Un ed States Patent

Un ed States Patent

Un ed States Patent

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

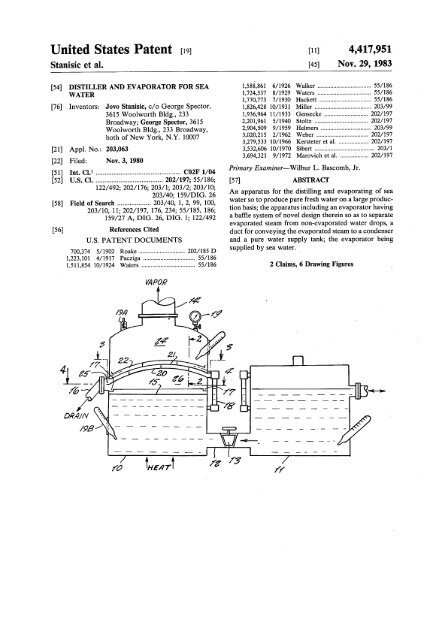

<strong>Un</strong> <strong>ed</strong> <strong>States</strong> <strong>Patent</strong>S~c et al.Ill] 4,417,951~ Nov. 2~ 1983[54] DISTILLER AND EVAPORATOR FOR SEA I~8~861 6/1926 Walker ...............................55/186WATER1fl2~5378/1929Waters...............................55/1861fl7~7737/1930Hackett..............................55/186[76] Inventors: Jovo Stani~ c/o George SpectoL 1~2~42810/193! Miller ...............................203/993615 Woolworth Bldg., 2331)3~96411/1933Gensecke............................202/197Broadway; George Spectoh 3615~201~61 5/1940Stoltz...............................202/197Woolworth Bldg., 233 Broadway, ~90~509 9/1959Helmers..............................203/99both of New York, N.Y. 100073~2~215 2/1962Weber...............................202/1973,279,533 10/1966Kersteteret al ....................202/197[21]Appl. No.: 20a,0633,532,606 10/1970Sibert...............................203/1~69~3219/1972Marovichet al ...................202/197[22] Fil<strong>ed</strong>: Nov. 3, 1980Prima~ Examiner--Wilb~ L. B~com~ J~[51] InL Cl) ................................................C02F 1/04[52] U.S. Cl .......................................202/197; 55/18~ABSTRACT122/492; 202/17~ 203/1; 203/2; 203/10;An appar~us ~r the ~stilhng and evap~ating of sea203/40; 159/DIG. 26water so ~ produce pu~ ff~h w~er on a large produ~[58] Field of Search ................... 203/40, 1, 2, 99, 100,fion bails; the appar~us ~u~ng an evapor~or hav~g203/10, 11; 202/197, 17~ 234; 55/185, 18~159/27 A, DIG. 2~ DIG. I; 122/492a ba~e sy~em of novd defign ther~n so as to separateevapor~<strong>ed</strong> steam from nomevapor~<strong>ed</strong> water drop~ a[56] References Cit<strong>ed</strong>du~ ~r conve~ng the evapom~d ~eam ~ a conden~rU.S. PATENT DOCUMENTSand a pure water sup~y ~n~ the evapor~or bring700~74 5/1902 Roake .............................202/185 Dsupp<strong>ed</strong> by ~a w~e~1~2~I01 4/1917 Pac~ga .................................55/1861,511,854 10/1924 W~ers ..................................55/1864

U.S. <strong>Patent</strong>Nov. 29, 1983 4,417,951

4,417,951DISTILLER AND EVAPORATORFOR S~drMns water from the evapormor when ff~becomesheavily saturat<strong>ed</strong> with brin~ Another drainpipe 16 withWATER ’ a colMction canM 17 ~ a ring plme 15 colMc~ nonevaporM<strong>ed</strong>brine water droplets. ~ :T~s ~vem~n r~es g~em~y m eq~pmem ~r ~e 5 The evaporator ~ provid<strong>ed</strong> wffh a water Mv~ gauge~ation and ~~ ~ ~a w~ ¯ 18, vacuum gauge 1~ a manom~er 19A and a s~om~It h wall known that ~th inc~as~g ~p~ the~ te~ , ~ ....is an ~c~g ~n~m~ of drin~ng w~er, and In the evaporator, the steam space 24 g ~NMd withwkh a g~ ~fi~z~o~ ~e ~ a h~ amoum baffles 2~,21 and 22, for the evapora~d ~eam. The10 purpose of the baffles N to separNevaporat<strong>ed</strong> steamof pure water ~q~d ~ various en~rg<strong>ed</strong> and newph~es of manu~ufing W~u~. Accor~n~% ~om non-evapor~<strong>ed</strong> water drops wh~h are not asthere ~ ~ a more ne<strong>ed</strong> to find other sources of jet-pure as distilMd ~eam. Each baffle 2~ and 21 aspu~ w~ than ~ pr~enfly b~ng o~n<strong>ed</strong> from ~k~, shown in FIG. 2, has ope~ngs 23 of diffuser shape.rivers and the 1~ pa~u~fly ~ ~ew that more and Such diffuser-shap<strong>ed</strong> openings acc~r~e the separ~nmore of k ~ ~ p~l~<strong>ed</strong> due to chem~s of l~ of saturat<strong>ed</strong> ~eam. The last component baffle 22 forms~du~ and w~te of mod~n ~v~g b~ng dump<strong>ed</strong>~ d~oy~g the n~ur~ puny of such waterbo~. It i~ ~e~, n~ur~ ~ a~enfion ~ nowa Nst barrier for non~vaporat<strong>ed</strong> water drops and fordisti~<strong>ed</strong> geam before entering steam space 2& Thebaffle surNce N equM ~ area to the ~Nde transverseb~ng ~ven to obt~n pur~ flesh w~ o~ of s~y ~a area of the evapor~or, and is arcuate for more effectivew~ ~ ~ me~ ~e p~nt day ~q~me~s. In ~me 20 separ~ion of distill<strong>ed</strong> ~eam. The lowermo~ baffle 2~countries flesh water ~ ration<strong>ed</strong> pa~afly ~ dry or has the Nrge~ surNc~ and on ~s peripherN <strong>ed</strong>ge has ahot season~colMcting vault 25 in which non-evapor~<strong>ed</strong> waterAccor~n~ ~ ~ a prin~p~ o~e~ of the w~em drops colMct and are convey<strong>ed</strong> to the drNn canM 17 ~~vem~n ~ prov~e an ~W~ ~s~Mr and evapor~tot ~r converting sea w~ ~ pure ff~h w~. 25 througri hng plat~h~5~iffuseE rVap°ratesh dape~teao mpeNnf~s°m2;reaand2~hePnAnther o~e~ h to pin,de a distiller and evaporator~r ~a w~ w~ch ~ one pa~uhr deign can be ~g coupe and b~ng partly dives~d of water drop~#nge on the second component baffle 21 while changus<strong>ed</strong>aboard a sh~ whe~ ~ t~s time there ~ a gre~ After g~ng through the openings 23 of the secondwa~e of he~ by ~e exhau~ g~ of ~e large en~n~baffle 21 pure steam and non-evaporat<strong>ed</strong> water dropspas~ng out of the s~p ~nnd and ~to the ~mosphe~, 30 are separ~<strong>ed</strong>, the pure ~eam then Maving ~eam spaceand wh~n t~s w~d heat ~ the ~nnd can be h~ness<strong>ed</strong>to produce ~ of the s~s ~q~mem of ~h24 through outlet pipe 14 to the condenseLTwo or more baffles ~ a same evapormor may bewater during an ocean voyag~ ~t any ad~fion~expens~ The ~a w~ us<strong>ed</strong> ~ co~ ~e en~n~ can beemploye~ as may be req~r<strong>ed</strong> for ma~mum effect.us<strong>ed</strong> as ~ ~ ~ready p~e~<strong>ed</strong> ~ to 45 degrees cen~ 35 In FIG. ~ a mottle design of ~ffuser opening 23 ~grad~ so it ~ ready ~r ~o~n.provid<strong>ed</strong> by a diffuser 30 of Venturi shape wffh dectriccontac~ 31 and 32 on 0ppo~te ~des so thin ~rge w~erO~ o~ec~ are to pro~de a distiller and evaporator~r ~a w~ w~ch ~ ~m~e in deign, inexpensiv<strong>ed</strong>rops entering the same will dose an dectric~c~t~ manu~ rugg<strong>ed</strong> in con~ru~ easy to use andthat will thus cause a spark thin will vaporize the w~ereffl~em ~ ~.40 drop. Thus preventing water drop passage therethrough.Contact 31 ~ ~ationary whim contact 32 isThese and ~~s ~1 be ready e~dem upona ~udy of the ~l~w~g ~e~fic~n and the accomp~ slidable closer ~her~o where ~eam pre~ure ~de arean~ng ~a~ wh~n26 is increas<strong>ed</strong>, at wh~h time there are Mrger concentrationof w~er drops so that they must be vaporiz<strong>ed</strong>.FIG. 1 ~ a ~mmm~c ~de vMw of a sy~em of the~em ~venfion.45 T~s ~ accomplish<strong>ed</strong> by a hollow accordian shap<strong>ed</strong>,FIG. 2 ~ an e~g<strong>ed</strong> det~ ~ cross section of ~e expandable case 33 interconnect<strong>ed</strong> to area 2~ andim~r baffle co~u~n ~e ~o~ t~ ~ong which pushes a #votabM lever 34 connect<strong>ed</strong> to slide 35section 2--2 of FIG. 1.which carries contact 32.FIG. 3 ~ a ~p ~ew ~ ~e baffle con~rucfion ~de While various changes may be made in the d~ilthe evapor~o~ as ~ew<strong>ed</strong> ~ direction 3--3 of FIG. 1. 50 construction, ff ~ unde~tood that such changes will beFIG. 4 ~ a cross secfion~ew on fi~ 4--4 of FIG. within the s#rit and scope of the present ~vention as ~1. defin<strong>ed</strong> by the append<strong>ed</strong>Mms.FIG. 5 is an e~g<strong>ed</strong> cross secfion~ ~ew on fine The following ~ dMme~5--5 of FI~ ~ ~o~ a peripher~ dr~nage can~. 1. A Sea water distiller comprising a sea w~er supplyFIG. 6 ~ a mo~ficafion of the ~venfion show~g a 55 tank connect<strong>ed</strong> by a conduito the bottom of an evaporatorwith heating mean~ ~duding a ring plmecross section ~rough a mottl<strong>ed</strong> ~se~. The proem ~vent~n is ~own ~ FIG. 1 to ~ude mount<strong>ed</strong> around the ~de periphery of sMd evaporatoran evapor~or 10 and a sea water sup~y water tank 11 at a pr<strong>ed</strong>~erm~<strong>ed</strong> levd, s~d ring pl~e ~u~ng aw~ch are ~onne~<strong>ed</strong> by a sup~y ~pe 12 ha~ng a pefipher~ dr~nage can~ ~ com~nation with a pluralsup~yv~ve 1~ w~ch ~ a~om~c~y ~g~<strong>ed</strong> by 60 Ry of spac<strong>ed</strong> venally curvate baffles above s~d pl~¯ e water Mvd ~t~n the evaporato~ The ~p of the the lowermo~ of s~d baffles having a peripher~ <strong>ed</strong>geevapor~or ~ connect<strong>ed</strong> w~h a condenser ~ot show~ portion<strong>ed</strong> above and l~er~ly adjacent s~d can~by a ~pe 14 ~r ~u~ ~o~ steam ~to ~econdenser whe~ a vacuum ~ o~n<strong>ed</strong> by vacuum ~e~whereby moi~ure ~ direct<strong>ed</strong> and dron<strong>ed</strong> from s~dbaffle to s~d can~, ~ fu~her combination with a dr~ntor~~ ~ow~. Condens<strong>ed</strong> water from a condens<strong>ed</strong>65 age pipe having an inl~ ~ commu~c~n wffh s~dsuction pump ~ show~ ~k~ wa~r and discharges k~ drin~ng w~er mn~ ~ ~ow~. A dr~n ~pe ~show~ ~ the b~mm of the evapor~or periodicallycanM for drayage purposes, sMd baffles having upwardorient<strong>ed</strong> diffusers and an upper solid baffle superimpos<strong>ed</strong>over sMd baffles with the diffuser~ sMd upper2

