Duplex stainless steel rigid coupling 17.33 - Victaulic

Duplex stainless steel rigid coupling 17.33 - Victaulic

Duplex stainless steel rigid coupling 17.33 - Victaulic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DUPLEX – grooved Couplings<strong>17.33</strong><strong>Duplex</strong> Stainless SteelRigid CouplingStyle 489DXStyle 489DX is designed for 2 - 12"/ 50 - 300 mm piping systems and features a maximumworking pressure up to 1200 psi / 8273 kPa on cut grooved Schedule 40S duplex/superduplex pipe. See pressure rating table.The housing key is designed to clamp the bottom of the groove, thus providing an essentially<strong>rigid</strong> joint. To achieve this <strong>rigid</strong>ity, it is necessary to torque the nuts to the values shown in thetable below.Style 489DX will greatly reduce linear or angular movement and is useful for valve connectionsand other points where <strong>rigid</strong>ity is required. The <strong>coupling</strong> is provided with <strong>stainless</strong> <strong>steel</strong> boltsand silicon bronze nuts and WRAS-certified, Grade "EW" EPDM gasket material with approvedmicrobiological resistance.See page 3 for pressure ratings based on ANSI wall thicknesses and page 4 for pressureratings for ISO wall thicknesses.NOTE: For the Type 316 <strong>stainless</strong> <strong>steel</strong> <strong>rigid</strong> <strong>coupling</strong>, please see submittal publication 17.25 forthe Style 489 Stainless Steel Rigid Coupling.material specifications Housing: <strong>Duplex</strong> <strong>stainless</strong> <strong>steel</strong> (CE8MN) conforming to ASTM A-890Optional Housing: Super <strong>Duplex</strong> <strong>stainless</strong> <strong>steel</strong> (CE3MN) conforming to ASTM A-890Housing Coating: NoneGaskets:• Grade “EW” EPDMEPDM (Green W color code). Temperature range -30°F to +230°F/ -34°C to +110°C.Recommended for hot water service within the specified temperature range plus a variety of diluteacids, oil-free air and many chemical services. WRAS-certified material with approved microbiological resistance to BS 6920 for cold and hot potable water service up to +149°F/+65°C.UL Classified to ANSI/NSF 61 for cold +86°F/+30°C and hot +180°F/+82°C potable water service.NOT RECOMMENDED FOR PETROLEUM SERVICES.Optional Gaskets: (Specify choice)• Grade “E” EPDMEPDM (Green Stripe color code). Temperature range -30°F to +230°F/-34°C to +110°C.Recommended for cold and hot water service within the specified temperature range plus avariety of dilute acids, oil free air and many chemical services. UL Classified to ANSI/NSF 61 forcold +86°F/+30°C and hot +180°F/+82°C potable water service. NOT RECOMMENDED FORPETROLEUM SERVICES.* Services listed are General Service Recommendations only. It should be noted that there areservices for which these gaskets are not recommended. Reference should always be made to thelatest <strong>Victaulic</strong> Gasket Selection Guide (05.01) for specific gasket service recommendations andfor a listing of services which are not recommended.Hardware:Bolts: ASTM F-593, Group 2, type 316 <strong>stainless</strong> <strong>steel</strong> oval neck track boltsNut: ASME/ANSI B18.22, Type 651 silicon bronze heavy hex nutOptional Nut: ASTM F-594, Group 2, Type 316 <strong>stainless</strong> <strong>steel</strong> heavy hex nuts with galling resistantcoatingWashers: ASME/ANSI B18.22.1, Type 316 <strong>stainless</strong> <strong>steel</strong> flat washerjob/owner contractor engineerSystem No.___________________________ Submitted By_________________________ Spec Sect_____________ Para___________Location_____________________________ Date ________________________________ Approved____________________________Date ________________________________www.victaulic.com<strong>Victaulic</strong> is a registered trademark of <strong>Victaulic</strong> Company. © 2013 <strong>Victaulic</strong> Company. All rights reserved.REV_H<strong>17.33</strong>_1

