Keyless frictional shaft/hub locking devices - Houston Bearing and ...

Keyless frictional shaft/hub locking devices - Houston Bearing and ...

Keyless frictional shaft/hub locking devices - Houston Bearing and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE B-LOC SOLUTIONB-LOC <strong>Keyless</strong> Frictional Shaft/Hub LockingDevices provide the ultimate solution byincorporating all the advantages of interferencefits, while eliminating mounting <strong>and</strong> removalproblems.B-LOC Locking Assemblies <strong>and</strong> Shrink Discs relyon the proven wedge principle to create akeyless, mechanical interference fit by converting<strong>locking</strong> screw tension into radial contact pressureson <strong>shaft</strong> <strong>and</strong> <strong>hub</strong>. This connection, while in manyways similar to conventional shrink or press fits,has several distinct advantages:1. In the relaxed position, B-LOC keylessconnectors provide a generous clearance foreasy mounting <strong>and</strong> dismounting.2. B-LOC keyless connectors generate highercontact pressures than those obtained by ashrink or press fit, thereby allowing for shorter<strong>hub</strong> lengths <strong>and</strong> eliminating the problem offretting corrosion associated with widerconnections.3. B-LOC keyless connectors facilitate simpleaxial <strong>and</strong> angular timing of <strong>hub</strong>.B-LOC CORPORATION:COMMITTED TO QUALITYPRODUCTS AND SUPERIORCUSTOMER SERVICESince 1982, B-LOC has been committed toproviding the highest quality keyless <strong>locking</strong><strong>devices</strong> to customers worldwide. All B-LOCkeyless <strong>shaft</strong>/<strong>hub</strong> connectors are manufacturedin strict accordance with ISO 9002 requirements,<strong>and</strong> are available in a variety of styles <strong>and</strong> sizes– 1/4" up to 40" <strong>and</strong> larger, both inch <strong>and</strong> metric– to suit any application. B-LOC also has thecapability to design <strong>and</strong> produce special units,even for small quantity production runs.Our application engineers have over 20 years ofexperience <strong>and</strong> would be pleased to provide freedesign assistance for any kind of equipment.Finally, our dedicated customer service staff isready to provide you with prices, stock quantities<strong>and</strong> delivery information, <strong>and</strong> can process mostorders to ship the same day.COMPARISON CHARTB-LOCKeyedConnectionSplinedConnectionQD or TaperLockShrink orPress FitB-LOC FrictionalShaft/Hub LockingDevices haveProvides a keyless<strong>frictional</strong> connectionEasily mounted& dismounted!!! ! !!several distinctPermits simple axial& angular timing!advantages over allother commonlyused methods.Transmits reversingbending momentsProvides a backlashfree connection!!!!3

PRODUCT INDEXPAGER =Stan(α + γ) + µM t = R µ d 2p = RdπLp H =RDπL13R =Stan(α + γ) + µM t = R µ d 2p = RdπLp H =RDπL14R =Stan(α + γ)M t = R µ d 2p =RdπLp H =RDπL14R =Stan(α + γ)M t = R µ d 2p = RdπLp H =RDπL16R =Stan(α + γ) + µM t = R µ d 2p = RdπLp H =RDπL18R =2 Stan(α + γ) + µM t = R µ d 2p = RdπLp H =RDπL20R =2 Stan(α + γ) + µM t = R µ d 2p = RdπLp H =RDπL22R =2 Stan(α + γ) + µM t = R µ d 2p = RdπLp H =RDπL23R =2 Stan(α + γ)M t = (R-R cl ) µ d 2p = (R-R cl )dπL28R =2 Stan(α + γ)M t = R µ d 2p = RdπL30R = radial load generated by tightening <strong>locking</strong> screwsR cl = radial load required to bridge fit clearanceS = <strong>locking</strong> screw clamp loadM t = rated torque capacityp = <strong>shaft</strong> contact pressurep H = <strong>hub</strong> bore contact pressureα = taper angleγ = friction angleµ = coefficient of friction (= tan γ)d = <strong>shaft</strong> diameterD = <strong>locking</strong> assembly ODL = <strong>locking</strong> device contact length5

