High mast lighting systems - Abacus Lighting

High mast lighting systems - Abacus Lighting

High mast lighting systems - Abacus Lighting

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>High</strong> <strong>mast</strong><strong>lighting</strong> <strong>systems</strong>

Derek BrewerChief Executive of NottinghamshireCounty Cricket Club“Our working relationship with<strong>Abacus</strong> has been the epitome of astrong, creative two-way partnership.Timescales throughout theredevelopment were very tight;yet the strong understanding andexcellent communications between usmeant that the project was completedbang on time and within budget.”Brian TownsendChairman of Brocton FC“We would like to congratulate<strong>Abacus</strong> on their professionalismthroughout the project – from the earlystages of conceptualisation and design,through to manufacture, site installationand commissioning. We have nohesitation in recommending <strong>Abacus</strong>and their products to others: indeed,we now see our ground as a‘show piece’ for all sporting clubs.”Angus FraserManaging Director of CricketMiddlesex County Cricket Club“I think the <strong>lighting</strong> is excellent andI’ve had the same response fromMiddlesex players.”Stephen BusuttilProjects ManagerMalta Freeport Terminals Ltd.“I’ve seen for myself how long-lastingand durable the <strong>Abacus</strong> base-hinged<strong>mast</strong> is. They are quick and simple toinstall, and very low-maintenance.”

A bit about <strong>Abacus</strong>Over 50 years have passedsince <strong>Abacus</strong> first started itsmanufacturing business inNottinghamshire, UK. We’vedeveloped a lot in that time,but our values are the sametoday as they’ve alwaysbeen. Technical brilliance andoutstanding customer servicearen’t just shallow promises:they’re inherent in everythingwe do. They come naturallyto us. And as a result, so doour customers – from all overthe globe.Renowned worldwide for ourcontinuous innovation inflood<strong>lighting</strong> and high <strong>mast</strong><strong>systems</strong>, <strong>Abacus</strong> UK,Shanghai and Russia havebeen commissioned byleading internationalcompanies to providebespoke solutions frombase-hinged to telescopic<strong>mast</strong>s – in projects bigand small, from Surreyto Singapore.And it’s not just our <strong>mast</strong>sthat are built to order.Whether you need supplyonlyor a start-to-finishservice complete with regularongoing maintenance, wehave the package to suit you.Our <strong>lighting</strong> has an enviablereputation around the world,with our Challenger ® rangeproving unbeatable and theRhea and Trent areafloodlights offering superbcoverage. For a high <strong>mast</strong>system there is only oneplace to come – <strong>Abacus</strong>.Using this brochureAs you work through thisbrochure, refer to the backpage for clear applicationsymbols and a range offlood<strong>lighting</strong> options.KeySportIndustryAirportsPortsContentsRailCase studiesSports <strong>lighting</strong> 04Commercial and industrial <strong>lighting</strong> 08Airport <strong>lighting</strong> 10Port <strong>lighting</strong> 12Rail <strong>lighting</strong> 14Road <strong>lighting</strong> 16Our productsBase-hinged <strong>mast</strong>s 20Lowering headframe <strong>mast</strong>s 30Fixed <strong>mast</strong>s 36Telescopic <strong>mast</strong>s 44Control gear cabinets 48Foundations 50Flood<strong>lighting</strong> 56Installation and maintenance 68RoadEnergyCommunicationsIf you don’t find whatyou’re looking for hereor would like to see ourcomplete productportfolio, visitwww.abacus<strong>lighting</strong>.comor contact our sales teamfor help and advice on+44 (0)1623 518 333.abacus<strong>lighting</strong>.com03 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>

Sports <strong>lighting</strong>Lord’s Cricket Ground<strong>Abacus</strong>’ innovative, elegantlights have adorned thehallowed ground of worldfamouscricket club, Lord’s,since the 2009 cricket season.Situated as it is in a residentialarea in the heart of London,getting planning permissionfor permanent flood<strong>lighting</strong>was always going to be achallenge. And that’s wherewe came in.As Lord’s principal contractor,we had to find a solution thatwould provide optimumillumination of the wicketarea while minimising lightpollution and satisfying thestrict planning criteria.Our unique telescopic <strong>mast</strong>s,which take a mere 20 minutesto raise and lower fully, werethe ideal solution.Designed, engineered andmanufactured right here at<strong>Abacus</strong>, each 25-tonne<strong>mast</strong> took around 10 weeksto manufacture. After beingtransported to site in threepieces, the <strong>mast</strong>s werehoisted onto their own20m-deep concretefoundations using a500‐tonne crane.Mounted at the top ofeach one, 100 Challenger ® 3floodlights produce up to2,000 lux of match‐friendly<strong>lighting</strong> – all digitallycontrolled from one remotetouch‐screen panel.We’re keeping the whole lotin perfect working order too,thanks to our ongoing servicingand maintenance contract.04 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

For information on suitablefloodlights, see back pageSouth Bristol MUGA, UKTrent Bridge Cricket Ground, UKThe right <strong>mast</strong> system for your needsFixed <strong>mast</strong>s areideal for:– <strong>High</strong> structures up to 70m– Large quantities of floodlights (asmany as 200 Challenger ® 3 stadiumfloodlights)– Accessing by fixed ladders ormanrider elevator <strong>systems</strong> to anupper platform, with furthermaintenance access to thefloodlights via laddersBase-hinged <strong>mast</strong>s areideal for:– Fast installation and smallerequipment– Easy access for maintenance,so no health and safety worries ordamage to surfaces from heavycherry pickers– Great aesthetics, as there is noladder or platform– Virtually maintenance-free <strong>mast</strong>system thanks to simple but robustengineering – the hydraulic unit doesall the workTelescopic <strong>mast</strong>s areideal for:– Locations where obtaining planningfor permanent high <strong>mast</strong> <strong>lighting</strong> isgoing to be tough– Minimising impact on the skyline– Creating an exceptionaldesign impact– Easy control using the latesttouch-screen technologyabacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 05

Sports <strong>lighting</strong>Mission Hills Golf ClubSince opening in 1994,Mission Hills Golf Club Chinahas established itself as theworld’s largest golf club.The club includes ten golfcourses, each designed andendorsed by the likes of GregNorman, Ernie Els, Nick Faldoand Vijay Singh; not tomention the 230 room hotelcomplex, 300,000 sq ftCountry Club and luxury,five-starresidential development.For Mission Hills, quality iseverything; so when theyneeded to commissionflood<strong>lighting</strong> for their ‘Duval’and ‘Sorenson’ courses,<strong>Abacus</strong> was the natural choice.Having already completed the<strong>lighting</strong> for their Ernie Els andJumbo Ozaki courses, ourrelationship and knowledgemeant we beat theinternational competitionhands-down. Given thescale and location of theinstallation, we enlisted ourEastern counterparts,Shanghai <strong>Abacus</strong>, tomanufacture and install the<strong>mast</strong>s and <strong>lighting</strong> <strong>systems</strong>.The project involved <strong>lighting</strong>the fairways, tees and greensof both courses – a challengingengineering feat, made all themore complex by the fact thatthe courses run parallel witheach other.To achieve the optimum levelof light, a total of 150 basehinged<strong>mast</strong>s were installedacross the course and fittedwith over 400 Challenger ® 1floodlights, each featuring adouble-ended 2kW metalhalide lamp. Challenger ® 1floodlights are highperformanceunits withdouble asymmetric beamdistribution,minimising lightpollution, overspill andunwanted glare for onlookers.In the words of Geoff Hall,Managing Director of <strong>Abacus</strong>,“We have extensiveinternational projectmanagement expertise in thedesign, manufacture andinstallation of exterior <strong>lighting</strong><strong>systems</strong>. Working withShanghai <strong>Abacus</strong> means wecan continue to deliver value,competitive lead times andlocalised service to our clients06 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

For information on suitablefloodlights, see back pageLiberec Ski Jump, Czech RepublicDubai Rugby Sevens, DubaiNottingham University, UKDubai Creek Golf Club, Dubai Colorline Stadium, Norway Kempton Park Racecourse, UKThe right <strong>mast</strong> system for your needsFixed <strong>mast</strong>s areideal for:– <strong>High</strong> structures up to 70m– Large quantities of floodlights (asmany as 200 Challenger ® 3 stadiumfloodlights)– Accessing by fixed ladders ormanrider elevator <strong>systems</strong> to anupper platform, with furthermaintenance access to thefloodlights via laddersBase-hinged <strong>mast</strong>s areideal for:– Fast installation and smallerequipment– Easy access for maintenance,so no health and safety worries ordamage to surfaces from heavycherry pickers– Great aesthetics, as there is noladder or platform– Virtually maintenance-free <strong>mast</strong>system thanks to simple but robustengineering – the hydraulic unit doesall the workTelescopic <strong>mast</strong>s areideal for:– Locations where obtaining planningfor permanent high <strong>mast</strong> <strong>lighting</strong> isgoing to be tough– Minimising impact on the skyline– Creating an exceptionaldesign impact– Easy control using the latesttouch-screen technologyabacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 07

