Barcham Trees in the white bag - Forestry Journal

Barcham Trees in the white bag - Forestry Journal

Barcham Trees in the white bag - Forestry Journal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

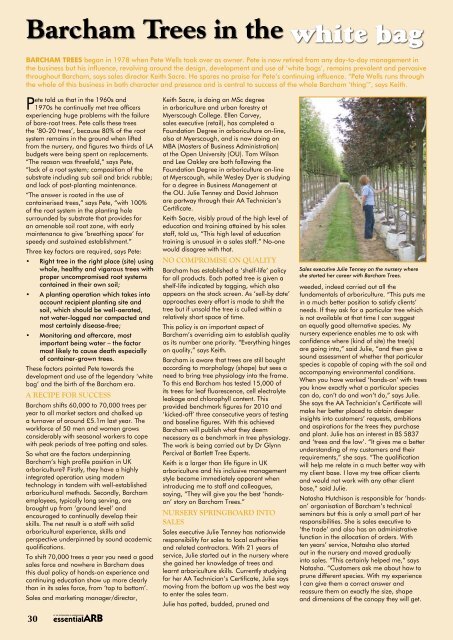

<strong>Barcham</strong> <strong>Trees</strong> <strong>in</strong> <strong>the</strong> <strong>white</strong> <strong>bag</strong><strong>Barcham</strong> <strong>Trees</strong> began <strong>in</strong> 1978 when Pete Wells took over as owner. Pete is now retired from any day-to-day management <strong>in</strong><strong>the</strong> bus<strong>in</strong>ess but his <strong>in</strong>fluence, revolv<strong>in</strong>g around <strong>the</strong> design, development and use of ‘<strong>white</strong> <strong>bag</strong>s’, rema<strong>in</strong>s prevalent and pervasivethroughout <strong>Barcham</strong>, says sales director Keith Sacre. He spares no praise for Pete’s cont<strong>in</strong>u<strong>in</strong>g <strong>in</strong>fluence. “Pete Wells runs through<strong>the</strong> whole of this bus<strong>in</strong>ess <strong>in</strong> both character and presence and is central to success of <strong>the</strong> whole <strong>Barcham</strong> ‘th<strong>in</strong>g’”, says Keith.Pete told us that <strong>in</strong> <strong>the</strong> 1960s and1970s he cont<strong>in</strong>ually met tree officersexperienc<strong>in</strong>g huge problems with <strong>the</strong> failureof bare-root trees. Pete calls <strong>the</strong>se trees<strong>the</strong> ‘80-20 trees’, because 80% of <strong>the</strong> rootsystem rema<strong>in</strong>s <strong>in</strong> <strong>the</strong> ground when liftedfrom <strong>the</strong> nursery, and figures two thirds of LAbudgets were be<strong>in</strong>g spent on replacements.“The reason was threefold,” says Pete,“lack of a root system; composition of <strong>the</strong>substrate <strong>in</strong>clud<strong>in</strong>g sub soil and brick rubble;and lack of post-plant<strong>in</strong>g ma<strong>in</strong>tenance.“The answer is rooted <strong>in</strong> <strong>the</strong> use ofconta<strong>in</strong>erised trees,” says Pete, “with 100%of <strong>the</strong> root system <strong>in</strong> <strong>the</strong> plant<strong>in</strong>g holesurrounded by substrate that provides foran amenable soil root zone, with earlyma<strong>in</strong>tenance to give ‘breath<strong>in</strong>g space’ forspeedy and susta<strong>in</strong>ed establishment.”Three key factors are required, says Pete:• Right tree <strong>in</strong> <strong>the</strong> right place (site) us<strong>in</strong>gwhole, healthy and vigorous trees withproper uncompromised root systemsconta<strong>in</strong>ed <strong>in</strong> <strong>the</strong>ir own soil;• A plant<strong>in</strong>g operation which takes <strong>in</strong>toaccount recipient plant<strong>in</strong>g site andsoil, which should be well-aerated,not water-logged nor compacted andmost certa<strong>in</strong>ly disease-free;• Monitor<strong>in</strong>g and aftercare, mostimportant be<strong>in</strong>g water – <strong>the</strong> factormost likely to cause death especiallyof conta<strong>in</strong>er-grown trees.These factors po<strong>in</strong>ted Pete towards <strong>the</strong>development and use of <strong>the</strong> legendary ‘<strong>white</strong><strong>bag</strong>’ and <strong>the</strong> birth of <strong>the</strong> <strong>Barcham</strong> era.A recipe for success<strong>Barcham</strong> shifts 60,000 to 70,000 trees peryear to all market sectors and chalked upa turnover of around £5.1m last year. Theworkforce of 