Download a PDF version of this Issue (10MB) - Alberta Pork

Download a PDF version of this Issue (10MB) - Alberta Pork

Download a PDF version of this Issue (10MB) - Alberta Pork

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE TRUE ALTERNATIVESwine Swine Management Services Services (SMS) (SMS) <strong>of</strong> Fremont, <strong>of</strong> Fremont, Nebraska Nebraska is the is world’s the world’s largest largest swine swine benchmarking service. service. Genesus Genesus has hasparticipated in SMS in SMS Benchmarking since since 2006 2006 as the as Service the Service has has grown grown from from 380 380 farms farms with with 722,417 722,417 females females to its to present its present2009 2009 level level <strong>of</strong> 683 <strong>of</strong> 683 farms farms with with 1,215,511 1,215,511 females. females. Genesus Genesus has has grown grown along along with with SMS SMS but one but one thing thing remains remains consistent,our our domination <strong>of</strong> the <strong>of</strong> results the results with, with, 8 <strong>of</strong> 8 top <strong>of</strong> 10 top farms 10 farms for all for four all four years years and and 9 to 915 to <strong>of</strong> 15 the <strong>of</strong> top the 20 top over 20 over the same the same period. period.SMS SMS Genesus Performance Data Data(January (January 1st 2006 1st 2006 – – December 31st 31st 2009) 2009)Year Year 2006 2006 2007 2007 2008 2008 2009 2009No. No. <strong>of</strong> SMS <strong>of</strong> SMS Farms Farms 380 380 467 467 585 585 683 683No. No. <strong>of</strong> SMS <strong>of</strong> SMS Females Females 683,570 683,570839,998 839,998 1,106,344 1,215,511Genesus Genesus Top Top 10% 10% 29.45 29.45 29.97 29.97 29.71 29.71 30.06 30.06SMS SMS Average Average All All 22.58 22.58 22.94 22.94 23.30 23.30 23.80 23.80Genesus Genesus Average Average All All 26.41 26.41 26.55 26.55 26.78 26.78 26.82 26.82SMS SMS Bottom Bottom 25% 25% 18.98 18.98 18.82 18.82 19.72 19.72 20.16 20.16Genesus Genesus Bottom Bottom 25% 25% 24.89 24.89 25.17 25.17 25.19 25.19 25.26 25.26Genesus Genesus Herds Herds in SMS in SMS Top Top 10 10 8 8 8 8 8 8 8 8Genesus Genesus Herds Herds in SMS in SMS Top Top 20 20 9 9 14 14 15 15 13 13All major All major genetic genetic companies are are represented in the in SMS the SMS database. database. The The facts facts are are indisputable; Genesus Genesusis the is number the number one one female, female, with with consistent, significant, dominant dominant performance four four years years running. running.Isn’t Isn’t it time it time you you moved moved up to up the to Genesus the Genesus Advantage?GeNeSuS IS SeCoND IS SeCoND To NoNe To NoNe - - ANyTHING LeSS LeSS IS A IS A CoMPRoMISe.www.genesus.comRead Read Jim Jim Long’s Long’s Commentary at at www.genesus.com

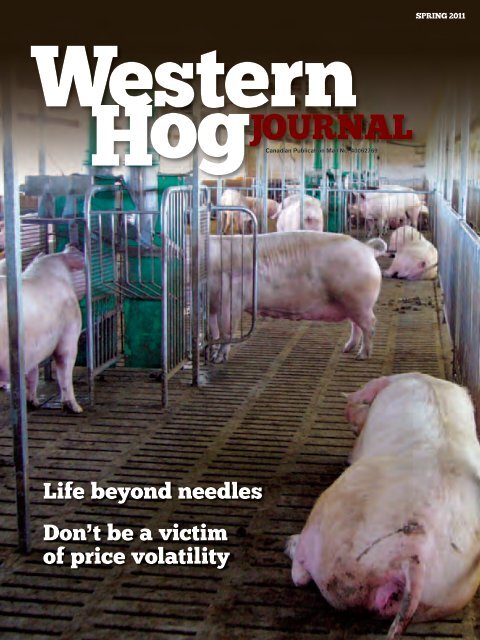

Volume 32 | Number 5Spring 2011Date <strong>of</strong> <strong>Issue</strong>: May 2011SpecialFeaturesPage 48Published quarterly by <strong>Alberta</strong> <strong>Pork</strong> withcooperation from the British ColumbiaHog Marketing Commission, Sask <strong>Pork</strong>and Manitoba <strong>Pork</strong> CouncilSubscriptionsFor new subscriptions, change <strong>of</strong>address or other subscription queries,please contact <strong>Alberta</strong> <strong>Pork</strong>Phone: 780-474-8288Fax: 780-479-5128Email: info@albertapork.comPublications Mail AgreementNo. 40062769Return UndeliverableCanadian Addresses to:Circulation Department4828 - 89 StreetEdmonton, <strong>Alberta</strong> T6E 5K1PublisherDarcy FitzgeraldBusiness Manager& Editorial DirectorBernie PeetPhone: 403-782-3776Fax: 403-782-4161Email: bjpeet@telusplanet.netAdvertisingJames Shaw1 Burnhamthorpe Park Blvd.Islington, OntarioCanada M9A 1H8Phone: 416-231-1812Fax: 416-233-4858Email: jamesshaw@rogers.comCover PhotoAn Australian group sow housing systemwith the German FitMix feeding system(photo courtesy John Riley).Editor’s Notes...................................................................................................................4News and Views.............................................................................................................6Industry Viewpoint................................................................................................... 15Manitoba Swine SeminarNutrition and management during lactation:effects on future parity productivity....................................................................21Life beyond needles................................................................................................... 26Glycerine in swine diets........................................................................................... 30Practical nursery management: Doing the basics right................................ 32Special FeaturesHealthBehaviour <strong>of</strong> pigs in large group auto-sort systems...................................... 36Don’t be a victim <strong>of</strong> price volatility..................................................................... 40Feeding increasing levels <strong>of</strong> yellow- vs. dark-seededcanola meal to hogs................................................................................................. 44Is potato starch an alternative toantibiotics in weaned pig diets?........................................................................... 48<strong>Alberta</strong> Hog Price Insurance Program close to launch.................................. 53Dietary co-products may enhance porkomega-3 fatty acid and reduce feed costs withoutaffecting carcass quality and growth................................................................. 56Swine health bulletins address potential health threats.............................. 59PRRS free herd certification pilot program for western Canada................................... 60International Round-up........................................................................................61View from EuropeCarrying out a stress audit..................................................................................... 65British producers have their backs to the wall again................................................... 68Pigs Down UnderPig producers battle Nature....................................................................................71Ad Index............................................................................................................................ 74Western Hog Journal | Spring 2011 | 3

News and Viewsis variable, which meansthat in practice producerscarry out two or even threeinseminations over a two-dayperiod in order to ensure thatfresh semen is present in thefallopian tubes at the time <strong>of</strong>ovulation. The new device –the Draminski Oestrus Detectorfrom Poland – can measure theER and provide a guide to theoptimum insemination time.ER is highest during the lutealphase <strong>of</strong> the oestrus cycle,which is when the sow is notin oestrus, and lowest duringthe follicular phase whenovulation occurs.The researchers used realtime ultrasound to determinewhen sows ovulated so <strong>this</strong>could be compared withmeasurements taken by the ERdevice. On days 4 and 5 threemeasurements were taken and2 on day 6, otherwise it wasonce per day. Oestrus startedfrom the time <strong>of</strong> the secondreading on day 4 and laststanding oestrus was observedat the second reading on day6. Oestrus was observed afterthe lowest ER readings wererecorded. Ovulation occurredbetween late on day 5 and lateon day 6 after weaning, whileER values were still increasing.The researchers concludedthat there was a definite trendobserved in the ER readingsfrom days 1 to 7, indicatingthat they may be useful as apredictor <strong>of</strong> when ovulationoccurs.Research tackleschallenges <strong>of</strong>group housingMaintaining sow bodycondition and controllingaggression are the twomain challenges faced whenconsidering group housingfor sows, Prairie Swine Centreresearcher Dr. Harold Gonyoutold producers at a recentseries <strong>of</strong> meetings in Manitobaand <strong>Alberta</strong>. The solutionis to control individual feedintake and develop suitablemanagement systems for<strong>this</strong> housing method. “Wedon’t want to let the sow wina competition for access t<strong>of</strong>eed because that results inaggression,” he says. “Withelectronic feeding systems(ESF), dominant sows get intothe feeder earlier in the day,Free access stalls <strong>of</strong>fer a group housing system which ensures individualsow feed intakebut don’t get any more feed.”However, he notes that if thereare too many sows per feeder,then there will be competitionfor access that will lead toaggression.“There is notmuch difference inperformance betweenstatic and dynamicgroups”Gonyou and his co-workershave studied an electronicsow feeding and a free accessstall system over a number <strong>of</strong>years. Mixing sows either atweaning or later in gestationcan impact both farrowing rateand litter size, he notes. In thelarge dynamic groups typicallyused in ESF systems, mixing ismore <strong>of</strong> a challenge. “Mixinga new group <strong>of</strong> sows into anestablished group every 4 weeksinstead <strong>of</strong> weekly is preferableto mixing new sows in everyweek,” Gonyou explains. “Bythe time the new sows aremixed, the previous group ispast the implantation stage.”There is not much difference inperformance between static anddynamic groups, but there is adifference between mixing preorpost- implantation, he adds.CONTINUED ON PAGE 10PARKSWith over 30 years <strong>of</strong> experience in the livestock industry,we continue to provide today’s producers withThe Best Full Service Marketingin North AmericaA Member <strong>of</strong> The Parks CompaniesFeeder PigsS.E.W.sCall today to talk to our team ~ Toll Free: 1-800-821-7418 ~ Email: jasonmills@parkslivestock.com8 | Western Hog Journal | Spring 2011

