125 2.4 million tons in2005, a slight increase over 2004. During 100 the year, Butler achievednumerous production records, including peak 175periods of hot-band1600800100$509060$504030201018001600 5014001200 010001800600100302520151050-5-10$250020001500$250010002000500150001000500020001600120020008001600400120008004000200501501252 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 20051500100100075

6 A rail-welding facility at Columbia City. This investment should total$15 million and provide us with the capability to weld together 320-or 240-foot sections into rail strings up to one-quarter mile in length.When these facility upgrades are completed and the operationsof Roanoke Electric <strong>Steel</strong> are integrated into <strong>Steel</strong> <strong>Dynamics</strong>,<strong>SDI</strong> will have increased its annual production capacity to about6 million tons per year, a 50 percent increase over the currentTen Years of ProgressTo date, <strong>Steel</strong> <strong>Dynamics</strong> has invested nearly $1.5 billion in productivephysical assets. As impressive as these facilities are, as can be seenin the aerial views on the following pages, it is our employees thatare the key to making these physical assets highly productive.In the beginning, there were only a few who understood theopportunity that lay ahead in a cornfield in northeastern Indiana.capability. In addition, we will have expanded the diversity of ourproduct mix and continued our initiative to expand our productofferings with more value-added products.We continue to pursue opportunities to gain better control of ourraw materials costs, principally of steel scrap and scrap substitutes.One such opportunity is the Mesabi Nugget project in which wehave a continued interest because of its cost savings potential inthe domestic production of high quality iron units for consumptionat our Butler and Pittsboro steel mills. Discussions are continuingwith potential partners in this project.We expect to continue to implement our growth strategy viainvestments in new greenfield projects and/or acquisitions thatmeet our criteria of business compatibility, market and productviability, and an expected high rate of return on investment. Ourfinancial results demonstrate that such investments in the pasthave paid off. Our level of business activity has reached a pointwhere we are generating significant positive cash flow, much ofwhich can be earmarked for our capital spending requirements.Ten years later, <strong>SDI</strong> employees are among the finest steelmakersin the world.In the pages that follow, we feature groups of employees and otherindividuals who have been key to the company’s success in the first10 years of production. They continue to have a can-do spirit, a driveto succeed, a competitive attitude, creativity, and a confidence inthe future.To these featured people and to all the other <strong>SDI</strong> employees, I wouldlike to say thank you for making <strong>Steel</strong> <strong>Dynamics</strong> the business successstory that it is. And to all of you outside <strong>SDI</strong> who have put your trustin us—customers, suppliers, investors, lenders, and governmentleaders—we very much appreciate your support, past and future.Sincerely,Keith Busse<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 5

John NolanVice PresidentRichard TeetsVice PresidentRobert WaltersAttorney, Barrett & McNagnyJohn BatesPresident, Heidtman <strong>Steel</strong>Jerome Henry, Jr.President, Paragon <strong>Steel</strong>Mark MillettVice PresidentA DECADE OF GROWTHIn 1993 Keith Busse and a cadre ofassociates set out to create a newsteel company. The combination of theirindustry expertise, management skills,and a willingness to embrace riskallowed them to quickly gain financing,build a mill, and start steel productionat the beginning of 1996.On the following pages, we chroniclethe company's development as toldby people who created the companyand nurtured its growth.This first discussion group includes individuals who were involvedin forming <strong>Steel</strong> <strong>Dynamics</strong>. Dick Teets and Mark Millett joinedKeith Busse to found the company in September 1993. Theyworked with Keith at Nucor Corporation, where they had builtand managed the world’s first mini-mill to produce flat-rolled steel.There the team overcame numerous technical obstacles to make thethin-slab casting process a commercial success. Dick, a mechanicalengineer, had gained technical expertise in steelmaking andexperience in the planning and construction of mini-mill steeloperations. Mark, a metallurgical engineer, had led the teamthat refined the casting technology, paving the way for mini-millproduction of high-quality flat-rolled steel. Both gained previousexperience managing steel production operations before founding <strong>SDI</strong>.John Bates stepped up in 1993 as an initial investor in <strong>SDI</strong>, andHeidtman <strong>Steel</strong> Corporation later became <strong>SDI</strong>’s largest customer.John Nolan joined the team in 1994 to head up marketing for thenascent <strong>SDI</strong>. Fort Wayne businessman Jerry Henry was an earlyfriend of the company, and contributed to its success as a businesspartner and as a steel customer through several businesses that heowns and operates. Bob Walters has observed <strong>SDI</strong> at close rangefor more than a decade as the company’s legal counsel.6 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005

Starting a steel company from scratch is not somethingthat happens every day. What was the thinking that ledyou to take the risk and make the investment in a newsteel enterprise?Dick To me, it was an exciting chance to pursue somethingnew, another project. We had been successful as a team,and we thought there was a market opportunity for the flat-rollsteel that we would produce. I didn’t think past the original flat-rollconcept initially. I wasn’t necessarily thinking about creating acompany that would get into structural steel, bars, and everythingelse that we have. I never envisioned <strong>SDI</strong>’s being where it is todayfrom a size standpoint.Mark It was a unique opportunity for further personal challengewhile working with partners who shared similar values of integrity,honesty, loyalty, and trust. Sometimes what drives you is just ahandshake and being involved in a project with talented peopleyou like and enjoy working with.Bob It may have been the allure of a challenging project, but youhave to respect the pure entrepreneurial spirit and guts of leavingsecure jobs and risking failure. The same goes for those whorisked capital in the start-up.John Bates We recognized that in making our investment in<strong>Steel</strong> <strong>Dynamics</strong>, we risked our total net worth, but the conceptwas just so exciting. We were looking for an uninterruptible supplyof steel from a source that we could depend on. At that time,Heidtman was buying steel from everyone—17, 18, 19 steel mills.If <strong>SDI</strong> became successful, it would provide us an assured supplyof steel that would enable our continued growth. Getting to knowKeith, Dick, and Mark, I was convinced they could do the job.Bob In the end, you invest in people. I still marvel at the geniusof Dick, Mark, and Keith, who, from scratch, based solely on theirown brilliance, created this concept and built it from the ground up.It’s hard for people to appreciate the details and the complexityof building a steel mini-mill—not only the bricks and mortar of it,but also the mechanicals and designing and engineering it. Whenyou have people in whom you have confidence, that makes youtake the risk.John Nolan How remarkable it was for three guys to cometogether, join forces with John and with other investors, and put$360 million together in nine or 10 months, based on their solidexperience in the steel industry. That’s a remarkable accomplishment.Once the financing was lined up and mill constructionwas underway, how did the company’s production andmarketing strategy evolve?Mark From the beginning, we had a vision to differentiateourselves from our competitors with value-added products thatwould allow us to profit well in the good times and to survive thebad times. We also designed the Flat Roll mill to produce somespecial grades and lighter gauges of steel that would set us apart.John Bates I recognized that the <strong>SDI</strong> team had a unique grasp ofthe capabilities of mini-mills to produce high-quality, high-strengthsteels. The Big <strong>Steel</strong> companies said, “The mini-mills are outthere, but we won’t worry about them because they cannotmake automotive-grade steel.” <strong>Steel</strong> <strong>Dynamics</strong> became the firstmini-mill to really make a push into automotive. Chrysler stoodup and said, “OK, we’ll give it a try.” The next thing you know,the <strong>Steel</strong> <strong>Dynamics</strong>-Heidtman team earned Chrysler’s DirectorAward as its No. 1 overall steel supplier.John Nolan No question, that teamwork with John really wasa key to our early success and continues to be a valuable partof our business. We also consciously developed customerMark Millett Co-founder of <strong>Steel</strong> <strong>Dynamics</strong>;<strong>SDI</strong> vice president and general managerof Flat Roll Division; general managerof Iron <strong>Dynamics</strong> Division; company director.Richard Teets Co-founder of <strong>Steel</strong> <strong>Dynamics</strong>;<strong>SDI</strong> vice president and general managerof Structural and Rail Division; company director.John Bates President and owner of Heidtman <strong>Steel</strong>Corporation; company director; early investorin <strong>Steel</strong> <strong>Dynamics</strong>.John Nolan <strong>Steel</strong> <strong>Dynamics</strong> vice president of salesand marketing.Robert Walters Attorney; partner in Fort Wayne law firmBarrett & McNagny; <strong>SDI</strong> legal counsel since 1994.Jerome Henry, Jr. Entrepreneur; presidentof Paragon <strong>Steel</strong> (co-owned by <strong>Steel</strong> <strong>Dynamics</strong>);president of Midwest Pipe & <strong>Steel</strong>.<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 7