3baffle having an outer <strong>ed</strong>ge spac<strong>ed</strong> from evaporator~ner sur~ce whereby deflect<strong>ed</strong> ~eam vapor ~ direc~dpefipher~ly to the s~d <strong>ed</strong>ge and to a ~eam space aboves~d upper baffle ~duding a ~eam outlet above s~d~eam space wheron s~d diffusers ~duding means forvafia~y restrict~g water drops from pas~ng therethroughcompiling a Vemufi sect~n in s~d diffusers4,417,9514wi~ O~c~ m~ns ~ ~e Ve~ufi ~n ~r v~ofiz-~g water drops upon con~ of sa~ de~fic~ meanswith water drop~2. A ~sfil~r ~ ~ clam 1 wh~n s~d de~fic~means include ~e~fic con~ vafia~y spac<strong>ed</strong> respon-~ve to steam pressure.10152o253O355055

<strong>Un</strong> <strong>ed</strong> <strong>States</strong> <strong>Patent</strong>EII~ J~Ill]<strong>Patent</strong> Number:~ Date of PatenUWATER DEGASIFICATION AND3,479,949 11/1969Reynoldset al ......................99/295DISTILLATION APPARATUSL53L60610/1970Sibert...............................202/180L83E016 9/1974Powers...............................~ Invento~202/181John ~ EIH~ J~ 1084 P~m~ Ave, L935,0771/1976Dennison............................202/180LarchmonL N.Y. 10538~081~31 3/1978Weiss................................202/181~1] Ap~. N~: 48~767~13L984 1/1979Kirschmann..........................202/83~17~84212/1979Vitous...............................99/295~ ~l<strong>ed</strong>: Ap~ 2~ 1983~18~150 2/1980Rich............................203/DIG. 16~24L369 1/1981Bean................................202/181Rd~<strong>ed</strong> ~ A~ ~~25~616 2/1981Glazer...............................202/181~261fl964/1981Lemoine.............................202/181C~u~a~ ~ ~ No. 26~88~ Ju~ 3, 1981, ~269~63 5/1981McFee................................202/202Pa~ N~ ~3~.~41~95111/1983Stanisicet al .......................202/197~42~37412/1983Ellis................................202/176~1] InL ~? ...........................B01D 3/0~ ~2F 1~[5~ ~ ~ .....................................~ 202/18~FOREIGN PATENT DOCUMENTS202/181; 202/185.5; 2~/188; 202/19~202/197; 202/202; 202/23~ ~2~ ~203/1~ 203~ 203/2~ 203/DIG. 16;109551 1/1940 Amtmha .............................202/196Prima~ Examiner~Wiibur B~comb~ 22 Attorney, Agen~ or Firm--Eugene E Geoffre~ JL~ ~fld of Seth ..................... 202/188, 185.5, 17~ABSTRACT202/19~ 2~ 19~ 181, 18~ 83, 19~ 19~ 19~195, 202; ~. 17, 1~ I1, DIG. 2~ 2~ W~er deg~ific~n and ~stillation apparatus ha~ng aDIG. 16; 99/295 cont~ner ~r wa~er to be dega~fi<strong>ed</strong> and ~still<strong>ed</strong>, a~ R~ ~t<strong>ed</strong>~lativ~y small boiler a~ng s~d container and ha~~g a first condor e~en~ng ~to the cont~ner so thin a~S. PATENT DOCUMENTSs~e~<strong>ed</strong> wmer ~v~ ~ ~e confiner will fill s~d boiler284~II 8/1883Her~ck .......................~3~ 17 to a s~ec~d h~ght, a condenser w~n the con~er771,832 I~19~ R~ ..............................~I~ and immer~d ~ the water contain<strong>ed</strong> there,, a second851,~5 ~1907 ~ck ................................20~/196 cond~t e~en~ng ~om the space above the water ~9~9,6259/1910Ho~et ~ .....................2~/I~ s~d b~r to the ~t of the condense, an outlet on theI~I~508 2/1911 ~Cu~ ..............................202/196 condenser ex~n~ng ~rough a cont~ner w~] for ~~13~8 10/1938 Kess~ .................................202/1892~75~82 7/1949~em~s ..............................202/194char~ng dega~fi<strong>ed</strong> and ~s~d water and heating3~2~214 2/1962B<strong>ed</strong>uhn e~ ~ ....................203~0 X means m s~d boiler for heating the water therei~3~2~215 2/1962W~er ...............................203~ X3~4~305 ~1966 W~|~m~n .....................202/19~ X

U.S. Patem s~ 1~ 1~6 ~t3 ~S 4~12~90

U.S. <strong>Patent</strong> se~ 16, 1986 She~ 4 of 8 4,612,090

U.S. <strong>Patent</strong> se~ 1~ 1986 She~5 of 8 4,612,090

~S. Patem sev 16, 1986 S~ 6 ~8 4~12~900 o 0

-U.S. Palm s~ 16, 1986 S~ 7 a8 4~12~900

U.S. <strong>Patent</strong> se~ 16, 1986 She~ 8 of 8 4,612,090

~61~090A s~l ~h~ o~e~ of the invention re,des ~ theWATER DEGA~CA~ON AND D~LLA~ON prov~ion of a novd and ~ wm~ d~c~APPARATUSand d~t~n apparatus char~ri~d by ~s ~m~ff~ ~ ~~ and mMn~nance and r~mi~y ~wTMs ap~m~n ~ a continuation-in~a~ cf applic~ 5 cos~tion Se~ N~ 269,880 ~<strong>ed</strong> June 3, 1981 entitl<strong>ed</strong> "Wmer A s~l ~h~ o~e~ of the ~vention ~Nd~ ~ theDegasification and D~tillm~n Apparatus" now U.S. provM~ ~ a ~vd ~d ~pro~d b~ ~r ~e ~s~Pro. No. ~42~37~fion of water wNch mi~m~ ~e accum~ation ofTh~ ~vention r~a~s to d~ng apparmus and mo~ ~am ~ the b~er caus<strong>ed</strong> by sNt~ d~e~ and otherspe~ficflly to novd and improv<strong>ed</strong> water ~fl~tion10 water ~ma~ms wMch can ~nm~ the waterapparatus.bNng ~s~&Known ~sti~ng apparmus generally ~v~ve ~eutil~m~n of a dos<strong>ed</strong> boiler and means ~r continuoufly ~c~dan~ ~ ~e ~v~fion ~ud~ a ~n~r ~~e~ng wmer to the boiler. As the wmer ~ the boil~ m m~ ~d ~ ~c~ ~e wm~ ~ ~ ~s~d. A ~heat<strong>ed</strong> to produce wmer vapor or ~eam, v~ati~ cherub15 b~Mr ha~ng he~ng demems mourn<strong>ed</strong> ~on ~ p~Gc~ componen~ of water ha~ng boiling p~nts ~wer e~ secur<strong>ed</strong> to one ~de of the rank and a fl~d condMtcou#~ ~e bMMr ~ ~e rank ~ ~ ~e l~d Mvdthan the wmer will boil off and combine with the steam.The steam tog~her with the v~a~e vaporiz<strong>ed</strong> chemic~compone~s will then be condens<strong>ed</strong> ~ a s~tab~m ~e b~ ~H be conffdMd by ~e fiq~d Mvd ~ ~econdenser so that the ~sdm~ ~s~ wffi cont~n the 20 a__condense~ ank" A ~eam~o~ly~and ~ap°r ~d°Ufl~ ~ ~nthe b~er~ ~mkeou#<strong>ed</strong> tov~a~e chemic~ In ca~s wher~n ~e wmer has a outlet of the conden~r ex~nds ~rough the w~ of th<strong>ed</strong>isagreeable odor produc<strong>ed</strong> by s~phur compounds and tanZ The conden~r may be ~ ~ such a mann~~m ~e hq~d ~ ~e mk ~H ~r pm ~ ~ ~ ~ethe ~k~ known apparatus ~nds to concentra~ the odorcondenseL ~ ~ a~mm and wffh the heatersanp drior u.sm āke th;a~WateNr~ eve4, n33~30m 7°~fUlg "ran~d j~yApN~ant’l s3, 1982 25 ~ ~e bMMr ~g ~ ~e ~uM ~ ~e ~r ~Hen~tl<strong>ed</strong>: "D~tillm~u Apparmuf’ dNcloses distiNng heat Mmo~ ~anmneoufly and ~em ~H be ~ outappar~us embod~ng upper and ~wer chambers with ¯rough the condenseL As the p~e wff~ thethe condenNng coil ~spo~d ~ the upper chamber b~er exce<strong>ed</strong>s the capm~ of the outlet to rec~vewMch N normally fill<strong>ed</strong> wi~h w~er and graduNly ~d steam or water v~oL p~u~ will ~e water in theinto the ~wer chamber wNch N heat<strong>ed</strong> by a s~tab~means ~ order to prodnce geam. The steam g then ~d~ ~ ~& wm~ ~H ~Mn ~w ~o ~e b~upwardly through a condenser ~ the upper chamberand ~ then discharg<strong>ed</strong> ~om the condenser as a ~q~& ~ of the d~ apparatus. ~nee hot wmer ~By opiating the apparmus ~r a sho~ period of time 35 b~ c~smfly ~d ~ ~e mk and ~ ~m ~prior to the co~ection of the ~<strong>ed</strong> wate~ the condens~w~ ~cre~e ~e ~mperature of the wa~r ~ thecon~anfly ~mov<strong>ed</strong> ~om the c~m~ by ~e w~er~t~n ~e tanL ~e w~ wi~ ~e tank w~ ~e~eupper chamber ~nd bNl off vMa~e chemicN comp~ ~ mm~e and b~ off ~M ~e~c~ ~nent~tMn<strong>ed</strong> ~ ~e wm~ prior m ~s~lm~n ~e~o~ C~dTh~ ~vention constitutes an improvement over prior~ water ~ ~r~y ~d to ~e mk at ~e ~Mt to theknown ~stilling apparatus ~u~ng the apparmus d~dos<strong>ed</strong>~ apN~ant’s prior U~d Stat~ pment ~ Ihm ~ time ~e b~ ~ ~M~ Means may M~ be pro~d~b~ler so that the boiler wiB ree~ve cold wmer ~hembod~s a novd and improv<strong>ed</strong> smNI bNler ~ud~g ~ a~o~afion w~h the rank ~r ~e~ng condens<strong>ed</strong> ~instantaneous ~eating mean~ a conden~r ~nd a re~b ~Md ~d ~g~d ~ ~m ~e~ ~s ~rvNr wNch pro~d~ ~n a~omatic supNy ef wm~ to the 45 ma~ng co~ tea or merdy pro~de hot wmer ~rbN~r and may Nnction to con the condenser. With other pu~th~ arrangement, lhe water ~ the ~rvN~ ~ w~ be The ~ove and other ~ec~ and advanmg~ of theshowm ~rcMm~ m and from the boiler to repeme~y ~v~ti~ w~ become mo~ appa~m ~m the ~w-~rrupt boiling and hem thus impal<strong>ed</strong> lo the wmer ~ ~g ~ri~ and ~mpan~ d~ ~rm~g¯ e re~rvNr tog~her w~h ~e hem m ~t pa~ of ~ pa~ of t~s ~#c~.wMch may be impal<strong>ed</strong> by the condenser wffi heat thewater in the ~rvNr to a ~mperatu~ that w~ effectivdyboil off chemicN constituents of the water and FI~ 1 ~ a ~agmemary p~ ~w ~e m~mm~ ~E D~N~the time req~d for operation of the ~stil~r ~ order ~ ~ d~g ~m ~ ~e ~h ~ ~to produce a ~stillate free of the m~als and undesirab~ 55 tio~odors ~ mmeriN~ r<strong>ed</strong>uc<strong>ed</strong>.FIG. 2 ~ a ~o~ ~ctionM ~ew of FIG. 1 ~ ~Another o~ect of the ~vention reNdes ~ the provi- the ~ne 2--2 ~e~o~~on of novd and improv<strong>ed</strong> wmer dgtiHation apparmus FIG. 3 ~ a cro~ ~ctionM ~ew of FIG. 1 token MongwNch not o~y avNds co~rM means for fe<strong>ed</strong>~g wm~ the ~ne 3--3 ~e~and ~t~ ~ ~cd~ meansfrom a re~rvoir ~o a bNler but also embodi~ an arrangeme~and orga~zation of ~ements wher~n all FIG. 4 ~ a cro~ sectionM ~ew of the b~er and a60 cam<strong>ed</strong> by the comMne~potions of both the reservoir and boiler are readily ~agmemary po~on ~ the tank token ~ong the l~eacc~s~ for ~ea~ng and m~ntenanc~~ thereof of FIG. ~A still N~her o~e~ of the ~vention reNdes ~ the FIG. ~ ~ a ~de d~M ~ew of a mottl<strong>ed</strong> emprovisionof hot ~stil~d and sub~antially odobffee65 bo~mem of ~e ~vem~n ~r produ~ng d~Md wm~water ~r the brewing of coffee and ~a ~ well as for use ~r ~e and other ~od~~n the preparation of other ~ods such as soups and the FIG. 6 ~ a cro~ ~ctionM ~ew of FIG. 3 token Mong~k~the ~e a--6 m~eo~2