Superior GeneticsDelivering more.Backed by world-class service and technical support, Fast Geneticsdelivers a superior portfolio <strong>of</strong> terminal and maternal products. Weunderstand your bottom-line focus and go beyond the norm in today’smarket. Aided by biosecurity advantages, we deliver industry-leadinghealth. Our prolific parent females produce large litters that make it tomarket, and our terminal sires deliver rapid growth and excellent carcasscomposition. At Fast Genetics we pride ourselves on delivering qualityservice from people you can count on.Fast Genetics Corporate Office#2–2175 Airport DriveSaskatoon, SK Canada S7L 7E1 Fast Genetics is a trademark <strong>of</strong> Fast Genetics Inc. 10009 06.10T 306.667.1420T 306.667.1421E contactus@fastgenetics.comwww.fastgenetics.com

News and ViewsNew Pfizer swineterritory managerfor ManitobaDennis Stevenson has joinedPfizer Animal Health’s swinebusiness unit as TerritoryManager for Manitoba andis responsible for the salesand support <strong>of</strong> the company’sextensive line <strong>of</strong> swineproducts. He joins a team<strong>of</strong> six dedicated Pfizerterritory managers acrossCanada, focused entirely onthe swine industry.Dennis brings extensiveexperience and knowledge <strong>of</strong>swine production managementto his new position with Pfizer,and will work with producers,swine production systems, feedcompanies and veterinariansin Manitoba. He graduatedfrom the University <strong>of</strong>Saskatchewan with a diplomain agriculture, and also holds ajourneymen in pork productionfrom the Apprenticeship andTrade certification program inRegina, SK.“Dennis understands theCanadian swine industry,especially in Manitoba wherehe has worked with some<strong>of</strong> the largest systems in theprovince,” says Tom Elskamp,National Sales Managerfor Pfizer’s Canadian swinebusiness unit. “Dennis is aterrific asset to the Pfizer teamand we know he’ll be a greatdynamic resource for Manitobahog producers too.”Manitobaproducers unveilwide-rangingplans for greeneroperationsBy Myron LoveThe plaudits are coming infrom all corners <strong>of</strong> NorthAmerica for the Manitoba<strong>Pork</strong> Council’s new 82-pointsustainable developmentprogram which the MPCunveiled on Wednesday,March 16.“We have had a very positiveresponse from most people,”says Andrew Dickson, theMPC’s executive director,“although we know there is nopleasing the anti-hog people.The government has been verysupportive.” MPC chairmanKarl Kynoch adds that thedocument is an open bookthat lets the public know thegood things that hog producersare doing. “We are beingproactive rather than justwaiting to react to situationsthat occur.Called Embracing a SustainableFuture, the 54-page documentspells out 82 commitmentsthe council has endorsed onbehalf <strong>of</strong> local producers. Thedocument, Kynoch points out,is divided into a number <strong>of</strong>different sections includingFeed costs too high?This is just one <strong>of</strong> the challenges that Danisco can help you solve.Phyzyme XP is a highly efficient phytase feed enzyme that improves the digestibility <strong>of</strong>phosphorus, calcium, energy and amino acids contained in many feed ingredients.Reduce your feed costs by minimizing the need to add expensive inorganic phosphorussources and reformulate the feed to take account <strong>of</strong> the improvements in energy andamino acid digestibility.- more pr<strong>of</strong>it from lower feed costsTo find out more please contactHalchemix Canada IncTel: 1-800-540-4756halchemix@halchemixcanada.comwww.halchemixcanada.comJohn Van OortTel: 403-701-2445john.vanoort@danisco.comwww.danisco.com/animalnutrition10 | Western Hog Journal | Spring 2011

With youall the way.> Save time> Save money> Save labourProvenprotectionyou canbank onWith Ingelvac CircoFLEX vaccinate early forproven protection, healthier growth cycle andan ROI you can take straight to the bank.Safe. Efficient. Convenient.Ask your veterinarian about the Ingelvac CircoFLEX ® vaccination fromBoehringer Ingelheim or visit us online at www.boehringer-ingelheim.ca.Ingelvac CircoFLEX ®©2008 Boehringer Ingelheim Vetmedica, Inc. Ingelvac CircoFLEX is a registered trademark <strong>of</strong> Boehringer Ingelheim Vetmedica, GmbH, Ingelheim, Germany.

News and ViewsEmployers who fail to meetthe new requirements will berefused work permit applicationsfor any foreign national <strong>of</strong>feredemployment by that employerand will be ineligible to hireTFWs for two years.Using Net Energysystem can save$2-3 per pigWith energy representing by farthe most expensive component<strong>of</strong> pig diets and the price <strong>of</strong>cereal grains skyrocketing, itis increasingly important tomatch the energy content <strong>of</strong> thediet with the pigs’ requirements.Using the Net Energy (NE)system to quantify the energyvalue <strong>of</strong> feed ingredients cansave $2-3 per hog, accordingto Dr. Denis Beaulieu fromthe Prairie Swine Centre.“The NE system provides amore accurate way <strong>of</strong> pricingand evaluating ingredientsaccording to the energycontent,” she said, speakingat a series <strong>of</strong> recent producermeetings in Manitoba and<strong>Alberta</strong>. However, she noted,there are several differentapproaches to measurement,which is why people have beenslow to adopt it.“The difference can beas high as 10 cents perkilo <strong>of</strong> gain or $5 perfinishing pig”Using the NE system allowsdiets to be formulated withlower crude protein levels.This is because the DE systemovervalues the energy content<strong>of</strong> protein sources such assoybeans and canola meal.“Crystalline amino acids reallyshine when the NE systemis used and their use allowsthe crude protein content tobe reduced considerably,”Beaulieu explains.With the increasing use <strong>of</strong>by-product ingredients such asDDGS, the NE system is evenmore advantageous, Beaulieupoints out. “The NE in DDGSfor finisher pigs is significantlyhigher than for growersbecause bigger pigs can digestit better,” she explains. “Thecost per Mega calorie <strong>of</strong> energyis much lower using NE andthe difference can be as highas 10 cents per kilo <strong>of</strong> gain or$5 per finishing pig.”In addition to reducing costs,the NE system allows veryaccurate prediction <strong>of</strong> feedintake and gain, although notFCE, Beaulieu notes. “We canpredict the composition <strong>of</strong>weight gain in the pig, thatis, how much protein and fatdeposition will occur.”CorrectionIn the Banff Seminar issue <strong>of</strong>WHJ, Kevin Grier from theGeorge Morris Centre wasmisquoted in the report <strong>of</strong> thebreakout session “BuildingCanada’s future in exports”.The article said that “the EUprotects its pork industry plusits consumer.”“I actually said the EU protectsits pork industry, ‘if not itsconsumers,” says Kevin Grier.“The EU pork industry isprotected by extraordinarilyhigh protective tariffs andexceptionally small accessquotas as well as a creativearray <strong>of</strong> non-tariff barriers.Rest assured that consumersare nowhere near the top <strong>of</strong>the priority pile in Euroland,”he comments. nHOG PRICE INSURANCE PROGRAMThe Hog Price Insurance Program (HPIP) is marketdriven price insurance for hog producers in <strong>Alberta</strong>.Offered continuously throughout the year, HPIP willbe an easy to use risk management tool that willprovide protection against a decline in <strong>Alberta</strong> hogprices over a defined period <strong>of</strong> time.HPIP - COMING SPRING 2011For more information, call AFSC at 1-877-899-AFSC (2372),visit www.AFSC.ca or stop in at any AFSC District Office.14 | Western Hog Journal | Spring 2011