elationships outside the automotive arena to ensure that wedid not grow too dependent on one end market. As Mark said,we moved quickly into value-added processing to produce notonly the basic commodity of the flat-roll market, hot-band steel,but also different products, such as cold-rolled and galvanizedcoils. It was a natural flow, or evolution. By 1998, we had addeda finishing mill at Butler including a pickling line, a cold-rollingmill, annealing, and two galvanizing lines.How do you decide what products to make and marketsto enter next?John Nolan Market opportunity. There are moment-in-timeopportunities. You have to be smart enough to recognize themand quick enough on your feet to capture them. Sometimes wesee the world differently from the way others do.Dick One of the things we’ve done is not necessarily listen towhat everyone else is saying. First, we were told that nobodyneeded a flat-roll mill, that there was no crying need for flat-rollcapacity. Note that our flat-roll mill that “wasn’t needed” shipped2.4 million tons last year. Then, when we announced we wouldbuild a structural mill, there were concerns that we were ruiningthe market, destroying it with over-capacity. If we had listenedto conventional wisdom, we would not have built the mill.In only its third year of operation, our structural mill has beensold out for the past six or eight months.John Nolan There are other examples, such as Dick’s designingthe structural mill to have the capability to produce rails as wellas beams. Nobody else in North America can do that. Expandingour SBQ bar mill into finishing operations is another opportunity.“It was a perfect storm—everything cametogether—timing, talent, opportunity,market conditions, and risk. And it allcame to fruition at a tipping point thatwas unprecedented in our industry.”– Jerry Henry“You have to have that intuitive sense.When the hair stands up on the back ofyour neck, you just know the opportunity isthere. Sometimes we’re much more carefuland considered, but looking back over ourdozen years as a company, I would say thatsuccess is the synergy of recognizing andexecuting on opportunities.” – John NolanWhat part of <strong>SDI</strong>’s success can be attributed to engineeringand steelmaking expertise?Dick We’re open to new approaches and anticipating technologiesthat are yet to be explored. I’m very proud that we were the firstin the world to have a two-stand cold-reversing mill, a solutionthat was lower-cost and has proved to be very effective. Sucha mill had been on the drawing board for years, but nobody elsehad the guts to try it. We took the opportunity to look at it and said,“That’s an interesting concept. Now let’s delve deeper into thedetails to determine whether we really believe it will work and dothe job for us.” We invested in it because it had sound principles.There are numerous other examples—we were the first touse polypropylene pickle tanks that can’t rust out, first to havedual-output grinding machines in the roll shop, and so on.Mark The technology we use is an important element in oursuccess. It’s important to have the best state-of-the-art technologyin the world, but creating the culture to exploit it has made uswho we are. We are fortunate to have so many talented engineers,metallurgists, computer specialists, and technicians who ensure thatour processes and technology are top-notch. We have a top-notchworkforce and a unique work culture in the mills and plants.What special type of people did you hire to take on thesechallenges?Mark During our start-up, most of our core management groupof 40 or so supervisors and professionals actually came to us afterthey heard what we were setting out to do. They were experiencedpeople from different companies, mostly steel producers, but oftenyounger people who recognized the opportunity we offered.They took a major risk to join our new company. And talk aboutentrepreneurial spirit—they had it!8 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005

Jerry <strong>Steel</strong> <strong>Dynamics</strong> attracted talented and bright people lookingfor a better way. The Big <strong>Steel</strong> companies had a way of destroyingincentive and innovation. They didn’t want people thinking outsidethe box. <strong>SDI</strong> created a culture of: “It might be a crazy idea, but atleast I’ll get an audience.” That’s the way you attract talented people.Dick One of the novel things, whether by design or necessity, wasthat we didn’t always hire people with experience. If we liked whatwe saw in the individual—enthusiasm and evidence of a strongwork ethic—that caught our interest. We hired people who hadthe right attitude with the expectation they would master the job.“This company hasn’t aspired to growfor growth’s sake; it’s been very choosyas to where it’s gone. I think the investmentcommunity recognizes that.”– Bob WaltersAt <strong>SDI</strong>, it seems that no one balks at taking theinitiative to get things done. Isn’t that unusualfor a steelmaking enterprise?John Bates If there’s a problem at an <strong>SDI</strong> mill, all the employeesrun to the problem to fix it. At an integrated mill, everybody runsaway from the problem. It’s a matter of culture.Dick Well, I can vouch for the first part of that. We do have aculture of personal initiative, with everyone in the shop having theresponsibility to keep things running smoothly in their area. Ourpeople do react fast and work together to resolve any productionproblems, whether in their department or not.Mark Our production workers are also challenged to come up withideas to improve productivity, enhance safety, reduce costs. Theyhave the opportunity to take initiative. They have the freedom andflexibility to make decisions. They’re allowed to make mistakes.They can’t make the same mistake 10 times, of course, but theyhave the flexibility and freedom to try new ideas. We expect ourmanagers to lead, not so much by telling people what to do, asby helping them understand what direction we want them to go,and letting them figure out how to get the job done. And ouremployees are well rewarded for their efforts, with bonuses,profit sharing, and stock options. It’s a culture that’s so simplethat visitors often miss it. They look for the secret in our technology,but the secret to our success is in our people.<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 9

FLAT ROLL DIVISIONFLAT ROLL MILLButler, IndianaStart-up 1996Employees* 550Hot-band capacity 2.6 million tons2005 Shipments (in thousands of tons)Hot-rolled 1,053Pickled & oiled 182Cold-rolled 137Galvanized 580Painted 208GALVANIZING OPERATIONJeffersonville, Indiana (not shown)Start-up 2003Employees* 40Light-gauge coating capacity 240,000 tons2005 Shipments (in thousands of tons)Flat-roll galvanized 215* Employees at year-end 2005