APPLICATION EXAMPLESAE1B-LOC Locking Assemblies <strong>and</strong> ShrinkDiscs are operating worldwide inthous<strong>and</strong>s of applications, including:AGITATOR SHAFTSBRAKE DISCSBUCKET WHEELSBULL GEARSCRUSHER ROTORSCLUTCHESCOUPLINGSCRANE WHEELSCAMSCONVEYOR PULLEYSFLYWHEELSFLANGESSPUR GEARSHYDRAULIC MOTORSBEVEL GEARSWORM GEARSLEVERSPUMP IMPELLERSPINION GEARSPINSROLLSSHEAVESSHIP PROPELLERSSPEED REDUCERSSPROCKETSTIMING PULLEYSUNIVERSAL JOINTSWINCH DRUMSAND MORE...AE2AE3AE4Miter gearconnected withSeries B112installed overadaptor sleevethat also servesas <strong>shaft</strong>coupling.Engineered classbelt conveyorpulley withadvancedT-shaped enddisc connectedto <strong>shaft</strong> withSeries B115.Typical SplitShrink Discarrangement.Narrow, hightorquepressgear modifiedfor repair usingboth Shrink Disc<strong>and</strong> Series B112LockingAssembly(adaptor sleeveallows use oflarger LockingAssembly,increasingtorque capacityof connection).6

AE11AE14Selective screwtightening onopposing SeriesB400 unitspermits preciseadjustment offlange pilot <strong>and</strong>axial <strong>and</strong> radialrunout.Mounting ofdrive directlyonto driven <strong>shaft</strong>results inmaintenancefreeconnection.See Page 31 formoreinformation onB-LOC sleeve<strong>and</strong> flange-typerigid couplings.AE12AE15Series 6903applies thrustagainst bearinginner raceduring assemblyin lieu of typicalarrangementusing lock nut<strong>and</strong> threaded<strong>shaft</strong>.Socket headscrews <strong>and</strong> webclearance holespermittightening ofinboard ShrinkDisc.AE13AE16Low profileflange for disctypeflexiblecouplings(<strong>locking</strong> screwscan be insertedfrom either end).Slit adaptorsleeve betweenvertical <strong>shaft</strong><strong>and</strong> Series B113acts as shoulderto transmitsubstantialvertical load intospherical rollerthrust bearing.8

AE17AE20Shrink Disc withasymmetrictapers permitsmounting of A-plate roller chainsprocket overmodified outerring wherehighest torque isgenerated.Inverted ShrinkDisc connectscoupling flangeto counterbored<strong>shaft</strong>; <strong>shaft</strong>strengthreductionsurprisingly low.AE18AE21Modified ShrinkDisc formounting disctypeflexiblecoupling flangein applicationwhere low WR 2value is critical.Series B106used to connectlever arm.LockingAssemblyconnectionpermits quick<strong>and</strong> easy timingof several suchlever armsmounted onsame <strong>shaft</strong>.AE19AE22Inverted B800allows forextremely small<strong>hub</strong> bores.Series B112supplied withtapered-boreadaptor sleeveused to connectlarge fan wheel<strong>hub</strong> directly totapered motor<strong>shaft</strong>.9