Industry ViewpointBy Bernie PeetOver the last few years, the Industry Crisis column has looked at what has been going on in theCanadian industry as our producers have battled a series <strong>of</strong> unprecedented challenges which has seenthe industry reduce in size by nearly a quarter. WHJ Editor Bernie Peet continues to review industryevents and trends that will shape the industry in future, both in North America and around the world.He will comment on industry developments and how they impact Canadian producers, providing hisunique perspective and personal viewpoint on the important issues.Has the bleeding stopped?After five continuous years <strong>of</strong> decline, hog numbers in the January 1 census report appear to have stabilized and in someprovinces increased slightly. Total Canadian hog inventory increased by 0.6% compared to the previous year, totalling 11.9million. However, over the five years to January 1 hog numbers have fallen by a massive 21%. There were 1.3 million sows andgilts reported in January, down 1.1% fromone year earlier and down 17.5% fromfive years ago. “Sow inventories havenot been at <strong>this</strong> level since 1999, whichwas the start <strong>of</strong> a five-year industry wideexpansion,” notes the Statistics Canadareport. Domestic hog slaughter for 2010was 21.3 million, down 2.4% from 2009.In the east, the decline in sow numbersin Ontario seems to have been arrested,with a 0.9% increase year-on-year. Overthe last 5 years the number <strong>of</strong> sows andgilts has fallen by 18.8%, from 424,000to 344,500, while total hog numbershave reduced by 26.7%. NeighbouringQuebec has seen a much less dramaticfall, with roughly a 10% fall in both sowand total hog numbers since the January2006 census.In the west, Manitoba has fared the bestin terms <strong>of</strong> both sow and gilt and totalhog numbers, showing a 3.6% increasein pig numbers over the past year. Whilesow numbers have fallen by 13.4% overthe last 5 years, total hog numbers havefallen only 10.9% reflecting the higherproportion <strong>of</strong> pigs finished in the province.Saskatchewan showed a slight increase inhog numbers year-on-year, but has seensow numbers drop by 31.8% over the fiveyearperiod and total hog numbers 42.5%.Sow numbers in <strong>Alberta</strong> fell 3.2% during2010 and decreased by 23.7% over theprevious five years, while total hogs fellCONTINUED ON PAGE 16Western Hog Journal | Spring 2011 | 15

Industry Viewpoint Continuedby 26.8% over the same period. British Columbia now onlyhas 9,400 sows compared to 18,100 five years ago, a decline<strong>of</strong> 48.1%, with both sow and total hog number dropping about20% in the last year alone.The number <strong>of</strong> farms with hogs continues to fall, with 6,985farms on January 1, down 5.6% in the last year and 41% overthe past five years. Once again the Statistics Canada producernumbers appear to be suspect, as they show 810 producersrecorded in <strong>Alberta</strong>, less than half the actual numbers and655 in BC which has very few pigs left.“British Columbia now only has 9,400 sowscompared to 18,100 five years ago”Live pig exports in 2010 were down by 10.1% compared to2009, at 5.7 million head and down by 42.9% from theirpeak in 2007. However, there are signs that the decline isstabilizing as US packers adjust to complying with COOLrequirements for hogs <strong>of</strong> Canadian origin.So has the bleeding stopped? Numerically it appears so.The question is whether a combination <strong>of</strong> high feed pricesand only moderate hog prices will put further pressure onproducers, most <strong>of</strong> whom have no AgriStability referencemargins left to provide a safety net. COOL has been disruptive and damagingCountry <strong>of</strong> Origin Labeling (COOL) has proved a ‘disruptiveand damaging trade distorting measure’, according to KevinGrier, a senior market analyst at the George Morris Centre. Ina paper titled Country <strong>of</strong> Origin Labeling: The Damage Doneand the Fight Underway, he notes that country <strong>of</strong> originlabeling in the US has become a non-tariff barrier examplethat other countries are now following. If left in place, thesemeasures will have an enormous impact on trading nations.“During the first year after the introduction <strong>of</strong> the COOLmeasure, there was a reduction in the prices for Canadiancattle and hogs relative to the US,” Grier points out. “Forexample, during 2009 the George Morris Centre calculatedthat weaner and feeder prices were about $US3-4/headlower relative to the US in the post-COOL period, comparedto the pre-COOL period. Canadian market hogs traded intothe US were priced more than $10/head less than in the pre-COOL period.”“The bottom line for COOL is that it has served nocommercial interests and provided no benefits toconsumers or industry”The data also show that there has been a reduction in the flow<strong>of</strong> Canadian livestock into the United States in the pre- andpost-COOL measure periods, notes the report.“During the first quarter that COOL was ineffect in late 2008, slaughter hog exportsdeclined by more than 60%,” Grier explains.“During the first half <strong>of</strong> 2009, slaughter hogexports were down by nearly 60%. Thereis no doubt COOL was the cause <strong>of</strong> both thepricing discounts and the dramatic reductionsin trade volumes.”Grier says that one <strong>of</strong> the most impactedsectors <strong>of</strong> Canadian livestock was Manitobaweaner producers. “A material number<strong>of</strong> these farrowing businesses lost theircontracts due to the fact that the Iowafinishers no longer had a market forCanadian hogs,” he points out. “Livelihoodsin <strong>this</strong> sector have been lost.” During 2010, the impact <strong>of</strong> COOLameliorated, first because the US industrybecame more comfortable and pr<strong>of</strong>icientat handling meat from Canadian livestockand second because supplies <strong>of</strong> US livestockcontinued to decline during 2010. “The USindustry’s willingness and ability to discountCanadian livestock lessened, commentsCONTINUED ON PAGE 1816 | Western Hog Journal | Spring 2011

PROLIFIC.EFFICIENT.CONSISTENT.FAST GROWING.CANADIAN.©2011 PIC Canada, LTD. All Rights Reserved.®®CALL 1-800-661-1543 or visit us on the web at www.pic.comNEVER STOP IMPROVING

Protect Your Whole HerdRight From Day One.Discover the Power <strong>of</strong> Maternal ImmunityCIRCOVAC ® is the only PCV2 vaccine approved for use in sowsto provide herd protection when it is needed most – the fi rst fewweeks <strong>of</strong> life. Vaccination with CIRCOVAC is an effi cient way toensure your piglets get continuous protection from start to fi nish,plus it improves reproductive performance and piglet growth. 1Times have changed.It’s time to take a look at CIRCOVAC.Talk to your veterinarian today.www.merial.ca1Data on fi le at Merial Canada Inc.® CIRCOVAC ® is a registered trademark <strong>of</strong> Merial Limited.© 2011 Merial Canada Inc. All rights reserved.CIRCO-11-7005-JA SPRING 2011(E) MERO-2018

Industry Viewpoint Continuedlivestock industry, with producer pr<strong>of</strong>itability determiningavailability <strong>of</strong> meat, Lochner suggests. “The drivers <strong>of</strong>pr<strong>of</strong>itability and production have changed,” he says. “The oldparadigm was that pr<strong>of</strong>itability and production are driven bydomestic demand. The new paradigm is that they’re largelydriven by grain costs and exports.” Overall US meat supplieshave declined for at least three years and probably will shrinkagain <strong>this</strong> year, Lochner adds.Food security is now a hot topic in the media, with countlessarticles published over the last six months. It is also now onthe agenda <strong>of</strong> the G20 nations and has achieved prominencedue to the demonstrations in Middle Eastern countries, whichare said to be partly related to higher food prices. There seemsno doubt that pig producers, whether in Canada or around theworld, are now facing Jim Lochner’s new paradigm and willneed to adjust to the new economic environment.European industry shrinkingMost European countries have seen a drop in pig numbersover the past 12 months, with the EU sow herd falling by3% in the period to December 2010. The Danish January 1,2011 census showed that there were 4.5% fewer pigs thanon the same date in 2010, while the total number <strong>of</strong> sows(1.057 million) was 4.6% lower. The industry in neighbouringSweden, which has the highest animal welfare standardsin Europe, is in crisis due to its high production costs andproducers are quitting in droves. According to the SwedishFarmers Federation, 20% <strong>of</strong> producers will have disappearedby the end <strong>of</strong> 2011.EU producers are being hammered by high feed costs and thecost <strong>of</strong> complying with welfare and environmental legislation.The impending ban on sow stalls, which means that sowsmust be loose-housed for all but 28 days <strong>of</strong> gestation fromJanuary 1, 2013, is expected to result in an exodus from theindustry as many producers cannot afford the cost <strong>of</strong> newbuildings or con<strong>version</strong>.A number <strong>of</strong> countries have called on Brussels to delay theimplementation <strong>of</strong> the partial stalls ban, which has angeredcountries such as the UK, which is already compliant, andDenmark, which says it will meet the deadline. There seemsno doubt that some other countries such as France, Italy andGermany, will be a long way <strong>of</strong>f complying by the end <strong>of</strong>2012. This could mean that they are unable to export pork toother countries that are compliant. The result is likely to bean exodus from the industry and a significant shortfall in porkproduction by the end <strong>of</strong> 2013. n10205 Standard Nutrition:Layout 1 7/5/10 1:00 PM Page 1Your #1 source <strong>of</strong> viable microbial swine feed supplement!Send your hogs to market sooner with MaxiPlex.The results are in the bag!Standard NutritionStandard nutritionCOME SEE US AT ANY ONE OF OUR 4 LOCATIONS!COME SEE US AT ANY ONE OF OUR 4 LOCATIONS!Winnipeg, MB Brandon, MB Lethbridge, AB Red Deer, AB1-800-273-8763Winnipeg, MB1-888-728-7807Brandon, MB1-877-329-1414Lethbridge, AB1-403-352-0006Red Deer, AB1-800-273-8763 1-888-728-7807 1-877-329-1414 1-403-352-0006MaxiPlex is a registered CFIA productMaxiPlex is a registered distributed CFIA in product, Canada distributed and the US. in Canada and the US.www.standardnutrition.comww.standardnutrition.com20 | Western Hog Journal | Spring 2011