FLAT ROLL DIVISIONSome of the company’s first employees,who shared the responsibility for theconstruction and start-up of <strong>SDI</strong>’sfirst steel mill, recently met to recounttheir memories of that time. Today,they manage and operate <strong>Steel</strong><strong>Dynamics</strong>’ flat-roll facilities at Butlerand Jeffersonville, Indiana.of contractor employees as well as our own. There wasn’t timeto take a breath for nine months.Barry Many of us moved here without our families at first, andsome of us lived in a house on site. Everything we did was aboutconstruction. Every day we got up together and went to work onthe site. Every night we went home and ate the same dinners.Most of you joined the company at the very beginning,setting out to build the Flat Roll mill at Butler. How wouldyou describe that experience?Bob Soden When we got here, there were four trailers, fourtelephone lines available. No utilities. It wasn’t just that we hadto build the buildings; there was nothing here but farm fields. Westarted with computers, then roads, and then we began hiringpeople. Once people began coming, they kept coming. HundredsRandy RathburnHot Mill SupervisorBarry SchneiderCold Mill ManagerKen KinseyCasting ManagerCraig LongardnerTransportationManager12 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005

my time preparing for this—I’m going to be there.” And there wasnothing like seeing that first coil, with the whole group of guysaround it, and Dick Teets standing there, popping the cork on thechampagne. We all tipped our glasses and, ah, it was a great senseof accomplishment.Karl Those times bring people together to form bonds youwill not make professionally doing anything else.You succeeded in building this mill in record time. Did any ofyou ever think about the risks of the venture—what wouldhappen if it didn’t work out or didn’t start up on schedule?Karl HermannPaint LineOperationsSupervisorDeb DeKoninckWarehouseSupervisorBrent LeiningerCold Mill SupervisorJeff BaumanJeffersonvillePlant ManagerDuring that time, our sole focus was on getting the mill builtand running.Craig Working to build the mill gave us a tremendous sense ofownership. It was like having a baby. You felt like you created thisentity, or at least played a big part in creating it. My role was tobuild our railroad and our on-site scrap-handling infrastructure—buying locomotives and cranes, laying track, and all that.The instruction I got from Keith went like this: “I’m going to buyscrap. It’s going to be here on this date. Be ready for it.” AlthoughI had never overseen rail construction before, I had worked withKeith. I knew that he had confidence in my ability to get the jobdone. And there was no question in either of our minds that itwould be done on schedule.Brent The word “failure” is just not in the vocabulary of Keith,or Mark, or Dick, or any of the people who started this company.We never considered it.Karl That sense of confidence really filtered down to everyoneworking here. There was simply the assumption: “We’re goingto be successful. We’re going to do this.”Craig I don’t think we really understood the risks that we weretaking. We just saw this as a tremendous opportunity, went at it,and didn’t look back.Bob Soden It was critical to bring the project in on time andon budget, to start selling and shipping steel to cover theinterest payments.Tom We had a bank consultant with several years of constructionexperience, who couldn’t believe we were building the mill at sucha low cost. He kept going back to the banks, saying “It’s going toBob Soden Well, Mr. Busse does have a way of drawing a linein the sand. I’ll always remember one of our last constructionmeetings. A consultant who helped us with timelines attended themeeting, and he didn’t know Keith had announced that we wouldroll our first coil before the December 1995 Christmas party,which was coming up in a couple weeks. As each person at themeeting reported when they’d complete their section, people gavea date of December 10. The consultant said, “Two weeks ago,you said you needed six weeks!” Finally somebody said, “Youdon’t understand: that’s not an option anymore. It’s going to beDecember 10.” And that’s pretty much when it happened.Randy I remember the day we ran the first coil. It was my onlyday off that week, and I got a call: “Hey, we’re going to run a coiltoday. You don’t have to come in.” I said, “Yes, I do. I’ve spent allBob SodenManager ofEngineering& ServicesTom HartmanControllerBob BlyHot Mill ManagerTim GephartCasting Supervisor<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 13

take more money to build this place.” And we were saying,“No, we’re right on budget.”Deb The consultant would swear that after he left at 5 o’clock,hundreds of people were coming in and working on construction,because when he came back the next morning, the place would bevisibly different. Of course, we were building 24/7. But he couldn’tbelieve it could change so much overnight.Part of <strong>SDI</strong>’s start-up approach is to get the employees whowill operate the mill involved in its construction. In whatways did hiring some production people early on pay off?Barry I think when you’re responsible for building the mill, itdefinitely changes how you feel about it. Your future is in yourown hands, not somebody else’s. When we started to commissionthe mill—turn it on and make things work—we knew wherethings were. Our guys put all the panels and buttons and pipesand hoses where they are. We saved a lot of money building itourselves, and we did it quickly, but that construction phase primedus to be able to turn it into a revenue-making machine as fast aspossible. When our people actually commission a plant, we hit theground running, and that’s when our approach proves itself.Craig There was a tendency for new people to ask questions like,“Where will they want this?” But there was no “they.” There wasno mother company, no “mother ship” we could fall back on fora set of rules or guidelines. We were literally creating the companyon the fly. It didn’t take long for people to realize that things hadto be done right, not to please somebody else, but for themselvesbecause they were the ones who would soon be running the place.What other factors made the start-up go smoothly?Bob Soden The sheer level of technical talent and managementcapability was a huge factor. The experience and talent and knowledgethat we gathered here is stunning. I doubt if anybody ever beforehad put together a group of people as well-suited to this task.“When you’re responsible for building themill, it definitely changes how you feelabout it. Your future is in your own hands,not somebody else’s.”“A lot of companies talk about theiremployees’ being the greatest resource,but at <strong>SDI</strong>, it’s not just a catch phrase.Every employee recognizes that what heor she does, counts.”– Karl HermannKen Another factor is the strong work ethic and commitment ofour workforce—what we refer to as our “culture.” We hired a lotof people who had no previous steelmaking experience or formaltraining, but they were smart people who were eager to be part ofthis operation. In the melt shop, we had only two operators belowthe supervisor level with prior steel experience—out of roughly100 people. But we had a wealth of experience and knowledgeat the supervisor level and above. That was key to a quick start-up.We taught the rest of the guys what to do, and they learned quickly.Since the completion of the Butler cold mill in 1998, theFlat Roll Division has added two more finishing operationsto diversify its product mix. Jeff, tell us about creating theoperation you lead in Jeffersonville, Indiana.Jeff Jeffersonville is a satellite plant, similar to Galv Line 2 at Butler.We acquired the idled plant in 2003. When Mark Millett and I talkedabout the new operation, we agreed that the most important thingwas to bring the <strong>SDI</strong> culture to Jeffersonville. Actually, the Butlermanagers here helped with the interviews, looking for people whohad the right work ethic and attitude.Barry Our new projects present a great opportunity for careergrowth for some of our people. Three of our people from the Butlercold mill left to join the Jeffersonville start-up, and the move gavethem the opportunity to assume greater leadership responsibilities.Jeff We started up the facility quickly and began making moneyin a few months. The plant continues to run extremely well. Werecently announced plans for a significant plant expansionat Jeffersonville, including the company’s second paint line.– Barry Schneider14 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005

