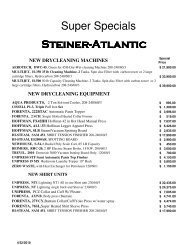

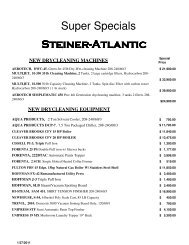

4VT SERIES - Steiner-Atlantic

4VT SERIES - Steiner-Atlantic

4VT SERIES - Steiner-Atlantic

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

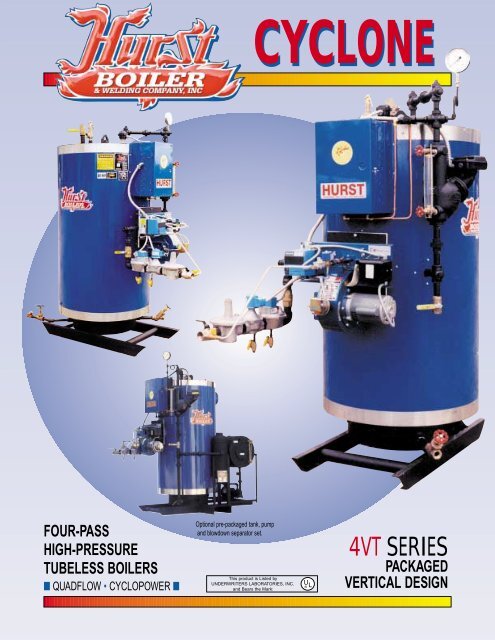

CYCLONEFOUR-PASSHIGH-PRESSURETUBELESS BOILERS■ QUADFLOW • CYCLOPOWER ■Optional pre-packaged tank, pumpand blowdown separator set.This product is Listed byUNDERWRITERS LABORATORIES, INC.and Bears the Mark:U® L<strong>4VT</strong> <strong>SERIES</strong>PACKAGEDVERTICAL DESIGN

four-passFin SystemINSPECTION ACCESS■ The waterside openings arelocated in the most effectivepositions. The lower handholesoffer far better access for bothcleanout and inspection.■ These more functional locationsavoid the obstructing handhole“tunnels” used by ourcompetitors.■ The top opening offers a strategicview of the furnace crown sheet.MORE STEAM STORAGE■ Capacity to handle swing andspike loads – quick recovery -quick response.■ The larger steam-release surfaceis calmer, reducing carry over ofunevaporated water.■ The resulting drier steam alsoreduces system scaling.■ In addition, dry steam helps toeliminate unnecessary extracondensate. Energy and fuelare saved. Longer life results.FOUR-PASS DESIGN■ The gases leaving the furnaceare split four ways and travelthrough four individual serpentinefin passages to the stack outlet.■ Each quarter of the heattravels its own four-pass path(see illustration below).■ Heat transfers evenly to the finsand boiler shell, eliminating themetal stress due to uneven heattransfer common in other designs.This illustration showsthe progression of fourgas paths around thecircumference of the boiler shell.1. Primary-pass in furnace pipe.2. Second-pass follows paththrough fins along outsideof shell.3. Third-pass follows path throughfins along outside of shell.4. Fourth-pass follows paththrough fins along outsideof shell, then merges togetherto exit exhaust stack.OPTIONS AND ALTERNATIVES■ We specialize in customizing yourboiler. The Cyclone can beequipped to suit a wide variety ofinstallations and specifications.We will help direct you to the mostcost-effective models and features.SIMPLE INSTALLATION■ Unit is skid mounted for easyhandling.■ Factory wired with wiring schematicincluded in the manual.■ Efficient and space saving layout.AVAILABLE ACCESSORIES■ The Cyclone is available in acomplete package with anoptional compact boiler-mountedfeedwater system for a finishedwired and piped, ready-to-fire unit.■ Blowdown separators are alsoavailable.

Four-PassCycloPower Fire<strong>4VT</strong> Cyclone SeriesFOUR-PASS ■ SPACE SAVING ■ TUBELESSTURBULENT FLAME■ Heat is forced down, with thefire whirling and spinning againstits natural flow. This patternenhances recirculation, mixingand heat transfer, driving moreenergy into the water for greaterfuel-to-steam efficiency.RELIABILITY■ The furnace crown is watercooled, eliminating troublesomerefractory breakdown inherent inunits of inferior design.■ No fire tubes, water coils or“in the fire” mud rings to burnout.“EYE HIGH” BURNER■ No step ladder is needed toservice.■ No bending over or sitting on thefloor.■ The air intake is located in thecenter of the unit so dust is notpulled from the floor.DURABILITY■ Fire does not pass under thebottom mud ring, eliminating theblistering that occurs with otherdesigns.■ Cooler furnace gases are locatedat the bottom of the vessel wherescale is most likely to occur.Baking of scale is alleviated.EASIER SERVICE■ Fireside fin access in top andbottom.■ Access opening above feedwaterinlet for easy cleaning.■ Thoughtfully engineered with theowner in mind.■ No heavy doors or covers tocomplicate service procedures.SAFETY■ Electrical components are locatedaway from the floor, helpingeliminate the possibility of watercoming in contact with electricity.■ Boiler built to ASME Section 1,High Pressure Boiler Code.■ CSD-1 approved.■ Burner/Boiler UL Packaged.