Manitoba Swine SeminarNutrition and management during lactation:effects on future parity productivitySows have limited feed intake capacity in lactation, such that protein and fat reserves may be severely depletedduring the suckling period, notes Dr. Bas Kemp from the Department <strong>of</strong> Animal Sciences at Wageningen Universityin the Netherlands. He points out that weight and protein losses exceeding 12% during lactation have been shownto result in reproductive problems such as extended weaning to oestrus intervals, lower conception rates and reducedsubsequent litter sizes. First litter sows are especially at risk since they still have significant nutrient needs forgrowth to maturity, a lower feed intake capacity and lower metabolizable fat and protein reserves, Kemp explains.He discusses the impact <strong>of</strong> inadequate lactation feed intake and examines feeding and management strategies bothduring lactation and after weaning that can help to maximize subsequent performance in the sow and gilt.Effects <strong>of</strong> limited feed intake on reproductionThe impact <strong>of</strong> feed restriction has changed considerably over the last 20 years due to genetic selection for a shorter weaning tooestrus interval. “In the seventies and early eighties, feed restriction during lactation resulted in a big increase in weaning tooestrus interval, up to about 10 days, but had hardly any effects on ovulation rate and embryo survival,” Kemp explains. Morerecent data show that the impact on weaning to oestrus interval is less than one day, while the effects on ovulation rate andembryo survival are much more pronounced.” Feed restriction appears to decrease ovulation rate by about 2 to 4 ova and embryosurvival by about 10 to 20%, Kemp says. First litter sows are especially vulnerable, due to their restricted feed intake capacity,he notes. The so-called ‘second litter syndrome’, where litter size is reduced in parity two, typically results in lower litter sizesin subsequent parities and culling oneparity earlier compared to sows showingincreased litter size in parity two.Potential ways to optimizepost weaning reproductiveperformanceGilt developmentGilt development and age/weight atfirst mating have a large effect onlifetime productivity, Kemp believes.“Although mating gilts at a youngage or a relatively low body weightmay not have negative consequencesfor first litter size, second litter sizemay still be compromised sinceyoung sows have the desire to growand feed intake capacity is limitedduring first lactation,” he points out.“Experimental data from our researchgroup indicate that sows with a lowbody weight after first lactation - lessthan 150 kg - have a reduced secondCONTINUED ON PAGE 23For more information: www.hypor.comor call us toll free +1 800 667 5960Western Hog Journal | Spring 2011 | 21

They’ll fall in lovefor the last timeBait does not have to be sprinkledin a heart-shaped form to be effective.Starbar ® Premium Fly Bait contains the long-lasting,powerful attractant that flies always fall for.Tried and true Starbar ® Premium Fly Bait has long-lasting residualactivity for effective fly control. Muscamone ® attracts male andfemale flies. Flies remain in treated areas – thereby feeding longerand ensuring complete kill.www.vetoquinol.caAlways read the label before using <strong>this</strong> product.® Starbar and Muscamone are registered trademarks <strong>of</strong> Wellmark International.

Farm Manitoba Focus Swine Seminar Continued Continued“Management techniques like removingthe whole litter for part <strong>of</strong> the day orsplit weaning, where part <strong>of</strong> the litter isremoved a few days before weaning, canbe successful but a drawback <strong>of</strong> the use<strong>of</strong> these techniques can be the occurrence<strong>of</strong> oestrus prior to weaning,” Kempcomments. Also, he adds, with currentgenetics, litter sizes are so high thatthere is no opportunity for having lowernumbers <strong>of</strong> suckling piglets on gilts.Potential for postlactation repairAlthough lactation feed intake hasthe biggest impact on subsequentreproductive performance, there are anumber <strong>of</strong> management techniques thatcan be used after weaning to ‘repair’ thedamage caused by inadequate intake.Loss <strong>of</strong> weight during lactation result in problems such as extended weaning to oestrus intervals,lower conception rates and reduced subsequent litter sizes.Post weaning feeding“Ad lib feeding after weaning has beenshown to increase the percentage <strong>of</strong>sows in oestrus within 7 days afterweaning to 62% as compared to 52%for restricted feeding,” Kemp notes.“Feeding carbohydrate rich diets afterweaning compared to fat rich diets hasresulted in a shorter weaning to oestrusinterval.”CANADA FARM DISTRIBUTORS LTD.Exclusive Canadian DistributorAnimal Carcass IncineratorsINCINERATORS FOR THE 21ST CENTURYFEATURING... our new refractoryblock lined incinerator• Patented Burning • Heavy Duty Construction• Pollution Free Disposal • Completely AutomaticFor All Pricing & Technical Inquiries Contact:UP TO 75%ENERGYSAVINGSEnergy Sustaining TechnologiesWinnipeg, ManitobaPh: (204) 222-2712Fax: (204) 222-5573Email: estbizmail@mts.netUnit shown is a model 36in a typical setting.Other models andconfigurations available.“Ad lib feeding after weaninghas been shown to increase thepercentage <strong>of</strong> sows in oestruswithin 7 days after weaning”“Dextrose supplementation betweenweaning and oestrus does not resultin a shortening <strong>of</strong> the already shortweaning-to-oestrus interval, but leadsto numerically higher and more uniformbirth weights <strong>of</strong> piglets and increasedpreweaning survival <strong>of</strong> small piglets,”he continues. “Also, inclusion <strong>of</strong>fermentable non-starch polysaccharidessuch as sugar beet pulp, from weaninguntil mating, increases the number <strong>of</strong>total and live-born piglets.”Boar stimulationResearch has shown that intensive boarcontact after weaning improves thepercentage <strong>of</strong> sows showing heat within9 days post weaning from 30 to 51%. Inthese studies no effects were found onovulation rate or embryonic survival.24 | Western Hog Journal | Spring 2011

Manitoba Swine SeminarUse <strong>of</strong> PG600“The use <strong>of</strong> PG600 directly after weaning results in animprovement <strong>of</strong> the weaning to oestrus interval in manystudies but sometimes it results in lower pregnancyrate or lower litter sizes,” Kemp points out. “The lattermay be related to differences in follicle development atthe time <strong>of</strong> PG600 injection, but no data is available tosubstantiate <strong>this</strong>.”Use <strong>of</strong> progesterone analoguesOvulation rate and embryo survival may be improved byallowing the first parity sow to recover for a longer periodafter lactation, Kemp suggests. “One way to do <strong>this</strong> is totreat sows with altrenogest (Matrix or Regumate TM) for3-7 days after weaning to artificially extend the weaning tooestrus interval,” he says. “In research trials, <strong>this</strong> resultedin an increase in pregnancy rate <strong>of</strong> 5.6 to 15.7% and anincrease in subsequent litter size <strong>of</strong> about 0.2 - 0.8 piglets.”The application <strong>of</strong> altrenogest for short periods like 7days is especially effective in sows with depressed follicledevelopment at weaning, which are the sows that losesubstantial body reserves during lactation, says Kemp.“Extending the use <strong>of</strong> altrenogest to a 14 day treatmentseems to result in better and more consistent results,” hepoints out. “More detailed studies show that application<strong>of</strong> altrenogest after weaning results in increased ovulationrate, less variation in embryo development and/or ahigher embryo survival.”Skip a heatAnother approach which allows the first litter sow torecover from her previous lactation is to inseminate thesow at the second heat after weaning instead <strong>of</strong> the firstone (skip a heat). “Skipping the first heat can improvepregnancy rates by 15% and subsequent litter sizes by 1.3to 2.5 piglets,” Kemp explains. “However, whether or not<strong>this</strong> technique should be used is a matter <strong>of</strong> economics.”Feeding levels during early pregnancyAfter weaning, sows need to restore body reserves thatwere lost during lactation, however <strong>of</strong>ten feed levels are toolow in practice, Kemp believes. “Recently, we studied theeffects <strong>of</strong> feeding 2.5 or 3.25 kg per day from day 3 to 32<strong>of</strong> pregnancy on litter size and farrowing rate,” he explains.“The high feeding level increased total born and live bornpiglets by 2.1 and 1.8 piglets, respectively. Piglet weightswere similar at both feeding levels.” However, he notes,farrowing rate was lower for the sows fed at the higherlevel (77 vs. 90%). “High feeding levels lead to increasedlitter size but may also result in more sows returning tooestrus after first insemination,” Kemp concludes.CONTINUED ON PAGE 26Western Hog Journal | Spring 2011 | 25