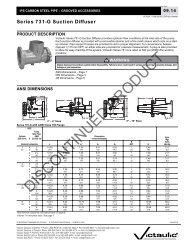

DUPLEX – grooved Couplings<strong>Duplex</strong> Stainless SteelRigid CouplingStyle 489DX<strong>17.33</strong>dimensionsXYZNominalSizeInchesmmSizeActualOutsideDiameterInchesmmAllow. PipeEnd Sep. #Inchesmm@ Bolts/NutsNo. - Size Nut Torque Dimensions Inches/millimetersInchesmmft-lbsN•m X Y ZApprox.Weight Each2 2.375 0.0545 - 60 3.44 6.18 1.95 3.02 – 1/2 x 2 3/450 60.3 1.3 60 - 80 87.4 157.0 49.5 1.42 1/2 2.875 0.0560 - 90 4.00 7.22 1.95 3.92 – 5/8 x 3 1/265 73.0 1.3 80 - 120 101.6 183.4 49.5 1.876.1 mm3.000 0.0560 - 90 3.96 7.42 1.95 3.92 – 5/8 x 3 1/276.1 1.3 80 - 120 100.6 188.5 49.5 1.83 3.500 0.0560 - 90 4.69 7.84 1.95 4.62 – 5/8 x 3 1/280 88.9 1.3 80 - 120 119.1 199.1 49.5 2.14 4.500 0.1985 - 125 5.94 9.68 2.09 8.52 – 3/4 x 4 1/4100 114.3 4.8 115 - 170 150.9 245.9 53.1 3.9139.7 mm5.500 0.2585 - 125 7.01 10.94 2.31 11.82 – 3/4 x 4 1/4139.7 6.4 115 - 170 178.1 277.9 58.7 5.36 6.625 0.25125 - 200 8.16 12.70 2.31 15.52 – 7/8 x 5 1/2150 168.3 6.4 170 - 275 207.3 322.6 58.7 7.0165.1 mm6.500 0.25125 - 200 8.03 12.70 2.31 15.52 – 7/8 x 5 1/2165.1 6.4 170 - 275 204.0 322.6 58.7 7.08 8.625 0.25200 - 300 10.62 15.04 2.62 24.02 – 1 x 5 1/2200 219.1 6.4 275 - 400 269.7 382.0 66.5 10.910 10.750 0.25250 - 350 13.09 17.29 2.69 33.02 – 1 x 6 1/2250 273.0 6.4 339 - 475 332.5 439.2 68.3 15.012 12.750 0.25250 - 350 15.13 19.13 2.81 40.02 – 1 x 6 1/2300 323.9 6.4 339 - 475 384.3 485.9 71.4 18.1Lbs.kg# For field installation only. Style 489DX is essentially <strong>rigid</strong> and does not permit expansion or contraction.@ Metric thread size bolts are available for all <strong>coupling</strong> sizes upon request. Contact <strong>Victaulic</strong> for details.www.victaulic.com<strong>Victaulic</strong> is a registered trademark of <strong>Victaulic</strong> Company. © 2013 <strong>Victaulic</strong> Company. All rights reserved.<strong>17.33</strong>_2REV_H

DUPLEX – grooved Couplings<strong>Duplex</strong> Stainless SteelRigid CouplingStyle 489DX<strong>17.33</strong>PERFORMANCE ON ANSI WALL THICKNESSESPipe DiameterStyle 489DXPipe DiameterStyle 489DXNominalPipeSizeActualOutsideDiameterPipeWallThicknessGroovingMethodWorkingPressureMaximumEnd LoadNominalPipeSizeActualOutsideDiameterPipeWallThicknessGroovingMethodWorkingPressureMaximumEnd LoadInchesmm250Inchesmm2.37560.321/2 2.87565 73.0380410061503.50088.94.500114.36.625168.3Inchesmm0.217ANSIScheduleNumberSt = StandardRoll SetRX = SS RollSetC = Cut GroovePSIkPa80SC750 33235.5 5171 147800.154 <strong>Duplex</strong>/Super <strong>Duplex</strong>40SC1200 53163.9 8273 236560.15440SSt/C750 33233.9 5171 147800.11010SRX500 22172.8 3447 98610.0675SRX325 14401.7 2241 64050.27680SC750 48697.0 5171 216580.203 <strong>Duplex</strong>/Super <strong>Duplex</strong>40SC1200 77905.2 8273 346660.20540SSt/C750 48695.2 5171 216580.12210SRX500 32483.1 3447 144490.0835SRX325 21102.1 2241 93860.29980SC750 72167.6 5171 320980.216 <strong>Duplex</strong>/Super <strong>Duplex</strong>40SC1200 115455.5 8273 513750.21740SSt/C750 72165.5 5171 320980.12210SRX500 48143.1 3447 214150.0835SRX325 31272.1 2241 139100.33980SC750 119288.6 5171 530590.237 <strong>Duplex</strong>/Super <strong>Duplex</strong>40SC1200 190846.0 8273 849240.23640SSt/C750 119286.0 5171 530590.12210SRX400 63623.1 2758 282980.0835SRX250 39792.1 1725 177000.28040SC750 258547.1 5171 1150030.237 <strong>Duplex</strong>/Super <strong>Duplex</strong>40SC1200 413706.0 8273 1840300.28040SSt/C750 258547.1 5171 1150030.13410SRX300 103243.4 2068 459250.1105SRX250 86182.8 1724 38334LbsNInchesmm82001025012300Inchesmm8.625219.110.750273.012.750323.9Inchesmm0.323ANSIScheduleNumberSt = StandardRoll SetRX = SS RollSetC = Cut GroovePSIkPa40SC600 350498.2 4136 1559030.323 <strong>Duplex</strong>/Super <strong>Duplex</strong>40SC1200 701108.2 8273 3118700.32340SSt600 350498.2 4136 1559030.15010SRX300 174993.8 2068 778380.1105SRX200 116862.8 1379 519800.36640SC600 544469.3 4136 2421880.366 <strong>Duplex</strong>/Super <strong>Duplex</strong>40SC1200 1089209.3 8273 4845000.36640SSt600 544469.3 4136 2421880.16510SRX300 271844.2 2068 1209180.1345SRX250 226913.4 1724 1009330.37440SC600 765909.5 4136 3406870.374 <strong>Duplex</strong>/Super <strong>Duplex</strong>40SC1200 1532109.5 8273 6815200.37440SSt600 765909.5 4136 3406870.18110SRX300 382394.6 2068 1700970.1565SRX200 255364.0 1379 113590LbsNwww.victaulic.com<strong>Victaulic</strong> is a registered trademark of <strong>Victaulic</strong> Company. © 2013 <strong>Victaulic</strong> Company. All rights reserved.REV_H<strong>17.33</strong>_3