3~61~090FIG. 7 ~ a fide devafionfl ~ew ~ parti~ section of 41 and the boiler can be readily disassem~<strong>ed</strong> for deaning.The heating dements 13 and 14 in the ~ant em-the water tank and b~Mr of FIG. 5;FIG. 8 ~ a cross ~ction~ew of FIG. 5 taken ~ong bo~ment of the ~vention are carri<strong>ed</strong> by the w~141 andthe line 8--8 thereo~are connect<strong>ed</strong> in series by a lead 44 connecting oneFIG. 9 ~ a cro~ sectional ~ew ~ pe~pective of a 5 ~rmin~ of one heater to one term~ of the othermo~fi<strong>ed</strong> embo~ment of a d~fiNer ~ accordance wkh heate~ The power ~ne 45 has one lead 46 connect<strong>ed</strong> tothe invenfio~the other ~rm~ of the he~er 14 while the second leadFIG. 10 ~ a fragmentary crcss ~ction~ew of still 47 ~ connect<strong>ed</strong> through a thermo~ 48 to the otheranother embo~ment of the ~ventio~termin~ of the heater 13. The thermo~ is moun~d onFIG. 11 ~ an dev~ion~ ~ew of the water Mvd 10 a bracket 49 ~ dose pro~mky to the heater 13 and incontrol of FIG. 1~the even the heater 13 reaches a ~mperature above theFIG. 12 ~ an devation~ ~ew ~ partifl section taken norm~ operat~g ~mperatur~ the thermo~at will operateto open the drc~t and d~energ~e both heaters 13~ong the Nne 12--12 of FIG. 1~FIG. 13 is a cross sectionfl ~ew of FIG. 12 taken and 1~ R ~ evident however that heaters 13 and 14flong the l~e 13--13 thereo~15 cord be arrang<strong>ed</strong> for paralld operation or ~ the ~te~FIG. 14 ~ a cross section~ew of FIG. 13 taken nativ~ a ~ngle he~er may be employ<strong>ed</strong> provid<strong>ed</strong> howeverk drivers the quantky of heat necessary for oper~~ong the fine 14--14 thereo~ andFIG. 15 ~ a top ~ew ~ parti~ section of the boiler tion of the apparatu~shown ~ FIG. 10.If de,r<strong>ed</strong>, the tank or cont~ner 10 may be prov~<strong>ed</strong>Re~rring now to the drawings and more sp<strong>ed</strong>fic~ly 20 with a convention~ cover having openings therdn or ~to FIGS. 1 through ~ the ~g apparatus ~ acco~ the ~ternative may util~e forc<strong>ed</strong> ~r Orculation meansdance with the ~vention compds~ a cylindric~ tank or for the remov~ of unde~rable vapo~ Hbera~d from thecont~ner 10 ha~ng a p~r of handMs 11 secur<strong>ed</strong> to the Nquid w~hin the tank 10 during the course of the d~tillationprocess. One embodiment of air circulating meansfide thereo£ A boiler 12 ha~ng in~antaneous heatingdements 13 and 14 ther~n ~ affix<strong>ed</strong> to the fide of the25 ~ illustrat<strong>ed</strong> in FIG. & The ~r drculating means ifidudesan ~ve~<strong>ed</strong> dish<strong>ed</strong> cover gener~ly denot<strong>ed</strong> bytank 10 by the fl~d connectors 15 and 1~ The fl~dconnector 15 ~dud~ an ~bow 17 ha~ng a sho~der 18 the numer~ 50 which ~dudes a flat upper wall 51, anand a thread<strong>ed</strong> shank e~en~ng through cooperm~g upwardly extending pefipher~ wall 52 and a downwardlycurv<strong>ed</strong> peripher~ w~l 53. The lower peripher~ope~ngs ~ the wall 19 of the b~Mr 12 and the wM1 ofthe tank 10. A nut 20 engages the shank of the fitting 15 30 <strong>ed</strong>ge of the wMl 53 carries three or more angularlyand tog~her with a resilMnt w~her 21 pro~d~ a wv dispos<strong>ed</strong> rolM~ 54 each having space discs 55 rota~~r-tight seM for both the tank 10 and the b~ler 12. A ably carri<strong>ed</strong> by a sha~ ~ The discs 55 engage thewmer i~ tube 22 ~ fixe~y cou#<strong>ed</strong> to the fitting 13 by rolMd <strong>ed</strong>ge 10’ of the tank 10 and accordin~y providemeans of a nut 23 so that water wren the tank 10 will an annular vent b~ween the cover 15 and the <strong>ed</strong>ges ofbe automaticaNy ~d ~to the b~Mr 12 until the water35 the tank 10.levd wff~n the b~ler co~esponds to the wmer levd ~ The wall 51 of the ~r drculat~g means shown ~the tanL ~ w~ Mso be observ<strong>ed</strong> thin the wmer Mvd ~ FIG. 3 includes a motor gener~ly denot<strong>ed</strong> by the numer~57 which has a sha~ 58 extending through thethe tank ~ pre~raMy mMntMn<strong>ed</strong> m a Mvd to effe~ |olMor ~ Mast sub~antiM immerfion of the heating dements perforat<strong>ed</strong> wall 51 and carries a fan 59. Power ~ f<strong>ed</strong> to13 and ~4 ~ the wmer wff~n the boiler.40 the motor 57 by a ca~e 60 connect<strong>ed</strong> in a convention~The ~eam outlet fltt~g 16 ~ of conventionM con- manner to the moto~ If des~<strong>ed</strong>, sw~ch means may be~ruction and ~dud~ an outlet #pc 24, a thread<strong>ed</strong> provid<strong>ed</strong> for operation of the fan. The fan motor ~shank 2~ ex~nd~g through the walls of the tank and cover<strong>ed</strong> by a dome~hap<strong>ed</strong> houfing 61 securdy fi~<strong>ed</strong> tothe boiler and secur<strong>ed</strong> thereto by a nut 25. A sealing the cover 53 and secur<strong>ed</strong> thereto by any s~ta~e means.w~her 26 ~ d~po~d b~ween 1he tank and the boiler Io45 In the in~ant embodiment of lhe ~vention, the domeshap<strong>ed</strong>houfing 61 ~ adapt<strong>ed</strong> to frictionally engage thepro~de a w~evtight connection. The condenser 27 ~the ~ant embo~ment of the ~vention ~ ~ the form of peripher~ wall 52 of the cover 50. In operation, ~r ~a c~Md tube of m~M such as ~M~s ~<strong>ed</strong>, copper or drawn in through an opening 62 and the perforat<strong>ed</strong> wallthe Nke and has the ~Mt end potion 28 seMably connect<strong>ed</strong>to the fitting 16 wit~n the tank 10. The oufl~ 29 50 in the container and d~charg<strong>ed</strong> through the annular51 whereupon k ~ direct<strong>ed</strong>ownwardly over the w~erof the condenser 27 has a fitt~g 30 ex~nd~g through opening between the container 10 and cover 50.the wall cf the tank 10 and pro~d~ the fl~d oufl~ 31. In the operation of the di~ill~ion apparatus d~The tank fu~her ~dud~ ~n overflow p~e 22 w~ch ~ scrib<strong>ed</strong> abov~ the tank 10 and boiler 12 are fir~ filMdconnect<strong>ed</strong> to a fitt~g 33 seal<strong>ed</strong> to the wMl of the tank 10 with water to a Mvd at Mast substantially covering theand a drMn cock 34 for drM~ng l~d from the tanL A 55 heating dements 13 and 14 as wi~ be observ<strong>ed</strong> morew~er ~Mt vMve 34 ~ card<strong>ed</strong> m the upper potion of the deafly in FIG. 2. R will be observ<strong>ed</strong> th~ when fill~gtank or contMner 10 and has an inlet 3~ an outlet 37 the tank 10, water wi~ automatically flow through conduit22 ~to the boiler so that the Mvd of the water inwithin the tank and a hand-wheal 38 for reg~ating thewmer sup#y ~ order to mMntMn substantially constant lhe lank will be lhe same as the wa~r Mvd in the boile~Mvd of lhe w~er wff~n the tank.60 Energy ~ then suppN<strong>ed</strong> to the heating demen~ 13 andThe boiler ~ shown more deafly ~ FIG. 4 and confi~sof two hous~g demen~ 39 and 40. A drc~ar wMl boiler 12. S~am ~om lhe boiler win emerge through14 which win function to boil the water wkhin theor partition 41 ~ ~spos<strong>ed</strong> b~ween the houfing demen~ the outlet 24 and then flow through the condenser 1739 and 40 and ~dudes a p<strong>ed</strong>pherM seM 42 w~ch ~ and the condens<strong>ed</strong> ~eam will then be d~charg<strong>ed</strong> as ardeasably damp<strong>ed</strong> b~ween the outer alms of the hou~ 65 Hq~d ~om the outlet 31. When initi~ly operating this~g dements 39 and 40 by clips 43 about the periphery apparatu~ k ~ gener~ly defirabM to discard the d~tillateuntil the water within the tank 10 has attun<strong>ed</strong> aof the boiler 12. T~s arrangement com~etely ~Ms thechamber form<strong>ed</strong> by the hous~g posen 39 and the wall normally operat<strong>ed</strong> ~mperature which ~ ra~dly ~-4

