Eugene Water & Electric Board The Basics of Water Service Delivery ...

Eugene Water & Electric Board The Basics of Water Service Delivery ...

Eugene Water & Electric Board The Basics of Water Service Delivery ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Eugene</strong> <strong>Water</strong> & <strong>Electric</strong> <strong>Board</strong><strong>The</strong> <strong>Basics</strong> <strong>of</strong> <strong>Water</strong> <strong>Service</strong> <strong>Delivery</strong> and Challenges in the Spring Blvd Area1

All water systems start with a safe or treated source <strong>of</strong> supply that can be a river, areservoir, a well or even another water system. <strong>The</strong> water is then pumped into adistribution system <strong>of</strong> pipes with customer connections. Storage is also provided asa method <strong>of</strong> conserving energy by allowing the pumps to run at there most efficientrate. Storage also provides an emergency source <strong>of</strong> supply for when the regularsource is unavailable. 100’ <strong>of</strong> water is approximately 40 pound per square inch <strong>of</strong>pressure.3

SANTA CLARARESERVOIRHAWKINS HILLRESERVOIRCOLLEGE HILLRESERVOIROverall EWEB System MapSource: Mckenzie RiverPumping: Hayden Bridge Treatment PlantStorage: 3 major base level reservoirsCollege Hill 15.0 MGHawkins Hill 20.0 MGSanta Clara 20.0 MGAverage winter day water usage is 20 million gallons per dayPeak Day demand was 69 million gallons on 7/27/984

Base level system schematic:Serves 85% <strong>of</strong> EWEB customers located on the valley floor up to elevation 500’Note that customers are below elevation 500’ but the gravity storage reservoirs are100’ higher at 600’.(OAR requires 20 psi minimum pressure at any service connection to the system.Note that SC must pump into systemHawkins is deeper than College HillSystem pressure relates to water level in the reservoirs and pumping rates.)5

Spring Blvd service area (Point out major streets, Agate, N. Shasta Loop, E 43 rd ,Vine Maple)<strong>The</strong> Woodson 975 zone (pink area) gets all <strong>of</strong> its water from the Shasta 1150pressure zone (blue area) and is dependent on the same infrastructure for waterservice.<strong>The</strong>re are just under 200 customers in this area.6

<strong>The</strong> original source <strong>of</strong> water is the Base Level system I showed earlier.Shasta 800 PS - 3245 Potter St – Built in 1999Shasta 800 Reservoir – 1.25 MG built in 1963Shasta 975 PS – 3425 Agate St – built in 2001Shasta 975 Reservoir – 1.75 MG built in 1967Shasta 1150 PS – 3689 N. Shasta Loop<strong>The</strong> Shasta 975 reservoir and Shasta 1150 Pump Station are located behind 3693 &3695 N. Shasta LoopNote that customers in the 800’ and 975’ pressure zones have two sources <strong>of</strong> water,while spring Blvd has only a single source, the Shasta 1150 PS.<strong>The</strong> Shasta/Woodson zones used and average <strong>of</strong> a little over 44,000 gallons <strong>of</strong> watera day in January, February and March <strong>of</strong> 2008, the maximum day demand recordedwas 327,000 gallons on 8/12/98.Shasta 800 zone has 179,000 GPD winter demand, 890,000 GPD peakShasta 975 has 99,000 GPD winter demand, 408,000 GPD peakFew other areas in <strong>Eugene</strong> at upper elevations are served solely by a pump station,but those that are have much fewer customers.7

<strong>Service</strong> Standards for <strong>Water</strong> SystemsHealth and Safety• State law requires 20 psi, EWEB uses 30 psiEmergency Supply• One day <strong>of</strong> average usage w/o electric powerFire Protection• 1,000 gpm for 2 hours (120,000 gallons) w/o powerReliability/Redundancy• No more than 30 customers out <strong>of</strong> service at one timeStandards Can be Legal/Regulatory, Industry or even EWEB.Minimum pressure is 20 psi (pounds per square inch) by law keeps ground waterand backflow out <strong>of</strong> system, but EWEB standard is 30 psi minimum with a desiredminimum pressure <strong>of</strong> 40 psi for service quality. A typical house in <strong>Eugene</strong> hasbetween 40 and 80 psi. If the system falls below 20 psi EWEB is required to takeaction from flushing pipes up to a boil water notice.Industry and EWEB standards are to have 74% <strong>of</strong> Maximum (or peak) DayDemand/usage or about one day <strong>of</strong> back up supply as storage or a back-up powersource that can run for 24-hours.Fire Protection should be available independent <strong>of</strong> the electric grid at the requiredfire flow for a specified number <strong>of</strong> hours. In the Spring Blvd area the minimumrequired fire flow for single family residences is 1000 gpm and the required time is2 hours, it can be higher for larger homes. This equates to 120,000 gallons <strong>of</strong>gravity storage or 120,000 gallons <strong>of</strong> pumping that is powered by an emergencygenerator.State law requires most water mains to be looped so that they have a minimum <strong>of</strong>two sources <strong>of</strong> water. This means that the number <strong>of</strong> customers that will be out <strong>of</strong>service during an outage or maintenance shutdown will be minimized. <strong>The</strong> EWEBstandard is to try to have less than 15 customers out <strong>of</strong> service but no more than 30out <strong>of</strong> service during maintenance shutdowns.(Reference 2004 Master Plan, ISO/NFPA, OAR/EWEB)8