DUPLEX – grooved Couplings<strong>Duplex</strong> Stainless SteelRigid CouplingStyle 489DX<strong>17.33</strong>PERFORMANCE ON ISO WALL THICKNESSESPipe DiameterStyle 489DXPipe DiameterStyle 489DXActualNominal OutsidePipe Size DiameterPipeWallThicknessGroovingMethodWorkingPressureMaximumEnd LoadActualNominal OutsidePipe Size DiameterPipeWallThicknessGroovingMethodWorkingPressureMaximumEnd LoadInchesmmInchesmm11/2 1.90040 48.32502.37560.376.1mm 3.0076.1Inchesmm0.197St = StandardRoll SetRX = SS RollSetC = Cut GroovePSIkPaLbsNC750 21265.0 5171 94590.142St/C750 21263.6 5171 94590.126St600 17013.2 4137 75670.102RX475 13472.6 3275 59910.079RX425 12052.0 2930 53600.063RX400 11341.6 2758 50450.220C750 33235.6 5171 147800.157St/C750 33234.0 5171 147800.142St675 29903.6 4654 133020.126St600 26583.2 4137 118240.114St525 23262.9 3620 103460.102RX475 21042.6 3275 93600.091RX425 18832.3 2930 83750.079RX375 16522.0 2586 73470.063RX325 14401.6 2241 64050.280C750 53017.1 5171 235820.252C750 53016.4 5171 235820.197St/C650 45955.0 4482 204380.157St575 40644.0 3964 180790.142St550 38883.6 3792 172930.122St500 35373.1 3450 157330.114RX475 33582.9 3275 149350.102RX425 30042.6 2930 133630.091RX350 24742.3 2413 110050.083RX325 22972.1 2241 102200.079RX325 22972.0 2241 10220Inchesmm3804100Inchesmm3.50088.94.500114.3139.7mm 5.500139.7Inchesmm0.315St = StandardRoll SetRX = SS RollSetC = Cut GroovePSIkPaLbsNC750 72168.0 5171 320980.220St/C750 72165.6 5171 320980.157St600 57734.0 4137 256780.142St550 52923.6 3792 235380.126St500 48113.2 3450 213980.114RX475 45702.9 3275 203280.102RX425 40892.6 2930 181890.091RX350 33672.3 2413 149790.079RX325 31272.0 2241 139100.346C750 119288.8 5171 530590.248C750 119286.3 5171 530590.177St575 "91454.5 3964 406790.142St450 71573.6 3103 318360.114RX375 59642.9 2586 265300.102RX325 51612.6 2238 229580.079RX232 36912.0 1600 164170.394C750 1781910.0 5171 792610.280C750 178197.1 5171 792610.260St750 178196.6 5171 792610.260C750 178196.6 5171 792610.248St/C700 166316.3 4826 739770.220St/C600 142555.6 4137 634090.197St525 124745.0 3620 554870.157St375 89094.0 2586 396310.134RX300 71163.4 2068 316520.126RX300 71273.2 2068 317040.118RX275 65343.0 1896 290620.110RX275 65342.8 1896" 290620.102RX20 59402.6 1724 264200.079RX232 55132.0 1600 24525www.victaulic.com<strong>Victaulic</strong> is a registered trademark of <strong>Victaulic</strong> Company. © 2013 <strong>Victaulic</strong> Company. All rights reserved.<strong>17.33</strong>_4REV_H