Speaking of that, how did <strong>SDI</strong>’s first paint line, at Butler,come about?Bob Bly We’re a company that seeks to keep growing as appropriateopportunities arise, and the opportunity to provide our customerswith high-quality pre-painted steel was a good one. We were sellingcold-rolled and galvanized steel that was shipped to third-partyfacilities to be painted before it reached our customers. Some ofus in the shop realized that the paint process is not much differentfrom pickling or galvanizing—it’s a continuous-process line thatapplies paint instead of zinc.We studied it, looking at the margins to be made, evaluating theinvestment required, and calculating an expected return. MarkMillett reviewed the idea and the numbers, and a viable projectemerged. Two months later, the board of directors approved aninvestment of nearly $30 million.I became the line’s first employee, but I’d never had responsibilityfor starting up a new operation. Glenn Pushis, who headed up thecold mill, guided me with a lot of helpful ideas on how to proceed.Before we finished construction of the paint line, the company gotstarted on other projects, and I was promoted to another position.Karl When Bob left to manage the hot mill, I took over the project.It was an incredible experience, being given the responsibility fora construction project—which I’d never had before—and thengoing through the whole commissioning phase and start-up.Bob Bly Like Jeffersonville, the paint line generated a lot ofenthusiasm and new opportunities for our people. We hired onlytwo people from the outside who had paint experience—outof 34 people. Most of the rest came from other units of <strong>SDI</strong>.Our guys picked up the art of painting in no time.Karl When that first painted coil came off the line, it brought atremendous feeling of accomplishment for everybody on the crew.It was truly rewarding.We’re all very proud of what we’ve accomplished here in the last10 years, and we keep moving forward. I’m not sure all of us haveyet grasped just how significant an accomplishment it has been:taking an Indiana farm field and turning it into one of the mostprofitable steel operations in the world.Ken Everybody came to <strong>SDI</strong> to create something better than whatthey left behind. And I think that’s still the philosophy today. We wantto continue to make it a better place to work, a better company to workfor, a company that continues to produce better and better results.<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 15

STRUCTURAL ANDRAIL DIVISIONColumbia City, IndianaStart-up 2003Employees* 400Capacity 1.0 million tons2005 Shipments (in thousands of tons)Total 827* Employees at year-end 2005

STRUCTURAL AND RAIL DIVISIONAn important part of the <strong>Steel</strong> <strong>Dynamics</strong>story is the way the company’s growthhas created career opportunities.Since its start-up, <strong>SDI</strong> has createdjobs for nearly 1,800 people. Thisgroup of Structural and Rail Divisionemployees at Columbia City, Indiana,is representative of workers who joined<strong>SDI</strong> and have since taken advantageof career-growth opportunities withinthe company. In numerous cases,employees who started on the factoryfloor have attained supervisory positions.Tell us how you came to work for <strong>Steel</strong> <strong>Dynamics</strong> and whatjobs you have held.Brian I had moved to Florida, working in quality control, but back inIndiana, my mother saw a newspaper article about a new companycalled <strong>Steel</strong> <strong>Dynamics</strong> building a steel mill in Butler. She suggestedI apply for a job. I did, and was hired, moving back to Indiana in 1994.Joshua GrahamCastingSupervisorRoxy HagansInside SalesRepresentativeDean ScheumannRolling MillSupervisor18 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005

to shuttle coils over to the neighboring Heidtman <strong>Steel</strong>, Paragon,and New Millennium plants. I worked for a time as a switchmanon that crew. When the opportunity arose, I decided to apply forshipping supervisor here at Columbia City. I now oversee the crewsthat load our products onto trucks and railcars for shipment.Dean I’ve been with <strong>SDI</strong> 10 years, and I’ve had five differentpositions. Every couple of years, through company growth orpromotions, there’s been an opportunity to move to another jobwithin the company. Some people are happy staying in thepositions they’re in, but the opportunity for career growthis always there should they decide to take it.Craig BeverfordenCasting SupervisorRichard HogueBreakdownMill OperatorTom MorkenMill AdjusterCurt ButlerRoll ShopSupervisorI worked in the lab in the rolling mill at Butler for a little over a year.I wanted to make more money, so I applied for a burner-bander job.It was hot work, banding the coils; those coils are 1,300 degrees.Richard and I worked together there, which worked out well,considering our statures [Richard is 6'7"]—he banded the topof the coil, and I banded the bottom. When I heard they were goingto build the Columbia City mill, I applied to come over here. NowI’m a breakdown mill operator, which means I work in a controlroom above the first of two rolling mills we have here, directingthe preliminary shaping of hot blooms into beams.Richard I had worked for the contractor that installed fencing inButler when the Flat Roll mill was being built. I decided to interviewfor a job, and like Brian says, we worked together at the coiler onthe hot mill. When the Columbia City mill came along, I transferreddown here. As luck would have it, we’re both now operating thecontrols of the breakdown mill, but on different crews. It’scompletely different work and greater responsibility, which I enjoy.Tom I worked at General Electric in Fort Wayne. I was in processcontrol and environmental health and safety. One by one, pieces ofthe operation started going away—to Mexico and other places—and I thought, “There’s not going to be much to control around hereanymore.” I became friends with neighbors who worked at <strong>SDI</strong>,and I decided to apply for a job at Butler. I was hired and for a yearand a half, like Brian and Richard, I worked as a burner-bander.Dean was the coiler operator then. After that, I had a series ofinteresting jobs, and now I’m a mill adjuster here at Columbia City.Roxy I had worked previously in the healthcare field and hadno steel or manufacturing experience, so I didn’t think <strong>SDI</strong> wouldhire me. The day I got that call offering me a job in the financedepartment changed my life.From December 1998 to April 2002, we worked in constructiontrailers and built a lot of rapport with a “family” of about 45 people.Craig I started out in a refractory job at Butler, went from refractoryto the ladle wall, then from the ladle wall to the caster. And thenI became casting supervisor. All in about 10 years. You work hard;they reward you for it.Mark Curt and I came from a nearby steel fabricating business.I got a job at Butler in the shipping department, loading coils forshipment to customers. After that, I took a rail switchman’s job, andthat was interesting, because that was when Butler went from onecaster to two—from a 1-million-ton capacity to 2 million tons ayear. Then Butler’s shipping department added a locomotive crewMark MaguireShipping SupervisorBrian BrownBreakdown Mill Operator<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 19