Commercial and industrial <strong>lighting</strong>Asda (Wal Mart), UKDalian Petrochemical CorporationAsda (Wal Mart), UKEvery year, hundreds of retailsites worldwide choose<strong>Abacus</strong> to supply, install andmaintain their exterior <strong>lighting</strong><strong>systems</strong>. Asda – one of theUK’s leading supermarketchains – use our high-<strong>mast</strong>system with loweringheadframes to guide shopperssafely and securely to andfrom their cars at numerousstores across the country.As well as creating a welcomingfeel for people as they enterthe car park, the chosenoption of lowering headframesmakes it easy to maintaineach <strong>lighting</strong> unit withoutcausing too much disturbancefor customers – or losingvaluable car parking space.Dalian PetrochemicalCorporationChina’s largest producerand supplier of oil and gas,China National PetroleumCorporation (CNPC), is thefifth largest oil producer inthe world and a globallyreputed contractor inengineering construction.The company’s subsidiary,Dalian PetrochemicalCorporation, produces,supplies, stores and transportsaround 1,050 million tonsof over 200 petrochemicalproducts to the whole ofChina – from gas and coal tooil and diesel.When Dalian needed ahigh‐<strong>mast</strong> <strong>lighting</strong> system fortheir plant in North EastChina, they asked for our help.We used our loweringheadframe <strong>mast</strong>s to ensurethat the <strong>lighting</strong> could alwaysbe maintained at ground level– no matter what the accessor clearance situation aroundthem at any one time.08 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

For information on suitablefloodlights, see back pageDalian Petrochemical Corporation, ChinaBowmer Container Area, UKThe right <strong>mast</strong> system for your needsFixed <strong>mast</strong>s areideal for:– Maximum flexibility for big top-loads– Sites on a road system withunimpeded cherry picker access– Projects with smaller capital budgetsfor contractorsBase-hinged <strong>mast</strong>s areideal for:– Projects needing a quick turnarounddue to the speed of installation– Fixed headframe provides betterfloodlight stability over loweringheadframe option– Virtually maintenance-free <strong>mast</strong>system thanks to simple but robustengineering – the hydraulic unit doesall the workLowering headframe <strong>mast</strong>sare ideal for:– Sites where access to the <strong>mast</strong>is difficult– Peace of mind, thanks to theoptional headframe latching system– Reducing risks of multiple internalcable-snagging problems by using asingle multi-core electrical cablesystem for up to 12 floodlights– Robust engineering – first patentedby us over 40 years agoabacus<strong>lighting</strong>.com<strong>High</strong> <strong>mast</strong> <strong>systems</strong> 09

Airport <strong>lighting</strong>Bristow HelipadBristow is the largesthelicopter-operating companyin the world. Their site atNorwich Airport, whichcontains a total of 12 helipads,takes passengers to andfrom the North Sea oil rigs allyear round.When it came to redevelopingtheir facility and adding anew hangar, Bristow neededa <strong>lighting</strong> upgrade thatwould combine excellentperformance with minimalglare – an essentialconsideration when pilots aretaking off or landing at night.Masts also had to be installedaround the perimeter of thesite without encroachingonto the runway or controlledair space.Low-maintenancebase‐hinged <strong>mast</strong>s and Rheafloodlights with integratedbaffles were the ideal solution.A combination of eleven 15m,25m and 35m <strong>mast</strong>s wereinstalled and painted in theairfield’s standard red andwhite, with warning lights ontop for low-flying craft.Our <strong>lighting</strong> design, whichdirects a pool of light onto thecircular apron, ensures thathelicopter pilots can alwayssee ground staff clearly whentaxiing, enabling all othertasks to continue quickly andsafely (cleaning, refuelling,off-loading passengers andfreight, etc.).10 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

For information on suitablefloodlights, see back pageSharm El Sheik Airport, EgyptShanghai Pudong International Airport, ChinaThe right <strong>mast</strong> system for your needsFixed <strong>mast</strong>s areideal for:– Maximum flexibility for big top-loads– Sites on a road system withunimpeded cherry picker access– Projects with smaller capital budgetsLowering headframe <strong>mast</strong>sare ideal for:– Easy maintenance access at<strong>mast</strong> base– Peace of mind, thanks to theoptional headframe latching– Reducing risks of multiple internalcable-snagging problems by using asingle multi-core electrical cablesystem for up to 12 floodlights– Robust engineering – first patentedby us over 40 years agoBase-hinged <strong>mast</strong>s areideal for:– Projects needing a quick turnaround,with quick assembly and installation– Practical maintenance which can becarried out quickly at ground levelwith minimum disturbance– A range of uses – CCTV andspeakers as well as floodlights– Easy re‐painting at ground level,if necessary– Virtually maintenance-free– Protecting your <strong>mast</strong>s and <strong>lighting</strong> inareas suffering from hurricanes andstormsAirport projects include:Chek Lap Kok, Hong KongVienna Airport, AustriaAl Ain International Airport, UAEAuckland Airport, New ZealandKeflavik Airport, IcelandEast Midlands Airport, UKNairobi Airport, Kenyaabacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 11

Port <strong>lighting</strong>Kalifa Bin Salman Port at Hidd, BahrainBahrain is a country withinfrastructural developmentand modernisation at theheart of its future plans.An important hub for cargowithin the Middle East, thisport was built on 400 hectaresof land reclaimed from theexisting Hidd port’s basin,berths and shipping channels.The 1,800m long, 15m deepquay wall, houses twocontainer berths, a generalcargo berth, 1,500 metresof additional berthing andassociated docking facilities.We were commissioned bythe port owner and operators,APM, to design and install arobust, state-of-the-artflood<strong>lighting</strong> system whichwould be both moistureresistantand easy to maintain.The solution: fourteen 40mand twenty-six 35m <strong>mast</strong>s– base-hinged for easy lanternaccess and a proven, trustedtechnology worldwide.All fitted with Rhea 1kWfloodlights – speciallydesigned to IP66 to protectagainst the excess moistureinevitable in a port setting.Since working with APM,we’ve gained worldwideacclaim and repeat businessin other ports – not justbecause of the strength ofour product, but also thesingle‐solution design andinstallation package wedeveloped hand-in-hand withthe port’s consultant.12 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

For information on suitablefloodlights, see back pageRosyth, UKDalian Sea Port ,ChinaThe right <strong>mast</strong> system for your needsBase-hinged <strong>mast</strong>s areideal for:– Projects needing a quick turnaroundwith quick assembly and installation– Practical maintenance, which can becarried out quickly with minimumdisturbance at ground level– A range of uses – CCTV andspeakers as well as floodlights– Easy re-painting at ground level,if necessary– Virtually maintenance-freeLowering headframe <strong>mast</strong>sare ideal for:– Easy maintenance access at<strong>mast</strong> base– Peace of mind, thanks to theoptional headframe latching– Reducing risks of multiple internalcable-snagging problems by using asingle multi-core electrical cablesystem for up to 12 floodlights– Robust engineering - first patentedby us over 40 years agoFixed <strong>mast</strong>s are ideal for:– Maximum flexibility for big top-loads– Sites on a road system withunimpeded cherry picker access– Projects with smaller capital budgetsPort projects include:Bilbao, SpainTangiers, MoroccoPort Said, EgyptApapa Port, NigeriaLuanda Port, AngolaVlissingen Port, HollandAntwerp Port, BelgiumTilbury, UKFelixstowe, UKKings Lynn, UKShanghai Wai GaogiaoContainer Port, ChinaOdessa Port, UkraineSt Petersburg Port, RussiaMalta Freeport, Maltaabacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 13

Rail <strong>lighting</strong>Tinsley Rail Yard Depot, UKThe Tinsley rail yard neededa <strong>lighting</strong> solution that wouldprovide optimum visibility fordrivers, without producingdangerous or distracting glareto them or road-bridge users.After consultation with ourteam of experts, the clientopted for thirteen of our 20mbase-hinged <strong>mast</strong>s, fittedwith 55 Rhea medium-beam400kW floodlights.These came complete withintegrated baffles and specialcowls to prevent lightpollution and overspill.But the benefits didn’t endthere. Our base-hingedtechnology also enabledmaintenance and re-lampingto be carried out with theminimum effort, risk and costto the depot – essential whenthese lights are in operation365 days per year.We’re a Link-upapproved contractor14 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

For information on suitablefloodlights, see back pageAlnabru Terminal, OsloTinsley Rail Yard Depot, UKThe right <strong>mast</strong> system for your needsBase-hinged <strong>mast</strong>s areideal for:– Projects needing a quick turnaround,with quick assembly and installation– Practical maintenance, which can becarried out quickly with minimumdisturbance at ground level– A range of uses – CCTV andspeakers as well as floodlights– Easy access– Easy re-painting at ground level, ifnecessary– Virtually maintenance-freeLowering headframe <strong>mast</strong>sare ideal for:– Easy maintenance access at<strong>mast</strong> base– Peace of mind, thanks to theoptional headframe latching– Reducing risks of multiple internalcable-snagging problems by using asingle multi-core electrical cablesystem for up to 12 floodlights– Robust engineering – first patentedby us over 40 years agoFixed <strong>mast</strong>s are ideal for:– Maximum flexibility for big top-loads– Sites on a road system withunimpeded cherry picker access– Projects with smaller capital budgetsabacus<strong>lighting</strong>.com<strong>High</strong> <strong>mast</strong> <strong>systems</strong> 15

