Dimensional Metrology: Applications and Techniques

Dimensional Metrology: Applications and Techniques

Dimensional Metrology: Applications and Techniques

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

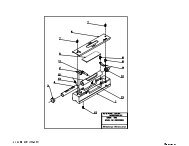

Seminar 102A<strong>Dimensional</strong> <strong>Metrology</strong>: <strong>Applications</strong> <strong>and</strong> <strong>Techniques</strong>Overview:This two-day course presents the science of measurement for students of dimensional metrology.It is intended for anyone who wishes to learn the basic tools <strong>and</strong> techniques required for reliablemeasurement. The course covers a variety of related topics to apply measurement principles with“best practices” <strong>and</strong> presents fundamental considerations for the proper selection, application, <strong>and</strong>care of typical measurement systems.A principle course objective is to develop awareness, knowledge <strong>and</strong> basic skill necessary for thereliable measurement applications. Technical terms <strong>and</strong> principles will be covered in depth. Theclassroom will provide opportunities for some h<strong>and</strong>s-on experience, <strong>and</strong> the instructor will workwith the attendees to demonstrate the proper use of common h<strong>and</strong>-held measuring tools.Measurement applications for Geometric Dimensioning <strong>and</strong> Tolerancing (GD&T) <strong>and</strong> assessmentof measurement quality will be introduced.I. Introduction – manufacturing challenges <strong>and</strong> modern measurement.II. Basic Conceptsa. Language of measurement, types of data, variable versus attribute, the“usefulness” of datab. Units of measure, expression of inch <strong>and</strong> SI metric systemsc. Process of measurement, the properties of reliability <strong>and</strong> uncertaintyd. Fundamental Laws of <strong>Metrology</strong>: Abbe’s Law, Comparator Law <strong>and</strong> otherse. St<strong>and</strong>ards <strong>and</strong> traceability, absolute length st<strong>and</strong>ard, NMIsf. Temperature issues <strong>and</strong> control for dimensional measurementg. Direct versus comparison measurementh. Introduction to a universal Error modelIII. Measurement of GD&T (ANSI Y14.5)a. History, concerns <strong>and</strong> conflicts of GD&T measurementb. Geometric tolerances – size, form, orientation, location, runout, profilec. Underst<strong>and</strong>ing the Feature Control Framed. Datum, datum reference frame, <strong>and</strong> modifierse. Attribute <strong>and</strong> functional gaging for GD&Tf. Review of variable measurement methods for GD&TIV. References <strong>and</strong> st<strong>and</strong>ard gagesa. Gage blocksb. Surface platesc. Cylindrical mastersd. Optical flats <strong>and</strong> parallelsV. Basic “H<strong>and</strong>” Tools – mechanical <strong>and</strong> digital, proper use <strong>and</strong> applicationsa. Calipersb. Micrometersc. Indicators (dial <strong>and</strong> test)VI. Attribute gages – class, selection, <strong>and</strong> proper usea. Cylindricalb. Threadc. Radius

VII. Introduction to Advanced Measurement Systemsa. Optical Comparator (profile projector)b. Cylindrical form measurement - straightness, flatness, circularity (roundness) <strong>and</strong>cylindricityc. Surface finish <strong>and</strong> basic parametersd. Coordinate Measuring Machines (CMMs)Introduction to Gage R&R (MSA) <strong>and</strong> measurement uncertaintyCourse Materials:The "<strong>Metrology</strong> H<strong>and</strong>book", 2 nd edition, 280 page, full color reference book, written by NobuoSuga, Mitutoyo Institute of <strong>Metrology</strong>, is included with this course.Additional materials provided by the Instructor.Instructor:Gordon Skattum is an ASQ Fellow, CCT, <strong>and</strong> Senior Member of SME with over 36 years inquality engineering <strong>and</strong> manufacturing technology. He is a recognized expert in dimensionalmetrology, measurement systems analysis, <strong>and</strong> process control. As a member of the TechnicalWriting Group for the AIAG, he provided significant contributions to the automotive industryMSA Reference Manual, 3rd edition.CURRICULUM:DIMENSIONAL METROLOGY is a 2-day class, followed by Gage Calibration Systems& Methods, also a 2-day class. These 4 days are held consecutively in the same week ateach location.Integrated GD&T is a 4-day class that follows the week of <strong>Dimensional</strong> <strong>Metrology</strong> <strong>and</strong>Gage Calibration Systems & Methods at each location, within a week or two.H<strong>and</strong>s-On Gage Calibration is a 3-day class held every other month at our world-classCalibration Laboratory in Elk Grove Village, IL.Measurement Uncertainty is a 2-day class in which we hold once a year at mostMitutoyo locations.On Dem<strong>and</strong> courses in CMM, MSA, Gage R&R, Surface Finish <strong>and</strong> Form Measurementcan be provided.Mitutoyo <strong>and</strong> its Institute of <strong>Metrology</strong> is a worldwide organization. We are proud to state thatmore than 200,000 engineers have attended our metrology seminars over the years. If you wish toregister or if you have additional questions, please contact us at 630-723-3620, 888-MITUTOYO,or email mim@mitutoyo.com