Beru Glow Plugs - W124 Performance

Beru Glow Plugs - W124 Performance Beru Glow Plugs - W124 Performance

Causes for sheathed glow plug failureThe cause of a sheathed glow plug failure can often beidentified at the heating element. A heating elementshowing signs of melting indicates for example an injectionfault or a so called oil puller. Damage of this kindcannot be attributed to a defective glow plug.As the injection fault example shows, to simply replacethe defective glow plug is not sufficient; the cause of thedamage must also be rectified. The following illustrationsshow typical plug damage and the various causes.This diagnosis aid will in most cases enable faults to bequickly rectified.Wrinkled and dented heating elementsCauses:Filament open-circuit due to:a) operation at excessive voltage, e.g. when jump startingb) power supplied too long due to a sticking relayc) incorrect post-heating with engine runningd) post-heating glow plugs not usedRemedial action:a) jump start only with 12V vehicle systemb) and c) test the pre-heating system,replace glow timer relayd) install post-heating glow plugs– not a glow plug warranty case –6

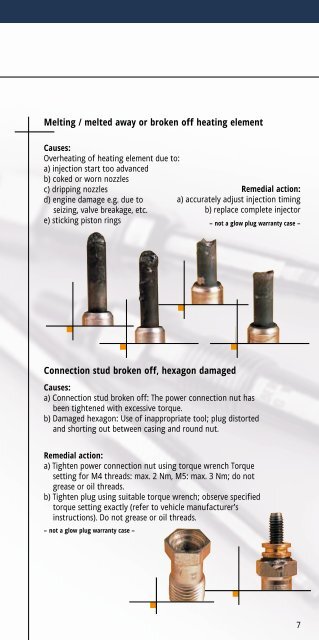

Melting / melted away or broken off heating elementCauses:Overheating of heating element due to:a) injection start too advancedb) coked or worn nozzlesc) dripping nozzlesd) engine damage e.g. due toseizing, valve breakage, etc.e) sticking piston ringsRemedial action:a) accurately adjust injection timingb) replace complete injector– not a glow plug warranty case –Connection stud broken off, hexagon damagedCauses:a) Connection stud broken off: The power connection nut hasbeen tightened with excessive torque.b) Damaged hexagon: Use of inappropriate tool; plug distortedand shorting out between casing and round nut.Remedial action:a) Tighten power connection nut using torque wrench Torquesetting for M4 threads: max. 2 Nm, M5: max. 3 Nm; do notgrease or oil threads.b) Tighten plug using suitable torque wrench; observe specifiedtorque setting exactly (refer to vehicle manufacturer’sinstructions). Do not grease or oil threads.– not a glow plug warranty case –7

- Page 1 and 2: Beru glow plugsMaking your diesel s

- Page 3 and 4: a modern glow plug?The Beru glow pl

- Page 5: Which diesels can be retrofitted?Th

- Page 9 and 10: The construction of a pencil-type g

- Page 11 and 12: 3.) Power connection nuts must be t

- Page 13 and 14: Glow plug body manufactureGlow tube

Melting / melted away or broken off heating elementCauses:Overheating of heating element due to:a) injection start too advancedb) coked or worn nozzlesc) dripping nozzlesd) engine damage e.g. due toseizing, valve breakage, etc.e) sticking piston ringsRemedial action:a) accurately adjust injection timingb) replace complete injector– not a glow plug warranty case –Connection stud broken off, hexagon damagedCauses:a) Connection stud broken off: The power connection nut hasbeen tightened with excessive torque.b) Damaged hexagon: Use of inappropriate tool; plug distortedand shorting out between casing and round nut.Remedial action:a) Tighten power connection nut using torque wrench Torquesetting for M4 threads: max. 2 Nm, M5: max. 3 Nm; do notgrease or oil threads.b) Tighten plug using suitable torque wrench; observe specifiedtorque setting exactly (refer to vehicle manufacturer’sinstructions). Do not grease or oil threads.– not a glow plug warranty case –7