After we started up, I transferred to customer service in the salesdepartment. Last August, I was promoted to inside salesrepresentative. My work includes prospecting for businessand handling major customer accounts.What type of help does <strong>SDI</strong> give you in building skillsfor personal advancement and to gain supervisoryand management experience?Josh An important thing to me is the ability to cross-train, that is,learning jobs other than the one you are currently doing.Tom It’s nice to know that if you want to come in on your day offand learn another job, the company doesn’t have a problem withthat. It’s a good way to advance, and it shows that you really wantto move up in the world.Dean More than just a few people take advantage of that. On acrew, you try to encourage cross-training, because you needsomebody trained in every position. In shift work, personal thingsmay come up from time to time, causing our members to misswork—family emergencies and other situations. Most peopleare more than willing to come in on their day off to cover for aperson who can’t work, but to fill in, the substitute has to knowthe job. In that situation, we must have somebody qualified andcross-trained, or we’re not running. It’s advantageous to thecompany and to the crew to have cross-trained workers, so if thecrew’s one person short, or somebody gets sick and has to gohome, everybody else can still work.Brian Also, when there’s a job opening, having someone alreadytrained for the job allows the company to fill the position morequickly, and the transition is a lot smoother for the crew than itwould be if a new operator had to be trained.“One of the great things about <strong>Steel</strong><strong>Dynamics</strong> is that there’s always some newproject, some new opportunity just aroundthe corner.”– Roxy Hagans“Everybody listens to each other’s ideas.If the guy down on the floor tagging beamshas an idea that makes the job quicker andbetter up on the caster, then we’lltry it.”–Craig BeverfordenWhat other aspects of your training stand out?Brian I really like the fact that <strong>SDI</strong> sends us wherever we need togo to acquire knowledge that will benefit the company. For instance,a number of us were sent to Germany for training before we startedup this mill. [A major equipment supplier is based in Germany.]We definitely picked up knowledge touring other steel mills. Ratherthan hold us back, management at <strong>SDI</strong> encourages us to broadenour knowledge.Curt In the <strong>SDI</strong> world, traveling to Europe or getting additionaltraining at the hourly level is not that big a deal. But when youmention it outside <strong>SDI</strong>, it gets a big reaction: “You’re not uppermanagement, you’re not salaried, and <strong>SDI</strong> sent you to Europe fortraining?” They can’t believe <strong>SDI</strong> invests so much in people atdifferent levels to help the company. Instead of sending only theengineers, <strong>SDI</strong> also sends the people who are going to operateand maintain the equipment. It’s funny that the rest of the steelworld can’t believe we do things that way. In our world, that’sthe norm.What do you like about your job at <strong>Steel</strong> <strong>Dynamics</strong>?Mark Well, I think the company as a whole likes self-starters,people who see a problem and go ahead and attack it—not askingpermission, but taking care of it as best they can. You have to thinkon your feet. You’re given a lot of responsibility.Richard I enjoy the competition between the crews. We’re all prettycompetitive, pushing hard to better our own record, and challengingthe other crews, too.Curt What drives me is the challenge—first at the Butler mill, thenwhen I came here—I’ve been challenged. That’s what’s kept me at<strong>SDI</strong>. It’s what I enjoy most about my work life right now.Brian No two days are the same. There’s always something newhappening today that didn’t happen yesterday—newsituations to address. There’s so much variety. It’s exciting.20 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005

What particular advantages or benefits do youespecially value as an <strong>SDI</strong> employee?Curt One thing that I really appreciate is that the pay working heregives us the option for our spouses to stay at home to raise ourchildren. That’s a nice position to be in. A lot of people don’t havethat choice because they have trouble making ends meet with onebreadwinner. So if we choose, our spouse can work and make extramoney, or we can be a little more conservative with finances and stillhave a nice lifestyle with the one income.Brian Getting stock options was a surprise. At other places I’veworked, it was unheard of for an hourly person on the floor to getstock options. My wife and I really appreciate them.Tom I think stock options give you more motivation to help seethat the company performs well, knowing your options will beworth more. It makes you feel more a part of the team—partof the company.Roxy You’re more aware of costs. If we were frivolously spendingmoney on things we shouldn’t be, that could hurt the company’sprofits and reduce bonuses and the value of stock options. Havingstock options provides a feeling of ownership. This is our company.Tom With the company’s strong results during the last coupleof years, profit-sharing has been fantastic, too. The companyincreased its contribution rate to our profit sharing and retirementplans from 5 percent to 6 percent of <strong>SDI</strong>’s pre-tax profits. Mostof this money goes into our individual investment accounts forretirement. We also have the option to add 401(k) contributionsto it with a company match.How do you feel about the contributions you have madeworking at <strong>SDI</strong>?Curt We—the people in this group—have had the goodfortune to help build two steel mills, and it has been a rewardingexperience. At the Butler mill, we went through growing pains,but it’s now one of the most productive mills in the world. At thestructural mill, we had a lot of pressure to ramp up productionquickly due to a long delay in starting construction of the mill.Having been through the learning experiences at Butler helped ussolve problems we’ve encountered with the structural mill. We feelwe’re on track to make this mill even more productive. We’reexcited about the progress we’ve made and look forward tomaking continued improvements in the mill’s performance.<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 21

BAR PRODUCTS DIVISIONPittsboro, IndianaStart-up 2004Employees* 300SBQ capacity 500,000 tonsFinishing capacity 160,000 tons(facility under construction)2005 Shipments (in thousands of tons)Total 357* Employees at year-end 2005

BAR PRODUCTS DIVISIONIn 2003, a committed team of <strong>SDI</strong>managers and mill workers set out tobring back to life a bar mill that <strong>SDI</strong> hadpurchased out of bankruptcy. Here, theyexplain the challenges of restarting thePittsboro mill and reflect on the role<strong>SDI</strong>’s culture has played in the progressthey’ve made in <strong>SDI</strong>’s newest business.Doug My first task was trying to figure out how to turn on thelights—the ones that actually worked, which were very few. Iwalked into the mill and thought, “Holy cow, what did I get myselfinto?” It was a dirty mess. It had sat through two winters with noheat and no one in it. Nothing was winterized, so all the pits wereflooded. The first month was spent trying to clean up, get rid of allWhat sorts of challenges did you facein getting this facility going?Glenn The people on this team were picked for this start-up; this isthe core technical group that I knew could get this place going. Asthese folks will tell you, I’m a pretty competitive person. But gettingthis mill up and running was a challenge. We were determined tobring this mill back to life quickly.Damon KeckRefractorySupervisorGlenn PushisGeneral ManagerTony FauldsMelt Shop ManagerSean EvansLMF Operator24 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005