Road <strong>lighting</strong>St Petersburg Ring Road, RussiaThis ambitious developmentwas designed to helpsolve many of St Petersburg’straffic and ecologicalproblems. The eastern halfhas eliminated all cargotransport from the city centre,significantly improving theenvironment for the cityresidents and businesses.<strong>Abacus</strong> has supplied andinstalled the largest numberof high-<strong>mast</strong> <strong>lighting</strong>structures for the ring roadsince the project began.The system, which has<strong>mast</strong>s of up to 46m in somesections, incorporateslowering head frames thatallow maintenance to becarried out at ground level inthe central carriageway.The <strong>mast</strong>s, which havespecial design modificationsto withstand harsh climacticconditions (temperaturescan dip as low as -30°C),will serve the ring road for aminimum of 25 years.The Bolshoi Obukhovskysuspension bridge, which hasbeen part of the road’sconstruction, meant workingto devise a solution that notonly brings the bridge to life atnight, but once again, survivesthe Russian climate.And our involvement in thecity’s transport systemdoesn’t end there.St Petersburg is also home tothe largest port in North-WestRussia, handling over aquarter of the country’s cargoper year. The port chose our30m lowering headframe<strong>mast</strong> system with triplepulleys to light its 307,211square metres of shelteredwarehousing.The key advantage of thelowering headframe system isthat it can operate in confinedareas. The headframe canbe lowered to the groundusing an electrically-poweredwinch system.16 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

For information on suitablefloodlights see back pageNottingham, UKNottingham, UKThe right <strong>mast</strong> system for your needsBase-hinged <strong>mast</strong>s areideal for:– Projects needing a quick turnaroundwith quick assembly and installation– Practical maintenance, which can becarried out quickly with minimumdisturbance– A range of uses – CCTV andspeakers as well as floodlights– Easy re‐painting at ground level,if required– Virtually maintenance-freeLowering headframe <strong>mast</strong>sare ideal for:– Easy maintenance access at<strong>mast</strong> base– Peace of mind, thanks to theoptional headframe latching– Reducing risks of multiple internalcable-snagging problems by using asingle multi-core electrical cablesystem for up to 12 floodlights– Robust engineering – first patentedby us over 40 years agoabacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 17

Our products<strong>High</strong> <strong>mast</strong> <strong>lighting</strong> is rarely a simple matter;but at <strong>Abacus</strong>, we’ve developed a suiteof flexible products that will suit virtually anysituation – no matter how complex.This at-a-glance guide has been designed tohelp you identify the right solution for you.Our products at a glanceBase-hinged <strong>mast</strong>s– Mid range base-hinged 10m to 20m– Grand range base-hinged 20m to 50mFixed <strong>mast</strong>s– Club range 15m to 30m– Area range 20m to 50m– Stadium range 30m to 70mLowering headframe <strong>mast</strong>s– 15m to 50mTelescopic <strong>mast</strong>s– Club range to 20m– Stadium range to 50mWind turbine <strong>mast</strong>s– Base-hinged range to 25m– Fixed <strong>mast</strong> structuresTelecommunication <strong>mast</strong> structures– Monopole structures to 60m18 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

Buyer’s guideSolution What are the benefits? ConsiderationsBase-hinged <strong>mast</strong>sSimple, robustly engineered<strong>mast</strong>s requiring virtually nomaintenance for the first 25years of their life.Lowering headframe <strong>mast</strong>with winchA fixed <strong>mast</strong> with raisingand lowering headframe.Ideal for accessingheadframes at ground-levelwhen space around the <strong>mast</strong>is tight.Fixed <strong>mast</strong> – with ladder orman rider accessThe best choice if you needa large quantity of floodlights– most often commissionedby sports stadia.Fixed <strong>mast</strong> – no ladderor platformSimple and elegant.Telescopic <strong>mast</strong>sOur newest and mosttechnologically sophisticated<strong>mast</strong> – perfect for areaswhere it may be difficult tosecure planning permission.Foundation and planning notes– Can be installed and maintained at ground level– Three times faster to install than a loweringheadframe <strong>mast</strong>– No platform means a clean, attractive profileallowing for lower wind loading and foundationsas a result– Can be supplied complete with all control gearand protection equipment fitted into <strong>mast</strong> baseor cabinet– Any necessary maintenance is quick and simple,with few health and safety considerations– Fixed headframe means floodlights stay stable,even in strong winds– Headframe and lanterns can be lowered to thebase of the <strong>mast</strong> for easy maintenance– Optional headframe latching system for extrasecurity and stability– Single multi-core electrical cable managementsystem for all floodlights, in comparison to othermulti-cable <strong>systems</strong>– Featuring a 3‐pulley design, providing significantbenefits over a 2‐pulley competitor system.– Can mount up to 200 2kW Challenger ® 3floodlights– Mast bases can be designed to incorporate upto 70 sets of 2kW control gear and protectionequipment– Practical access for regular maintenance– Low cost option– Like base-hinged <strong>mast</strong>s, the headframe issimpler with lower wind loading and smallerfoundations– No separate cabinets needed, as <strong>mast</strong> basescan be designed to incorporate up to 60 sets of2kW control gear and protection equipment.– Low mounting height with raising and loweringcapabilities makes this a great <strong>lighting</strong> solutionfor heavily built-up areas– Aesthetically striking – a real landmark feature formany stadia– You will need enough ground spaceto enable the <strong>mast</strong>s to be loweredfully. This is dependent on theheight of the chosen <strong>mast</strong>.– You’ll need to make arrangementsfor regular servicing andmaintenance. Regulations vary frommarket to market, but this can berequired as often as once per year– Installation requires large cranesand can take up to three timeslonger than a base-hinged <strong>mast</strong> dueto the number of components andmoving parts– You may need to budget for extrainsurance costs, as trainedspecialists will be required to climband maintain these high structures.<strong>Abacus</strong> are fully insured andexperienced to carry out all types ofmaintenance, offering a packagetailored to suit your needs– Best placed in situations which areeasy to access using crane-andbasketequipment, with minimal riskof ground damage– <strong>High</strong>-end engineering solutionGuidance on foundationsTo help you plan the <strong>mast</strong> foundations,refer to the technical data tables, whereyou'll find a foundation referencealongside each <strong>mast</strong> height. Thisreference is calculated based ona maximum load and wind speed foreach product. The correct concretedimensions can be determined bycross referencing this code with ourfoundations section.Planning the assemblyand installationTo help plan your installation,talk to us for advice on the following:– guidance on what key equipmentyou will need– guidance on how long it takes toassemble and install any of therange of <strong>mast</strong>s– assembly and operating instructionsfor the rangeabacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 19

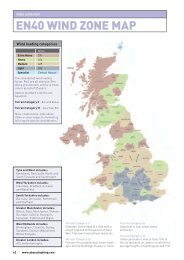

Base-hingedraising and lowering <strong>mast</strong>s<strong>Abacus</strong> base-hinged <strong>mast</strong>s do exactly what they say on the tin: raiseand lower from ground level up to a height of 50 metres. There areeight models to choose from – mainly used to mount floodlights,CCTV cameras, wind turbines and compact communication devices.Since the first model was introducedover 50 years ago, <strong>Abacus</strong>base‐hinged <strong>mast</strong>s have becomesome of our most popular productsworldwide. Robust, simple to installand easily accessible, they’reincredibly cost-effective – especiallysince they require minimal ongoingmaintenance.The unique operating system –the first and still best of its kindon the market – is as safe as it issimple, with its gravity lock andquick-lowering mechanism.Why base-hinged?– Quick and simple to assemble andinstall – up to three times faster thanfixed or winch-lowering models– Safe – no climbing, as allmaintenance and floodlightadjustments can be done atground level– Virtually maintenance free – thanksto straightforward design and robustengineering– Attractive – with no ladder orplatform to interrupt the <strong>mast</strong>’sclean, modern lines– Versatile – with eight models, alldesigned for different load weights– Particularly suitable for high-wind orhurricane-prone zones, as <strong>mast</strong>s canbe lowered in advance of storms.SpecificationAll <strong>mast</strong>s are designed to the British<strong>High</strong> Mast standard, Institution of<strong>Lighting</strong> Engineers’ Technical ReportNo. 7. All models are hot-dip galvanisedto ISO EN 1461. Base-hinged raisingand lowering <strong>mast</strong>s with gravity locksare installed and operated using anindependent hydraulic cylindercounterbalance unit.20 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