Manitoba Swine Seminar ContinuedLife beyond needlesNeedleless injectors seem to <strong>of</strong>fer many advantages over conventional injection methods, especially because theycompletely remove the risk <strong>of</strong> broken needles. They are easier for staff than using a syringe and are safer because there isno risk <strong>of</strong> accidental injury from needles, says veterinarian Karine Talbot, with HyLife (formerly Hytek) <strong>of</strong> La Broquerie,Manitoba. In addition, she points out, they provide improved welfare for the pigs. Although there are some disadvantagessuch as the high initial cost and the need for a compressor and other additional equipment in the barn, needleless injectorshave been working well within the HyLife system and 315,000 injections are now carried out each month. Talbot reviewsthe needleless injection system, its advantages and disadvantages and how it has been working at HyLife.Mode <strong>of</strong> action“The concept <strong>of</strong> the needle-free device is to accelerate a jet<strong>of</strong> fluid, and nowadays even powder, at a speed high enoughto give it penetrative power,” explains Talbot. “This poweris provided by an energy source such as a spring, gas or abattery and is used to drive a plunger or a piston into thedrug, accelerating it through a fine diameter nozzle. The drugthen penetrates the skin and reaches various depths <strong>of</strong> tissue -sub-cutaneous, intra-dermal and/or intramuscular - dependingon the pressure applied and the type <strong>of</strong> device.”Two types <strong>of</strong> unit are used in the Canadian pig industry: oneis a battery-powered injector (Acushot) and the other one isgas-powered (Pulse). The advantages and disadvantages listedbelow apply to both types <strong>of</strong> device.Advantages“The reasons to use needle-free injectors in pigs are numerousand the advantages are considerable,” Talbot believes. “First,the risk <strong>of</strong> having a consumer finding a needle in pork is notacceptable and such a finding would negatively impact thewhole industry. The use <strong>of</strong> a needle-free device eliminates <strong>this</strong>risk and ensures a safer product to consumers.”One <strong>of</strong> the concerns about the needle-free injectors is theincrease in neck and head abscesses at the slaughter plant, butstudies have shown that the incidence <strong>of</strong> carcass defects is thesame as with conventional needles, Talbot points out.“Needle-free injectors are also more worker-friendly thanneedles,” she continues. “Their use eliminates the risk <strong>of</strong> needlestick injury and also reduces injuries caused by repetitivemovements when injecting with a conventional syringe. Theiruse also eliminates the need for needle disposal.”Some recent research has also demonstrated a reduction intransmission <strong>of</strong> some diseases like PRRS, Talbot notes. Theconventional needle, when used from pig to pig, has thepotential to transfer blood and pathogens. The needlelessdevice, even if it does not eliminate <strong>this</strong> risk, reduces it greatly.“Another important advantage <strong>of</strong> these units is the consistency<strong>of</strong> the amount <strong>of</strong> drug delivered,” Talbot adds.DisadvantagesTalbot believes that the disadvantages <strong>of</strong> the needle-freeinjectors could explain its low implementation rate in foodanimal production, notably in the pig industry. “These includethe cost <strong>of</strong> the injector as well as the cost for maintenance<strong>of</strong> the unit,” she explains. “In addition to <strong>this</strong>, some <strong>of</strong> thedevices may require special installation and additional cost forequipment such as a CO2 tank, air compressor or carts.”“For the needle-free injector to function properly,regular maintenance and cleaning <strong>of</strong> the unit is required”“For the needle-free injector to function properly, regularmaintenance and cleaning <strong>of</strong> the unit is required,” Talbotstresses. “Moreover, people performing those tasks need sometraining in order to use the device safely and efficiently.”Depending on the amount <strong>of</strong> drug administered and the waymass vaccination is performed – for example picking upevery pig vs. using a board to crowd them - the needlelessinjector might be slower and increase the time required toperform the task.“The device and all its components are also heavy if they areworn when injecting,” Talbot notes. “However, alternativemethods can be used such as a special cart or a tray that holds26 | Western Hog Journal | Spring 2011CONTINUED ON PAGE 28

It’s time for a gut check.You want your piglets to have the healthiest guts possible. If you wait until you see scours fromcoccidiosis, you’re too late. By the time symptoms appear, gut damage has already taken place,reducing weaning weights and adding days to market. Ask your veterinarian about diagnosingcoccidiosis before it’s too late.®Bayer and Bayer Cross are registered trademarks <strong>of</strong> Bayer AG, used under license by Bayer Inc.Learn more at BayerPigletHealth.ca

Farm Manitoba Focus Swine Seminar Continued ContinuedTable 1: Advantages and disadvantages<strong>of</strong> needle-free technologyAdvantagesEliminates the risk <strong>of</strong> broken needlesEliminates the risk <strong>of</strong> needle sticksEliminates multiple-use injuries(e.g. carpal tunnel)Reduces the transmission <strong>of</strong> diseasesElimination <strong>of</strong> needle disposalEasy to useConsistent vaccine deliveryDisadvantagesCost (device and maintenance)May require new equipment(compressed air, CO2)Higher requirement for maintenanceHigher requirement for trainingSlower speed <strong>of</strong> injectionWeight <strong>of</strong> the unitNot practical for individual treatmenteverything needed to inject. The user then only needs to holdthe handle piece which is very light.”Needle-free injectors are difficult to use for individualtreatment <strong>of</strong> pigs. “Also, drugs like penicillin cannot be usedin some needle-free devices as the components <strong>of</strong> the drugseparate in the injection process under the high pressurerequired for injecting,” she points out.Even if some <strong>of</strong> these disadvantages are significant, they canbe overcome, Talbot believes. The disadvantages need to beconsidered when thinking <strong>of</strong> purchasing a needle-free injector,however, they should not stop anybody from making <strong>this</strong>change,” she says. “The advantages <strong>of</strong> the system, mainly theelimination <strong>of</strong> broken needles, can certainly overcome most<strong>of</strong> the disadvantages.” Moreover, she notes, the Province <strong>of</strong>Manitoba has a financial incentive for every producer to buyone <strong>of</strong> these needle-free devices.EfficacyAmong the different vaccines tested in pigs are Mycoplasmahyopneumoniae, Swine influenza, pseudorabies, APP andPRRS. These studies have shown that needle-free injectionsare as good as or better than injections with needles.Needle-free injectors can also be used with other medicationsin addition to vaccines, for example iron for piglets,Talbot notes. “In one study the growth, performance andhaematological values <strong>of</strong> piglets that received iron through aneedle-free injection were the same as those for piglets thatwere injected with a conventional needle.”HyLife’s experienceIn 2008, HyLife started a trial in a research barn with needlefreeinjectors to investigate if the use <strong>of</strong> such a device waspractical in a pig barn. “It did not take much time to realize that<strong>this</strong> technology was really promising and even though we hadsome small challenges, it was possible to implement it in theentire system,” comments Talbot. “In 2009, when the Federal-Provincial Growing Forward program was announced, <strong>this</strong> wasthe final incentive that HyLife needed to make the decision to goahead and use needle-free injection in all <strong>of</strong> the barns.”“As a fully integrated company owning a slaughter plant, HyLifedecided to be completely needle-free, from birth to slaughter,”Talbot explains. “This includes the injection <strong>of</strong> vaccines, ironand any treatment with antibiotics. Needles are still used forsows as the risk <strong>of</strong> broken needles was judged to be very lowand they are not slaughtered at the Springhill plant.”“A person was hired as a full time needle-less injectiontechnician and trained to use and repair the injectors,”continues Talbot. “His job was to implement the technology inContact David Scott @ (204) 834-2707www.maximumswine.com28 | Western Hog Journal | Spring 2011Get the MAXIMUM advantageWe have buyers waiting to pay top dollarfor your weaner and feeder pigsMaximum Swine Marketing has extensive industry contacts toconsistently market your hogs at all stages <strong>of</strong> the life cycle.You receive extra value through:• Clean, Dependable Transportation • Veterinary Consultation• Prompt payment terms• Pr<strong>of</strong>essional After Sales Service and SupportKnowledge and skill to market swine throughout the life cycle