5~61Z090tin<strong>ed</strong> in the following manne~ HeMers 13 and 14 are fion a ~m~ircd~ brackm 84 of L6hap<strong>ed</strong> section ~rdefign<strong>ed</strong> to hem the water wit~n the boiler at a rate ¯ dably recoving a basket 85 ~u~ramd ~ brokendines~ster than the condenser 27 can accommodMe the ~ FIG. 5 wMch may normally h~d a fi~er and groundsteam produc<strong>ed</strong>. Accordin~ pressure ~ devdop<strong>ed</strong> coffee. A base 86 engages and suppo~s the Z-shap<strong>ed</strong>within the boiler 12 and will force ~q~d ~om the boiler5 brack~ 72 and ~Oud~ a convenfionM de.fie heatingthrough the tube 22 back ~to the ~nk 1~ As soon as the dement 8% The heating dement 87 ~ prodd<strong>ed</strong> wffhpressure ~ reliev<strong>ed</strong> w~n the boile~ water w~ ag~n suitabl ener#zing conducmn and swim~ng means not~ow through the tube 22 back ~to the b~r w~h the shown so that ff may be turn<strong>ed</strong> on and off as defi~&resdt that there w~ be a perio~c reve~ of water The space b~ween ~e b~mm of ~e basket 85 and ~eflow through the tube 22. T~s action resu~s ~ a sub-10 top of the heating demem 87 ~ of ~ffident magnitude~anti~ ~crease ~ temperature of the wa~r w~n Ihe to ~cdve a s~m~e ~cepm~e 88 ~r ~c~ng b~wCd~nk 10 and contributes to the he~ impal<strong>ed</strong> to the coffee. It ~ ob~o~ ~om ~e ~g~ng d~cus~on thMwMer ~ the ~nk 10 by the action of the condenser 2~ the basket 85 may be a~ang<strong>ed</strong> to aceommodMe teaThe ~mper~ure of the w~er tank 10 however ~ ~- ~aves ~r the brewing of tea or ~ the ~rnative theways brow the boiling ~mperature and shodd pre~ra-15 distill<strong>ed</strong> water ~om the fittMg 83 can be f<strong>ed</strong> ~ctly~y be ~ the range of 180’ F. to 19& ~ ~ order to be ~to ~e ~ce~ac~ 88 ~r making soup or any otherce~n that undesirab~ componen~ ~ the water are purple ~r w~ch purifi<strong>ed</strong> ~s~l<strong>ed</strong> w~ may be ~-boil<strong>ed</strong> off prior to a~u~ d~tiH~n.q~&In one form of the ~vention utilizing a tank 10 hating The cont~ner 70 ~dud~ a ~sh<strong>ed</strong> cover gener~lya v~ume ~f 1 to 2 gallons of w~e~ a b~lCr 12 h~d~g20 denot<strong>ed</strong> by the num~ 89 wMch may be affix<strong>ed</strong> ~ theappro~m~dy 16 ounces of wate~ heating dements contMner 70 by any s~tab~ mean~ The cover 89 ~-deign<strong>ed</strong> to d~fipMe from 1,500 to ~000 wMt~ ~ wffi ~udes an ope~ng 90 for ~e~ng wMer ~to the cont~ner70 and a cooperat~g rid 91. Forc<strong>ed</strong> Mr O~-take appro~m~dy 15 minu~s of operM~n for thewater ~ the ~nk to reach a ~mperature of approxim~dy18~ ~ lo 19& F. and the b~r wffi normally25 ri<strong>ed</strong> on the top ~de of the cover 91 and ~dud~ an~g means general~ denot<strong>ed</strong> by the nume~l 92 ~ ca~hem tap water above the boiling p~nt wit~n about 45 de~ric m~or and ~n subs~ntially ~mil~ ~ ~M ~u~second~ W~h t~s a~angement and after the warm-up tm~d and describ<strong>ed</strong> m connection wi~ FIG. & The airperiod, subsmnfi~ly all v~atile chem~s ~ the wa~r circ~ating means ~dud~ an air inl~ opening 93 on theare boil<strong>ed</strong> off prior lo ~stil~tion with the resdthM the mp ~de ~eof and appropriMe ope~ngs not shownd~tiHMe ~ subs~nfi~ly odorless and bee of all unde~ 30 a~ ~rm<strong>ed</strong> ~ the top of the cover 89 ~ permk theab~ component~ In actu~ te~ ~ has been found that ~oduction of ~r ~to the space defin<strong>ed</strong> by the cont~ner70 and Hd 8~ The ~r ~ exhau~<strong>ed</strong> from one orw~h distillation apparatus as describ<strong>ed</strong> abov~ distill<strong>ed</strong>w~er w~ be produc<strong>ed</strong> ~ the rate of on~h~f to thre~ mo~ oufle~ 94 ~ the cover and an dectdc cab~ 95 ~quarters of a gallon per hou~utiliz<strong>ed</strong> ~r en~ng ~e ~n and may ~dude appro-A mottl<strong>ed</strong> form of the ~vention ~ ~ustra~d ~ 35 prime swish mean~FIGS. 5 through 8. Th~ form of the ~vention m m- The operation of ~e apparat~ illu~t<strong>ed</strong> ~ FIGS. ~tend<strong>ed</strong> for the brewing of coffee and for the production ¯rough 8 ~ mb~anti~ly ~e~ to thM describ<strong>ed</strong> ~of hot d~til~d wMer for other purposesuch as the connection wi~ the p~ce~ng embo~me~ of the m-brewing of te~ ma~ng of soups and the ~ke.ventiom Howeve~ ~nce the defice ~ not a~ang<strong>ed</strong>,~ w~ become apparent ~om the following descriptionof FIGS. ~ through 8 of the drawings thM the ~ ~e com~ner ~ initiMly ~d wi~ w~ ~o ~ ~e~ ~ough k may b~ ~r the continuous ~ffiation of w~operation cf the brewer ~ substantially ~entic~ to lhe ~vd ~ ju~ brow the portion of ~e ~1~ 81 of theoperation of the form of the invention shown ~ FIGS. condenser 80. g ~e container 70 ~ of mffidet s~ |he1 through & More speOfic~l~ the brewer comprises a d~lation proce~ can continue until the vessd 88 hastank or cont~ner 70 having an outwardy form<strong>ed</strong> pe-4ripherM ~p 71. The conta~er ~ suppos<strong>ed</strong> by a p~r of q~ ad~tion~ wMer can be add<strong>ed</strong> through thebeen ~d. If ~rger amounts of ~s~d wM~r are re-Z-shap<strong>ed</strong> brack~s 72 cou~<strong>ed</strong> by a transverse dement ope~ng 90 as may be ~q~d ~ order ~ m~nt~n the72 w~ch m~nt~ns the two brack~s 72 ~ spac<strong>ed</strong> rdafions~p.The confiner 70 ~ suppos<strong>ed</strong> by the upper cause ~e heating dements ~ the boiler 74 ~ be M ~ast~vd of ~e wM~ ~ ~e container M a h~g~ ~M w~horizont~ bracket potions 73 w~ch engage ~e peripher~p71 on the ~des of the cont~ner 70. A b~r Re~rring now to ~e ~rms of the ~venfion shown ~50 ~a~ially covere&74 substantially ~entic~ to the boiler 12 shown on FIG. FIG. 9 and FIG~ 10 ~rough 1~ ~ has been ~und th~4 ~ affix<strong>ed</strong> to one end of the confiner 7~ ~nce the improv<strong>ed</strong> results can be obtain<strong>ed</strong> by ~<strong>ed</strong>ing the wat~boiler functions ~ the same manner as the b~ler 12 and sup~y controll<strong>ed</strong> by lhe wM~ inl~ v~ve 35 as sho~n~ substantially ~entic~er~ a fu~her description ~ 55 ~r ~s~nce ~ FIG. 1, ~rough an dongat<strong>ed</strong> tube 37tot deem<strong>ed</strong> necessary.w~ch ~rm~ates adj~ng lhe bo:l~ i~ 22’. TheThe boiler 74 ~ cou~<strong>ed</strong> to the confiner 70 by a wM~ inl~ tube ~7’ ~ p~rab~ a~ang<strong>ed</strong> ~ swivd ~fitt~g 75 having a w~er inlet 76 secur<strong>ed</strong> to one ~de ~dicat<strong>ed</strong> ~ FIG. 9 so ~ ~ can ~e rais<strong>ed</strong> ~ ~cilita~lhereof and a w~er out~t 77 d~pos<strong>ed</strong> w~n the boiler a~u~mem of ~e w~ ~<strong>ed</strong> ~ just main~ ~e defi<strong>ed</strong>74. A second fitting 78 extends through the walls of the60 wMer ~vd ~ the cont~ner 10 as de~rib<strong>ed</strong> ~ connectionw~h FIGS. 1 and ~ It w~ be observ<strong>ed</strong> ~ thecont~ner 70 and boiler 74 and card~ a ~ream outlet 79on one end thereo~ WitCh the confiner, the ~t end water inlet 22’ to ~e boiler ~ a ~rmght tube ~a~ng81 of the condenser 80 ~ affix<strong>ed</strong> to the fitting 78 and the ¯ ~etly ~ ~e ~w~ po~icn of ~e b~r and ~ atilt!on~ ~c~ng c~d ~let wM~ ~ctly from ~e ~beoutlet end 82 of the condenser ~ secur<strong>ed</strong> to a fitting 83extend~g through an ope~ng ~ the bottom of the65 3T, ~e tube 22’ ~ ea~ ~ ~e~n as w~ be ~d ~cont~ner 70.more detail m connection with FIGS. 10 ~rough 15.The underfide of the cont~ner 70 as shown ~ FIGS. It has been ~und ~ ~e ~s~fion of wM~ ~M ~e5 and 8 ~dudes ~ the ~stant embodiment of the ~ve~ presence of s~, de~rgen~ and o~ ~mil~ chemicals6