RLH14/RLT RLH15 RLH16 RLH17Manufactured to order800mm 900mm 900mmGL620GL720GL800GL1000Floodlightcap. no.**Max headload (Kg)Height (m)Productcode***Floodlightcap. no.**Max headload (Kg)Height (m)Productcode***Floodlightcap. no.**Max headload (Kg)Height (m)Productcode***Floodlightcap. no.**Max headload (Kg)Height (m)Productcode***GL62030SL 30 260 10GL72030SH 30 1200 62GL80030SH 30 1580 82GL100030SH 30 3850 190GL62030SH 30 950 30GL72035SH 35 890 42GL80035SH 35 1190 58GL100035SH 35 2700 133GL62035SL 35 260 10GL72040SH 40 730 32GL80040SH 40 1110 50GL100040SH 40 1960 96GL62035SH 35 475 18GL72045SL 45 250 10GL80045SH 45 680 26GL100045SH 45 1470 72GL62040SL 40 365 10GL72045SH 45 420 15GL80050SH 50 400 18GL100050SH 50 1150 56Lid/base section: control gearand protection equipment capacity1kW/2kWx8Lid/base section: control gearand protection equipment capacity1kW/2kWx4Lid/base section: control gearand protection equipment capacity1kW/2kWx4Lid/base section: control gearand protection equipment capacity1kW/2kWx4Foundation assemblyFoundation assemblyFoundation assemblyFoundation assemblyBolts and basetemplateTop templateFA008CGFC028Bolts and basetemplateTop templateFA/GL720FC/GL720Bolts and basetemplateTop templateFA800GFC800Bolts and basetemplateTop templateFA/GL1000FC/GL1000CounterbalanceRLH14/RLTCounterbalanceRLH15CounterbalanceRLH16CounterbalanceRLH17Note:The base-hinged <strong>mast</strong>s are subject both to maximum headload capacities and wind area load limits. The floodlight quantities are to be used solely as a guide.Please check with our sales office for maximum floodlight capacities.abacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 23

Mid range (10-20m) <strong>mast</strong>s and accessoriesOur two mid range <strong>mast</strong>s – otherwiseknown as the HL250 and HL330 – aremade with octagonal shafts and agravity-lock mechanism, ensuringthe <strong>mast</strong> is securely positionedbefore it’s lowered to ground level formaintenance. Cable glands mountedin the base also ensure a secure,watertight fit.The SB range of brackets can beused with both models, plus thespigot bracket supplied with each<strong>mast</strong> is suitable for a wide varietyof floodlight configurations.See p26-27 for the full range ofbrackets available.HL250 base-hinged <strong>mast</strong>s: 10m to 15mYou have two options for delivery and installation of the HL250 product range:Easy-fit on site– Mast base is factory-fitted, with asteel cabinet pre-wired and fitted tothe <strong>mast</strong>. This comes complete withcontrol gear and protectionequipment (as needed for yourindividual project)Standard supply– Mast and cabinet are suppliedempty for your contractor to fiton-site– Fast on-site assembly and installation– <strong>Abacus</strong> seal of qualityHL250 product rangeProduct codes Mast height (m) Sets of gears 1kW or 2kW Switching RCD socket <strong>Abacus</strong> installHL250 <strong>mast</strong>s factory fitted with electrical equipmentHL250D1522XRA 15 2 2 • •HL250D1522SRA 15 2 2 • • •HL250D1522XRC 15 2 2 • ClientHL250D1522SRC 15 2 2 • • ClientHL250D1532XRA 15 3 2 • •HL250D1532SRA 15 3 2 • • •HL250D1532XRC 15 3 2 • ClientHL250D1532SRC 15 3 2 • • ClientHL250D1542XRA 15 4 2 • •HL250D1542SRA 15 4 2 • • •HL250D1542XRC 15 4 2 • ClientHL250D1542SRC 15 4 2 • • Client(For 12m, HL250S12,10m HL250S10)HL250 range for client to fit out12 - - - - -HL250S10 10 - - - - -HL250S12 12 - - - - -HL250D15 15 - - - - -HL250BOX/SUPPLY Gear cabinet - - - - -Foundation assemblyFA003GFC023Bolts and base templateTop template24 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

Brackets for base-hinged <strong>mast</strong>sThe SB bracket range is compatiblewith all base-hinged <strong>mast</strong>s. Bracketsincorporate a standard flange,enabling them to be fixed to thematching flange supplied withthe <strong>mast</strong>.The <strong>mast</strong>s can also be fitted withan additional clamp-on bracket forlower-height floodlights (requiringon-site drilling to feed throughadditional cabling).The brackets also feature an M20bolt with an anti-rotation ‘cup’, whichprevents the stirrup from moving.In addition to the standard bracketsshown, we can also design andsupply bespoke brackets if required.There are two categories of brackets– sports and area <strong>lighting</strong>. Both typesare fitted with <strong>Abacus</strong> anti‐rotationfloodlight cups.The brackets are supplied ineasy‐to‐assemble kits, requiring theminimum equipment to put together.SB bracket rangeSB1 SB2 SB3 SB4SB4H SB5 SB6SB8The SB8 carries either seven or eight Challenger ® 1 floodlights. To be used in conjunction with shortened 18m and 20mHL330 <strong>mast</strong>s as follows: HL33017.3 / HL33019.3Clamp on bracketSBC16 Clamp on at 6m HL250 onlySBC18 Clamp on at 8m HL250 onlySBC3306 Clamp on at 6m HL330 onlySBC3308 Clamp on at 8m HL330 only26 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

Sports <strong>lighting</strong>Sports <strong>lighting</strong> brackets feature angled-back cross arms as standard, directing the floodlights to their target positions moreeffectively. To maintain the necessary central floodlight mounting height, some brackets require a <strong>mast</strong> height reductionof either 1.5m or 2.5m. The product code for the <strong>mast</strong> is adjusted accordingly.SB10SB12SB16SB16SMast spigotMast reduction-SL.7m (HL33017.3 only)Mast spigotMast reduction-SLNoneMast spigot -SHMast reduction 1.5mMast spigot -SHMast reduction 1.5mSB20SB20SSB24SSB32SMast spigot-SHMast reduction 1.5mMast spigot-SHMast reduction 1.5mMast spigot-SHMast reduction 1.5mMast spigot-SHMast reduction 2.5mSB36SSB40SSB44SMast spigot -SHMast reduction 2.5mMast spigot -SHMast reduction 2.5mMast spigot -SHMast reduction 2.5mArea <strong>lighting</strong>Practical, simple to build on site and cheap to transport, the ‘hub and spoke’ bracket arrangement is most common forArea <strong>lighting</strong>. They make it possible to achieve both 180° and 360° floodlight layouts.SB4XSBA6XSBA8XSBA10XMast spigotMast reduction-SLNoneMast spigotMast reduction-SLNoneMast spigotMast reduction-SLNoneMast spigotMast reduction-SLNoneAccessoriesProductProduct codeDouble obstruction light: 2 x 55W lamps, each with an 8,000hour lifeTHO003Bracket to mount double obstruction light onto 114mm diameter cross-armBKT/F22SBA12XTwin obstruction light LEDTOL/LED/220VMast spigotMast reduction-SLNoneLightning rod, copper, 1000mm(h), to fix to canopy of <strong>mast</strong> (M16 fixing)LPS225abacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 27

Base-hinged <strong>mast</strong> with automatic sequencingFor many years, the base-hinged<strong>mast</strong> has been a popular choiceamongst clients. As such, wedecided to build upon its successand take the concept one stepfurther.This involved developing and patentingan automatic sequencing system withinthe <strong>mast</strong> – a feature that enablesseveral <strong>mast</strong>s to be raised and loweredat the same time, all from a singlecentral point.Together with positional sensors, aProgrammable Logic Control (PLC) unitco-ordinates and monitors the wholeraising and lowering process. Hydrauliccylinders fitted to the base of the <strong>mast</strong>work together with a mechanised pivot,allowing the <strong>mast</strong> to raise or lowersmoothly in a single failsafe operation.Operator remotely engages pivotwithin <strong>mast</strong>……which releases the internal lockingmechanism……which enables the <strong>mast</strong> to be loweredautomatically in just a few minutes.ApplicationsBecause automatic sequencingeliminates the need to move acounterbalance unit from <strong>mast</strong> to<strong>mast</strong>, it’s the ideal solution insituations where several <strong>mast</strong>sneed to be quickly lowered at thesame time.Hurricane and typhoon wind zonesoffer one example of an idealapplication for automatic sequencing.Before the arrival of tropical storms,high-cost capital equipment can beprotected by lowering the structuresto safety.28 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

<strong>Lighting</strong> solutions in actionKempton Park Racetrack, UKKempton Park racecourse is set inbeautiful countryside surroundings andwe wanted to keep it that way.There were strict planning regulationsgoverning the use of flood<strong>lighting</strong> at thecourse, which even went so far as tostipulate no permanent upright floodlights.Our patented automatic sequencingsystem was the perfect solution,providing Kempton Park with <strong>lighting</strong><strong>mast</strong>s which could be raised togetherand lowered after each race.We manufactured and installed 24 ofour base-hinged <strong>mast</strong>s for the scheme,ensuring the racecourse was lit tothe highest standard, whilst the impacton the skyline was minimised by thesequencing system.The system is easy to install (as with allour base-hinged products) and easy tooperate, with simple electrical controls.“ We wanted to create an environment that would allow morepeople to enjoy horse racing throughout the year,in order to survive in what will become an increasinglycompetitive marketplace. Through extensive public consultationI am confident that we have created a showpiece stadium thatbenefits everyone.”Julian Thick, Managing Director, Kempton Parkabacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 29