Manitoba Swine Seminarall the barns, starting in June 2010. As<strong>of</strong> November 2010, all nurseries and sowbarns were using the needle-less injectorand the last needles were removed fromthe barns in December.”“The transition to <strong>this</strong> newtechnology went much betterthan expected and was wellaccepted by the employees”The transition to <strong>this</strong> new technologywent much better than expected and waswell accepted by the employees, Talbotsays. She notes that some modificationswere made to the barns; pipes forcompressed air with many dropsthroughout the barns were installed,special carts were designed so the userdid not have to bear the weight <strong>of</strong> theunit and special trays were designedto hold small air tanks for individualtreatments.“The devices are working well and aslong as the basic maintenance is doneregularly almost no problems have beenexperienced,” Talbot notes. “Exceptfor some damage caused by humanerror, the units have been very resilientconsidering the number <strong>of</strong> injections andthe environment in which they are used:some barns inject up to 5000-6000 pigsa week and in the whole HyLife systemabout 315,000 needle-free injections aredone monthly. This represents a hugenumber <strong>of</strong> needles that HyLife does notneed to buy anymore, and also a hugenumber <strong>of</strong> needles that do not have tobe disposed <strong>of</strong>.”Up to now, most <strong>of</strong> the small technicalproblems have been fixed in thebarn by the employees themselves,Talbot explains. “If ever they havequestions, or if they encounter a biggerproblem, the needle-less technicianor a maintenance employee that hasalso been trained to repair the devicecan always help, and the needle-lesscompany itself <strong>of</strong>fers a very goodservice,” she says.Since the needle-free injectors are veryexpensive, it was not economicallyfeasible to have a unit at every finishingsite, Talbot points out. The solutionto giving individual treatments wasto use a drench gun similar to the oneused in sows or cattle and administermedication orally.ConclusionOverall, the transition to the needle-freeinjectors within the HyLife system hasgone very well, indeed much better thanexpected, according to Talbot. “The risk<strong>of</strong> broken needles in the pigs from birthto slaughter is eliminated, the injectionseems less painful and less stressful onpigs and, most <strong>of</strong> all, staff like <strong>this</strong> newtechnology,” she concludes. “One wouldnow have a hard time to convince anemployee to go back to using needles!”CONTINUED ON PAGE 30Western Hog Journal | Spring 2011 | 29

Farm Manitoba Focus Swine Seminar Continued ContinuedGlycerine in swine dietsAn increase in biodiesel production in North America has led to the availability <strong>of</strong> glycerine - a by-product from theprocess - as a possible energy source in pig diets. Up to 15% crude glycerine can been fed to pigs without negativeconsequences, according to Dr. LeAnn Johnston, technical services manager with Amlan International. However, shepoints out, crude glycerol contains varying concentrations <strong>of</strong> methanol, which is potentially toxic to swine. Becausecrude glycerine is a liquid it can cause problems with feed manufacturing and feed flowability but has been shownto improve pelleting, notes Johnston. Although glycerine is not currently approved for use in swine diets, there is aconsiderable amount <strong>of</strong> interest in its potential and recent research has been evaluating its use. Johnston looks at thefactors that need to be considered when using glycerine in pig diets.What is glycerine?“Glycerine, which is also called glycerol, is traditionally usedin the making <strong>of</strong> soaps, cosmetics, and lotions,” explainsJohnston. “It has a sweet taste and can be used as a sweetenerin human foods or animal feeds.” When fats and oils aremade into biodiesel, crude glycerine is a by-product; 79 g <strong>of</strong>crude glycerine is produced per litre <strong>of</strong> biodiesel. “In the bodyit can be broken down by the liver and converted to glucose tobe used by the body as an energy source,” Johnston continues.“Energy cost is sixty percent <strong>of</strong> the total cost <strong>of</strong> swine diets.Therefore, because <strong>of</strong> the increase in biodiesel production therehas been increased interest in using glycerine as an energysource in animal feeds.”Glycerine and pig performanceEnergy calculationsTo use glycerine as an energy source it is important todetermine the amount <strong>of</strong> energy available to the pig, saysJohnston. However, she notes, there can be tremendousvariability between sources <strong>of</strong> glycerine. “Kerr et al. evaluatedthe digestible and metabolizable energy values from severalsources <strong>of</strong> crude glycerine for nursery pigs and reporteda range <strong>of</strong> gross energy (GE) from 3,173 to 6,021 kcal/kg;<strong>of</strong> digestible energy (DE) <strong>of</strong> 3,022 to 5,228 kcal/kg; and <strong>of</strong>metabolizable energy (ME) from 2,535 to 5,206 kcal/kg,”Johnston informs.A number <strong>of</strong> formulae have been developed to predict theenergy content <strong>of</strong> glycerine from its composition. These canbe used when formulating diets.Nursery pigsWork by Zijlstra et al. at The University <strong>of</strong> <strong>Alberta</strong>, showedincreased body weight when 4 or 8% glycerol replaced wheat(with the appropriate additions <strong>of</strong> crystalline amino acids) indiets for nursery pigs. “Feed intake also tended to increase,which resulted in no change in feed efficiency during thetwenty-one day experiment,” comments Johnston. “In asimilar trial, ADG improved linearly in nursery pigs when fed3 or 6% glycerine replacing corn.”Grow-finish pigsLammers et al. added 5 or 10% glycerine to diets for pigsstarting one week after weaning (from a weight <strong>of</strong> 7.9 kg) andcontinuing through the finishing period. “The addition <strong>of</strong>glycerine did not have any effect on animal performance inany stage <strong>of</strong> the trial or overall,” Johnston explains. “Therewere also no effects on carcass characteristics except for thefatty acid pr<strong>of</strong>ile.” Diets in <strong>this</strong> experiment did not simplyreplace corn or wheat with glycerine but were formulated tohave the same ME, lysine, sulphur amino acids, threonine,tryptophan, available phosphorus, sodium and chlorine contentas the control diets. “When 5% glycerol was added to the dietit replaced 6% <strong>of</strong> the corn and 50% <strong>of</strong> the sodium chloridewhile soybean meal increased by 5% in the formulation,”Johnston points out. “In the diets with 10% added crude30 | Western Hog Journal | Spring 2011

Manitoba Swine SeminarTable 1: Summary <strong>of</strong> results for trials using glycerine in swine dietsReference AgeCrude glycerinein diet, %Effect on growth performance Effects on meat quality CommentsGroesbeck et al.,2008Lammers et al.,2008aNursery pigs 0, 3, 6, 9, 12, & 15Growing pigs 0, 5, & 10Zijlstra et al., 2009 Weaned pigs 0, 4, & 8Mendoza et al.,2010Schieck, et al.,2010Increased ADG, tended to increaseADFI, no difference on G:FNo treatment difference on ADG,ADFI or G:FWeight increased with increasingglycerol, quadratic increase in ADFI,no difference on G:FFinishing pigs 0, 5, 10, & 15 No effect on growth performanceFinishing Pigs 83 % increase in gain, 2% decreasein G:F when fed from 31.3 kg <strong>of</strong>body wtNo effect any carcasscharacteristic except fattyacid pr<strong>of</strong>ileNo effect <strong>of</strong> glycerin oncarcass characteristics ormeat qualityIncreased belly firmnesswhen fed the last 8 wks <strong>of</strong>the finishing periodAdding up to 9% glycerin increased pellet durabilityand decreased delta temperature, amperage, motorload, and improved production efficiency.Diets formulated on an equal energy basisEnergy digestibility increased linearly with increasingglycerinNo effect <strong>of</strong> different pre-slaughter handlingtechniques on pork qualityNo change in drip lossglycerol 16% corn and 90% sodium chloride were replaced andsoybean meal increased by approximately 9%.“Up to 15% refined glycerine was fed with no effecton growth performance, carcass or pork qualitymeasurements”In one trial, up to 15% refined glycerine was fed with no effecton growth performance, carcass or pork quality measurementswhen diets were formulated to the same ME, Johnston notes.However, she says, another trial saw increased ADG and ADFIand decreased Gain:Feed ratio when 8% crude glycerine was fedfor 12 weeks in the grow-finish period. “Adding glycerine in<strong>this</strong> experiment improved belly firmness but had no other effecton carcass quality, water-holding capacity, or taste,” she adds.Concerns with the use <strong>of</strong> glycerine in swinedietsApprovalCrude glycerine is not currently listed in Schedule IV forswine in Canada. It is, however, listed in Schedule IV for usein beef cattle feeds up to 5% <strong>of</strong> the total diet. “CFIA requiresthat glycerine contains not more than 0.1% (1000 ppm)residual methanol,” explains Johnston. “They also requirethat it is labelled with guarantees for minimum percentglycerol, maximum percent moisture and maximum percentmethanol.”ImpuritiesMethanol is used during the biodiesel manufacturing processand some methanol will remain in the crude glycerine byproduct.“Sodium and chloride can also be found in crudeglycerine in relatively high concentrations,” notes Johnston.“It may be advantageous to adjust the amount <strong>of</strong> salt inthe diet based on the amount <strong>of</strong> Na and Cl in the glycerine.Adding glycerine to the diet has been shown to increasewater intake and urinary output.”FormGlycerine is typically a liquid at room temperature. Thismeans that it needs to be stored in a tank at the feed mill andadded as a liquid. “Adding more than 6% glycerine to a mashdiet can result in feed with flowability problems,” Johnstoncomments. “However, research suggests that adding up to 9%glycerine increased pellet durability and decreased friction atthe pellet mill, improving production efficiency.”ConclusionsWhile not currently approved for use in swine in Canadacrude glycerine is a good energy source for swine, Johnstonconcludes. “There is variability in the energy available fromcrude glycerine, but the energy content can be estimatedby the composition,” she says. “When diets are formulatedwith crude glycerine they will have lower amounts <strong>of</strong> energysources such as wheat and higher levels <strong>of</strong> protein sources,also salt may need to be decreased.”TOPIGS fact <strong>of</strong> the monthWhy TOPIGS?• One <strong>of</strong> the largest swine breeding companies in the world• Active in more than 50 countries worldwide• True R & D programs resulting in genetics that work for you• Large genetic base with more than 20 million records• Selling more than one million gilts each year• More than 415,000 sows averaging 27.7 pigs weaned/sow/year• Terminal sires producing the performance and carcass you need• The fastest growing breeding company in Canada• CALL US!TOPIGS: 1 866 355-5132CONTINUED ON PAGE 32Western Hog Journal | Spring 2011 | 31