50 men and women growsconsiderably with seasonal workers to copewith peak periods of tree pott<strong>in</strong>g and sales.So what are <strong>the</strong> factors underp<strong>in</strong>n<strong>in</strong>g<strong>Barcham</strong>’s high profile position <strong>in</strong> UKarboriculture? Firstly, <strong>the</strong>y have a highly<strong>in</strong>tegrated operation us<strong>in</strong>g moderntechnology <strong>in</strong> tandem with well-establishedarboricultural methods. Secondly, <strong>Barcham</strong>employees, typically long serv<strong>in</strong>g, arebrought up from ‘ground level’ andencouraged to cont<strong>in</strong>ually develop <strong>the</strong>irskills. The net result is a staff with solidarboricultural experience, skills andperspective underp<strong>in</strong>ned by sound academicqualifications.To shift 70,000 trees a year you need a goodsales force and nowhere <strong>in</strong> <strong>Barcham</strong> doesthis dual policy of hands-on experience andcont<strong>in</strong>u<strong>in</strong>g education show up more clearlythan <strong>in</strong> its sales force, from ‘top to bottom’.Sales and market<strong>in</strong>g manager/director,30Keith Sacre, is do<strong>in</strong>g an MSc degree<strong>in</strong> arboriculture and urban forestry atMyerscough College. Ellen Carvey,sales executive (retail), has completed aFoundation Degree <strong>in</strong> arboriculture on-l<strong>in</strong>e,also at Myerscough, and is now do<strong>in</strong>g anMBA (Masters of Bus<strong>in</strong>ess Adm<strong>in</strong>istration)at <strong>the</strong> Open University (OU). Tom Wilsonand Lee Oakley are both follow<strong>in</strong>g <strong>the</strong>Foundation Degree <strong>in</strong> arboriculture on-l<strong>in</strong>eat Myerscough, while Wesley Dyer is study<strong>in</strong>gfor a degree <strong>in</strong> Bus<strong>in</strong>ess Management at<strong>the</strong> OU. Julie Tenney and David Johnsonare partway through <strong>the</strong>ir AA Technician’sCertificate.Keith Sacre, visibly proud of <strong>the</strong> high level ofeducation and tra<strong>in</strong><strong>in</strong>g atta<strong>in</strong>ed by his salesstaff, told us, “This high level of educationtra<strong>in</strong><strong>in</strong>g is unusual <strong>in</strong> a sales staff.” No-onewould disagree with that.No compromise on quality<strong>Barcham</strong> has established a ‘shelf-life’ policyfor all products. Each potted tree is given ashelf-life <strong>in</strong>dicated by tagg<strong>in</strong>g, which alsoappears on <strong>the</strong> stock screen. As ‘sell-by date’approaches every effort is made to shift <strong>the</strong>tree but if unsold <strong>the</strong> tree is culled with<strong>in</strong> arelatively short space of time.This policy is an important aspect of<strong>Barcham</strong>’s overrid<strong>in</strong>g aim to establish qualityas its number one priority. “Everyth<strong>in</strong>g h<strong>in</strong>geson quality,” says Keith.<strong>Barcham</strong> is aware that trees are still boughtaccord<strong>in</strong>g to morphology (shape) but sees aneed to br<strong>in</strong>g tree physiology <strong>in</strong>to <strong>the</strong> frame.To this end <strong>Barcham</strong> has tested 15,000 ofits trees for leaf fluorescence, cell electrolyteleakage and chlorophyll content. Thisprovided benchmark figures for 2010 and‘kicked-off’ three consecutive years of test<strong>in</strong>gand basel<strong>in</strong>e figures. With this achieved<strong>Barcham</strong> will publish what <strong>the</strong>y deemnecessary as a benchmark <strong>in</strong> tree physiology.The work is be<strong>in</strong>g carried out by Dr GlynnPercival at Bartlett Tree Experts.Keith is a larger than life figure <strong>in</strong> UKarboriculture and his <strong>in</strong>clusive managementstyle became immediately apparent when<strong>in</strong>troduc<strong>in</strong>g me to staff and colleagues,say<strong>in</strong>g, “They will give you <strong>the</strong> best ‘handson’story on <strong>Barcham</strong> <strong>Trees</strong>.”Nursery spr<strong>in</strong>gboard <strong>in</strong>tosalesSales executive Julie Tenney has nationwideresponsibility for sales to local authoritiesand related contractors. With 21 years ofservice, Julie started out <strong>in</strong> <strong>the</strong> nursery whereshe ga<strong>in</strong>ed her knowledge of trees andlearnt arboriculture skills. Currently study<strong>in</strong>gfor her AA Technician’s Certificate, Julie saysmov<strong>in</strong>g from <strong>the</strong> bottom up was <strong>the</strong> best wayto enter <strong>the</strong> sales team.Julie has potted, budded, pruned andSales executive Julie Tenney on <strong>the</strong> nursery whereshe started her career with <strong>Barcham</strong> <strong>Trees</strong>.weeded, <strong>in</strong>deed carried out all <strong>the</strong>fundamentals of arboriculture. “This puts me<strong>in</strong> a much better position to satisfy clients’needs. If <strong>the</strong>y ask for a particular tree whichis not available at that time I can suggestan equally good alternative species. Mynursery experience enables me to ask withconfidence where (k<strong>in</strong>d of site) <strong>the</strong> tree(s)are go<strong>in</strong>g <strong>in</strong>to,” said Julie, “and <strong>the</strong>n give asound assessment of whe<strong>the</strong>r that particularspecies is capable of cop<strong>in</strong>g with <strong>the</strong> soil andaccompany<strong>in</strong>g environmental conditions.When you have worked ‘hands-on’ with treesyou know exactly what a particular speciescan do, can’t do and won’t do,” says Julie.She says <strong>the</strong> AA Technician’s Certificate willmake her better placed to obta<strong>in</strong> deeper<strong>in</strong>sights <strong>in</strong>to customers’ requests, ambitionsand aspirations for <strong>the</strong> trees <strong>the</strong>y purchaseand plant. Julie has an <strong>in</strong>terest <strong>in</strong> BS 5837and ‘trees and <strong>the</strong> law’. “It gives me a betterunderstand<strong>in</strong>g of my customers and <strong>the</strong>irrequirements,” she says. “The qualificationwill help me relate <strong>in</strong> a much better way withmy client base. I love my tree officer clientsand would not work with any o<strong>the</strong>r clientbase,” said Julie.Natasha Hutchison is responsible for ‘handson’organisation of <strong>Barcham</strong>’s technicalsem<strong>in</strong>ars but this is only a small part of herresponsibilities. She is sales executive to‘<strong>the</strong> trade’ and also has an adm<strong>in</strong>istrativefunction <strong>in</strong> <strong>the</strong> allocation of orders. Withten years’ service, Natasha also startedout <strong>in</strong> <strong>the</strong> nursery and moved gradually<strong>in</strong>to sales. “This certa<strong>in</strong>ly helped me,” saysNatasha. “Customers ask me about how toprune different species. With my experienceI can give <strong>the</strong>m a correct answer andreassure <strong>the</strong>m on exactly <strong>the</strong> size, shapeand dimensions of <strong>the</strong> canopy <strong>the</strong>y will get.