Loweringheadframe <strong>mast</strong>sThe range of lowering headframe <strong>mast</strong>s from<strong>Abacus</strong> deliver precision engineering solutions fora great variety of different projects – from majorcontainer port terminals to international airportsThe engineered headframe,with its secure three-pulley system,is available with or without ourinnovative latching system. A singlemulti-core electric cable has its ownindependent pulley, meaning itdoesn’t become entangled with othercables in the <strong>mast</strong>.Features– Headframe supported by threestainless steel cables for longer-termstability than twin cable <strong>systems</strong>– Option to install mechanical latchingsystem on three arms, to releasestrain on cables when headframe isin the operating position– Headframe supplied preparedready for installation, complete withthree cables looped for droppinginto the <strong>mast</strong> shaft and junctionbox for the multicore cable mountedon headframe– Single 275Kg or single 550Kg winchlocated in the base of the <strong>mast</strong>.The winch is self-sustaining, with agravity latch on the input shaft– A 10mm earth terminal is provided inthe base of the <strong>mast</strong>– Single multicore cable for all lanternsis located on an independent pulley,stopping multiple cables frombecoming entangled inside the <strong>mast</strong>– Single multicore – with 18 coreson the 275Kg winch <strong>mast</strong> (for upto 8 floodlights/lanterns), or 25cores on the 550Kg model (for up to12 lanterns)– A multicore electric cable, withintegral signal cables for CCTV andWiFi, is available on request– Electrical cable is supplied with aplug and socket at lower end.This means you can detach thecable and power the headframe atground level using a separateextension cable– A lightweight dual-speed reversiblepower tool is supplied with its ownmounting bracket, which is clampeddirectly to the body of the <strong>mast</strong>.A remote hand-held box withnon-latching buttons controls theunit, enabling the operator to standat a safe distance when lowering.30 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

Building your <strong>mast</strong>Step 1– Identify the correct <strong>Abacus</strong> floodlightfrom the <strong>lighting</strong> design and then…Step 2Select the correct headframe optionbased on:– the floodlight arrangement– external IP65Step 3Select the central assembly codedetermined by:– <strong>mast</strong> height e.g. 30m isRLW-HF-30M-xxx-xx– multicore electric cable, for 275kgwinch is 18core (18C) & 550kgwinch is 25core (25C); e.g.RLW-HF-30M-18C-XX– whether the latching systemis required (-L) or not (-NL);e.g. RLW-HF-30M-18C-NLNote: the central assembly isdelivered to site fully assembled withstainless steel cables and multicorecable factory-assembled ready forimmediate installation.Step 4Select the correct <strong>mast</strong> structurebased on:– <strong>mast</strong> height– winch capacity (determined byheadframe choice)– site wind speed and headframe areaFor each height and winch capacitythere is a light duty and mediumduty <strong>mast</strong> option, which covers mostrequirements. Other <strong>mast</strong> structuresfor higher wind loads are availableon request.Step 5Select any necessary accessoriesfor example:– the floodlight mounting bracket,required if a floodlight with stirrup isselected– Power tool operating system,dependent on winch capacity– Lightning rodLatching optionThe <strong>Abacus</strong> headframe offers flexibilitythrough the opportunity to add alatching mechanism to the headframe,enabling it to be supported while raisedand removing strain on the stainlesssteel cables, for long term benefits.flagStep 1Latch engages when mobile headframeis raised towards <strong>mast</strong> head.Step 2Once mobile headframe has docked,latch engages, raising a flag confirmingto the operator that it’s secure.Step 3Mobile headframe is raised to disengagelatching, before being lowered toground level for maintenance.abacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 31

Headframe options with external gearLPS225Lightning rodRLW-HF-M-♦-•Central assemblyRLW-LC-ASS-#HeadframeExternal gearLowering headframex4 floodssymmetrical external gearLowering headframex6 floodssymmetrical external gearLowering headframex8 floodssymmetrical external gearLowering headframex10 floodssymmetrical external gearProduct codeRLW-LC-ASS-1Product codeRLW-LC-ASS-2Product codeRLW-LC-ASS-3Product codeRLW-LC-ASS-4Diameter1200mmDiameter1700mmDiameter2000mmDiameter2400mmCentral assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Total headframe area 2m 2Total headframe area 2.6m 2Total headframe area 3.3m 2Total headframe area 3.9m 2Winch capacity275KgWinch capacity550KgWinch capacity550KgWinch capacity550KgLowering headframex12 floodssymmetrical external gearLowering headframex4 floodsasymmetrical external gearLowering headframex6 floodsasymmetrical external gearLowering headframex8 floodsasymmetrical external gearProduct codeRLW-LC-ASS-5Product codeRLW-LC-ASS-6Product codeRLW-LC-ASS-7Product codeRLW-LC-ASS-8Diameter2700mmDiameter1700mmDiameter2400mmDiameter2700mmCentral assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Total headframe area 4.5m 2Total headframe area 2.1m 2Total headframe area 2.8m 2Total headframe area 3.3m 2Winch capacity550KgWinch capacity275KgWinch capacity550KgWinch capacity550KgNote: = Mast height in meters♦ = Add 18C for an 18 core cable or 25C for a 25 core cable• = NL not latched or L for latching e.g. 35m <strong>mast</strong> with an 18 core cable and latching RLW-HF-35M-18C-L32 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

Headframe options with internal gearLPS225Lightning rodRLW-HF-M-♦-•Central assemblyRLW-LC-ASS-#HeadframeLowering headframex4 floodssymmetrical internal gearLowering headframex6 floodssymmetrical internal gearLowering headframex8 floodssymmetrical internal gearLowering headframex10 floodssymmetrical internal gearProduct codeRLW-LC-ASS-9Product codeRLW-LC-ASS-10Product codeRLW-LC-ASS-11Product codeRLW-LC-ASS-12Diameter1200mmDiameter1700mmDiameter2000mmDiameter2400mmCentral assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Total headframe area 1.5m 2Total headframe area 1.9m 2Total headframe area 2.3m 2Total headframe area 2.7m 2Winch capacity275KgWinch capacity275KgWinch capacity550KgWinch capacity550KgLowering headframex12 floodssymmetrical internal gearLowering headframex4 floodsasymmetric internal gearLowering headframex6 floodsasymmetric internal gearLowering headframex8 floodsasymmetric internal gearProduct codeRLW-LC-ASS-13Product codeRLW-LC-ASS-14Product codeRLW-LC-ASS-15Product codeRLW-LC-ASS-16Diameter2700mmDiameter1700mmDiameter2400mmDiameter2700mmCentral assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Central assemblyRLW-HF-M-♦-•Total headframe area 3m 2Total headframe area 1.8m 2Total headframe area 2.5m 2Total headframe area 2.8m 2Winch capacity550KgWinch capacity275KgWinch capacity550KgWinch capacity550KgNote: = Mast height in meters♦ = Add 18C for an 18 core cable or 25C for a 25 core cable• = NL not latched or L for latching e.g. 35m <strong>mast</strong> with an 18 core cable and latching RLW-HF-35M-18C-Labacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 33