Farm Manitoba Focus Swine Seminar Continued ContinuedPractical nursery management:Doing the basics rightThe day <strong>of</strong> weaning and the subsequent period in the nursery are life-changing and incredibly stressful events for thepig, according to Blaine Tully, a veterinarian with Swine Health Pr<strong>of</strong>essionals Ltd., Steinbach, Manitoba. A weaned pig’sneeds are quite basic, and non-negotiable, in that if we want the pig to perform well, we need to provide food, waterand a dry place to lie, he believes. Assuming that good quality pigs are weaned into the nursery, it is in our control asstockpersons to facilitate a smooth transition for the weaned pig and ensure good performance, Tully says. He reviewscurrent nursery pig management practises and explores some practical approaches to easing life for the weaned pig.Food“Starting on feed immediately afterweaning is crucial not only to providenutrition for growth, but also for heat,”Tully points out. “The weaned pigwill generate heat as it digests feed,thereby reducing the potential foradditional chilling.”The transition period (first 72 hours)will be more successful if the pig hashad an opportunity to try chewing somedry, pelleted feed already, Tully stresses.“By providing a small amount <strong>of</strong> creep71916A02 SHAC Genetics:Layout 1 12/17/09 1:54 PMfeed for 3-6 days prior to weaning, weIntroducing SHACEnvironmental Products!Producers count onSHAC Feed Additive andManure Digester to improve theirlivestock production operations.SHAC products significantly REDUCEammonia gases, odors and the volume<strong>of</strong> manure solids in pits and lagoons.ContactMiles Bell 780-913-4953Doug Stebbings306-370-4400or callToll free 1-888-533-4446www.shac.ca32 | Western Hog Journal | Spring 2011can ‘train’ the pig to chew solid food,”he explains. “Once weaned, the type <strong>of</strong>feed will be one less novel experiencethe pig will need to deal with.” Ideallythe pre-weaning creep diet should bethe same as the first diet used in thenursery pen, Tully advises. “Creep feedshould be provided on mats or in traysto the weaned pigs to increase accessopportunities to the piglets,” he says.“Remember, the weaned pig was used toeating 20 or more times per day on thesow and therefore if we can hand feedthe creep feed - in small amounts tolimit wastage - we can also increase thelikelihood <strong>of</strong> a pig eating.”Another consideration with respect t<strong>of</strong>eeding is the nursery feeder design,spacing and setting. “When consideringthe amount <strong>of</strong> time spent at the feeder, adry multi-space feeder appears superiorto the wet/dry type feeders in a nurserysetting and does not appear to impactgrowth performance,” Tully notes.“This could imply that there is lessopportunity for aggressive behaviourand competition at the feeder.”“Newly weaned piglets mustfind and begin drinking from thewater source in the pen as soonas possible”Correct feeder setting will minimizefeed wastage while providing adequateaccess to feed, preventing competitionat the feeder and not reducing feedintake, Tully says. “Feeders shouldbe set to allow 25-60% <strong>of</strong> the feederbottom to be covered by feed. For the72-hour period following weaning, theentire feeder bottom should be coveredto ensure adequate and instant access tocreep feed, however for the remainingnursery period, target to have 40%<strong>of</strong> the bottom covered by feed.” Hesuggests that feeders should be assesseddaily to ensure feed stage changes havenot altered the feeder pan coverage andadjustments made accordingly. Also,dirty feeders reduce access to feed andfeed intake.WaterOften overlooked as the most importantnutritional requirement affecting piglethealth, adequate access to clean freshwater cannot be underestimated, Tullybelieves. “Newly weaned piglets mustCONTINUED ON PAGE 34

Farm Manitoba Focus Swine Seminar Continued Continuedfind and begin drinking from the water source in the pen assoon as possible,” he explains. “Piglets prefer a drinker that iseasy to find and simple to access water from. A nipple typedrinker may take advantage <strong>of</strong> the normal suckling behaviour<strong>of</strong> a piglet; however it will not increase water intake or impactpiglet performance relative to a push-lever bowl type drinker.”Nipple drinkers also dramatically increase water (and watermedication) wastage in nursery pens, he adds.The number <strong>of</strong> piglets per drinker, water pressure and flowrate will affect water access and intake. “Generally, theliterature suggests 1 drinker/10 pigs, a flow rate <strong>of</strong> 250-500 mlper minute, with a water pressure <strong>of</strong> 20 psi,” Tully points out.“Most nursery facilities in Manitoba will perform well with 20pigs per drinker. With adjustable height type drinkers, ensurethe nipple is adjusted to the top <strong>of</strong> the shoulder <strong>of</strong> the smallestpig in the pen.”Water samples should be analysed for bacterial contaminationand quality annually or more frequently depending on source,he advises.Dry place to sleepThe weaned pig has a large surface area to body mass ratio,and therefore is at real risk <strong>of</strong> losing a lot <strong>of</strong> body heat. “Asdiscussed earlier, if a weaned piglet does not begin eating anddrinking immediately after weaning, the lack <strong>of</strong> metabolic heatAre you readingsomeone else’scopy <strong>of</strong> theWestern HogJournal?If so, why not sign up for your ownsubscription? Just call Barb Kosak on780-474-8288 or email your contactdetails to info@albertapork.comSubscription is free!Get the latest technical information and pork industrynews sent direct to your mailbox – sign up now!production from the digestion <strong>of</strong> feed will begin adverselyaffecting normal body functions and health,” Tully notes. “For<strong>this</strong> reason, the nursery room must be preheated to 28-32°Cfor the first 36-72 hours as the pig transitions onto feed. Aweaned piglet prefers a warm environment, even if air quality(increased ammonia level) is reduced in the short term.”“Air current within a pen can reduce growth ratesand impact the health <strong>of</strong> a weaned pig”We must also consider the difference between ambient roomtemperature and the effective temperature - the temperature thepiglet actually feels, Tully believes. “The effective temperature ischanged by air speed, flooring type, and insulation <strong>of</strong> walls. Forexample, if the room air temperature is 24°C, but we have plasticflooring and a moderate draft, the effective temperature, or whatthe room feels like to the pig, is actually 13°C,” he explains.“This phenomenon explains why we <strong>of</strong>ten see weaned pigletshuddling in the corner <strong>of</strong> a pen, despite the thermometer in theroom indicating an appropriate temperature.”Farms that have heated floor pads in each pen can afford tohave ambient temperature 2-3°C lower than those without,however stocking density must allow all piglets within thepen to lay flat on the pad without piling, Tully adds. “Anydraft in the pen will still affect these piglets, despite havinga heated pad to lie on. Air current within a pen can reducegrowth rates and impact the health <strong>of</strong> a weaned pig includingincreased coughing, sneezing, diarrhoea, and skin lesions.”Another consideration is usable space within a pen, he notes.“If part <strong>of</strong> a pen is soiled due to poor dunging patterns, or wetfrom leaking water lines or drinkers, the usable space <strong>of</strong> thepen is reduced.”The stockpersonThe final ingredient in sound nursery management is anengaged stockperson. “The stockperson must be able to ‘bringtheir A-game’ each and every day,” Tully stresses. “The first72 hours post-weaning will set the course for the remainingnursery stay.” Every pig will need to be observed and assesseddaily to determine which pigs need more attention to begineating, drinking and fitting into the new social order, hesays. “This means that the stockperson is actually in the pen(crouching down with the pigs, to get a close look at all <strong>of</strong> thepigs), with marker and syringe in hand and ready to sort andtreat at-risk pigs.”Tully notes that many pigs are weaned on Thursday, whichmakes the management <strong>of</strong> the early weaned pig extremelychallenging, having the 36-hour mark fall on Fridayafternoon. “Many <strong>of</strong> us are already thinking <strong>of</strong> the weekend,not identifying at-risk pigs,” he points out. “Getting the rightperson in place for addressing these early challenges can makethe difference between average and superior performance.” n34 | Western Hog Journal | Spring 2011