~61L090~nd m cause the generat~n of foam in the boiler wh~h ing 10~ As v~w<strong>ed</strong> in FIGS. 10 and 13, the baffle whichadve~dy affects the dfimate distilhm and Mso neces~tatesmore ~equent dea~ng of the apparatus to attMn to the left so that the L-shap<strong>ed</strong> steam outlet 118 which~ of ~rc~ar configuration ~ inclin<strong>ed</strong>ownwardly andoptimum resets. A ~ructure for achieving lhes ends is ~ coupl<strong>ed</strong> to the fitting 16 ~es to the left of the baffle asillustrat<strong>ed</strong> in FIGS. 10 through 15 wheron the contMnerfor recoving the water sup#y ~ generally de-right ~de of the baffl~ The baffle ~ hid in place by a5 view<strong>ed</strong> in these figures while the heaters 111 are on thenot<strong>ed</strong> by the numerM lff while the b~Mr ~ generMly b~t 119 carri<strong>ed</strong> by the wall 103’ of the boiler sectiondenot<strong>ed</strong> by the numerM 12~ The boiMr 12’ ~ secur<strong>ed</strong> to 103 and extending through an opening in the baffle 117the contMner lff in the same manner as describ<strong>ed</strong> in to recove a cooperating nut 120 to hold the baffle inconnection wffh FIGS. I and 2 in thin lower and upper10 position. The baffle Mso includes a centrMly d~pos<strong>ed</strong>seM<strong>ed</strong> fittings 15 and 16 secure the boiler to the contMnerand at the same time provide a lower water inMt portion 122 extending inwardly ~om the fitting 15 pre-ope~ng 121 to recove the end of a water inlet tubeand an upper ~eam outleL The end of the fitting 16 viou~y describ<strong>ed</strong>. The ~eam outl~ tube as view<strong>ed</strong> ind~pcs<strong>ed</strong> wffh the contMner 10 ~ coupl<strong>ed</strong> to the inlet cf FIG. 12 preferably l~s b~ween 30° and 50* to the le~ ofcondenser 29 and the outlet of condenser 29 ~ con-1nect<strong>ed</strong> to an outlet fitting 30 which in~udes d~till<strong>ed</strong> holes 123 dispos<strong>ed</strong> wall to the right cf the center line ofverticM and the baffle 117 includes a plurMity of smallwater d~charge means having a pipe 31, an rusticoupling100 and an elbow 101 to facilffme collection of the generat<strong>ed</strong> principMly on the heater ~de of the baffle 117the boiMr 103. W~h this arrangemenL foam will b<strong>ed</strong>istilMd water in a suitabM receptaO~ The inl~ pipe 2T with the resulthat the baffle will tend to confine theextends through the fitting 15 and into the b~Mr in a 20 foam with only the ~eam or water vapor pas~ngmanner to be describ<strong>ed</strong> in connection with the succe<strong>ed</strong>ingfigures.thermor ~nce the ~eam outlet 118 ~ angularly d~-through the openings 123 to the ~eam outlet 118. FurRe~rring now to FIG~ 12 through 15, the boiler ~ pos<strong>ed</strong> r~ative to the openings 123, foam which mayform<strong>ed</strong> of two ~uncat<strong>ed</strong> hem~phericM or bowllike pos~bly pa~ through the openings 123 will not reachportions 102 and 103 having integrally form<strong>ed</strong> ~os<strong>ed</strong>25 the ~eam outlet 118 easily and accordingly only thebottom portions 10T and 103’ respectively. The boiler ~eam will pa~ through the ~eam outleL This actionsection 102 ~ provid<strong>ed</strong> wffh a peripherM flange 104 resul~ in the ~tainment of much purer water than in thewhile the boiler section 103 ~ provid<strong>ed</strong> wffh a ~miMr case where foam can reach the steam outlet and ultim~dybe recombin<strong>ed</strong> with the d~tilMte.peripherM flange 105. The boiMr sections 102 and 103are separat<strong>ed</strong> by a separate plate or partition 106 having30 Referring agMn to FIGS. 10 and 11, the contMner 10’a diameter ju~ slightly greater than the diameter of the includes an overflow control assembly generMly denol<strong>ed</strong>by the numerM 124. This a~embly inOudes aperipherM flanges 104 and 105. An annular U-shap<strong>ed</strong>gask~ 107 ~ fi~<strong>ed</strong> about the <strong>ed</strong>ge of the partition 106 fitting 12~ extending through the wall of the containerand a plurMffy of clips 108 engage the peripherM flanges 10’ and carrying an L-shap<strong>ed</strong> tube 126 rotatably dis-104 and 105 to secure the boiler portions one to the35 pos<strong>ed</strong> within the fitting. A hou~ng portion 127 rota~other and at the same time seM the boiler 103. For convenienceof assembly, the pa~ifion 106 wffh the gasket having soft and hard pos~ions as illustrat<strong>ed</strong> moreably recoves the tube 126 and suppo~s a fix<strong>ed</strong> scMe 128107 ~ secur<strong>ed</strong> in position rdative to the boiler section ~eafly in FIG. 11. A shaft 129 extends ~om the hou~ng102 by an dongat<strong>ed</strong> screw 109 extending through the 127 and ~ mechanicMly coupl<strong>ed</strong> to the tubular memberend wM1 102’ of the boiMr section 102 and through a 40 126 so that rotation of the shaft 129 will rotate the tubecen~M opening in the pa~ition and ~ secur<strong>ed</strong> in place 126 to move the angularly d~pos<strong>ed</strong> end potion 126’ ofby a s~tabM nut 110 and sealing washer 11ff.the tube 1264o Other a horizontM position or a verticMA pMr of heaters 111 idenficM to the heaters 13 and 14 position as illustrat<strong>ed</strong>. A knob 130 having a point<strong>ed</strong>of FIGE I and 2 are carri<strong>ed</strong> [y the pa~ition 106 and are portion 131 ~ carri<strong>ed</strong> by the shaft 129 and ~O~tesdispos<strong>ed</strong> slightly brow the central axis cf lhe boileL As 45 rotation of the shafto one or the other of the positions.shown in FIG. 1~ each hemer includes ffs individuM Wffh this arrangement, should lhe water be relativdythermostat 112 with each heater and thermo~at being hard, the pointer 130 ~ mov<strong>ed</strong> to the horizontal positionconnect<strong>ed</strong> in seriem The series connect<strong>ed</strong> heaters wffh to ~mit the quantity of water deliver<strong>ed</strong> to the boilertheir assodat<strong>ed</strong> thermostats are then connect<strong>ed</strong> in parMldas shown in FIG. 14 so that ~ne voltage ~ appli<strong>ed</strong> to 50 deliver<strong>ed</strong> to the boiler ~ increas<strong>ed</strong>. The verticM posi-while at the verticM positio~ the quantity of watereach heater and each heater ~ individually protect<strong>ed</strong> tion ~ us<strong>ed</strong> when rdatively soft water ~ encounter<strong>ed</strong>agMn~ overheating. The heating dements of ~ach of ~nce the verticM position will provide increas<strong>ed</strong> waterthe heaters 111 ~ dispos<strong>ed</strong> wffhin the boiler section 103 to the boiler and greater output without any adverseand ~ en~os<strong>ed</strong> by a w~er impervious hou~ng 111’ affect on the distilMte. The horizontM portion resul~ inwh~h not only protects the heating dement but Mso 55 a r<strong>ed</strong>uction of the quantity ~f distillate produc<strong>ed</strong>. It ~ toseMs the heater agMn~ the pa~ition 10& The heaters be underwood that the lower water Mvd will Mwaysare energiz<strong>ed</strong> by a power cabM 112 having three conducto~113, 114 and 115. The conductor 114 ~ a In order to avoi damage to the gasket 107 surround-produce the superior d~tiHat~ground conductor and ~ connect<strong>ed</strong> to the grounding ing the pa~ition 106 in the event pressure shouldescrew116 while the conductors 113 and 115 are con-6nect<strong>ed</strong> to the heating dements as illu~rat<strong>ed</strong> in FIG. l& sur~ a plug 132 form<strong>ed</strong> of plastic materiM ~ loosdyvdop wffhin the boiler 103 exce<strong>ed</strong>ing the de,r<strong>ed</strong> pres-As previou~y point<strong>ed</strong> ouL water for drinking and inse~<strong>ed</strong>a cooperming opening at the top of the boiMrother Furposes often contains relatively large quantitiesas will be observ<strong>ed</strong> more ~eady in FIGS. 10 and 13.of salt~ detergents and other chem~Ms wh~h produce The pre~ure requir<strong>ed</strong> to di~odge the plug 132 ~ exsubstantlMquantities of foam during the distilling pro-6ce~ and ff ~ of course desirabM to preventhe foam of rupturing the boiler 103 or even dislodging the resil-~emdy small so th~ there ~ no poss~ility whatsoever~om entering the condenser 29. For this purpose, a ~nt sealing member 107. In the event one or both of thebaffle 117 ~ angularly d~pos<strong>ed</strong> within the boiler hou~ heating dements 111 shodd become damag<strong>ed</strong> or

9the case may be so that the water w~ com~dy or~61~090burn<strong>ed</strong> ouL the section 102 ~g~h~ wRh the ~tion and a readily accesfible cover ~ate ~movably se~<strong>ed</strong> to106 can ready be ~m~ ~m ~e bA~r ~r ~ac~ s~d open fide ~r ready access to the bA~nmere ~ ~p~n ~ ~e same tim~ it ~ q~e ob~o~ ~ Z Water degafification and ~stiHation apparatusby ~ason of the umque a~n~ and con~ruction accor~ng to d~m 1 wh~n s~d cont~ner ~dud~ a~ ~e d~il~r ~ ~c~d~ ~ ~e ~, ~ ~ 5 cover and ~r ~ating means card<strong>ed</strong> by sfid covehpotions are ready acc~e ~r dean~&In the ~ of the d~tiller ~ ~eo~ w~hthe ~vention ~dud~g the ~rms of the ~ventionshown ~ FIGS. 1 and 2 as w~ as FIGS. 10 and 13, thes~d ~r ~rc~g means ~g ~r ~to s~d conminerand s~d cover ~dud~g means ~r dightings~d ~r from s~d conm~er whe~by vapo~ produc<strong>ed</strong>w~n s~d container are d~charg<strong>ed</strong> ~to the atmosphere.baler is portion<strong>ed</strong> rdative to the cont~ner 10 or lff as 10clemens ~nction to heat the water very m~y ~d asa ~s~t c~e a ~m~ ~ ~e bA~r w~ch ~the water ~t ~e b~ ~d b~k ~ ~e cont~ne~ 15In FIGS. 1 ~d 2 ~nce the hot water ~11 rise ~t~n the~n~r 1~ ~ w~ ~ ~ ~ ~d b~k ~m ~ebAMr but ~ the meantime b~ng has been com#~dym~up~d. ~ FIG~ 10 and 13 w~e the water doesnot e~rdy e~ose the hem~s when d~charg<strong>ed</strong> from 20the b~eL upon ~e~ng of cad water from the ~Mt#~ ~’ ~y m ~e ~ ~’ m ~e b~ ~e c~dwm~ w~ ~rm~e b~g ~ M~t momentarywhe~upon ~e ~ ~d d~ process ~ ~Mn 25~pe~e& H h~ b~n ~und ~ both ~s of the ~nventionthin exce<strong>ed</strong>~#y pure water ~ ~d wMch ~n~ o~M~bM wffh ~y ~h~ known de~c~ ~ compv~le fize and r~e of ~H~. In the ~ of the~vention shown ~ FIGS. 10 and 13, when the waterMvd ~ a~u~<strong>ed</strong> to the Mw Mv~ the pure~ water ~~n~M w~M at the ~gh Mv~ the w~er will meetp~db<strong>ed</strong> ~s ~r ~s~Md wmeL The ~gh Mvd~ prodd<strong>ed</strong> pa~ady ~r use wffh wmer ha~ng lowtotM ~v<strong>ed</strong> s~s and other impudt~s fince the 35~ w~ d~ver as much as three qua~e~ of ag~on of d~ti~<strong>ed</strong> water per hour w~M the apparatuswffh wm~ m ~e ~w Mvd w~ dd~ on~hMf a gM~nper houLW~M o~y ce~n e~m~ of the invention ~have been illustrat<strong>ed</strong> ~d describ<strong>ed</strong>, ff ~ apparent thatM~mtiom, changes and m~c~s may be madewffhom ~ng ~ the ~ue scope and s#~thereo~W~t ~ dMm~ ~: ~1. Wmer ~~ ~d ~11~ apparatuscomprising a contMner ~r h~ng w~er to be dega~fi<strong>ed</strong> and ~ a condenser ~ sMd comMn~ ha~ng~ ~ ~d oufleL ab~ ~vdy ~ v~um~ aMw~ wm~ ~ on sMd b~ ~d commu~c~g ~wffh sMd container at a pare s~y below theMvd of ~e w~ ~ sMd conm~ ~r ~e~ng w~ff<strong>ed</strong>y to ~d ~m sMd b~eL sMd bAMr bong point<strong>ed</strong>~ m ~d ~n~r m ~y mMmMn ap~d~d wamr Mvd ~t~n sMd b~eL an upper 55oufl~ on sMd b~er ~ove sMd ~e~M~ wmerMvd and ~mm~ wAh the ~Mt of sMd condenseLand means ~r being water ~ sMd bAMr andperio~cM~ ~e~ng ff ~effom ~Oud~g a he~ngdemem ~ sMd b~ ~d g~m~g h~t ~ a ~mp~v ~ture ~t to produce steam at a g~ rate thansMd ~eam can ~ ~ha~ from sMd upper omMt~e~ a pressure m sMd b~er ~em to ~rcewmer ~ sMd b~er ba~ ~to sMd contMner ~mugh~d Mw~ w~ ~ ~ ~e ~e~e ~ ~d b~ ~ ~r~ and b~ng ime~up~d wh~eupon w~ w~agMn flow ~m sMd b~ m sMd ~~d Mv~sMd bAMr bring ~<strong>ed</strong> of a fin#e opem~d<strong>ed</strong> hou~ng10& Wa|er deg~ification and ~stiHation apparatusaccording to d~m 2 wh~n s~d cov~ h~ a convexconfiguration, s~d ~r ~g means ~ m the ~rmof an de~ric ~n ha~ng a ~n motor c~fi<strong>ed</strong> by s~dcover and ~n ~ades a~x<strong>ed</strong> to the motor shaft, s~dcover ~du~ng opemngs ~r the admission of fir andmeans about the <strong>ed</strong>ge thereof ~r enga~ng s~d conminerand h~ng ~e <strong>ed</strong>ge of s~d cover ~ spac<strong>ed</strong>rdation~ m sfid container m pro~de ~r ~e ~charge of ~r ~rc~<strong>ed</strong> by s~d ~n.¢ W~er dega~fic~n and ~il~tion appar~maecor~ng to ~m 1 ~dud~g means ~r supportings~d conm~ above a ~pporting sur~c~ and s~dcondenser oufl~ emend~g ~rough the boRom wMl ofm~ cont~ner whereby a vessd may be d~pos<strong>ed</strong> b~neath s~d cont~ner and ~ hne w~h s~d condenseroufl~ m ~c~ve ~e ~s~d w~eL5. W~ degas~cation and d~lation ~pp~accord~g to d~m 4 ~dud~g means on the undersideof s~d container and mrroun~ng s~d condens~ oufl~~r supposing a b~k~ hav~g an ope~ng ~ ~e b~mmthereof ~r ~c~ng and h~ng a ~r eontaimngground coffe~ ~a or the ~ke whe~by s~d d~tiH<strong>ed</strong>w~ w~ first flow ~ said ba~ and ~ence ~ ~aidvessel.~ W~ deg~ification and ~stillation appallsaccording m d~m 1 whe~ said boiler ~ ~rm<strong>ed</strong> of ahollow, ~tantially hemi~he~c~ housing ha~ng aperipheral flange e~en~ng ~om ~e open end potionand pofition<strong>ed</strong> ~ a verfic~ ~an~ ~id cov~ ~e co~~rm~g ~ ~e fize and configuration of said flange anda g~k~ ~<strong>ed</strong> b~ween s~d bA~r and ~e andmeam ~mova~y ~curing s~d ~e and gasket ~ s~dflang~~ Water degafification and ~sti~n app~uscompdfing a coma~ ~r hA~ng w~ ~ te degasifi<strong>ed</strong>and d~till<strong>ed</strong>, a bA~r of ~latively sm~l vAum~ a~wer water inlet on s~d boiler and communicatingwi~ said ¢o~ner ~r ~e~ng w~ m said boiler, saidbA~r b~ng pofition<strong>ed</strong> ~tive to s~d conm~ tonormally m~m~n a pr<strong>ed</strong>eterm~<strong>ed</strong> water ~vd w~ns~d boile~ a condense~ an upper o~t on s~d bA~rabove said pr<strong>ed</strong>etermin<strong>ed</strong> wa~er ~vel and commun~at-~g w~h ~e inl~ of s~d condense~ and heating means~ said boil~ and gen~ating heat ~ a ~mperatu~ sufficfe~~ produce steam ~ a great~ m~ ~an said steamcan be d~charg<strong>ed</strong> from s~d upper oufl~ ~e~g ap~ure m s~d bA~r suffident m ~e w~ ~ s~dbAkr back into s~d container ~rough m~ ~wer waterinl~ un~ ~e p~u~ m s~d boil~ ~ ~ev<strong>ed</strong> whe~uponw~er w~ ag~n flow ~to s~d boiler to s~d p~de~rmin<strong>ed</strong>~vel, s~d bA~r b~ng ~rm<strong>ed</strong> of a fin~eopen-sid<strong>ed</strong> houfing and a ~adi~ accesfib~ cover ~e~movably sefl<strong>ed</strong> to s~d open fide ~r ready access ~¯ e boiler, sfid bA~r bring ~rm<strong>ed</strong> of a hollow, sub~antifllyhem~ph<strong>ed</strong>c~ houfing ha~ng a pefipherfl flangee~en~ng from ~e open end potion and position<strong>ed</strong> ~a v~tic~ ~n~ said cover plate con~rm~g m ~e fize