Clyde Seagrave on <strong>the</strong> nursery. Whitepots, 65-litre size.Close-up on a <strong>white</strong> pot show<strong>in</strong>gbiodegradable top with pull-tie, stitchedhandles and drip irrigation.Access<strong>in</strong>g trees via a prun<strong>in</strong>g platform. Lift<strong>in</strong>g trees for dispatch.Why we use <strong>white</strong> pots and slow releasefertiliser formulations are o<strong>the</strong>r frequentlyasked questions. Answers given providecrucial reassurance for customers that <strong>the</strong>yare gett<strong>in</strong>g a well-looked-after product,” shesays.Dispatch <strong>in</strong>side and outWesley Dyer (dispatch manager) and DavidSteedman (assistant dispatch manager)are sales team members ensur<strong>in</strong>g <strong>the</strong> righttrees get to <strong>the</strong> right customers <strong>in</strong> <strong>the</strong> rightcondition and as speedily as possible. Davidhas been with <strong>Barcham</strong> <strong>Trees</strong> s<strong>in</strong>ce 2002,always on dispatch but previously outsidelift<strong>in</strong>g orders and load<strong>in</strong>g vehicles, and<strong>the</strong>refore ano<strong>the</strong>r example of ‘bottom up’experience and skills.“I came <strong>in</strong>side <strong>in</strong> autumn/w<strong>in</strong>ter of 2008,”says David, “to be part of a two-man teamresponsible for organisation and logistics.This entails pick<strong>in</strong>g up orders on screen fromsales; l<strong>in</strong>k<strong>in</strong>g orders go<strong>in</strong>g to customers <strong>in</strong><strong>the</strong> same area of <strong>the</strong> country and <strong>the</strong>rebybuild<strong>in</strong>g up and consolidat<strong>in</strong>g loads;ensur<strong>in</strong>g that lorries have feasible loads <strong>in</strong>terms of volume on board, area with<strong>in</strong> which<strong>the</strong> load is delivered and <strong>the</strong> cost <strong>in</strong>volved,”he told us. “Dur<strong>in</strong>g <strong>the</strong> w<strong>in</strong>ter peak periodfive lift<strong>in</strong>g teams compris<strong>in</strong>g two men plusTom Howard, <strong>the</strong> overall team leader, arehard at work. Tom knows from experiencewhat trees, type, size and quantity can fit ona specific load. Both Wesley and I have <strong>the</strong>same k<strong>in</strong>d of background and experienceso we also know exact accommodationrequirements and limitations.” “For<strong>in</strong>stance,” says David,” <strong>the</strong> larger stuff won’tfit on rigid vehicles and we know exactlywhen to break down loads that will notfit <strong>in</strong>to a s<strong>in</strong>gle load. Understand<strong>in</strong>g andknow<strong>in</strong>g is down to first-hand experience,”he says.Direct<strong>in</strong>g operationsWendy Mears has three years’ service asPA to Warren Holmes Chatfield, <strong>Barcham</strong>’soperations director whose key role is buy<strong>in</strong>g<strong>in</strong> trees each season. “Warren,” saysWendy, “oversees <strong>the</strong> whole production areaat <strong>Barcham</strong> and also does human resourcesacross <strong>the</strong> entire company. This <strong>in</strong>cludeshir<strong>in</strong>g staff which <strong>in</strong>crease quite dramatically<strong>in</strong> September when temporary staff arrive onsix-month contracts. We have 50 full-timestaff but this goes up to 80 from Septemberwhen we start tak<strong>in</strong>g delivery of trees,<strong>in</strong>clud<strong>in</strong>g our own which are brought upfrom a separate field site. This is essentiallya replenishment period when we plant newstock,” she says.Sales kick-off <strong>in</strong> September and rema<strong>in</strong>buoyant through to April, cover<strong>in</strong>g <strong>the</strong> idealtree plant<strong>in</strong>g period. “Retail sales cont<strong>in</strong>ue toga<strong>in</strong> <strong>in</strong> importance,” says Wendy, “especiallys<strong>in</strong>ce <strong>the</strong> retail side of our bus<strong>in</strong>ess went live<strong>in</strong> <strong>the</strong> last 12 months with on-l<strong>in</strong>e sales.