DUPLEX – grooved Couplings<strong>Duplex</strong> Stainless SteelRigid CouplingStyle 489DX<strong>17.33</strong>PERFORMANCE ON ISO WALL THICKNESSESPipe DiameterStyle 489DXPipe DiameterStyle 489DXActualNominal OutsidePipe Size DiameterPipeWallThicknessGroovingMethodWorkingPressureMaximumEnd LoadActualNominal OutsidePipe Size DiameterPipeWallThicknessGroovingMethodWorkingPressureMaximumEnd LoadInchesmm61508200Inchesmm6.625168.38.625219.1Inchesmm0.433St = StandardRoll SetRX = SS RollSetC = Cut GroovePSIkPaLbsNC750 2585411.0 5171 1150030.280St750 258547.1 5171 1150030.280C750 258547.1 5171 1150030.197St500 172365.0 3447 766680.177St450 155124.5 3103 690020.157St375 129274.0 2586 575010.126RX275 94803.2 1896 421680.118RX275 94803.0 1896 421680.102RX232 79992.6 1600 355830.079RX232 79972.0 1600 355740.492C600 3504912.5 4136 1559030.315St/C600 350498.0 4136 1559030.256St/C475 277526.5 3275 1234490.248St/C475 277526.3 3275 1234490.197St375 219105.0 2586 974590.157St300 175284.0 2068 779680.142RX275 160673.6 1896 714700.126RX232 135553.2 1600 602950.118RX225 131463.0 1551 584760.102RX175 102252.6 1207 454810.079RX150 87642.0 1034 38984Inchesmm1025012300Inchesmm10.750273.012.750323.9Inchesmm0.559St = StandardRoll SetRX = SS RollSetC = Cut GroovePSIkPaLbsNC600 5444614.2 4136 2421880.492C600 5444612.5 4136 2421880.394C600 5444610.0 4136 2421880.248St/C425 385746.3 2930 1715850.157RX300 272294.0 2068 1211190.142RX250 226913.6 1724 1009330.126RX232 210623.2 1600 936900.1022.60.0792.0RXRXN/R0.492C600 7659012.5 4136 3406870.394C600 7659010.0 4136 3406870.280St/C450 574547.1 3103 2555680.197RX325 414955.0 2241 1845770.177RX300 383034.5 2068 1703790.157RX200 255364.0 1379 1135900.1263.20.1022.6RXRXN/Rwww.victaulic.com<strong>Victaulic</strong> is a registered trademark of <strong>Victaulic</strong> Company. © 2013 <strong>Victaulic</strong> Company. All rights reserved.REV_H<strong>17.33</strong>_5

DUPLEX – grooved Couplings<strong>17.33</strong><strong>Duplex</strong> Stainless SteelRigid CouplingStyle 489DXgeneral notesWorking Pressure and End Load are total, from all internal and external loads, based on <strong>stainless</strong><strong>steel</strong> pipe, roll grooved with <strong>Victaulic</strong> rolls in accordance with <strong>Victaulic</strong> specifications. “RX” rollsmust be used for Schedules 5S, 10S and 10. Standard rolls should be used for Schedule 40S andStandard Weight pipe. Contact <strong>Victaulic</strong> for performance on other pipe or cut grooved pipe. Seesubmittal publication 24.01 for more information pertaining to tools.WARNING: FOR ONE TIME FIELD TEST ONLY, the Maximum Joint Working Pressure may beincreased to 1 1/2 times the figures shown.Metric thread size bolts are available for all <strong>coupling</strong> sizes upon request. Contact <strong>Victaulic</strong> for details.WARNING: Depressurize and drain the piping system before attempting to install, remove, or adjustany <strong>Victaulic</strong> piping products.This product shall be manufactured by <strong>Victaulic</strong> or to <strong>Victaulic</strong> specifications. All products to beinstalled in accordance with current <strong>Victaulic</strong> installation/assembly instructions. <strong>Victaulic</strong> reserves theright to change product specifications, designs and standard equipment without notice and withoutincurring obligations.warrantyRefer to the Warranty section of the current Price List or contact <strong>Victaulic</strong> for details.For complete contact information, visit www.victaulic.com<strong>17.33</strong> 6440 rev H Updated 04/2013<strong>Victaulic</strong> is a registered trademark of <strong>Victaulic</strong> Company. © 2013 <strong>Victaulic</strong> Company. All rights reserved.<strong>17.33</strong>