Lowering headframe <strong>mast</strong> structureOnce you’ve chosen a headframeand central assembly configuration,use the table below to find theappropriate <strong>mast</strong>.The <strong>mast</strong>’s structure is determinedby your chosen headframe’s useableMast structureheadload area (detailed on theprevious pages) and the governingwind speed on your specific site. The<strong>mast</strong> is supplied as standard with theintegral winch. It is also available asan option without.The table below gives the principalstructures and loadings for mostrequirements. If you need moreinformation on <strong>mast</strong> structures forparticularly high wind loads orspeeds, please contact our salesoffice.Height(m)WinchcapacityKgProductcode15 275 RLW-15M275S-I120 275 RLW-20M275S-E120 550 RLW-20M550S-M125 275 RLW-25M275S-C2RLW-25M275S-C325 550 RLW-25M550S-I1RLW-25M550S-I230 275 RLW-30M275S-A3RLW-30M275S-A530 550 RLW-30M550S-F2RLW-30M550S-F435 275 RLW-35M275S-C1RLW-35M275S-C335 550 RLW-35M550S-D3RLW-35M550S-D740 275 RLW-40M275S-C1RLW-40M275S-C240 550 RLW-40M550S-C6RLW-40M550S-E5Basic site wind speed (m/s) **/Hourly mean wind speed (m/s) ***/Max 3 second gust (m/s) ****Headloadcapacity(m²)Useable Mast design informationheadweight (Kg)Top/base/flange Ø (mm)Bolt assemblycode and PCD*O.T.M (kNm)and shear (kN)2628.253.466 190 140/438/700 FA30/8/1220/600 104kNm,8.3kN48 3.63926 2.566 185 140/457.2/700 FA30/8/1220/600 130kNm,28.258.7kN48 2.59726 4.181 460 140/614/900 FA30/8/1220/800 190kNm,28.2512.5kN48 4.22226 2.000 180 140/478.8/750 FA30/8/1220/650 164kNm,28.259.7kN48 2.00526 2.264 180 140/476.8/750 FA30/8/1220/650 176kNm,28.2510.0kN48 2.36026 3.025 455 140/626/900 FA30/8/1220/800 222kNm,28.2513.1kN48 3.03126 4.483 455 140/624/900 FA30/8/1220/800 284kNm,28.2515.4kN48 4.53126 1.513 170 140/488.4/750 FA30/8/1220/650 200kNm,28.2510.6kN48 1.50626 2.295 170 140/484.4/750 FA30/8/1220/650 242kNm,28.2511.8kN48 2.36326 3.098 445 140/634/900 FA30/8/1220/800 307kNm,28.2515.5kN48 3.10126 4.442 445 140/630/900 FA30/18/1220/800 377kNm,28.2517.6kN48 4.50926 1.656 165 140/610.8/850 FA30/8/1220/750 290kNm,28.2514.5kN48 1.67626 2.25 165 140/606.8/850 FA30/18/1220/750 326kNm,28.2515.4kN48 2.22526 2.860 440 140/637/900 FA30/18/1220/800 384kNm,28.2517.3kN48 2.92826 4.330 440 140/631/900 FA30/18/1220/800 474kNm,28.2519.6kN48 4.28226 1.842 160 140/678.8/950 FA30/18/1220/850 396kNm,28.2518.1kN48 1.80826 2.177 160 140/676.8/950 FA30/18/1220/850 422kNm,28.2518.6kN48 2.13426 3.047 435 140/668/950 FA30/18/1220/850 503kNm,28.2520.3kN48 2.99226 4.059 435 140/748/1000 FA30/18/1220/900 586kNm,28.2523.6kN48 3.988Foundationrefs.†150M150,150P150150M150,150P150200M150,200P150200M150,200P150200M150,200P150300M150,300P150300M150,300P150200M150,200P150300M150,300P150400M150,400P150400M150,400P150300M150,300P150400M150,400P150400M150,400P150500M150,500P150400M150,400P150500M150,500P150750M150,750P150750M150,750P150Footnotes:* All <strong>mast</strong>s employ the same M30, 1220mm length foundation bolt, hot spun galvanised, Grade 8.8.** Site wind speed: this figure is based on an assumption that site is 1km from the sea at an altitude of 0m.*** Hourly mean is the UK standard for wind loadings. Many continental European countries specify “10-minute mean” wind speed, which varies slightly. ContactUK sales office for more information.**** 3 second gust is the wind load design velocity used in many countries.† For complete foundation details, refer to pages 50-55; the overturning moments (OTM) and shear forces are rounded up to the next level to calculate thesuitable foundations for the <strong>mast</strong>. There is a choice of either passive or non-passive foundations, both of which are non-reinforced. For a reinforced foundationdesign, use the same code but with 'R' replacing the 'M' and 'P' will fulfill the requirement.34 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

Accessory productsProduct codeDescriptionBKT/RLW/C/M20 or M12RLW07/PD/ARLW07/PD/1ARLW08/PD/DW/ARLW07/PD/PORT/**MRLW08/PD/PORT/**MRLW07/HANDLE/ASSYLPS225BALAPF1kWRLW-SUP-BKTBracket for floodlight with stirrup, with M20 or M12 fixing boltPower tool & torque limiter for single drum 275kg winchPower tool & torque limiter for single drum 550kg winchPower tool & torque limiter for double drum 1000kg winchPortable power tool and 275kg winch mounted on a mobile trolley.For multiple <strong>mast</strong> installations, no winch is mounted in <strong>mast</strong> base, thereby reducing costs.Portable power tool and 550kg winch mounted on a mobile trolley.For multiple <strong>mast</strong> installations, no winch is mounted in <strong>mast</strong> base, thereby reducing costs.Manual Crank Handle with Torque Limiter for 275kg WinchLightning rod, copper, 1000mm(h), to fix to canopy of <strong>mast</strong> (M16 fixing)<strong>Abacus</strong> 1kW encapsulated control gear, IP65, to be selected in combination with <strong>Abacus</strong> floodlight (240v)Set of 3 brackets to support headframe when lowered for maintenanceFloodlight mounting bracketBKT/RLW/C/M20IP65 1kWcontrol gearRLW07/PD/PORT/**M Portable power toolRLW08/PD/PORT/**M Portable power toolThe power tool in operation, using remote control at a safe distanceMulticore electric cableA single multicore cable is supplied witheach central assembly in the <strong>mast</strong>.This reduces the risk of multiple electriccables becoming entangled inside the<strong>mast</strong> over a period of time.A standard 18-core cable, sufficientto provide enough cores for up to 8floodlights.A standard 25-core cable, sufficientto provide enough cores for up to 12floodlights.16-core electric cable18-core electric cable25-core electric cableabacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 35

Fixed <strong>mast</strong>s:Sports and large area<strong>Abacus</strong> design and manufacture a huge range of products suitable touse for sports stadia, ports and wind turbines. Tackling complexitiesis what we do best; so whatever and wherever your project – small orlarge-scale – <strong>Abacus</strong> have the solution.Brilliant design has to be carefullythought-through. And with <strong>lighting</strong>,that means considering:– Methods of access for maintenance– Wind levels in the proposed location– Aesthetic options such as ‘designer’headframes– The location of control gear andprotection equipmentSpecificationAt <strong>Abacus</strong>, we take incredible pride inour work – and it’s that quality andattention to detail which has set usapart from the competition for over 50years. In addition to our seal of quality,you can also be assured of thefollowing specifications as standard:– Masts are designed in accordancewith ILE Technical Report No. 7– Masts above 20m are made fromfriction-fit tapered polygonal shafts– typically 18-sided for minimumwind resistance– Masts are hot-dip galvanised to ISOEN 1461We take great pride in ourworkmanship, from design throughto assembly and installation.Liberec ski jump, Czech Republic<strong>High</strong> quality manufacturing36 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

Problem-solving the world over<strong>Abacus</strong> have come up with completesolutions for fixed-<strong>mast</strong> flood<strong>lighting</strong>all over the world.Visit the Sheikh Zayed Cricket Stadiumin Abu Dhabi, for example, and you’llsee the 70m <strong>mast</strong>s we designed, madeand installed – not to mention the 200floodlights atop each one. Or, a littlecloser to home, the innovative circularheadframes we designed and installedfor the Trent Bridge Cricket Stadiumin England.Often, extreme weather plays its partin shaping our designs. For instance,the 55m <strong>mast</strong>s we installed at theKensington Oval in Barbados weredesigned to withstand hurricaneconditions.Tricky locations also pose their ownset of challenges. Installing seven<strong>mast</strong>s up to 55m high by helicopteron a 45-degree slope, for example,was no mean feat when we lit theWorld Cup Ski Jump in Liberec,Czech Republic.Sometimes it’s not the <strong>mast</strong>s themselvesbut the ongoing maintenance thatinforms product choice. For instance,many airports and large commercialareas choose fixed <strong>mast</strong>s over basehingedor winch‐lowering headframes,employing trained maintenancespecialists (often <strong>Abacus</strong> or one of ourinternational partners) to maintain their<strong>lighting</strong> at height.Whatever your requirements, we’ll finda solution that fits.F.C. Tournai, BelgiumThe Kensington Oval, Barbadosabacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 37

The Club range (15m–30m)Choose from our standard range orcommission a bespoke <strong>mast</strong>,depending on your project.– 15–20m: Tubular or octagonal steelconstruction– 20–30m: Multi-sided steelconstructionWhichever option you choose, controland protection equipment can befactory-fitted into the base of the <strong>mast</strong>itself, or placed in an external cabinetclose to the <strong>mast</strong>’s base.This fixed <strong>mast</strong> has electrical equipment factory-fittedand mounted into a cabinet in its base. Lights areaccessed by a ‘cherry picker’ for maintenance.Maintenance accessThere are three options for maintainingour Club range:– Ladder fixed permanently to <strong>mast</strong>,with security cable system– Removable climbing rungs withsecurity cable system– Cherry picker vehiclemounted platformFixed <strong>mast</strong> with ladder and twin platformFixed <strong>mast</strong> system, Czech Republic38 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

The range of 16m–25m Club <strong>mast</strong>s has a carryingcapacity of up to 8 Challenger ® 1 floodlights, withaccess by means of climbing rungs and a platform,with security cable. At 20m and 25m, we canconceal all 8 sets of control gear and protectionequipment in the <strong>mast</strong> base.20m18m25m15mSupport ringRest platformArea <strong>lighting</strong> <strong>mast</strong>s feature aladder or climbing rungs, arest platform (optional) at 20mon the higher <strong>mast</strong>s, and anenclosed platform onto whichfloodlights can be mounted onany side.2kW Control gearunits. Fitted at<strong>Abacus</strong> and wiredfor 400V supply.30mThe 28m and 30mClub <strong>mast</strong>s have acarrying capacity of upto 16 Challenger ® 3floodlights, accessed inthe same way as thesmaller <strong>mast</strong>s above.28m2kW Control gearunits. Fitted at<strong>Abacus</strong> and wiredfor 400V supply.Control gear andprotection equipmentcan be integrated intothe <strong>mast</strong> andfactory-installed by<strong>Abacus</strong>, enabling faston-site operations.Control gear can beeither IP65 orstandard, dependingon specification orlocal conditions.Circuit breaker toprotect of up to 17floodlights. Housedin an IP65 ratedenclosureContactors for 6switching levelsIsolatorIncoming terminal tosuit up to 25mm SQcables andincoming terminalsfor control wiring.abacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 39