114,612,090and conflgurm~n of sMd flange and a gask~ ~spos<strong>ed</strong> ~upt<strong>ed</strong> whereupon w~er will agMn flow ~to s~d boilerb~ween sMd b~Mr and #me and means removably to s~d pr<strong>ed</strong>~erm~<strong>ed</strong> lev~, sMd boiler b~ng form<strong>ed</strong> ofsecuring sMd ~me and gask~ to sMd fiang~ sMd he~- a ~n~e open-~d<strong>ed</strong> housing and a readily acce~ible~g means bring an de~ric hemer carri<strong>ed</strong> by sMd ~me cover ~me ~mova~y seM<strong>ed</strong> to sMd open ~de ~r readywith the dectricM connections therefor ~spos<strong>ed</strong> on the 5 acce~ to the boile~ s~d b~Mr ~ud~g a battle ~douter~de of sMd #me and a second h~low, sub~antiallyhemisphericM housing ~du~ng a peripherM outlet d~pos<strong>ed</strong> on one ~de thereof and s~d heating~g sMd boiler into two portions with s~d upper steamflange endoMng sMd decU~M connections and sMd means and ~wer water inlet on the other ~de thereofhou~ngs with sMd cover #me bring removably ~cur<strong>ed</strong> and s~d baffle ~ud~ m Mast one upper ope~ng anguoneto the other~10 lady ~splac<strong>ed</strong> from sMd upper ~eam outl~.8. W~er dega~fication and ~m~n apparatus 10. Water dega~fication and ~stiHation apparatuscompri~ng a contMner for h~ng w~er to be degasifi<strong>ed</strong>and di~ille~ a conden~r ~ sMd container ha~ng h~Mw, subsmntiMly hemisphericM hou~ng ha~ng aaccord~g to ~Mm 1 wher~n sMd b~Mr ~ form<strong>ed</strong> of aan inl~ and outleL a b~Mr of rdativdy small v~um~ a peripherM flange ex~n~ng from the open end, sMdlower wmer ~Mt on sMd boiler and commu~cming15 boiler bring affix<strong>ed</strong> lo the eu~r sMe of said containerwith sMd contMner at a p~nt sub~antiMly bdow the with ~ Mast sMd ~wer w~er inl~ e~en~ng throughMvd of the w~er ther~n for ~e~ng wmer fre~y m and sMd houfing and contMneL a ~<strong>ed</strong> wmer inlet carri<strong>ed</strong> byfrom said boiler, said boiler being position<strong>ed</strong> rd~Ne to sMd contMner for ~e~ng water to sMd contMner ~ thesMd contMner to normally mMnmin a pr<strong>ed</strong>etermin<strong>ed</strong> ~dnity ~f the b~ler wmer ~let, and a wmer cver£owwater levi wit~n sMd boile~ an upper outlet on sMd 20 outlet carri<strong>ed</strong> by sMd contMner to mMnmin a con~antboiler above sMd pr<strong>ed</strong>eterm~<strong>ed</strong> water Mvd and commu~catingwith the ~Mt of sMd condenseL and means 11. Water degasification and ~stilMtion apparatuswater Mvd ~ sMd contMneLfor heating wmer ~ sMd boiler and period~Mly ~ecfing comprising a contMner for h~ng wmer to ~e degasifi<strong>ed</strong>and ~still<strong>ed</strong>, a boiler of relativdy small vMum~ ait therefrom ~dud~g a heating ~ement ~ sMd bMl~and generating hem m a ~mpermure suffidem to pro-2duce ~eam at a gremer rate than sMd ~eam can be with said contMner for ~e~ng wmer to sMd b~ML sMdMwer wmer ~Mt on sMd boiler and commu~cm~gd~charg<strong>ed</strong> from sMd upper outl~ creating a pressure in boiler bring posffion<strong>ed</strong> r~ative to sMd container tosMd b~Mr suffident lo force w~er ~ sMd b~Mr back normally mMntMn a p~<strong>ed</strong>e~rm~<strong>ed</strong> w~er levi wff~n~to sMd contMner through sMd Mwer ~Mt until the sMd boile~ a condenseL an upper outl~ on sMd b~lerpre~ure ~ said boiler ~ rdMv<strong>ed</strong> and boil~g interrupt<strong>ed</strong> 20 above sMd pr<strong>ed</strong>etermin<strong>ed</strong> wmer Mvd and commu~cmwhereuponwmer w~ agMn flow ~to sMd boiler to sMd ~g wffh the inlet of sMd condenseL sMd heating meanspr<strong>ed</strong>~erm~<strong>ed</strong> Mvel, said boiler being form<strong>ed</strong> of a sin#e ~ sMd boiler and generating heat m a ~mperature suffidentto produce steam at a greater rate than said steamopen-sid<strong>ed</strong> hou~ng and a readily acce~ible cover #meremovably seM<strong>ed</strong> to sMd open ~de for ready acce~ to can be d~charg<strong>ed</strong> from sMd upper outl~ creating athe boileL said boiler being form<strong>ed</strong> of hollow, sub~anfiallyhemisphericM hou~ng ha~ng a peripherM flange boiler back ~to said confiner through said lower wmer35 pressure ~ sMd boiler suffident to force water ~ sMdex~nd~g from the open end potion and portion<strong>ed</strong> ~ inl~ until the pre~ure ~ sMd boiler ~ reliev<strong>ed</strong> wher~a ve~M #an~ and sMd cover #me conform~g to the upon w~er w~ ag~n flow ~to s~d boiler to sMd pr~~ze and configurm~n of sfid flange and a gaskm ~ de~rmin<strong>ed</strong> levi, sMd b~Mr bring form<strong>ed</strong> of a ~n#epos<strong>ed</strong> b~ween sMd boiler and #me and means remov-4ably ~curing sMd #me and g~km to sMd flang~ sMd removably seM<strong>ed</strong> to sMd open ~de for ready access toopen-sid<strong>ed</strong> hou~ng and a readily accessible cover #mehollow, substantially hemisphericM hou~ng ~dud~g the b~M~ said boiler being form<strong>ed</strong> of a hollow, ~u~s~nfiMlyhemisphericM hou~ng ha~ng a pefipherM flangean ~clin<strong>ed</strong> baffle with sMd ~eam outlet l~ng on one~de of the baffle and sMd heating means on the other e~en~ng from the open en~ s~d boiler bring affix<strong>ed</strong> to~de of the baffl~ sMd water inlet ~e~ng water to the45 the outer ~de of s~d contMner wffh at M~t sMd lowerheater ~de of sMd baffle and sMd baffle fu~her ~dud- water inlet ex~nd~g through sMd housing and containeLa ~<strong>ed</strong> water inlet carri<strong>ed</strong> by sMd container for~g m lea~ one ope~ng a~M~ng the top <strong>ed</strong>ge andang~ar spac<strong>ed</strong> from the ~eam oufleL~e~ng water to sMd contMner ~ the ~dnity of the¯ Water dega~fication and ~stilMt~n apparatus b~Mr w~er inlet, and a wmer overflow outlet ca~i<strong>ed</strong>compris~g a contMner for hM~ng wmer to be degasi-5fl<strong>ed</strong> and ~stilM~ a condenser ~ s~d contMner ha~ng sMd contMneL sMd wa~r overflow oufl~ compd~ng aby sMd contMner to mMntMn a constant water levi inan inl~ and outlet, a boiler of relatively smM1 vol~m~ a horizontally d~pos<strong>ed</strong> wmer d~charge tube rotmablylower wmer ~Mt on sMd b~Mr and commu~cm~g carri<strong>ed</strong> by a fitt~g e~en~ng through the wall of sMdwffh sMd contMner m a p~nt substantially bdow the containeL the ~ner end of sMd tube bring anguMriyMvd of the w~er there~ for ~e~ng w~er ~<strong>ed</strong>y to and55 ~spos<strong>ed</strong> rdmNe to the rema~der of the tub~ means onfrom sMd b~ML sMd boiler bring position<strong>ed</strong> rdative to the outride of sMd contMner and cou#<strong>ed</strong> to sMd tubesMd contMner to normally mMntMn a pr<strong>ed</strong>etermin<strong>ed</strong> for rotation thereof whereby the Mvd of the water ~w~er Mvd wff~n sMd boileL an upper oufl~ on sMd sMd contMner can be chang<strong>ed</strong> by ang~ady po~fio~ngboiler above sMd pr<strong>ed</strong>etermin<strong>ed</strong> water Mv~ and commu~c~gwith the inl~ of sMd condenseL and means60 12. Water dega~fication and ~m~n apparatusthe ~ner end of sMd tube.for heating wmer ~ said boiler and perio~cMly ~e~g compri~ng a contMner for h~ng water to be degafif<strong>ed</strong>and ~stiH<strong>ed</strong>, a b~Mr of relativdy smM1 v~um~ a~ therefrom ~du~ng a heating ~ement ~ sMd b~Mrand generating he~ ~ a ~mFer~ure suffident lo producesteam at a gremer rate than sMd steam can be wffh sMd contMner for ~<strong>ed</strong>~g wmer to sMd boile~ sMd~wer water inlet on sMd boiler and commu~cating¯ scharg<strong>ed</strong> from sMd upper oufl~ creating a pr~sure ~ 65 boiler bring poskion<strong>ed</strong> rdafive to sMd contMner tosMd b~Mr suffident to force wmer ~ sMd boiler back normally mMntMn a pr<strong>ed</strong>~ermin<strong>ed</strong> w~er Mvd withininto said container through said ~wer wmer inl~ until sMd boileL a condenseL an upper outlet on sfid boilerthe pressure ~ sMd b~Mr ~ reliev<strong>ed</strong> and boiling ~ter- above sMd pr<strong>ed</strong>~erm~<strong>ed</strong> wmer lev~ and commu~cm-12