“<strong>Barcham</strong> is keen to do bus<strong>in</strong>ess with allmarket areas and sectors,” says Wendy,“and <strong>in</strong>creas<strong>in</strong>gly encourages people tobuy on l<strong>in</strong>e but with <strong>the</strong> facility to view<strong>the</strong> company’s range of products byappo<strong>in</strong>tment.” Wendy designed <strong>Barcham</strong>’ssystems for delivery of trees <strong>in</strong> conta<strong>in</strong>ersand <strong>in</strong>to <strong>the</strong> field.Strict quality controlMaureen (Mo) Palmer, quality controlmanager with over 12 years’ service,is responsible for <strong>in</strong>com<strong>in</strong>g stock andsupervis<strong>in</strong>g <strong>the</strong> grad<strong>in</strong>g team which checkstrees for quality and health as <strong>the</strong>y come<strong>in</strong>. Mo also accompanies Warren HolmesChatfield to select trees for purchase over<strong>the</strong> summer period. Supervision of <strong>the</strong>prun<strong>in</strong>g team, prioritis<strong>in</strong>g prun<strong>in</strong>g workrequired throughout <strong>the</strong> year and yearroundcheck<strong>in</strong>g of stock for <strong>in</strong>sect andmite pests, diseases, w<strong>in</strong>d damage andnutrient deficiency symptoms are additionalresponsibilities assigned to Mo.“International arrivals demand particularlystr<strong>in</strong>gent health checks,” says Mo. For<strong>in</strong>stance, trees arriv<strong>in</strong>g from <strong>the</strong> United Statesrequire a DEFRA plant quarant<strong>in</strong>e officer <strong>in</strong>attendance and he/she will check both soiland tree. “Many people do not appreciatethat a conta<strong>in</strong>erised tree is actually a ‘m<strong>in</strong>iecosystem’and needs to be considered andtreated accord<strong>in</strong>gly,” Mo told us.The pott<strong>in</strong>g mach<strong>in</strong>eClyde Seagrave, with 13 years’ service anda profound understand<strong>in</strong>g of operationalactivities right across <strong>the</strong> nursery site, clearlyknows <strong>Barcham</strong> <strong>in</strong>side out.Clyde gave us a tour of <strong>the</strong> nursery site andbegan by expla<strong>in</strong><strong>in</strong>g how <strong>the</strong> trees arrive onsite from outside or <strong>Barcham</strong>’s own separatefield nursery. “Incom<strong>in</strong>g trees are prepared<strong>in</strong> <strong>the</strong> shed by Mo Palmer’s gangs,” saidClyde. “They are <strong>in</strong>spected for shape andhealth. Anyth<strong>in</strong>g we are not happy with isrejected. It is better to start out right than todiscover you have a bent or deteriorat<strong>in</strong>gtree six months down <strong>the</strong> l<strong>in</strong>e.”Prepared trees are placed <strong>in</strong> ‘stillages’,custom-designed mobile steel pallets thatprovide support for <strong>the</strong> trees as <strong>the</strong>y aremoved for load<strong>in</strong>g up on <strong>the</strong> bespokepott<strong>in</strong>g mach<strong>in</strong>e. “When I first came to<strong>Barcham</strong> everyth<strong>in</strong>g was potted outside <strong>in</strong>all wea<strong>the</strong>rs,” said Clyde, “but more speedand greater efficiency was needed whichcould only come from mechanisation. Theproposed mach<strong>in</strong>e was put out to tenderand <strong>the</strong> result is our unique mach<strong>in</strong>e. Butthis is more than a mach<strong>in</strong>e,” says Clyde,“with stillages and conveyors it is a system. Itwill prune roots to whatever size <strong>white</strong> pot isrequired, ma<strong>in</strong>ly 45-litre and 65-litre pots,”he said. The system looked complicated but<strong>in</strong> essence is logical and sequential. Theempty pot starts off <strong>in</strong> one corner and comesalong <strong>the</strong> conveyor where it meets up with<strong>the</strong> tree held by a clamp. Tree and pot arel<strong>in</strong>ed up and <strong>the</strong> tree let down to plant<strong>in</strong>glevel <strong>in</strong> <strong>the</strong> pot. The pot is filled up withcompost and settled <strong>in</strong> <strong>the</strong> <strong>bag</strong> by a vibrat<strong>in</strong>gplate. The