B-LOC INTERNAL DEVICES:LOCKING ASSEMBLIESDESIGN FEATURESTORQUEB-LOC Locking Assemblies are well suited to transmittorque, bending, thrust, <strong>and</strong> radial loads. Proper selectionresults in a zero backlash connection free of wear evenunder severe reversing loads.Use the following criteria to aid in selectingthe right unit for your application:T = peak drive torque = nominal torque multiplied by avariable safety factor to account for stall or start-upconditions, mass accelerations, impact loads, etc.Nominal drive torque can be calculated as follows:M tnom = 5252 x HP / rpmConsult with us in cases where “T” is uncertain.M t = rated torque capacity of (1) B-LOC LockingAssembly with all screws tightened to specified torqueM A as listed in specifications. Tabular values arecalculated without using a safety factor <strong>and</strong> should beconsidered as the point where a connection could slip if ahigher torque is applied. Therefore, you should alwaysselect a unit where M t ≥ T.Torque capacity <strong>and</strong> contact pressures are a linearfunction of <strong>locking</strong> screw tightening torque <strong>and</strong> may bevaried if this is advantageous for certain applications bychanging M A within the following limits:Series B400:Series B103/B106/B109:Series B800:Series B112/B113:Series B115:up to 20% higheror up to 20% lowerup to 20% lowerup to 20% lowerup to 40% lowerup to 30% lowerIn installations where two or more B-LOC LockingAssemblies are arranged in series with access to <strong>locking</strong>screws from one side only, total torque capacity is not alinear function of the number of units applied. In thesesituations, the factor f mu should be used to compute totaltorque capacity, as follows:M t total = n x M t x f muTHRUSTF ax = transmissable thrust, determined by using thefollowing equation:24 x MF ax = 24 t, where d = <strong>shaft</strong> diameter (in)dTORQUE AND THRUST COMBINEDSimultaneous transmission of torque <strong>and</strong>thrust requires calculating a resultant torque:M tres = T 2 + (F x D / 2) 2 , where:T = peak drive torque (ft-lbs)F = peak thrust load (lbs)D = <strong>shaft</strong> diameter (ft)Select a unit where M t ≥ M tres .BENDING MOMENTSBending moments are a crucial sizing factor inapplications where a radial load from chain pull, theweight of components, etc., acts significantly outside the<strong>locking</strong> assembly centerline. Typical applications includerolls or conveyor pulleys where <strong>shaft</strong> deflection due toradial loads results in a bending moment between <strong>shaft</strong><strong>and</strong> end disc. Generally, bending moments change froma positive to a negative value during each rotation <strong>and</strong>are designated as rotating or reversing bending moments.B-LOC Locking Assemblies are well suited to transmitrotating/reversing bending moments. As a result ofnumerous successful heavy-duty applications in conveyorpulleys <strong>and</strong> pertinent investigations by independentinstitutions, the following bending moment capacitiesapply:SeriesBending Moment CapacityB400= 0.22 x M tB103, B106, B109, B800 = 0.28 x M tB115= 0.32 x M tB112 <strong>and</strong> B113= 0.35 x M tConsult with us for applications where the bending momentcapacity exceeds these recommended limits.10Factors “f mu ”for determining total torque capacity inmultiple unit Locking Assembly installationsLocking Assembly n = number of units in seriesType2 3 4B400 & B103 .80 .75 .70B115 .80 .75 N/AB112 .85 N/A N/AB113 .90 N/A N/ATORQUE AND BENDING COMBINEDSimultaneous transmission of torque <strong>and</strong>bending requires calculating a resultant torque:M tb = T 2 + (2M b ) 2 , where:T = peak drive torque (ft-lbs)M b = bending moment (ft-lbs)Select a unit where M t ≥ M tb <strong>and</strong> M b is within the limitsshown above.