handle many types of projects. I was the first one on site, so I’veseen it come from its worst to the productive place it is today. It’sbeen exciting.Dan I was a production supervisor at Iron <strong>Dynamics</strong>, which isthe scrap-substitute department within <strong>SDI</strong>. I did that for five years.Then I transferred down here. I wanted to get more exposure tothe steelmaking side of <strong>Steel</strong> <strong>Dynamics</strong>—since that’s its corebusiness—to get more training and development in that area.Jeff EvansRolling Mill SupervisorMike MorrisManager of Engineering& ServicesDan KeowenCasting Supervisorthe water, get as much lighting on as possible, and get contractorsin. Those were long days.Tony We knew the plant had failed twice [under differentownership], but we were determined to make it successful. <strong>SDI</strong>is well-known for doing things quickly, but we did it really quicklyhere, even for <strong>SDI</strong>. Once we received our equipment, it was go,go, go. And that’s a reflection of the people doing the job. Wedidn’t have engineering drawings, and we didn’t know what wasunderground. We were lucky in that we had engineers who coulddeal with all the unusual things that popped up as we startedconstruction. We were also very lucky to be starting up in anextraordinary year for the steel industry as a whole. But to beprofitable so soon after start-up was just a fantastic achievement.[After its first shipments in January 2004, the mill turned profitablejust three months later, in April.]Jeff I’d been involved in two greenfield sites from constructionto the start-up phase. This move permitted me to transfer theknowledge I’d gained in the Flat Roll Division into the bar-makingarena. Coming to Pittsboro expanded my knowledge base intoshapes and rounds, and it gave me the chance to come back toa familiar environment, because I grew up in this area and havefamily here.<strong>SDI</strong> seems to attract people who are comfortableembracing change …Tony To work at <strong>SDI</strong>, you have to be someone who is veryaccepting of change, because every day, every hour, things change.Damon I took a chance. I knew the melt side of the business.I’d done that 15 years, but there was the personal challenge ofrebuilding the melt shop here and making it work. When someonetells me I can’t do a task, the drive in me says I can do it. I’ll makesure that it gets done. I like challenges.Danny Before I decided to transfer to Pittsboro, I talked to Glenn.Many of you came to Pittsboro from Butler. What made youdecide to move within the company?Mike I was the electrical engineer for the cold mill at the Flat Rollmill. I helped Glenn construct that facility. We were still completingButler’s new paint line when I decided to come down here. Itwas a good opportunity for me to expand my horizons, and get apromotion. Taking a steel mill that had failed twice, turning it around,and making something good out of it took a lot of faith. But it’sproven out. It’s been quite an adventure.Doug I was an electrician for New Millennium Building Systems inButler. When I heard that <strong>SDI</strong> had bought this facility, I thought it’dbe a good opportunity for me to work on a much larger facility andDanny GarciaRoll Shop MechanicJeremyHendersonLead Mill AdjusterLana JohnsonEngineering ClerkDoug AbbottPlant Electrician<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 25

I remember his telling me, “I’m taking my family there, too. Thisis going to work.” So I said, “All right. If you take a chance on me,I’ll take a chance on you.”<strong>SDI</strong>’s culture is often cited as an important ingredientin the company’s success. How does that culture setthe company apart?Lana We’re encouraged to consider ourselves owners of thecompany—because of the bonus structure. Whatever you dois going to have a direct impact on the bonus, and that affects youand your buddy and the guy on the next shift. Everybody seems tofeel that ownership. I’ve been impressed with that. I think peerpressure does a lot.Doug Everybody has heard that <strong>SDI</strong> runs lean. We don’t have alot of people milling around. This presents every employee witha challenge: it’s up to you to make the decisions and solve theproblems. And I think that makes much better employees in thelong run. It’s frustrating sometimes, but even with light staffingand tight schedules, it always seems to come together. And that’sbecause people put in the extra effort.Sean When I hired on, we had people with different types of workexperience. Everyone has that competitive drive and positive spirit.There’s one phrase that sums up our culture: “unity in diversity.” Wework as a team, bringing together all of our different perspectivesand backgrounds.Tony <strong>SDI</strong>’s culture comes from the individuals in it. We try to hirethe individual with the can-do attitude, and when you get a groupof people like that—working in a system that rewards motivationand thinking outside the box and overcoming challenges—theystart to feed off each other’s energy. It also gives people a chanceto really explore what they can do. Supervisors can’t say, “Hey, I’ma supervisor. I don’t have to worry about maintenance.” Thesupervisor is the maintenance guy because if a machine’s brokendown, we’re not making steel and that means we’re not makingmoney. <strong>SDI</strong>’s not afraid to hire people who want to make money.“Everybody has heard that <strong>SDI</strong> runs lean.This presents every employee with achallenge: it’s up to you to make thedecisions and solve the problems.”“<strong>SDI</strong>’s culture comes from the individualsin it. We try to hire the individual with thecan-do attitude, and when you get a groupof people like that—working in a systemthat rewards motivation and thinking outsidethe box and overcoming challenges—theystart to feed off each other’s energy.”– Tony Faulds<strong>Steel</strong>making is hard dirty work. It can be extremely hot at times.You want people who are motivated by making money, doingthe right thing for their family, wanting to work in a fantasticenvironment, and be able to contribute.Glenn When we interview people, we look for a positive spirit.Applicants go through a lot of steps to get a job at <strong>SDI</strong>, and that’sby design. As Tony said, these are tough jobs. And constant changeis controversial. You have to have people who are comfortable withit. It’s not for everybody, and that’s okay. But that culture of constantchange is ingrained in our organization from Keith Busse all theway down. If you’re not comfortable with it, then maybe it’s notfor you.Jeff The culture encourages everybody in the shop to be an activeparticipant in the outcome. You incorporate everybody’s ideas forthe greater good of the project. It adds value to the company. Wefeed off of that cohesiveness and encourage everybody to beinvolved in the process.You’re talking about encouraging people both personallyand professionally?Jeff Exactly. I think it’s very important, as a supervisor, to knowwhat’s going on with people on the shift, because let’s face it, weall have hurdles in life. I try to know what’s going on in their lives.From a professional standpoint, it’s a challenge for me to makesure that I’m creating opportunities for people who are looking forcareer growth. So my goal is to create every opportunity I can sothat our hardworking employees achieve their goals.– Doug Abbott26 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005

How do you feel about being part of the growing <strong>SDI</strong> family?Dan I think part of the reason we’ll always have a close-knit groupof people is that the people we hire treat each other like their ownfamily members. The attitude is: “If you need something, call me;I’ll be right over.” I know I could go up to Columbia City, for example,and they would accept me and help me do whatever I needed todo to get the job done there. That’s what keeps us strong.“We can get fairly intense with eachother. But it’s always rooted in the driveto do something better. That’s a verypositive thing.” – Glenn PushisGlenn But I’d like to take the family analogy even farther. Familiesargue, and we argue. We can get fairly intense with each other.But it’s always rooted in the drive to do something better. Now, withinthe gate, we challenge each other all the time. But it's with goodreason: it’s a passion for this business, this division. Against anyoutside force that can hurt us, we are a united front. That’s whenyou know you’re real family. That’s a very positive thing.What do you see ahead for Pittsboro in the next year or two?Mike We have plenty of mill capacity to increase production output.We will continue to dial in our SBQ product offerings to meet ourcustomers’ needs. We’ll continue to refine our processes, developnew alloys, and offer new products that our customers require.Working with engineered steels is quite eye-opening. Every weekor so, we learn something new about them.Sean I couldn’t agree more. I’m seeing all of these chemistriescome up in the melt shop. Our range for each element seemsto get tighter and tighter. As time progresses, we have thechallenge of continually improving the control of our processes.Mike The new facility we’re building here to further processthe long bars will change the nature of part of our business,from shipping less unfinished bar stock to shipping finished steel.That’s going to happen in 2006.Glenn I didn’t realize when I came down here, being honored withleading this team, that it would impact so many people and theirfamilies. When I reflect at our company picnic, for example,and look at all the kids running around, and all the people havinga good time, I realize that we’re making a difference in their lives.Over the last three years, we’ve created 300 good-payingmanufacturing jobs for this community, and that has impactedso many people positively.The high-quality SBQ bar business is a very good business for <strong>SDI</strong>.Our objective is to continue to build and grow this business for thelong run.<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 27