tree, now secure, is released by<strong>the</strong> clamp and a label attached. Tractors andtrailers remove <strong>the</strong> conta<strong>in</strong>erised trees.This is a highly <strong>in</strong>tegrated operation workedby 10 casuals <strong>in</strong> w<strong>in</strong>ter start<strong>in</strong>g at <strong>the</strong> endof November and f<strong>in</strong>ish<strong>in</strong>g by <strong>the</strong> end ofMarch. It pots between 40,000 and 45,000trees a year dur<strong>in</strong>g this period. Some 20,000to 25,000 trees are still potted outside,ma<strong>in</strong>ly <strong>the</strong> bigger trees which are too big for<strong>the</strong> system to handle.‘In <strong>the</strong> <strong>bag</strong>’Visitors are confronted with avenue afteravenue of potted trees represent<strong>in</strong>g almostevery temperate species imag<strong>in</strong>able, plusa good few that have seen warmer places.There are 430 species and varieties on thissite represent<strong>in</strong>g broadleaves, conifers, bothnative and exotic, and even palms.<strong>Barcham</strong> went for <strong>white</strong> <strong>bag</strong>s at a time whenmost o<strong>the</strong>r nurseries were still us<strong>in</strong>g rigidblack plastic pots. “The key po<strong>in</strong>ts mak<strong>in</strong>g<strong>white</strong> <strong>bag</strong>s’ volumes better than black rigidpots are related to heat, light and water<strong>in</strong>g,”said Clyde. He expla<strong>in</strong>ed how tree rootsgrow<strong>in</strong>g <strong>in</strong> black pots grow to <strong>the</strong> edge onlyto be forced left or right to subsequentlyproduce a circular root ball. “This is why wefavour <strong>white</strong> <strong>bag</strong>s,” says Clyde.The <strong>white</strong> <strong>bag</strong> lets a certa<strong>in</strong> amount of lightthrough and tree roots, be<strong>in</strong>g negativelyphototropic, retreat from <strong>the</strong> edge and turnback <strong>in</strong>to <strong>the</strong> compost with m<strong>in</strong>imal spirall<strong>in</strong>gand no root ball. <strong>Trees</strong> are immediatelyready for customer plant<strong>in</strong>g without any root31

Features: <strong>Barcham</strong> <strong>Trees</strong> <strong>in</strong> <strong>the</strong> White Bagprun<strong>in</strong>g necessary.All <strong>white</strong> <strong>bag</strong>s used by <strong>Barcham</strong> have abiodegradable top with a pull tie, whichcovers <strong>the</strong> soil compost surface to m<strong>in</strong>imiseevaporation and exclude weeds, and a pairof stitched handles. Landscapers value thisfeature as it means two guys can walk a longway carry<strong>in</strong>g a heavy potted tree.Fertigation – <strong>in</strong>tegratedirrigation and fertilisationEach tree <strong>in</strong> every l<strong>in</strong>e is l<strong>in</strong>ked up to anautomated water<strong>in</strong>g system based on atrickle (drip) design and micro-irrigation.Each potted tree has a four-spike dripmanifold and when <strong>the</strong> water comes onautomatically it simply drips <strong>in</strong>to <strong>the</strong> pot. Wewere <strong>the</strong>re dur<strong>in</strong>g <strong>the</strong> late spr<strong>in</strong>g droughtwhen <strong>the</strong> water was com<strong>in</strong>g on three timesa day, each cycle deliver<strong>in</strong>g 0.75 litres togive a total per tree application of 2.25 litresper day. “If this very dry wea<strong>the</strong>r persists wemight have to <strong>in</strong>crease <strong>the</strong> number of cyclesto four to give each tree three litres per day,”said Clyde.There are six pump<strong>in</strong>g stations across <strong>the</strong>200-acre nursery site. Each pump<strong>in</strong>g stationfeatures an electronic control system. Theoperator simply taps <strong>in</strong> numbers on a controlpanel to determ<strong>in</strong>e <strong>the</strong> irrigation tim<strong>in</strong>gcycle. No turn<strong>in</strong>g on of taps at <strong>Barcham</strong>.Outside each station is a 24,000-gallonwater storage tank and <strong>in</strong>side a 100-litreThere are a number of arboriculturalists who are officially