~61L090~g wffh the ~Mt of sMd condenses and heating means pfis~ at Ma~ one w~erproof de~ric heater carri<strong>ed</strong> by~ sMd boiler and generatMg hem ~ a ~mperMure suffl- sMd #~e wi~ ~e de~ric mrm~Ms ~spo~d on theOem m produce s~am ~ a gre~er r~e lhan sMd ~eam outer fide of sMd #m~can be d~charg<strong>ed</strong> ~om sMd upper oufl~ creating a 1~ Water degafification and distillation apparatuspre~ure ~ sMd boiler suffl~ento force wmer ~ sMd 5 according to dMm 13 wheron sMd boiler houfing indud~a baffle ~fid~g sMd housing M~ two ~para~boiler back ~to said container through said ~wer w~er~Mt until the pressure ~ sMd boiler ~ rehev<strong>ed</strong> whe~uponwmer w~ agMn flow ~to sMd b~Mr to to sMd fide of sMd baffl~ sMd heating means ~spos<strong>ed</strong> on thechamb~s wi~ sMd upper oml~ bong ~spos<strong>ed</strong> on onepr<strong>ed</strong>~erm~<strong>ed</strong> Mv~, sMd b~Mr b~ng form<strong>ed</strong> ofa sin#e other fide of sMd baffle and sMd ~wer w~er inlet ~<strong>ed</strong>open-s~<strong>ed</strong>houfing and a really accesfiMe cover #me10 ~g w~er to the heater fide ofsMd baffle and sMd baffleremovaMy seM<strong>ed</strong> to sMd open fide for ready acce~ to ~du~ng at lea~ one ope~ng near the upper <strong>ed</strong>gethe boileL sMd b~ler comprifing a sub~antiMly round the~of and angu~fly posff~n<strong>ed</strong> ~tive ~ s~d upperbowl6hap<strong>ed</strong> hou~ng ha~ng an omwar~y ex~nd~g ~eam oufleLflang<strong>ed</strong> rim and a flatten<strong>ed</strong> bottom dispos<strong>ed</strong> ~ a vertical 15. Water degafification and ~still~n apparatus#ane and smMler ~ ~ammer than sMd tim, sMd ~wer 15 according to dMm 14 where~ sMd condenser ~ ~water inlet ex~nds through sMd bosom, sMd upper pos<strong>ed</strong> wit~n sMd conmineL sMd b~Mr houfing m s~outlet extends through sMd bosom and carries a tube cur<strong>ed</strong> to the ou~r wall of sMd contMner wffh ~e upperwit~n sMd b~Mr hou~ng curv<strong>ed</strong> upwar~y and m an outl~ and ~wer ~l~ e~en~ng through the wMl ofsMdan#e rdafive to a ve~icM #ane normM to sMd bottom container, means ~r ~e~ng wmer to said container andand a #me conform~g to sMd flange secur<strong>ed</strong> ~ seM<strong>ed</strong>20 a container overflow to mMntMn a wamr Mvd ~ sMdrelationsh~ to sMd flang<strong>ed</strong> rim.contMner th~ will cause sMd boiler houfing to be nov13. Water degasiflcation and distillation apparatus mally ~l<strong>ed</strong> ~ sMd pr<strong>ed</strong>etermin<strong>ed</strong> Mvd.accord~g to OMm 12 wheron sMd heating means com-2514355565

<strong>Un</strong>it<strong>ed</strong> <strong>States</strong> <strong>Patent</strong>EIHs, Jr.I ll[lllllgll lllflll llllllllllllllHlllIHUS~0A[11] <strong>Patent</strong> Numbe~ 5,203,970~q Date of Paten~ Apr. 20, 1993METHOD FOR WATER DEGASIFICATIONAND DISTILLATION~ Invento~ John C. Elfi~ Jr., 1084 PMmer Av~,Larchmont, N.Y. 10538~1] Ap~. No.: 48~228~ Fil<strong>ed</strong>: Feb. 28, 1990FOREIGN PATENT DOCUMENTS8~8 12/1988 World Int. Prop. ~ .~ma~ Exam~er--V~nia Man~aranAttorn~ Ageng or Firm~We~eL Can~ Muter &Hayer~1] InL Ci.5 ........................B01D 3/0~ B01D 19/02; A m~hod ~r w~er d~on and distillation ~ anC02F 1/04 ~ratus ~v~g a conm~er ~r a reservo~ of w~er ~~ U~. Ci ...........................203/1~ 202/175; ~ ~g~d and distill<strong>ed</strong>, a rdafivdy sm~ b~r adj~ng~e con~ner ~d ha~ng a ~<strong>ed</strong> water cond~t202/17@ 202/180; 202/202; 202/203; 202/265;203/4; 203/22; 203/DIG. 18; 203/DIG. 22 co~e~ the con~ner and b~ler so that a s~ec~d~ Fi~ of Search ............ 202/175, 17G 203, 185.5, water ~vd ~ the conm~er w~ ~1 the ~fler to the202/265, 180, 202, 181, 188, 19~ 203/IK G 1, ~e ~v~ a coil~ tu~ condenser whh~ ~e con~er2, 2K DIG. 18, DIG. 22; 55/36 ~mer~d ~ ~e w~er ~ere~ the condenser coil hav-~g a ve~c~y ~spos<strong>ed</strong> ~n~u~n~ a~s, a secondReCreates Cit<strong>ed</strong>condor in the b~r conne~ the space above theU.S. PATENT DOCUMENTSwater levd ther~n to the ~et of the condenser so thatsteam flows ~om ~e ~r m the condenser, ~ oufl~567,434 9/1896Young.................................202/175on the condenser emen~ng ~rough a conm~er w~841,401/1907Hope...................................202/1751,30~508 6/1919Meakinet al .......................202/175~r ~schar~ng the condens<strong>ed</strong> steam as dega~fi<strong>ed</strong> ~sd~dw~eh a he~er ~ the b~er ~r being the water2,77~7231/1957Prymek...............................202/1653fl94,566 2/1974Raal.....................................202/202 ¯ erd~ and a m~or driven silver a~y ~ ~e c~L891~95 6/1975Winkler...............................159/901 tube condenser ~r gener~g a sw~g movemem of3,980,526 9/1976Kirschmann........................202/234 the reservoir water w~h ~on of steam bubbles4,045,293 8/1977Cooksley...............................203/10 therdm4,08%7505/1978Kirschmanet al ...................203/104,214,454 7/1980Taylor...................................203/10 O~on~% an over~z<strong>ed</strong> ~ter ~ mourn<strong>ed</strong> at the outlet4,26~6635/1981McFee..................................203/10 of the condense~4,34L6238/1982Loeffler................................203/104,61Z0909/1986Elli~Jr .................................203/102 Ci~ms, 2 Dra~ S~e~I004

U.S. <strong>Patent</strong> Apr. 20, 1993 Sheet 1 of 2 5,203,970tt5I00 ~38I I J ’ 1oo4

U.S. <strong>Patent</strong> Apr. 20, 1993 Sheet 2 of 2 ~203~70

5,203,970In the p~<strong>ed</strong> embo~mem of the ~vention herin ating the ~s~Mtion apparmus, it ~ generally defirabMillustrat<strong>ed</strong> a forc<strong>ed</strong> Mr ckculation means asd~s removM to ~scard the ~stilM~ produ~ until the water ~deof ~eam and undesiraWe vapo~ ~b~m<strong>ed</strong> fom He reserverwater with~ reservok container 10. The Mr ~mpermu~ w~ch Fre~raWy ~ 18~-19~ F. (w~chreservMr container 10 h~ retain<strong>ed</strong> a normM operat~gd~c~ating means w~ch ~ shown ~ FIG. 3 compri~s5 ra#~y mtMn<strong>ed</strong>). Heme~ 13 and 14 are d~n<strong>ed</strong> to heman ~vene d~h<strong>ed</strong> cover generally denot<strong>ed</strong> by the numerM~0 over re~rv~r container 10 w~ch ~dudes a condenser coil 27 can accommodme the ~eam pro-the water witch the boiler at a rate f~ter than thefiat upper wall $1 thin ~ perfora~dapenure~ an duc<strong>ed</strong>. Accor~n#% a head of ~eam ~ devdop<strong>ed</strong>upward~ emen~ng peripher~ wall 52 and a doww wit~n the boiler 12 and the steam pressure w~ forcewarty curv<strong>ed</strong> peripher~ wall ~3. The ~wer peripheral 10 hq~d fore the boiler back through the cond~t 22 ~to<strong>ed</strong>ge of the wall $3 carries three or more d~gon~ly the re~rv~r container 10 thereby reliev~g the ~teamdispos<strong>ed</strong> r~ 54 each ha~ng spac<strong>ed</strong> ~scs $~ romtablycarri<strong>ed</strong> by a sha~ 56. The ~scs $~ engage the ~ reliev<strong>ed</strong>, water will again flow through the conduit 22pressure. As soon as the steam pressure within the boilerroll<strong>ed</strong> <strong>ed</strong>ge 10’ of the reserver container 10 and accord- back ~to the boiler w~h the rese thin there will be a~y pro~de an ann~ r veto b~ween the cover $0 and 15 period~versal of wmer flow through the condu~ 22.the top <strong>ed</strong>ge of the re~rv~r container 10.Th~ pulsating action res~u ~ a mcre ~a#d ~crease ~The flat apenur<strong>ed</strong> wall ~1 of the air circulating means ~mpermure of the reservok wmer with~ the conm~ersupports an dectric motor gener~ denot<strong>ed</strong> by the 10 by contribut~g hem over and above the heat impal<strong>ed</strong>to the reservok wmer by the action of the con-numerM ~7 w~ch powers a shaft ~$ ex~n~ng throughthe perform<strong>ed</strong> w~l ~1. The ~n $9 ~ mount<strong>ed</strong> on sha~ 20 den~r c~l 27. The ~mperature of the reservo~ wmeL$$. Power ~ f<strong>ed</strong> tothe motor 57 by a cable 60 connect<strong>ed</strong> howeveL ~ Mwavs below the boil~g ~mperature (of~ a convention~ manner to the moto~ If d<strong>ed</strong>re~ the water ~ boiler 1~ so that ~me will be condens<strong>ed</strong>in condenser 27. Pre~raWy the reserver waterswitch means may be prov~<strong>ed</strong> for operation of the ~n.The ~n motor 57 is cover<strong>ed</strong> by a vent<strong>ed</strong> dom~shap<strong>ed</strong> sho<strong>ed</strong> be ke~ ~ the range of 18~ F. to 190" F. Thishou~ng 61 thin ~ securdy fia<strong>ed</strong> to the cover ~0 and ~ 25 ~mpermure Mvd w~ boil off undesirable componentsattach<strong>ed</strong> thereto by any s~tab~ means. In the ~us- from the reviver wmer (prior to actuM ~ation~at<strong>ed</strong> embo~ment of the ~ventio~ the dom~shap<strong>ed</strong> thereo0, and Mso serves to operme condenser 27 adequmdy.To mMnmin proper operation cf the apparmus,hou~ng 61 fri~ionally engages the peripher~ wall 52 ofthe cover ~0.a sub~antiM propo~ion of the ~<strong>ed</strong> water w~ch entersIn one mode of ~n operation, Mr ~ drawn ~to the Mr 30 m the ~1~ 37 ~timmdy ~ ~scharg<strong>ed</strong> as overflowdrcdating means ~mWy through an ope~ng 62 ~ through tube 32 and outlet 35.the dome~hap<strong>ed</strong> housing 61 and then down through Operm~n of ~krer Wades 102 mmeriMly changes thethe per~r~<strong>ed</strong> wall 51 whereupon it is direct<strong>ed</strong>ownwartyover the ~rv~r wm~ ~ re~rv~r contMner 102 generate a w~rling turb~ent motion of wmer ~-dynamics of the distillation apparatus. The sti~er blad~10 and therea~er is ~scharg<strong>ed</strong> through the ann~ar35 ~de cylindricM space 100 thereby improv~g heat exchangeconm~ b~ween the reservok water and theope~ng b~ween the ~rv~r contMner 10 and hscover $0. In the reverse mode of ~n operation the ~n tuMng of condenser coil 27. In addit~ motion of the59 draws Mr ~ through He ann~ opemng b~ween stirrer Wades generme ca~mtion w~ch ~ the d~t~vre~rv~r contMner 10 and ~s cover 50 up through pe~ don apparmus of th~ invention constitutes formation offora~d w~l ~1 and ope~ng out through vent 62 ~ 40 ~eam bubWes beneath the sur~ce of the wmer. Typicall%the bubWes contMn both ~eam and v~atil~<strong>ed</strong>motor hou~ng 61.As may be seen ~ FIG. 3, a stirrerod 101 extends gases and vapor~fom an integrM conne~n whh motor sha~ ~8 at the The ra#d romtionM movement of the sti~er Madeshub cf fan 59 pre~mWy but n~ necessarily axially of 102 genermes loca~z<strong>ed</strong> pressure ~fferentials ~ the rewthe cylindric~ re~rv~ re,on 100 ~dde of condenser 45 erv~r wmer cau~ng an increas<strong>ed</strong> (and super-atmospheri~pressure on the up,ream ~ce of the Mades andc~l 27 and ~rm~m~ ~ the stirrer Wades 102 immer~d~ lhe ~rv~r w~e~ The depth of immersion for a decreas<strong>ed</strong> relativdy negative Ond sub-mmospheriOstirrer Wades 102 is n~ critical, bm p~raWy, they are pre~ure on the down,ream ~ce of the Wades. S~cenot deeper than the bottom of coil condenser 27. In the the water ~ the reservoir ~ hot, desirably at betweenmode ~u~m~d hero~ the stirrer rod w~ position<strong>ed</strong> 50 18~-19~ F., generation of locM~<strong>ed</strong> sub-mmosphericmodestly off-center |o avid ~r~rence wi~h the cutletbend 29 of condenser coil 27, see FIGS. 1 and 2. w~ch steam flashes off fom the hot water (form~gpre~ure re#ons ~ the water creates a v~d space ~toIn the operat~n of the d~tiHation appara~s of t~s thereby the bubble~. Ev~v<strong>ed</strong> Mong with the ~eam, ~~vention, the reservoir container 10 and boiler 12 are any Mr still d~solv<strong>ed</strong> ~ the water and any volati~zabMfir~ fil<strong>ed</strong> wkh water to a levi at ~a~ substantially 55 components still present ~ the wmer. Moreover, as thecovering the heating dements 13 and 14 as may be bubWes pass up through the re~rv~r water to escape atobserv<strong>ed</strong> mo~ ~eady ~ FIG. 2. It will be observ<strong>ed</strong> thin the water suffac~ they scavenge Mr and v~mfl~abMwhen filling re~rv~r container 10, wmer w~l automaticallyflow through condor 22 ~to the boiler so that Thu~ mecha~cM ~ring of lhe hot re~rv~r wmercomponen~ fom the wm~.~fimmdy the ~vd of the water ~ the reservoir con-6miner 10 wi~ be the same ~ the wmer levi m the boiler remov~g M1 v~mfl~able components th~efom beforeasfis~ greatly ~ dea~m~g the re~rv~r water and ~12. When energy ~ then supp<strong>ed</strong> to the heating d~ wmer from the reservoir enters the boiler 12 to be ~men~ 13 and 14 they will function to boil the water till<strong>ed</strong> ~her~n. In ad~tio~ mecha~cM mkring ~cilimteswit~n the boiler 12. Steam fom the b~r will enter mMntenance of a good heat bMance witch the resevthe ~t 24 and then flow through the condenser coil 27 ~ v~L~o be condens<strong>ed</strong> therein. The condens<strong>ed</strong> steam will then In operm~n of the ~stilMtion apparatus, the heatdischarge ~rough filter 115 as the ~me Oiq~d) impal<strong>ed</strong> m b~Mr 12 ty the heating dements 13 and 14product fom the conden~r oufl~ 31. When firm opev can leave the ~fion app~mus o~y ~ the hem6