LAKE CITY, FLORIDABUTLER, INDIANANEW MILLENNIUMBUILDING SYSTEMSBUTLER OPERATIONButler, IndianaStart-up 2000Employees* 190LAKE CITY OPERATIONLake City, FloridaStart-up 2005Employees* 165* Employees at year-end 2005

NEW MILLENNIUMBUILDING SYSTEMSNew Millennium Building Systems,LLC, is a wholly owned subsidiaryof <strong>Steel</strong> <strong>Dynamics</strong> that now operatestwo fabricating plants. The first standsnext to <strong>SDI</strong>’s flat-roll steel mill inButler, Indiana, and a new plantstarted up in Lake City, Florida,in 2005. Here, New Millenniummanagers and employees provideinsights about the business.in electric-arc-furnace mini-mills. In contrast, New Millennium isthe company’s only steel-fabricating business. We use steel, muchof which is supplied by the steelmaking divisions, and turn it intoproducts for the commercial construction industry. Even thoughNew Millennium is listed in the “All Other” category in <strong>SDI</strong>’soperations, we are executing plans for rapid growth of theWhat is it that sets New Millennium apart from other <strong>Steel</strong><strong>Dynamics</strong> operations?Rick <strong>Steel</strong> <strong>Dynamics</strong>’ primary operations are its three steelmakingdivisions. They produce raw steel products by recycling steel scrapRick PoinsatteChief Financial OfficerNora StairhimeSchedulerArturo WisbrunInformationSystems Director30 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005

Why is it important to build more plants—and why locatein Florida?Steve A study identified the Southeast as a very large marketopportunity for future growth. Freight and delivery are veryimportant aspects of this industry, so to serve your customerswell, you need to locate in their region of the country. It’s best notto have to haul these products more than 300 or 400 miles to bemost responsive to customers. We expect to expand into otherparts of the country as well.How did <strong>Steel</strong> <strong>Dynamics</strong> get involved in New Millennium?Jim RedingerQuality ControlSupervisorGrace WangEngineeringDesignerSteve EckShipping Supervisorfabricating business and expect to become an increasinglysignificant contributor to <strong>SDI</strong>’s bottom line.Troy NortonLeadmanRiggerAriail We started the company in 2000 with a new plant at Butler,Indiana, as a joint venture of <strong>Steel</strong> <strong>Dynamics</strong> and New Process<strong>Steel</strong>. In 2003, <strong>Steel</strong> <strong>Dynamics</strong> bought out the other investorsand integrated the business into <strong>SDI</strong>. <strong>Steel</strong> <strong>Dynamics</strong> has madea commitment to expand our geographic coverage of the U.S.construction market by adding more plants. New Millenniumjoining <strong>SDI</strong> was the best thing that could have happened. It hashelped us grow.Was it difficult to blend the <strong>SDI</strong> and New Millennium cultures?Steve I think that culturally we were already an <strong>SDI</strong>-style company.The people who started New Millennium had previously worked withKeith Busse in the steel joist business and shared the same businessphilosophy. So, culturally, there was virtually no difference—theintegration was seamless.Rick The early part of Keith Busse’s career was in this sector ofthe steel industry. Bert Hollman, now a <strong>Steel</strong> <strong>Dynamics</strong> vice presidentin charge of New Millennium, had worked as an engineeringmanager with Keith in the joist business. At New Millennium, theyput together a management team of people who were experiencedin the business. One of those people is Ariail Smith, whose specialtyis joist-manufacturing methods. He became the production managerat Butler, and now coordinates manufacturing development for allthe New Millennium plants, both existing and future.Ariail I think I’ve worked for every major joist company in one wayor another. I knew the people starting New Millennium, and I knewthey were going to try to improve on everything everybody else wasdoing, even the “best-of-the-best” things. That’s what you do—youtake the weaknesses and improve on them. So, when they askedme if I was interested, I said yes.Troy The beauty of this company is we have people with so muchWhat products does New Millennium make?Nora Our main products are steel joists, girders, and trusses thatare welded together and painted in our plants and then transportedon trailers by truck to construction-project job sites. These productsare used to support a building’s roof and floors. They are usedmostly in non-residential projects, such as commercial andindustrial buildings, big-box stores, schools, hospitals, and the like.We also make floor and roof decking, which are sections formedand cut from flat-rolled steel and used in the same types of projects.Ariail SmithManufacturingDevelopment ManagerKevin DisingerEngineerTodd SmithLine Supervisor<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 31

industry experience that they can choose the good things and leavethe bad behind—or as Ariail said, “improve on the weaknesses.”There were times when someone would say, “Well, back at my oldcompany, we used to do it this way.” And sometimes you’d hear,“Well, you know what? We’re improving on that.”Jim There was a lot of open-mindedness, too. What we’ve done isoften totally different from what anybody else has considered. Manythings we’ve put into place are innovative in nature and havehelped us compete in the industry. I think that down the road,we’re going to make a huge impact on the industry.Ariail We’re not afraid to try new things. We always havesomething going on. Right now, we’re looking at what newthings we’re going to be doing in six months, a year from now.So part of the company’s success is based on noveland efficient manufacturing techniques?Todd When we first started out, we decided we could save moneyby roll-forming steel, but no one really knew how to do it. We wouldneed a roll-forming machine to “fold over” strips of flat-rolled steelinto right angles that could be used as components to be weldedinto the joists.Ariail The roll-forming Todd’s talking about represents somethingwe do differently from anybody else in the industry, so moving to itwas a big deal. Nobody out there made equipment to do exactlywhat we wanted to do. So we got everybody involved—everybodywho knew anything about engineering a machine—and we cameup with the solution.How does the work at New Millennium differ from the workin <strong>SDI</strong>’s steel mills?Troy Our work is more like an assembly line with variouscrews working together on a coordinated basis. We work fromindividual shop orders, building joists in custom sizes to meetthe specifications for the building project in which they’ll be used.“We don’t look to do things the way othercompanies do. We’re always trying to takeprocesses to the next level, to innovate. Andwe’ll continue to innovate as we expand.”– Rick Poinsatte“Word of mouth has been very good to us.I think our service—and our reputation forpleasing our customers—gives us an edgein the market.”– Nora StairhimeOther departments are responsible for cutting all the pieces,and my group is responsible for rigging—physically puttingthe joists together. I lead a team that assembles the parts ofthe joist and clamps them all together. We take two heavy steelchords, sandwich webbing between them, and hand-clampthe pieces together before sending them on to be welded.Jim Troy is their leader, but the guys really work as a team.Every guy gets to know instinctively what the guy standing besidehim is going to do, before he does it. Sometimes, Troy will justuse a hand signal, and everybody on the rigging table knowswhat to do. It’s very organized and usually runs quite smoothly.Do you notice a rhythm when you’re working on the line?Todd Oh, yes. There are four different crews on each line, andthey all work together. If one crew needs help, the others sendsomebody, but generally it flows very smoothly and naturally, bothwithin the crews and moving product from one crew to the next.You say the joists are made to order. How do they getspecified and engineered—what is the order process?Kevin Architects or contractors submit the building specs with abid request, and we engineer the proper joist system. We have thepeople and tools that permit us to do this work pretty efficiently.Grace is one of those people.Grace I come from Taiwan, and my English isn’t very good. WhenI first applied, they gave me a test, and it was like Greek to me.I thought, “They will never hire me.” But I knew if I understoodwhat I was doing, I could do a good job. I’m so glad to be giventhis opportunity. It was really hard the first few months becauseI didn’t know anything about the business; I had manageda restaurant before. But the people of this company wereso nice—they taught me.Kevin Grace isn’t giving herself enough credit—she’s alwaysbeen very capable. She moved fast through that learning curve,and now she’s the teacher. People go to Grace when they have32 <strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005