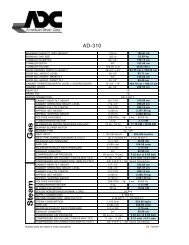

<strong>4VT</strong> Cyclone SeriesPROBE AUX.LOW WATER CUTOFFEDTO CENTER OF OUTLET(C) FEED WATERAABBBOILERHORSEPOWER6 10152025304050607080100STEAMFROM & AT 212 0FOUTPUTGROSSOUTPUTINPUTREQUIREDFIRING RATENAT.GAS 1000 BTU/FT3FIRING RATELP. GAS 91,500 BTU/GAL.FIRING RATE#2 OILSTEAM OUTLETHIGH PRESS.STEAM OUTLETLOW PRESS.BLOWDOWNHIGH PRESS.BLOWDOWNLOW PRESS.140.000 BTU/GAL.LBS./HR.K G./HR.(MBH), BTU X 1000KCAL X 1000BTU X 1000KCAL X 1000FT 3/HR.M 3/HR.GPHLPHGPHLPHIN.MMIN.MMIN.MMIN.MMC F EEDWATERIN.MMD S TACK DIA.IN.MME S TACK HEIGHTIN.MMF W IDTH WITHOUT TRIMIN.MMG W IDTH WITH TRIMIN.MMH O VERALL HEIGHTIN.MMIJLEFT SIDE VIEWPRESSUREGAUGECONTROLPANELBURNERH EIGHT WITHOUT TRIMIN.MMJ L ENGTHIN.MMW ATER CAP. @ NWLGALS.LITERSW ATER CAP. FLOODEDGALS.LITERSHITWO 3" X 4"HANDHOLESGFRONT VIEW207942015125163.32517.12.710.41.86.8125251125125.7519820352132135.289442106779200765165160152448182622353451563358441810541811.84.617.3311.3125251125125.7519820352132135.28944210677920076516516015244818262235PUMP CONTROL WITH LOW WATERCUTOFF AND GAUGE GLASS(A)STEAM OUTLET(B) BLOW DOWN51823550212762815862817.86.9264.517125251125125.7519820358147335.2894421067852159711803601524542046825769031367016983721183723.79.134.6622.6125376125125.7519820364162635.28944210678521597719566015245420479299TOP VIEWREMOVABLE TOP & BOTTOMPLATES FOR FIN CLEANING150# STEAM <strong>4VT</strong> CYCLONE <strong>SERIES</strong> SPECIFICATIONSFS HIPPING WEIGHTLBS.1700 1700 1850 1900 1900 2300 3900 5500 5500 7600 7600 9100KG.771 771 839 862 862 1043 1769 2495 2495 3347 3347 4128BOILERHORSEPOWER6 10152025304050607080100P. O. Drawer 52921971 US. Highway 319 N.Coolidge, Georgia 317381-877-994-8778 (Toll Free)(912) 346-3545 (Tel.)(912) 346-3874 (Fax.)e-mail: hboiler@rose.net8633918372111046264104629.611.443.37.528.31.2532376125125.7519820364162635.28944210678521597719566015245420479299103546910042531255316125535.513.751.9933.91.53841021.25321.25321251025463160041104147119485215977195678198173276113428138062613393371674422167447.418.369.21245.325141021.25321.253212512305731854501270551397932362882235872210122462208787172578216744222092527209259.222.986.614.956.62.56461521.25321.253212512305832108591499631600105266798248911529211585983131185STANDARD STEAM TRIMSteam pressure gauge with syphon andtest cockMcDonnell & Miller #157 combination lowwater cutoff and pump control with watercolumn blowdown valveMcDonnell & Miller probe auxiliary lowwater cutoff and relayASME safety relief valveOperating and highlimit pressure controlsSteam outlet valve, slow openig blowdownvalve, feedwater shut off valve, and checkvalves included on boilers through 30Hp.207093920095062511633251171.127.4103.917.967.92.56461521.25321.2532125123058321085914996316001052667982489115292115859831311852415109523435902929738292982.932121.220.979.22.56461521.25321.53812514356822083681727721829106269298248912030481967424401665Represented by:2760125226786753348844334894.836.6138.523.990.52.56461521.25321.53812514356822083681727721829106269298248912030481967424401665345015653348844418410544184118.545.7173.129.9113.13A 766A 1521.25B 321.5B 381.25C 3214D 35682E 208378.2F 198682G 2083106H 269298I 2489127J 3226Available with design pressures to 300 PSIG. Outlet connections over four inches on low pressure models are 150# flanges. All other connectionsare NPT. We assume no responsibility for errors in data. Consult factory for certified drawings.www.hurstboiler.com29010985912237Revised 03/00-BPC