Fixed Stadium and Area <strong>mast</strong>s (20m–70m)In addition to our base-hinged range,<strong>Abacus</strong> design and manufacturea wide range of fixed <strong>mast</strong>s for largescaleflood<strong>lighting</strong>.50 years’ engineering experience onprojects all over the world has taughtus a lot about the importance offlexibility, attention to detail andcustomer service. As such, we offer arange of solutions to suit you.– External ladder access with optionalrest platforms– External access using the manriderelevator system– Internal access, with a ladderrunning up the inside of the <strong>mast</strong>– External access by means of craneand basketFoundationsPart of our <strong>mast</strong>-design serviceincludes providing you with a <strong>mast</strong>foundation reference, which can becross-referenced in our standardfoundations guide. This will indicate thedimensions and volume of concreteand steel required to support your <strong>mast</strong>in situ. Find out more on pages 50-55.Fixed <strong>mast</strong> system, BarbadosThe manrider external-access system at work.A 40m external-access <strong>mast</strong> being lifted into positionat Shanghai’s 80,000 seater stadium.40 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

Access <strong>systems</strong>Typical height range35–70m35–55m30–55m20–40mEXTACC/MOBILEEXTACC/LADDERINTACC/LADDEREXTACC/MANRIDERAccess by independentmobile platformAccess by fixed external ladderto platformAccess by fixed internal ladderto platformAccess by external manrider elevatorto platformAccess <strong>systems</strong> close-upTwo anti-climb devices are available: the anti-climb door forground-level ladders, or the anti-climb collar for ladderswhich start 3m above ground level.A hatch provides directaccess to the platform.The manrider uses a winchto reach the maintenanceplatform.abacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 41

Sports stadium headframesHeadframe configurations4/8 floodlights incross-armarrangement6/12 floodlights incross-armarrangementOur stadium headframes arerenowned for their superioreffectiveness, clean aestheticappeal and uncomplicated assemblyand installation.Whatever the quantity of floodlightsrequired – up to 200 if you wish –configurations are always logical,making project planning as simpleas possible for both consultantsand engineers.Floodlight cables enter the <strong>mast</strong>through secure cable glands.Installation is straightforward, with clearassembly instructions included.8/16 floodlights incross-armarrangement10/20 floodlights incross-armarrangementAll headframe and ladder <strong>systems</strong>incorporate a security fall-arrestcable, in conformity with EN353-1and EN353-2.The table below lists the dimensions, wind-load area and configuration of each <strong>Abacus</strong> floodlight headframe. Each onerequires sets of cable security equipment depending on code types and quantities. Two, four or six sets will be needed forthe platform ladders and one for the main ladder, if required.Sports stadium <strong>mast</strong> headframe matrixNo.floodlightsFloodlightarrangement W x HHeadframedimensions W x H (m)No. crossarmsCalculatedwind area (m 2 )Headframeproduct code*Cable fall-arrest system productcodes to addHeadframe laddercable <strong>systems</strong>Main ladder(if required)20 4 x 5 3.5 x 3.9 2 7.775 HFRAME20/xxxx MIS4008 x 2 Apply ladder28 4 x 7 3.5 x 5.5 3 9.956 HFRAME28/xxxx MIS4008 x 2 length according30 6 x 5 5.1 x 3.9 2 11.349 HFRAME30/xxxx MIS4008 x 4to <strong>mast</strong>-centreheadframe height.42 6 x 7 5.1 x 5.5 3 14.775 HFRAME42/xxxx MIS4008 x 454 6 x 9 5.1 x 7.1 4 18.201 HFRAME54/xxxx MIS4008 x 4 MIS4015: 15m66 6 x 11 5.1 x 8.7 5 21.626 HFRAME66/xxxx MIS4008 x 4 MIS4020: 20mMIS4030: 30m72 8 x 9 6.7 x 7.1 4 22.766 HFRAME72/xxxx MIS4008 x 4MIS4030: 40m88 8 x 11 6.7 x 8.7 5 27.125 HFRAME88/xxxx MIS4008 x 4 MIS4050: 50m104 8 x 13 6.7 x 8.7 6 31.463 HFRAME104/xxxx MIS4010 x 4 MIS4060: 60m120 8 x 15 6.7 x 11.9 7 35.801 HFRAME120/xxxx MIS4010 x 4136 8 x 17 6.7 x 13.5 8 40.138 HFRAME136/xxxx MIS4015 x 4Larger headframes with capacities of up to 200 are available on request.*Product code dependent on flange diameter matching between headframe and main shaftAccessoriesProductSafety harness and karabiner: to be used in conjunction with MIS3014 fall-arrestorFall-arrestor for use with Cable Security System: for use on 8mm security cable systemDouble obstruction light: 2 x 55W lamps, each with an 8,000hour lifeBracket to mount double obstruction light onto 114mm diameter cross-armTwin obstruction light LEDProduct codeMIS3013MIS3014THO003BKT/F22TOL/LED/220V42 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

Custom headframe designAs leaders in <strong>lighting</strong>, <strong>Abacus</strong> arealways developing innovative newengineering solutions to enhance thestadium environment.Talk to us about your ideas – you’ll beamazed at the possibilities.Available in 76 and52 floodlight options(52-floodlightcapacity shown)Curved headframe canaccommodate 100 floodlights orbe designed to suit your specificrequirements.Trent Bridge Cricket Ground, UKArea <strong>lighting</strong> headframes and platformsHeadframes are generally accessedby a ladder and platform or by a cherrypicker. These are designed to suit eachproject requirement.Control gear and protection equipmentMost of the time, control gear andelectrical protection equipment ismounted in cabinets at or near the <strong>mast</strong>base. If space is limited, however, oryou’d rather preserve the clean, straightlines of your <strong>mast</strong>, we can increase thedimensions of its base and conceal theequipment and access ladder inside (upto a limit of around 60 2kW floodlights).Control gear is mounted onthe inside wall of the <strong>mast</strong> andaccessed by ladder.abacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 43

Telescopic<strong>mast</strong> <strong>systems</strong><strong>Abacus</strong>’ comprehensive range of telescopic <strong>mast</strong>s has been developed toaddress the increasingly difficult planning requirements that clients have to meetin ‘sensitive’ locations. This highly engineered, patented solution provides theideal alternative to fixed-<strong>mast</strong> flood<strong>lighting</strong> – even in space-restricted areasThe Stadium range (up to 50m)The colossal Stadium range can accommodate 100 Challenger ® 3 2kW floodlights at a mounting height of 50m –an imposing and highly effective solution for any major sports stadium.Engineering without compromiseIncorporating the finest precision-engineering for a long, hassle-free life, the telescopic <strong>mast</strong> represents the pinnacle oftechnical achievement in high-<strong>mast</strong> <strong>lighting</strong>. Driven by a 7m double-acting ram producing 45 tonnes of lift-thrust, the <strong>mast</strong>works in conjunction with a secondary leaf chain-management system. A supporting negative-chain system and linear stringencoder, linked to a remotely located PLC (Programmable Logic Control) unit, mean the <strong>mast</strong>s can be controlled andmonitored from the safety and comfort of a main control room.The Brit Oval, UK44 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

The <strong>mast</strong>s are delivered to site part-assembled. The headframe is pre-wired in-house before shipping. The headframe wiringis then connected on-site to the main multi-core cables running through the <strong>mast</strong>’s centre section, using an instant plugand-socketsystem.The <strong>mast</strong>s can becontrolled digitally from onemain control room.50m telescopic <strong>mast</strong>s at Lord’s cricket stadium and45m <strong>mast</strong>s at the Brit Oval stadium, both in London.Strict planning controls in these sensitive residentialneighbourhoods meant that retractable <strong>mast</strong>s werethe only practical solution for flood<strong>lighting</strong> bothstadiums.The 40m telescopic <strong>mast</strong>sinstalled at the Al Shamalstadium in Qatar. Located infour corner turrets designedto emulate a traditional fort,each carries up to 100Challenger ® 3 floodlights forHDTV broadcasts. Afteruse, each <strong>mast</strong> retracts intoits own turret and out ofsight at a height of 22m.abacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 45

The Club range (up to 20m)The Club telescopic range is perfectfor medium-sized sports, recreationalor commercial facilities wherefull-height permanent <strong>mast</strong>s aren’tfeasible or necessary. Incorporatinginnovative, user-friendly engineeringsolutions, our range is as flexible asit is practical – with <strong>mast</strong>s that morethan double in height from theirretracted position. They also lower toground level from the base.Easy operationMasts can be raised and lowered eitherremotely (from the club house, forexample) or individually from the base ofeach <strong>mast</strong>. The range has a load capacityof up to five Challenger ® 1 floodlights,either with a 1kW or 2kW lamp.The <strong>mast</strong>s are delivered fully assembled,with integrated electrical and mechanicalequipment ready for fast on-siteinstallation. Engineered to the higheststandards, all Club <strong>mast</strong>s feature aproxy sensor height-managementsystem and fully adjustable Nyoilself-lubricating bearing pads –technologies that monitor and controlheight, alignment and internal workings.Maintenance friendlyAnother unique feature of the Clubrange is <strong>Abacus</strong>’ tried-and-testedbase‐hinged mechanism, whichenables engineers to lower <strong>mast</strong>squickly and safely to ground level formaintenance (using an RLH5counterbalance unit).Key switch operation locally, at <strong>mast</strong>base, or remote control operation15m telescopic <strong>mast</strong>s at Stone Dominoes FootballClub in the UK. The local Planning departmentpermitted a maximum permanent height of 8m.46 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