CONCENTRICITYB-LOC Locking Assemblies provide good to perfectconcentricity in a variety of applications. The level ofconcentricity depends on taper angle <strong>and</strong> length, <strong>hub</strong>pre-centering, <strong>and</strong> mode of screw tightening. The followingdescription of features should be helpful in selecting themost suitable device to meet specific concentricityrequirements.TEMPERATURE INFLUENCESimilar to conventional shrink or press fits, B-LOCLocking Assembly connections are not affected bytemperature changes as long as they apply equally to<strong>hub</strong> <strong>and</strong> <strong>shaft</strong>. Since temperatures above 400 deg. Flower the strength of most commonly used materials,special considerations are necessary for connectionsworking in temperatures higher than 400 deg. F.SERIES B400: The relatively narrow width of thesedouble collar <strong>devices</strong> usually necessitates the need for apre-centering <strong>hub</strong> section. Type of fit as well as the lengthof this pre-centering section greatly influences concentricity.The use of pilot bushings permits the reduction of <strong>hub</strong>length or even the elimination of pre-centering <strong>hub</strong>sections in the case of a roll configuration. These unitsprovide concentricity sufficient for low to medium speedcomponents.SERIES B103, B106, B109, B800: TheseLocking Assemblies do not require a pre-centering <strong>hub</strong>section. The I.D., O.D. <strong>and</strong> taper of these units aremachined in a single set-up ensuring perfect concentricityfor the <strong>locking</strong> assembly itself. Total system concentricity willdepend on installed components, but is typically excellent,even for high speed applications.SERIES B115, B112, B113: The good precenteringcharacteristics of these <strong>devices</strong>, combined withtheir wide double taper design, provides excellentconcentricity for any type of application.RADIAL LOADSRadial loads are generated by forces appliedperpendicular to the centerline of the <strong>shaft</strong>, <strong>and</strong> arefrequently associated with pin or axle connections.B-LOC Locking Assemblies are well suited to provide atight, backlash-free fit for such connections (see illustrationbelow).F rad = radial load capacity = d x L x P, where:d = <strong>shaft</strong> diameter (in)L = contact length (in), see spec. tablesP = <strong>shaft</strong> contact pressure (psi)Typical pressure distribution in backlash-free pin connectionsd=pin diameterHOLLOW SHAFTSSECURING OF LOCKING SCREWSRELEASABILITYMATERIALHollow <strong>shaft</strong>s with bores exceeding 35% of outsidediameter usually require a reduction of contactpressures in order to avoid permanent <strong>shaft</strong>contraction. Consult with us for the amount of reductionrequired or for corrective measures available for atrouble-free hollow <strong>shaft</strong> application.Specified <strong>locking</strong> screw tightening torque M A assuressufficient pre-load so that screws are self-<strong>locking</strong>, evenin cases where B-LOC Locking Assemblies aresubjected to extreme vibratory conditions.B-LOC Locking Assemblies <strong>and</strong> Shrink Discs aredesigned for fast <strong>and</strong> easy removal. Our B400 LockingAssemblies, as well as all B-LOC Shrink Discs, featureself-releasing tapers. All other types use self-<strong>locking</strong>tapers for a more efficient clamp load conversion <strong>and</strong>higher bending moment capacities. For these units, asufficient number of integrated push-off holes assurepositive dismounting even after many years of service.B-LOC Locking Assemblies are manufactured from heattreated high-carbon <strong>and</strong> alloy steels. Please contact usfor applications requiring stainless steel. Corrosionresistance can be improved through the application ofindustry st<strong>and</strong>ard plating materials <strong>and</strong>/or the use ofprotective cover plates.Loadp min. = p - p L≥ 0Explanations:p = contact pressure providedby Locking Ass’y.p L = contact pressure onprojected contact areaload=d x contact lengthY. P. = yield point of pin materialLUBRICANTSB-LOC Locking Assemblies are supplied lightly coatedwith ordinary machine oil.p max. = p + p L≤ Y. P.11