retired butstill active <strong>in</strong> <strong>the</strong> field and to whom UK <strong>in</strong>dustry owes a great deal.Pete Wells, founder of <strong>Barcham</strong> <strong>Trees</strong>, is one of <strong>the</strong>se. Pete started outas a tree contractor fell<strong>in</strong>g diseased elms across ‘Constable Country’(East Anglia). “English elms were sometimes <strong>the</strong> only natural treesgrow<strong>in</strong>g <strong>in</strong> neat Fenland fieldsand, not want<strong>in</strong>g dy<strong>in</strong>g trees <strong>in</strong><strong>the</strong> corners of <strong>the</strong>ir fields, farmerswere eager to have <strong>the</strong>m felled,”says Pete. They soon realised <strong>the</strong>yneeded someth<strong>in</strong>g to replace<strong>the</strong>m and this is where Pete came<strong>in</strong>, fell<strong>in</strong>g <strong>the</strong> diseased elms andplant<strong>in</strong>g native trees as required.“I was already rais<strong>in</strong>g Englishoak, common ash and field maplefrom seed, ma<strong>in</strong>ly for motorwayplant<strong>in</strong>g,” says Pete. He eventuallybegan to w<strong>in</strong> county councilcontracts, and was soon plant<strong>in</strong>gnative trees, <strong>in</strong>clud<strong>in</strong>g hazel andguelder rose, across virtually everyparish council <strong>in</strong> Norfolk, Suffolkand Cambridgeshire.“What really prompted meto concentrate on <strong>in</strong>ner cityra<strong>the</strong>r than rural landscapes was<strong>the</strong> purchase of trees by localauthorities from a bus<strong>in</strong>ess perspective. They are not strapped forcash, place big orders and are prompt payers,” he said. “As <strong>Barcham</strong>developed, I became aware that <strong>the</strong> urban forest was vital to <strong>the</strong>human race. People now live <strong>in</strong> towns and cities and that’s where<strong>the</strong> tree men must grow <strong>the</strong>ir trees. It’s become a mission, ‘trees andpeople’.”Local authorities were purchas<strong>in</strong>g and plant<strong>in</strong>g a lot of trees butviability was not good. Pete believes a lot of material was com<strong>in</strong>g <strong>in</strong>from <strong>the</strong> cont<strong>in</strong>ent. The arrival and plant<strong>in</strong>g of foreign provenances<strong>in</strong> British native trees was a brisk trade go<strong>in</strong>g on for a lot longer than32tank for mix<strong>in</strong>g a N:P:K 27-7-22 pluscomplete trace elements water-solublefertiliser formulation <strong>in</strong>to <strong>the</strong> irrigationwater. “This is a general feed,” says Clyde,“provid<strong>in</strong>g all th<strong>in</strong>gs to all trees given <strong>the</strong>huge variety of trees on site.”The Dosatron pump<strong>in</strong>g mechanism poursmixed liquid fertiliser feed <strong>in</strong>to <strong>the</strong> 100-litrewater tank to provide <strong>the</strong> exact concentrationfor application to potted trees. Thoughreferred to as an irrigation system this is <strong>in</strong>fact a highly sophisticated form of fertigation.<strong>Barcham</strong> has built two reservoirs with naturalclay l<strong>in</strong><strong>in</strong>g each hold<strong>in</strong>g n<strong>in</strong>e million gallonsof water. Alongside is a m<strong>in</strong>i water treatmentplant with water pass<strong>in</strong>g through sand filters.Chlor<strong>in</strong>e is added for dis<strong>in</strong>fection to keep <strong>the</strong>pipework clean of bacteria, algae and watermould growth. The whole water storage andtreatment complex is located alongside oneof <strong>the</strong> natural dra<strong>in</strong> dykes that criss-cross <strong>the</strong>Fens.