75,203,970energy content of the hot (condens<strong>ed</strong> ~eam) d~tiHate pipe 32 ~ r<strong>ed</strong>uc<strong>ed</strong> substantially by indu~on of ~rerprodu~ or of the hot reserver wmer discard<strong>ed</strong> through 102 ~ the distillation apparmus.overflow ~pe 32 or as the hem energy in the (heat<strong>ed</strong>) A ~m vernon mode of the distillation apparmus fllu~~r and vapor vent<strong>ed</strong> by fan 59 ~hrough ~ther the trat<strong>ed</strong> her~n was made and test<strong>ed</strong> wkhou the ~rer inann~ar ven~ in cover 50 or the opening 62 in motor5 opermion (reservoir depth 5½’3. Convection was reli<strong>ed</strong>hou~ng 61 depending on how ~n 59 ~ operm<strong>ed</strong>). To upon for stirrin& The ~mper~ure m the bottomof thethe extenth~ ~rer 102 causes cavitation and generationof ~eam bubbles in the reservoir water which bub-the reservo~ was 180" F. The temperature of the d~fibreservoir was 160" F. The temperature ~ lhe surface ofbles in turn escape the reservoir water to become late product was 200* F., and an appr<strong>ed</strong>able amount ofvente~ the proportion of boiler hem vent<strong>ed</strong> to the a~ 10 steam was being produc<strong>ed</strong> ~ong w~h the distillate.mosphere ~ increas<strong>ed</strong>. This increase ~ substanti~. Co~ About 2.5 g~lons of cooling water per gallon cf distilrespon~ngl%the quantity of heat<strong>ed</strong> reservo~ water ~te product was being us<strong>ed</strong>. Then, when the stirrer wasthat mug be discharg<strong>ed</strong> through overflow pipe 32 to operat<strong>ed</strong> the tempermure of the distillate rapidly becamer<strong>ed</strong>uc<strong>ed</strong> to below about 155" F. The~ ~o r~se them~ntain a proper heat b~ance in the reservoir watermay be and is r<strong>ed</strong>uc<strong>ed</strong>.15 tempermure in the reservo~ to above 180" F. the ratioAs a pra~ mm~L operation of stirrer blades 102 of cooling water to distil~te was r<strong>ed</strong>uc<strong>ed</strong> ~om the Z5di~inctly increases the ~mpermure differenti~ between to 1 to about 1.2 to 1. The distil~ temperature rose tothe ~eam in,de condenser coil 27 and the water in above 190" F. Then, operation of the sti~er was discontinu<strong>ed</strong>,whereupon the outlet of the condenser ~eam<strong>ed</strong>reservoir container 10 adjacent condenser coil 27. hsho<strong>ed</strong> be appr<strong>ed</strong>m<strong>ed</strong> that ~though the decreas<strong>ed</strong> pres-2sure zones on the down,ream ~ces of stirrer 102 are ~ystem return<strong>ed</strong> ~o normS.profusely. Then, the ~irrer was turn<strong>ed</strong> on again and thelocat<strong>ed</strong> and are trandent in nature, more ~ not ne<strong>ed</strong><strong>ed</strong> As has ~ready been point<strong>ed</strong> cut, a mechan~ exp<strong>ed</strong>ient~o facilita~ m~ntenance of a di~tin~ tempermureto create a bubble wher~n pan of the hem<strong>ed</strong> reservoirwater flashes into ~eam, concurrently dgnificantly across the condenser coil tubing ~ illustrat<strong>ed</strong> in FIG. 5.cooling the reservoir wmer adjacent the bubble25 Shown there ~ an charg<strong>ed</strong> pa~i~ cross-section of condensercoil tubing. In,de the tu~ng ~ a deflector 77~hrough Io~ there~om of the hem of vaporizmion forthe steam). ~nce the steam bub~e and the hct reserver whose purpose ~ to generate spir~ flow movement ofwater can coe~ at the sub-mmosphefic pre~ure ~vd steam and condensa~ to the tube wa~. Also, flow becomesmore turbulenthereby haling hem exchangegenerm<strong>ed</strong> by the stirrer 102, the buboes form readilyand do not collapse imm<strong>ed</strong>imdy when norm~ pressure30 across the tube wall. A ~ke deflector 79 may be provid<strong>ed</strong>in the cond~t connecting reservoir container 10~ re~or<strong>ed</strong>. Mostly, the ~eam bubbles escape over headof the reserv~and boiler 12 ~ee FIG. 6). The purpose of deflector 77Of cou~ the stirrer ~ in constant motion, mi~ng the is, of cours~ to create turbulent mi~ng of the water soreserver wmer q~te thoroughly so thin distin~ zones as to avid any ~mpermure ~r~iflcm~n ~lher in rese~of ~mpermure differences never can become e~ab-35 voir container 10 or in boiler 12.Hsh<strong>ed</strong> in the reservoir wmer. HoweveL generation of An addition~ option~ exp<strong>ed</strong>ient which has beenlhe ~eam ~om the locat<strong>ed</strong> (and ~anfitory) r<strong>ed</strong>uc<strong>ed</strong> found advantageous in practice of this invention ~ thepre~ure zones is ~nu~ly in~antaneou~ Once the bubbleis form<strong>ed</strong>, its collapse, however, ~ not instantaneouscondenseroufl~ 31. In the embodiment illustrat<strong>ed</strong>provision ofa fil~ pre~ra~y an over~z<strong>ed</strong> filte~ at theso th~ the bubbles la~ long enough to rise up through 40 her~n the over,zeal filter 115 is a carbon filter.the reservoir water and escape through the sur~ce FiRer 115 absorbs any orga~c mmeri~s thin are carri<strong>ed</strong>over with the condensate. ~ polishes the conden-thereo£ Since the reservoir wmer ~ hot, des~a~y in the180"-190 ° F. range, a sub~anti~ pa~i~ pre~ure of sat~ so to speak but ~so ~ achieves a superior aermionsteam e~s, which ~ to say, that the stirrer generates for the condensate.many ~eam bubbles and in tot~ the ~eam bubbles re-4move a condderable quantity of hem energy ~om the r~us of this ~vention opermes in a pulsating fashionAs has ~ready been poin~d out the d~tillation appa-reserver wmer.cau~ng water to flow through the connecting cond~tThus, generating a micro environment of tran~tory 22 back and fo~h b~ween boiler 12 and reservo~ 12.sub-mmosphefic pressure zones at the down,ream ~ce The same pulsmions affect condenser 27. A p~se ofof the stirrer 102 genermes a ~g~ficant change in the50 (steam) pressure ~om boiler 12 passes through the condensertubing in a forwar d~ection during a ~eammacro en~ronment of the reservo~. The ~mpermureof the water in the reservoir as a wh~e ~ r<strong>ed</strong>uc<strong>ed</strong> by genermion pulse, sending condensate out through filterthe flashing of ~eam to form the bubbles. Although 115. Then during the ~ eve~e suct~n prise, ~r ~ drawnonly the wmer adjacent the buboes becomes cooler, the into the filter 115, and even into the outlet end of conra~dswirling water movement caus<strong>ed</strong> by stirrer 10255 denser 27. Thu~ the filter 115 acts as much to filter ~rm~es the w~er ~most imm<strong>ed</strong>iatdy so (hm the ~mpe~ drawn into the condenser tubin~ as it does to filterature of the reservoir water over~1 has been r<strong>ed</strong>uc<strong>ed</strong>. distiH~e ~aving the condenser tubing.Moreove~ the coole reservoir water ~ adjacenthe Ma~festl% the p~ses are not equ~ in thor effect.condenser coil tubing. Thus, a better ~mpermure diffeb Steam ~ being generm<strong>ed</strong> in boiler 12, then ~ condens<strong>ed</strong>enti~ b~ween the condenser coil and the reservoir 60 in condenser coil 27. The d~tillme ~ discharg<strong>ed</strong> m thewater ~ generat<strong>ed</strong> and m~ntain<strong>ed</strong> by the stirring improvingthereb~ the opermion of condenser 27. movement of ~stil~d wmer through filter 115 res~.oufl~ 31 through filer 115. A n~ movement outflowAnother important overall pra~ effect of the At the same fim~ a small net inflow of~r into fil~r 115~fing to remove more of the baler he~ overhead of and condenser 27 result. The distiH~ ~g., atthe reserver ~ to save wate~ Le~ of the boiler hem65 190°-195 * F., is hot enough to heat filter 115 and preven~m~ro~ contaminmion of the fil~ Th~ meansmu~ be remov<strong>ed</strong> by d~carding w~er through overflowpipe 32. The proportion of the ~<strong>ed</strong> wmer in the distill~ that ~r which enters over,zeal filter 115 during thetion apparmus thin mu~ be discard<strong>ed</strong> through overflow su~n p~ses is ret~n<strong>ed</strong> ther~n and becomes ~eril~<strong>ed</strong>8