a question about how to design a joist or how they can makea joist more efficient.Rick The order process begins with a quote, and it may takesome time to result in an order. When Nora sees that an orderhas been received by the sales department, she calls the customerright away to ask when they want delivery. We’re focused on fastresponse to our customers. Nora can better speak to that—shesees it every day.Ariail They’ve had a smoother start-up because we outfitted theplant there with equipment that had been proven and debuggedat Butler. The Florida crews lacked experience, but that’s coming.You don’t get that overnight.Rick The market there has been very strong, and they are makinggreat progress from a commercial standpoint since their start-upin March 2005.Nora Word of mouth has been very good to us. I think our serviceand our reputation for pleasing our customers gives us an edge inthe market. We try very hard to be flexible. If we can make it work,we will. Customers also tell us they are happy they can trust thepromises we make. We deliver when we say we will, and theyremember that.Rick Much of our engineering, production, and service capabilitiesare due to our information systems. Arturo has basically createdour software. It’s a great system, and it keeps getting better.Arturo Our systems are what they are because of everyonehere—you’re the ones who come up with the ideas.Rick Yes, but with some other IT departments, it’s six months beforeanyone gets back to you, and then you don’t even remember whatyou asked for. Here, it actually gets done right away. That’s uniquein the IT world.Arturo I love what I’m doing, although the first year or so was quitechallenging, and it made for some long days to get our IT just right.In the past couple of years, we’ve worked with the shop to automatesome of the processes and eliminate much of the hand input.We’re always trying to automate, trying to use computers for whatthey are—tools. Sometimes it’s a bit overwhelming, but I’ve gota great team working with me.How is the Lake City plant doing?Todd They’re ramping up quickly. They haven’t had quite as longa learning curve as we had. Some of the new Florida employeescame up to Butler last winter to learn to work on the line, beforetheir plant was completed.<strong>Steel</strong> <strong>Dynamics</strong> <strong>Annual</strong> <strong>Report</strong> 2005 33

FORM 10-K

STEEL DYNAMICS, INC.2005 BOARD OF DIRECTORSKeith E. BussePresident and Chief Executive Officer<strong>Steel</strong> <strong>Dynamics</strong>, <strong>Inc</strong>.Mark D. MillettVice President<strong>Steel</strong> <strong>Dynamics</strong>, <strong>Inc</strong>.Richard P. Teets, Jr.Vice President<strong>Steel</strong> <strong>Dynamics</strong>, <strong>Inc</strong>.John C. BatesPresident and Chief Executive OfficerHeidtman <strong>Steel</strong> Products, <strong>Inc</strong>.Frank D. ByrnePresident, St. Marys HospitalMedical CenterMadison, WisconsinPaul B. EdgerleyManaging DirectorBain Capital, <strong>Inc</strong>.Richard J. FreelandPresident and Chief Executive OfficerPizza Hut of Fort Wayne, <strong>Inc</strong>.Dr. Jürgen KolbRetiredFormer member of Executive BoardSalzgitter, AGJames MarcuccilliPresident and Chief Executive OfficerSTAR Financial BankJoseph D. RuffoloPrincipalRuffolo Benson LLCSTEEL DYNAMICSEXECUTIVE TEAMKeith E. BussePresident and Chief Executive OfficerMark D. MillettVice PresidentGeneral Manager, Flat Roll DivisionRichard P. Teets, Jr.Vice PresidentGeneral Manager, Structural and Rail DivisionGary E. HeasleyVice President of FinanceChief Financial OfficerRichard J. BradyVice President of Ferrous ResourcesBert D. HollmanVice PresidentPresident, New Millennium Building Systems, LLCJohn W. NolanVice President of Sales & MarketingGlenn A. PushisVice PresidentGeneral Manager, Bar Products DivisionTheresa E. WaglerVice President and Corporate ControllerJanice E. ConwellCorporate Health & Safety ManagerMary L. FinkDirector of Tax & BenefitsRobert E. FrancisInformation Technology ManagerRichard A. PoinsatteChief Financial OfficerNew Millennium Building Systems, LLCBrent A. RitenourInternal Audit ManagerFredrick A. WarnerInvestor Relations ManagerANNUAL MEETINGMay 18, 20069 a.m. Eastern/8 a.m. CentralGrand Wayne CenterCalhoun Ballroom120 West Jefferson Blvd.Fort Wayne, Indiana 46802STOCKHOLDER RECORDSComputershare Trust Company, N.A.P.O. Box 43078Providence, Rhode Island 02940-3078Shareholder inquiries: (877) 282-1168www.computershare.comINVESTOR INFORMATIONFred Warner, Investor Relations Manager<strong>Steel</strong> <strong>Dynamics</strong>, <strong>Inc</strong>.Telephone: (260) 969-3564Fax: (260) 969-3590E-mail: f.warner@steeldynamics.comCORPORATE OFFICES6714 Pointe Inverness Way, Suite 200Fort Wayne, Indiana 46804Telephone: (260) 459-3553Fax: (260) 969-3590MARKET INFORMATIONThe company’s stock trades on theNASDAQ National Market underthe symbol STLD. <strong>Steel</strong> <strong>Dynamics</strong> isincluded in the S&P Mid-Cap 400 Index.Additional informationOur <strong>Annual</strong> <strong>Report</strong> on Form 10-K andits accompanying exhibits, as wellas other SEC filings, can be accessedat the SEC’s EDGAR database atwww.sec.gov or on the <strong>Steel</strong> <strong>Dynamics</strong>Web site, www.steeldynamics.com, in the“Investor Information” section.SHARE PRICE AND DIVIDEND INFORMATIONNASDAQ Symbol: STLDDividends2005 High Low DeclaredFirst Quarter $ 46.40 $ 32.86 $ 0.10Second Quarter 35.05 25.04 0.10Third Quarter 35.41 26.13 0.10Fourth Quarter 36.71 26.63 0.102004First Quarter $ 25.87 $ 20.85 --Second Quarter 29.09 20.77 --Third Quarter 39.38 27.93 $ 0.15Fourth Quarter 42.44 29.40 0.10© 2006 <strong>Steel</strong> <strong>Dynamics</strong>, <strong>Inc</strong>. Produced by Nichols & Company, <strong>Inc</strong>.

6714 Pointe Inverness Way, Suite 200Fort Wayne, Indiana 46804(260) 459-3553www.steeldynamics.com