Special FeaturesBehaviour <strong>of</strong> pigs in large group auto-sort systemsLarge group auto-sort (LGAS) systems require considerably more effort on the pigs’ part to access feed than in smallpens, according to Drs. Harold Gonyou and Jennifer Brown from the Prairie Swine Centre. They recently studied thepigs’ behaviour in two LGAS systems to determine what adaptations they made. Pigs were able to maintain their typicaldiurnal eating pattern, with peaks at ‘lights-on and lights-<strong>of</strong>f’ as seen in small pens, the researchers found. However, theyadd, the pigs modified their eating by having fewer (5 vs 10-15) but longer meals than in small pens. Pigs made use <strong>of</strong>all <strong>of</strong> the available feeder spaces within the food court, visiting several each day, Gonyou and Brown note. Although ableto adapt their eating behaviour to the large group system, some had difficulty learning to enter and leave the food courtseveral times a day, they observe. Management should ensure an adequate number <strong>of</strong> feeder spaces, sufficient room tomove in the food court and training methods to facilitate use <strong>of</strong> the auto-sort scale, Gonyou and Brown conclude. Theydescribe the studies they carried out and discuss the results and their implications for commercial producers.IntroductionThe use <strong>of</strong> large groups for grow/finishpigs makes it economically feasibleto introduce new technology, such asauto-sort scales, into pig production.One <strong>of</strong> the initial fears concerning largegroups <strong>of</strong> pigs was that they would fightlonger after being put together. Ourearlier research refuted these concernsas aggression per pig at group formationwas similar in small and large groups,and in fact, pigs from large groupsproved easier to combine with other pigswhen marketed. However, early attemptsto use auto-sort technology encounteredproblems with variable feed intakeamong the pigs. We continued ourstudies with a focus on eating behaviour.Experimental proceduresStudies were carried out at twolocations; the PSC Elstow ResearchFarm and a commercial grow/finishoperation. The Elstow facility housedapproximately 250 pigs in its LGAS(with 1 feeder space per nine pigs).The commercial farm maintained groups<strong>of</strong> 650 pigs with 60 feeder spaces. Atthe Elstow facility we studied thediurnal pattern <strong>of</strong> scale use, the use<strong>of</strong> individual feeder spaces within thefood court and the eating patterns <strong>of</strong>individual pigs. Movement throughthe scale (‘hits’) were studied usingautomated output from the auto-sortscale. We photographed all <strong>of</strong> the feederspaces at 5 minute intervals using a timelapse camera. To identify individualpigs, 10 pigs in each study group werepaint-marked. At the commercial farm,we again used output from the auto-sortscale, and supplemented <strong>this</strong> with liveobservations <strong>of</strong> four rooms <strong>of</strong> pigs for a24-hr period.Breeding HerdGilt PoolRapid data entryDrill-down reportingGrowing pigsShare reports via the InternetPlease call for more informationToll Free: 1-877-474-4946www.pigwin.com36 | Western Hog Journal | Spring 2011Body Weight (lb)160140120100806040200163248648096Sorter 10 – October 10112128Number <strong>of</strong> Animals144160176192208224240256272288304Figure 1: Distribution <strong>of</strong> weights recorded by sorter during period when pigs averagedapproximately 45 kg (98 lbs). Second cluster to right represents times when two pigswere in the scale. Weights in lbs.CONTINUED ON PAGE 38

WHATEVER THE SEASON,PROTECTYOUR LIVESTOCK FROMHEATSTROKE AND STRESS!THREE VÉTOQUINOL PRODUCTS CAN MAKEALL THE DIFFERENCEelectrolytes-A/FPrimarily for rehydrationelectrolytes plusWith vitamins, two possible doses, for animals witha slight loss <strong>of</strong> appetite and vitamin deficienciesstress-aidFor animals with a significant loss <strong>of</strong> appetiteand important vitamin deficienciesSimplify your life - download our FREE s<strong>of</strong>twareto calculate the dilution <strong>of</strong> our products:www.solublepowders.cawww.vetoquinol.ca

Special Featuresthe data for the number <strong>of</strong> pigs thatentered the food court each hour, a moredistinct diurnal pattern was found.The analysis <strong>of</strong> photos <strong>of</strong> the feederspaces (Figure 2) showed a clear diurnalpattern with an 8-fold increase in eatingduring the daytime peaks compared tothe midnight low. The pattern showed“Large group auto-sort systemspose some significant challengesto pigs in terms <strong>of</strong> eatingbehaviour”Figure 2: Example <strong>of</strong> photo used to assess eating patterns and feeder useResults and discussionPigs normally have a diurnal eatingpattern with most <strong>of</strong> the feeding takingplace during the ‘day’. When we firstexamined the pattern <strong>of</strong> ‘hits’ throughthe auto-sort scale the entry patternwas poorly defined. However, wedetermined that during the daytime, andwhen pigs were less than 75 kg, twopigs would <strong>of</strong>ten enter the scale at thesame time (Figure 1). After adjustingtypical peaks at ‘lights-on’ and ‘lights<strong>of</strong>f’.The pigs used each <strong>of</strong> the feederspaces fairly uniformly, somethingwe had observed in previous studies.Pigs in small groups typically have10 – 15 well defined ‘meals’ in a day.Pigs in the LGAS had approximately 5meals per day, but they were longer induration than in small group pens. Thisadaptation was successful as the pigsin LGAS performed as well as those insmall groups.Committed to producing pigssuperior in the industry!PEAK SWINE GENETICS#217, 5906 - 50 StreetLeduc, <strong>Alberta</strong> Canada T9E 0R6Phone: 780.986.4647Fax: 780.986.4694email: peak@peakswine.comwebsite: www.peakswine.comArt Goelema 403-963-0171Paul Klingeman 509-989-1347Toll Free 1-888-235-7325PEAK Durocs provideexcellent color andmarbling in pork loins.38 | Western Hog Journal | Spring 2011

Special FeaturesThe study at the commercial farmallowed us to examine the changein eating behaviour as pigs aged.Our study rooms varied in age bysix weeks. We determined that theaverage number <strong>of</strong> entrances intothe food court each day decreased asthe size (age) <strong>of</strong> the pigs increased,from nearly 4 entries per day at 40kg to approximately 2.5 per day at 90kg. The pattern <strong>of</strong> eating showed thetypical diurnal, two-peaked patterndescribed earlier (Figure 3). Of interestin <strong>this</strong> pattern was that younger pigshad less <strong>of</strong> a ‘drop-<strong>of</strong>f’ in the middle <strong>of</strong>the day. Comparing these results withother studies suggests that the youngerpigs were limited in the number <strong>of</strong>feeder spaces, and had to shift eatingfrom the normal peak periods to theless intensive mid-day period.The bottom lineLarge group auto-sort systems posesome significant challenges to pigsin terms <strong>of</strong> eating behaviour. Thefeeders are all located in a food courtwhich can only be accessed througha single sorter scale. The cost <strong>of</strong>moving to the feeders is greater thanin a small pen, where pigs may onlyhave to move a metre or so to findfeed. Despite these restrictions, pigspass through the sorter and eat in atypical diurnal pattern similar to thatseen in small pens. However, pigs inlarge group auto-sort pens only enterthe food court 2-4 times each day, andhave fewer meals (5 vs 10-15) thanin small pens. They compensate byeating longer during each meal. Theyalso move freely about the food court,eating from several feeder spacesevery day. Young pigs, who requiremore time to eat, may display a highermid-day rate <strong>of</strong> eating indicative <strong>of</strong>restricted feeder space. We believe akey to making food courts work is tomake sure the pigs know that food ispresent by introducing them to thefood court rather than the loafing area.The food court should be spacious% Time4035302520151050so that pigs have access to all <strong>of</strong> thefeeders, and a feeder space should beprovided for every 10-12 pigs.Acknowledgements: Project fundingprovided by the AgriculturalDevelopment Fund <strong>of</strong> Saskatchewan.Collaboration <strong>of</strong> Sierens Equipment aswell as that <strong>of</strong> the commercial farmPercent time in food courtMidnight Lights on NoonTime86 days 103 days 120 days 137 daysFigure 3: Diurnal pattern <strong>of</strong> eating by pigs within the food court in auto-sort rooms withdifferent aged pigs. The day was divided into eight 3-hour periods, starting at midnightwas greatly appreciated. Strategicfunding was provided by Sask <strong>Pork</strong>,<strong>Alberta</strong> <strong>Pork</strong>, Manitoba <strong>Pork</strong> Counciland Saskatchewan Agriculture to theresearch programs at PSCI.SYNERGIZEDISINFECTANTBecause Biosecurity Doesn’t Cost...It Pays!Synergize is the #1 veterinarian recommended disinfectantin the North American pork production industry. And for goodreason. From independent testing to university projects,from laboratory analysis to field trials, from PRRSV toPCV2 to Ileitis, to E. coli F18, to H3N2 Influenza A virus,Synergize meets and exceeds all expectations.Most importantly, Synergize provides today’s pork producer with thebest <strong>of</strong> all possible worlds; a powerful, non-irritating, non-corrosivedisinfectant at a competitive price. That's a tough combination to beat.Field Tested, Vet RecommendedSYNERGIZE DISINFECTANTPro-Ag Products, Ltd.Winnipeg, Manitoba R2J 0L1800.806.2737www.pro-ag.comCONTINUED ON PAGE 40Western Hog Journal | Spring 2011 | 39