Actual Time <strong>of</strong> Use ChangeSpring Blvd Area150012009006003006amNoon6pmMidnight2002 Max Flow gpm2007 Max Flow gpm0• Customer education and resulting customer actionshelped avoid up to $500,000 in unplanned expensesand allowed for planned solution to be undertaken.So what has EWEB been doing to try and maintain the service standards for theSpring Blvd area? This slide shows gallons per minute typically seen in 2002compared to 2007. In 2002 we were beginning to see peak use exceeding 1350gallons per minute, so action was necessary. An education effort began in 2004 withan immediate change in water use as indicated by the blue line. Due to the excellentresponse by these neighbors this water use change has been sustained over the lastfour years. This has helped EWEB maintain the Minimum pressure and Fire flowstandards for the area. However, this does not address service and health/safetyimpacts when power outages occur.9

Gravity Storage Facilities for <strong>Water</strong>•At-grade reservoirs• Must be constructed on land at the correct elevation.(1140 feet in this case)•Elevated tanks•Height is limited to 200 feet by seismic considerations<strong>The</strong> typical solution to this issue is to add gravity storage to the Spring Blvd watersystem.At-grade reservoirs like the Shasta 800 and 975 reservoirs require the land to be atthe desired elevation. Around 1140’ in this case to get an 1150’ storage elevation.Elevated tanks can be built at lower elevations and use the elevation to get thecorrect elevation, but there are engineering limits to how high a tank can be elevateddue to seismic resistance and other structural design concerns.10

At-grade reservoir currently under construction on Moon Mountain with 1.0 millioncapacity11

Finished at-grade reservoir <strong>of</strong>f City View Street on W.27 th with 1.0 Million GallonCapacity.(Show parcel EWEB purchased in the 1972 at the correct elevation and the twoareas in the park that are at the correct elevation. Talk about the pipelineconnections necessary to the sites.)12

Existing elevated tank in the Summit PUD (above Bailey Hill Road) as seen fromGimpl Hill Road with a capacity <strong>of</strong> 0.75 million gallons. This is not a tall tank withthe overflow only 80 feet above existing ground for a total height <strong>of</strong> around 90 feet.13

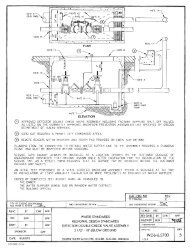

Pump Stations w/o Storage•Continuous running pumps• Maintains minimum pressure• Provides for domestic useage•Fire pumps on stand-by•Provide minimum fire flow with one pump out <strong>of</strong> service•Automated Back-up <strong>Electric</strong>al Power•Capacity to run fire pumps•Fuel to run for 24-hoursOne possible alternative solution would be to build two redundant pump stationsinstead <strong>of</strong> storage.Continuous running = electricity used or carbon footprintAutomated power can be diesel or propane but fuel must be stored on-site.14

Our Dillard 975 pump station on Old Dillard Road is typical <strong>of</strong> a PS that providescontinuous running “dead-end’ service. Back up power would be in a separateenclosure, this station does not have on-site back-up. EWEB has several generatorson trailers for back-up power, but it can be over an hour to get them on-site and inthe mean time pressures could drop below the 20 psi minimum.15

This is the existing Shasta 1150 PS which has hook ups for mobile generator but noon-site back-up power.EWEB has 8 other single source continuous running pump stations like Shasta 1150but only one on those serves more than 30 customers and it is scheduled to beconnected to a reservoir next year by a pipeline project.Fairmount 975 – 78 customersDillard 975 – 30 customersCollege Crest 1325 – 22 customersSummit Terrace 1250 – 18 customersStartouch 1325 – 18 customersFox Hollow 1150 – 17 customersGillespie Butte 800 – 15 customersSouth Louis Lane 800 – 10 customers16

Public Involvement Process Timeline/MilestonesTASKPublic Involvement Process Design to EWEB <strong>Board</strong>Education and Outreach EventsAssemble Task GroupTask Group Kick-Off MeetingTask Group DeliberationStatus Check with EWEB <strong>Board</strong>Develop Preliminary RecommendationDraft Summary ReportPresentation to EWEB <strong>Board</strong>TARGET COMPLETIONMay 20June/JulyJuly/AugustSeptemberSeptember/OctoberOctober 21NovemberDecemberDecember/JanuaryBefore I talk about next steps, any clarifying questions about Jay’s presentation?We recognize that this is a unique neighborhood with special qualities andcharacterstics we want to paying close attention to. We also know that all thepotential options we’ve just discussed will have impacts to this area. We are notcoming to you with a preconceived notion <strong>of</strong> what the solution is; instead areseeking to work collaboratively with neighbors and other stakeholders like trailusers to analyze the options and select an solution that seems to work best for all.Here’s the process that we’ve designed that we believe will foster a problem-solvingpartnership between EWEB, the neighbors, and our policy-makers, the <strong>Board</strong>. Anypublic engagement process is organic, so this is a framework to help guide us to adecision, knowing that the adjustments will be made along the way to accommodateyour needs. Quick clarification – envisioned as a two-part process. This timeline isjust around selecting a preferred alternative; more detailed design considerations sothat any proposed facility blends into the neighborhood will be Phase II. Run thrutimeline:Some underlying values for EWEB in its provision <strong>of</strong> services include reliability,responsive service, stable/reasonable rates. It also includes recognizing/addressingthe tensions between environmental, economic and social factors in the decisionswe make.Applying these to this project, what other community values or neighborhoodcharacteristics you want to make sure we pay attention to and share with the task17

www.eweb.org/news/projects/springblvdQuestions?18

Shasta 975 Reservoir19

Shasta 975 Pump Station20

Shasta 800 Reservoir21

Shasta 800 Pump Station22