<strong>Barcham</strong> has got a ‘W<strong>in</strong>ter ExtractionLicence’ through <strong>the</strong> Environment Agencyto fill up <strong>the</strong> reservoirs dur<strong>in</strong>g w<strong>in</strong>ter. Waterfrom <strong>the</strong> reservoir goes <strong>in</strong>to <strong>the</strong> treatmentsand filter and receives chlor<strong>in</strong>e before go<strong>in</strong>g<strong>in</strong>to a 36,000-gallon hold<strong>in</strong>g tank to supply<strong>the</strong> six pump<strong>in</strong>g stations around <strong>the</strong> nurserysite. We met Trevor Layton, <strong>Barcham</strong>’s‘Irrigation Man’ employed full-time onirrigation operations from March to Octoberand on ma<strong>in</strong>tenance work dur<strong>in</strong>g w<strong>in</strong>ter.In addition to be<strong>in</strong>g a sound and susta<strong>in</strong>ablefeat <strong>in</strong> horticultural eng<strong>in</strong>eer<strong>in</strong>g <strong>the</strong> reservoircomplex is an important habitat for wildlifeespecially waterfowl. Also lapw<strong>in</strong>gs, groundnest<strong>in</strong>gbirds <strong>in</strong>creas<strong>in</strong>gly rare <strong>in</strong> o<strong>the</strong>r partsof <strong>the</strong> country, apparently nest with abandon<strong>in</strong> <strong>the</strong> fields around <strong>the</strong> reservoirs.Dr Terry MabbettPete Wells – <strong>the</strong> founder of <strong>Barcham</strong> treesPete Wells (left) pictured here with Liz Wood, Tree Officer (Operations) atThurrock Borough Council, <strong>in</strong>side Coalhouse Fort at Tilbury with a 135- to 140-year old black poplar pollard. Pete is <strong>in</strong>strumental <strong>in</strong> preserv<strong>in</strong>g this provenanceby tak<strong>in</strong>g cutt<strong>in</strong>gs to propagate new trees (essentialARB, 32, 34 and 36).Maureen Palmer is <strong>in</strong> charge of quality control.Seen here with Liquid Amber.The electronically controlled irrigation system isoperated by tapp<strong>in</strong>g numbers <strong>in</strong>to a control panel.most people realise. Pete says a breakdown of trad<strong>in</strong>g carried out byCranfield University showed how <strong>the</strong> UK had been a net importer oftrees, mostly from <strong>the</strong> Ne<strong>the</strong>rlands and Italy, for a very long time.It was from <strong>the</strong>se problems responsible for poor tree survival thatPete came up with his orig<strong>in</strong>al concept of <strong>the</strong> ‘entire tree’, a conta<strong>in</strong>ergrownspecimen with a completeand unprejudiced root system.He selected <strong>the</strong> ‘<strong>white</strong> <strong>bag</strong>’ asperform<strong>in</strong>g <strong>the</strong> dual function ofpackag<strong>in</strong>g for tree transportationas well as a vessel <strong>in</strong> which <strong>the</strong>tree can grow. “This ready-made‘pack and wrap’ system preventsa lot of <strong>the</strong> physical damage thatcan o<strong>the</strong>rwise occur <strong>in</strong> <strong>the</strong> treepurchaser’s yard,” says Pete,”especially s<strong>in</strong>ce <strong>the</strong> days are gonewhen local authorities employed<strong>the</strong>ir own specialist workers tohandle trees. They now hire casuallabourers and with trees safelyand securely <strong>in</strong>side a grow<strong>in</strong>gvessel (<strong>the</strong> <strong>white</strong> <strong>bag</strong>) you don’teven have to cover up and protecttrees dur<strong>in</strong>g transit as you did withbare-root material,” he says. Petebemoans this well-establishedtrend towards contractors at <strong>the</strong>expense of <strong>in</strong>-house craft skills with<strong>in</strong> local authorities. “They claim <strong>the</strong>switch is all about sav<strong>in</strong>g money but much bigger costs are <strong>in</strong>curredfur<strong>the</strong>r down <strong>the</strong> l<strong>in</strong>e,” he says.These f<strong>in</strong>al comments cast me back to summer vacations <strong>in</strong> <strong>the</strong>1960s, work<strong>in</strong>g for my local authority as an assistant groundsman andpark-keeper alongside George Haynes, a First World War Veteranfrom <strong>the</strong> Battle of The Somme and already past official retirement age.I recall prick<strong>in</strong>g out wallflower seedl<strong>in</strong>gs <strong>in</strong> August 1968 alongsideGeorge <strong>in</strong> a greenhouse complex beh<strong>in</strong>d <strong>the</strong> council offices fromwhere he would provide every s<strong>in</strong>gle bedd<strong>in</strong>g plant for <strong>the</strong> town.