Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

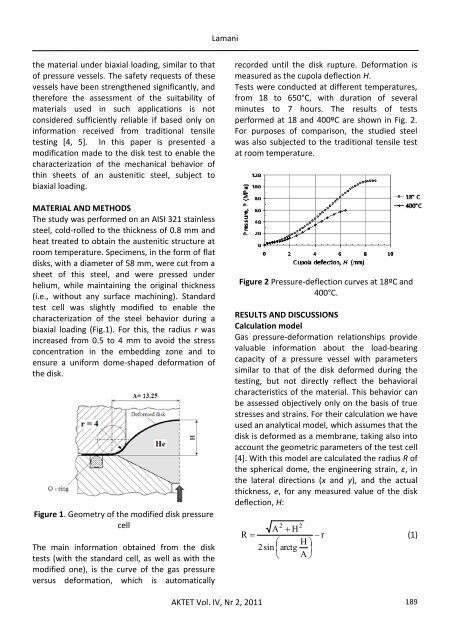

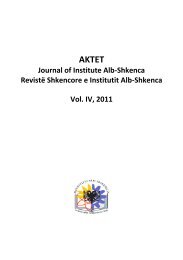

Lamanithe material under biaxial loading, similar to thatof pressure vessels. The safety requests of thesevessels have been strengthened significantly, andtherefore the assessment of the suitability ofmaterials used in such applications is notconsidered sufficiently reliable if based only oninformation received from traditional tensiletesting [4, 5]. In this paper is presented amodification made to the disk test to enable thecharacterization of the mechanical behavior ofthin sheets of an austenitic steel, subject tobiaxial loading.MATERIAL AND METHODSThe study was performed on an AISI 321 stainlesssteel, cold-rolled to the thickness of 0.8 mm andheat treated to obtain the austenitic structure atroom temperature. Specimens, in the form of flatdisks, with a diameter of 58 mm, were cut from asheet of this steel, and were pressed underhelium, while maintaining the original thickness(i.e., without any surface machining). Standardtest cell was slightly modified to enable thecharacterization of the steel behavior during abiaxial loading (Fig.1). For this, the radius r wasincreased from 0.5 to 4 mm to avoid the stressconcentration in the embedding zone and toensure a uniform dome-shaped deformation ofthe disk.Figure 1. Geometry of the modified disk pressurecellThe main information obtained from the disktests (with the standard cell, as well as with themodified one), is the curve of the gas pressureversus deformation, which is automaticallyrecorded until the disk rupture. Deformation ismeasured as the cupola deflection H.Tests were conducted at different temperatures,from 18 to 650°C, with duration of severalminutes to 7 hours. The results of testsperformed at 18 and 400ºC are shown in Fig. 2.For purposes of comparison, the studied steelwas also subjected to the traditional tensile testat room temperature.Figure 2 Pressure-deflection curves at 18ºC and400°C.RESULTS AND DISCUSSIONSCalculation modelGas pressure-deformation relationships providevaluable information about the load-bearingcapacity of a pressure vessel with parameterssimilar to that of the disk deformed during thetesting, but not directly reflect the behavioralcharacteristics of the material. This behavior canbe assessed objectively only on the basis of truestresses and strains. For their calculation we haveused an analytical model, which assumes that thedisk is deformed as a membrane, taking also intoaccount the geometric parameters of the test cell[4]. With this model are calculated the radius R ofthe spherical dome, the engineering strain, ε, inthe lateral directions (x and y), and the actualthickness, e, for any measured value of the diskdeflection, H:22A HR r(1) H 2sin arctg A AKTET Vol. IV, Nr 2, 2011 189