Asahi Kasei Plastics North America Inc. Xyron® G701V ... - Promaplast

Asahi Kasei Plastics North America Inc. Xyron® G701V ... - Promaplast

Asahi Kasei Plastics North America Inc. Xyron® G701V ... - Promaplast

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

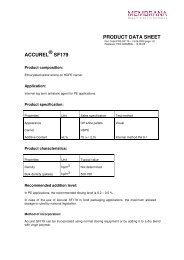

Xyron® <strong>G701V</strong><strong>Asahi</strong> <strong>Kasei</strong> <strong>Plastics</strong> <strong>North</strong> <strong>America</strong> <strong>Inc</strong>. - Polyphenylene Ether + PSActionsThursday, May 22, 2008Unit System: EnglishLegend (Open)GeneralMaterial StatusAvailabilityFiller / ReinforcementFeaturesUsesFormsProcessing MethodGeneral InformationCommercial: Active<strong>North</strong> <strong>America</strong>Glass fiber reinforcement, 10 % Filler by WeightFlame RetardantElectrical/Electronic ApplicationsPelletsInjection MoldingASTM and ISO Properties 1Physical Nominal Value Unit Test MethodSpecific Gravity 1.15 ASTM D792Density 1.15 g/cm³ ISO 1183Molding Shrink (Flow) 0.30 to 0.50 % ASTM D955Water Absorption (24 hr, 73 °F) 0.060 % ASTM D570Water Absorption (73 °F, 24 hr) 0.060 % ISO 62Mechanical Nominal Value Unit Test MethodTensile Strength (73 °F) 11300 psi ASTM D638Tensile Stress (Yield, 73 °F) 11300 psi ISO 527-1, -2Tensile Elongation (Break, 73 °F) 5.0 % ASTM D638Tensile Strain (Break, 73 °F) 3.0 % ISO 527-1, -2Flexural Modulus (73 °F) 569000 psi ASTM D790Flexural Modulus (73 °F) 550000 psi ISO 178Flexural Strength (73 °F) 18400 psi ASTM D790Flexural Strength (73 °F) 20000 psi ISO 178Impact Nominal Value Unit Test MethodCharpy Notched Impact Strength (73 °F) 4.76 ft·lb/in² ISO 179/1Notched Izod Impact ASTM D256(73 °F, 0.126 in) 2.21 ft·lb/in(73 °F, 0.252 in) 1.84 ft·lb/inThermal Nominal Value Unit Test MethodDeflection Temperature Under Load (264 psi, Unannealed) 266 °F ASTM D648Heat Deflection Temperature (264 psi, Unannealed) 262 °F ISO 75A-1, -2CLTE, Flow (-30°C to 65°C) 0.000028 in/in/°F ASTM D696Coefficient of Linear Thermal Expansion, Flow (-30°C to 65°C) 0.000028 in/in/°F ISO 11359-1, -2Electrical Nominal Value Unit Test MethodSurface Resistivity 1.0E+16 ohms ASTM D257Surface Resistivity 1.0E+16 ohms IEC 60093Volume Resistivity 1.0E+16 ohm·cm ASTM D257Volume Resistivity 1.0E+16 ohm·cm IEC 60093Dielectric Strength 2 (0.0787 in) 1040 V/mil ASTM D149Dielectric Constant ASTM D150(60 Hz) 3.000

(1E+6 Hz) 3.000Dielectric Constant IEC 60250(100 Hz) 3.000(1E+6 Hz) 3.000Dissipation Factor ASTM D150(60 Hz) 0.0020(1E+6 Hz) 0.0030Dissipation Factor IEC 60250(100 Hz) 0.00200(1E+6 Hz) 0.00300Arc Resistance 70.0 sec ASTM D495Comparative Tracking Index (0.118 in) 400 V IEC 60112Electric Strength (0.0787 in) 1000 V/mil IEC 60243-1Flammability Nominal Value Unit Test MethodFlame Rating - UL UL 94(0.0630 in) V-1(0.126 in) V-1Additional PropertiesThe value listed as Mold Shrinkage, was tested in accordance with <strong>Asahi</strong> <strong>Kasei</strong> method.Processing InformationInjection Nominal Value UnitDrying Temperature 175 to 195 °FDrying Time 2.0 to 4.0 hrDrying Time, Maximum 8.0 hrSuggested Max Regrind 20 %Rear Temperature 430 to 500 °FMiddle Temperature 435 to 510 °FFront Temperature 445 to 520 °FNozzle Temperature 445 to 520 °FMold Temperature 120 to 180 °FVent Depth 0.0012 to 0.0020 inInjection NotesScrew Type: General PurposeNozzle Tip: General PurposeMax. spiral flow distance: 2mm=17 in. 3mm=21 in.Vent width: 5.0 to 10 mmBoss Venting - Clearance at pin: 0.03 to 0.05 mmBoss Venting - Clearance at sleeve: 0.5 to 1 mmSpecial considerations: If splay is noticed, check melt temperature and moisture content of the material. If the splay is shaped like a U, it couldbe material that is not molten.1 Typical properties: these are not to be construed as specifications.2 Method A (Short-Time)NotesCopyright © 2008 IDES - The <strong>Plastics</strong> Web®The information presented on this data sheet was acquired by IDES from the producer of the material. IDES makes substantial efforts toassure the accuracy of this data. However, IDES assumes no responsibility for the data values and strongly encourages that upon finalmaterial selection, data points are validated with the material supplier.