TEL-8.0-RL/XXXXTEL-15.0-RL/XXXXTEL-18.0-RL/XXXXTEL-20.0-RL/XXXXFoundation reference 30P150*Foundation reference 50P150*Foundation reference75P150Foundation reference75P150Headframe to mount up to 5 No.Challenger 1 ® floodlights.To carry out maintenance, the <strong>mast</strong> islowered using an RLH5counterbalance unit (see page 22-23for full details).Motor, winch,gearbox assemblyLocal control pointElectrical cables for floodlightsare managed internally usinga small energy chain system.Hydraulic counterbalanceElectrical control boxDelivered to site fully assembled, complete with all equipment installedfor fast on-site assembly.*Assumes a ground bearing pressure of minimum 150kN/m 2 .abacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 47

Control gearcabinets<strong>Abacus</strong> will design, build and supply all the necessary controlcabinets for your project. Better still, we offer comprehensiveelectrical support, either through our complete installationservice or from one of our product supply packages.As an ISO9001-accreditedmanufacturer, you can rest assuredthat <strong>Abacus</strong> are fully covered ineverything from design andmanufacture to installation andongoing maintenance.Our control gear is designed with thefollowing considerations:– <strong>Lighting</strong> specification,allowing for lower switchinglevels where necessary– Correct standard of protectionequipment for each floodlight– PLC (Programmable Logic Control)unit(s) are used where necessary toprovide intelligent control for <strong>lighting</strong>and/or <strong>mast</strong> <strong>systems</strong>– Does the climate on-site requireforced ventilation and/or heating<strong>systems</strong> to be built in?– Is the cabinet built to withstandconditions on-site?– Packing and shipping requirementsfor safe delivery anywhere inthe worldThe touch-screen display at Al Shamalstadium in Qatar controls both <strong>lighting</strong> levelsand the telescopic <strong>mast</strong> system from the maincontrol room.Typical cabinet arrangement for a stadium.Cabinet installation and foundationFor further information on the different cabinet installation methods and foundations, please contact the <strong>Abacus</strong> sales office.48 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com

Cabinet configurations for 2kW and 1kWflood<strong>lighting</strong> projects2kWNo. of gears 2kW Dim A. Dim B. Dim C. Dim D. Dim E. Cabinet item no.10 - 12 2 1250 1600 450 1220 1445 ELF123413 - 15 2 1500 1600 450 1470 1445 ELF65916 - 21 2 1750 1600 450 1720 1445 ELF1102For larger quantities of 2kW floodlights (between 25 and 150), we design bespoke cabinets according to specificproject requirements.1kWNo. of gears 1kW Dim A. Dim B. Dim C. Dim D. Dim E. Cabinet item no.9 1 1250 1600 450 1220 1445 ELF123410-12 1 1500 1600 450 1470 1445 ELF65913-15 1 1750 1600 450 1720 1445 ELF110216-18 1 2000 1600 450 1970 1445 ELF201119-24 1 2250 1600 450 2220 1445 ELF1109abacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 49

Foundation designIn this section, you’ll find technical guidance on foundation designs – for boththe range of high <strong>mast</strong>s in this brochure and bespoke <strong>mast</strong>s designed by<strong>Abacus</strong> for specific clients’ projects. All foundations meet BS8004 standardsand comply with the Institute of <strong>Lighting</strong> Engineers’ Technical Report No.7.Allowable ground-bearing pressuresA key factor in determining the sizeof <strong>mast</strong> foundations is the bearingpressure of the ground in which itwill sit.Over the following pages, each standardfoundation reference incorporates theground-bearing pressure within its code,making it quick and simple to identifythe kind of foundation you need.Types of subsoilThe table below shows subsoilclassifications according to the BS8004standard, against the approximateallowable bearing pressure. We're alsoworking to the new eurocodes, so ifyou require any further help, please callus on +44 (0)1623 511 111.If there is any doubt over groundconditions, it is the client’s orcontractor’s responsibility to consult aqualified civil engineer to establish thetrue bearing pressures.Typical foundation details are providedfor guidance only and should bechecked with the client before use.<strong>Abacus</strong> <strong>Lighting</strong> Limited will not acceptresponsibility for any foundationsunless they are specifically designed byus at the client’s request.Types of subsoil Condition of subsoil Field test applicable Approximate allowance bearingpressure kN/m 2RockNot inferior to sandstone, limestone orfirm chalkRequires at least a pneumatic orother mechanically operated pick forexcavationGravel, sand Compact Requires pick for excavation.Wooden peg 50mm 2 in cross section ishard to drive beyond 150mmClay, sandy clay Firm Can be moulded by substantialpressure with the fingers andexcavated with graft or spadeSand*, silty sand*, clayey sand* Loose Can be excavated with a spade.Wooden peg 50mm 2 in cross sectioncan be easily drivenSilt*, clay*, sandy clay*, silty clay* Soft Fairly easily moulded with the fingersand readily excavatedSilt*, clay*, sandy clay*, silty clay* Very soft Natural sample in winter conditionsexudes between fingers whensqueezed in fistThese values are provided for guidance only. If in any doubt, consult a qualified civil engineer.*Foundations on these soils require assessment and design by a qualified civil engineer.1000Dense to very dense 150-400Loose to medium dense 50-25050-100

Planning the site: cable trenchesCables buried directly in the groundmust be marked by cable covers or asuitable marking tape.Cables, conduits and ducts must beburied deep enough to avoid damagefrom any reasonably foreseeableground disturbance. If you are in anydoubt, refer to national guidelines orstandards.Typical cable trenchtopsoil150mmmin /300mmmaxselected fill450mmto topof cablemin600mmminsand150 minFoundations and flange platesThe principal method for installing ahigh <strong>mast</strong> involves a flange platesupported by a prepared foundation*.The flange plate, which is welded tothe base of the <strong>mast</strong>, is designed toaccommodate the overturning moments(forces) for each specific <strong>mast</strong>.Bolt holes in the flange plate arearranged in one of two ways:1. In a square, where the stated‘bolt centre’ dimension is given.2. In a circle, where the ‘pitch circlediameter’ (PCD), is given.This diameter is stated for thedimension between bolt-hole centres(see diagram).*Root-mounting can be an option up to a height of18m, but we don’t cover this here. If you’d likemore information on this method, please contactthe <strong>Abacus</strong> sales office.1. 2.PCDPCDbolt centre dimensionSquare bolt configuration,with bolt centre dimensionsCircular bolt configuration,with PCD bolt centre dimensionsabacus<strong>lighting</strong>.com <strong>High</strong> <strong>mast</strong> <strong>systems</strong> 51

Assembling foundation bolts into concreteFoundation boltsFoundation bolts are supplied withnuts, washers, a spacer plate anda fixing template in either wood(smaller <strong>mast</strong>s) or steel. Make surethe foundation bolt is put togetheraccurately with bolts vertical and fixedrigidly so it won’t be displaced ormisaligned during concreting. Also,check that bolts project correctly abovethe foundation.After the concrete has cured, the<strong>mast</strong> is erected and levelled on thedouble nuts.The bolts should then be tightened inaccordance with the final torque value,as shown in the table to the right.ConcreteHolding-down bolt projectionand final torque valuesBolt size and grade Projection (mm) Torque (Nm)M16*500 long grade 4.6 125 25M20*500 long grade 4.6 125 50M24*600 long grade 4.6 125 160M30*800 long grade 4.6 150 310M24*880 long grade 8.8 150 425M30*1220 long grade 8.8 150 850M36*1200 long grade 8.8 175 1450M36*1350 long grade 8.8 175 1450M36*1590 long grade 8.8 175 1450M42*1700 long grade 8.8 210 2350M48*1870 long grade 8.8 210 3500Typical section through foundationFoundations should be constructed inaccordance with the following designand dimensional details. Unlessotherwise specified, they should use:Bolt projectionTemplateTemporary support– For reinforced foundations: gradeC28/35 concrete and high tensilereinforcement with a yield stress of485N/mm²– For unreinforced foundations:C20/25 grade concrete.BCable ductCable entry ducts should be placedcentrally within the concrete to facilitateentry into (and in some cases out of)the <strong>mast</strong> itself.Spacer plateConcrete will typically take a minimumof 14 days to cure – enough to erect the<strong>mast</strong> subject to various factors and inaccordance with recommendations.AGlossary of foundation reference codesThe foundation reference codes on the following pages are put together like this:500 M 150Overturning moment kNmType of foundationGround bearingpressure kN/m 2PMRPassive massconcreteNon-passive massconcreteReinforced52 <strong>High</strong> <strong>mast</strong> <strong>systems</strong>abacus<strong>lighting</strong>.com