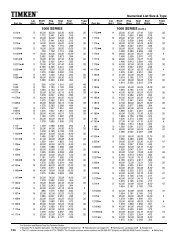

B109 SERIESScrew head height = screw dia. (mm)L 2L 1LdD D 1Ordering Information:Specify series & <strong>shaft</strong> size(e.g., Locking Assembly Series B109 ¼ ” )Larger sizes <strong>and</strong> sizes not shown are available on request.B109 METRIC SPECIFICATIONSPush-off screw threads.Notes:1. Tolerance for <strong>shaft</strong> <strong>and</strong> bore is ± .001″ for all sizes.2. Surface finish for <strong>shaft</strong> <strong>and</strong> bore is 63-125 µIN RMS.(Relaxed)M t p HSIZE68101112141516192022d0.23620.31500.39370.43310.47240.55120.59060.62990.74800.78740.8661D0.81250.87500.93751.06251.06251.18751.18751.18751.31251.56251.5625D 10.93751.00001.06251.18751.18751.31251.31251.31251.43751.75001.7500L0.3940.3940.3940.3940.3940.4720.4720.4720.4720.5910.591L 10.5160.5160.5160.5160.5160.5940.5940.5940.5940.7540.754L 20.6500.6500.6500.6500.6500.8070.8070.8070.8070.9840.984(in-lbs)1732573214715148999631,0271,2202,0982,308(psi)12,16212,54811,71113,77813,77815,43615,43615,43613,96615,30615,306D N*1.0721.1651.2241.4581.4581.6981.6981.6981.8092.2272.227Qty.3334466666624 0.9449 1.6875 1.8750 0.591 0.754 0.984 3,356 18,896 2.640 825 0.9843 1.68750.591 0.754 0.984 3,496 18,896 2.640 8NEW!! 28 NEW!!1.1024 1.8750NEW!!2.0000 0.669 0.829 1.102 4,405 16,901 2.783 930 1.1811 1.9375 2.0625 0.669 0.829 1.102 5,244 18,173 2.973 1032 1.2598 2.0000 2.1250 0.669 0.829 1.102 5,594 17,606 3.023 10imprecise keys 35TMflimsy imprecise 1.3780 set-screws keys2.1250flimsy imprecise 2.2500 set-screws keys 0.669 Mini Series flimsy 0.829 set-screws 1.102 Mini Series 6,118 16,570Mini 3.127 Series TM 10TMLocking ScrewsSizeM4 x 12M4 x 12M4 x 12M4 x 12M4 x 12M4 x 14M4 x 14M4 x 14M4 x 14M5 x 18M5 x 18M5 x 18M5 x 18M5 x 18M5 x 18M5 x 18M5 x 18M A(in-lbs)3842.542.542.542.542.542.542.542.58787878787878787Weight(lbs)0.10.10.10.10.10.10.20.20.20.40.40.40.40.60.60.60.6B109 INCH SPECIFICATIONSSIZE1/45/163/81/25/83/47/811 1/81 3/161 1/41 3/8d0.25000.31250.37500.50000.62500.75000.87501.00001.12501.18751.25001.3750D0.81250.87500.93751.06251.18751.31251.56251.68751.87501.93752.00002.1250TRUE ZERO BACKLASH CONNECTIONTRUE ZERO BACKLASH CONNECTIONTRUE ZERO BACKLASH CONNECTION(Relaxed)SIMPLE TO INSTALL, ADJUST, M t pSIMPLE REMOVE TO INSTALL, ADJUST, SIMPLE REMOVE H TO INSTALL, ADJUST, REMOVE Locking ScrewsD 1 L L 1 L 2 (in-lbs) (psi) D N* Qty. SizeSELF-CENTERING0.394 0.516 0.650 SELF-CENTERING 183 12,162 SELF-CENTERING 1.072 3 M4 x 120.394 0.516 0.650 255 12,548 1.165 3 M4 x 12LOW PROFILE FOR THIN-WALL LOW HUBS PROFILE FOR THIN-WALL LOW PROFILE HUBS FOR THIN-WALL HUBS0.394 0.516 0.650 306 11,711 1.224 3 M4 x 120.394 0.516 0.650 544 13,778 1.458 4 M4 x 12WORKS ON PLAIN OR KEYED WORKS SHAFTS ON PLAIN OR KEYED WORKS SHAFTS ON PLAIN OR KEYED SHAFTS0.472 0.594 0.807 1,019 15,436 1.698 6 M4 x 160.472 0.594 0.807 1,223 13,966 1.809 6 M4 x 16TRANSMITS TORQUES FROM0.591 0.754 0.984TRANSMITS 180 TO2,331TORQUES 15,306 FROM TRANSMITS 180 2.227 TOTORQUES 6 FROM M5 180 x TO206,100 IN-LBS6,100 IN-LBS 6,100 IN-LBS0.591 0.754 0.984 3,552 18,896 2.640 8 M5 x 200.669 0.829 1.102 4,496 16,901 2.783 9 M5 x 20HIGH STRENGTH ALLOY STEEL HIGH STRENGTH ALLOY STEEL HIGH STRENGTH ALLOY STEEL0.669 0.829 1.102 5,273 18,173 2.973 10 M5 x 200.669 0.829 1.102 5,550 17,606 3.023 10 M5 x 200.669 0.829 1.102 6,105 16,570 3.127 10 M5 x 200.93751.00001.06251.18751.31251.43751.75001.87502.00002.06252.12502.2500*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)M A(in-lbs)3842.542.542.542.542.5878787878787Weight(lbs)0.10.10.10.10.20.20.40.40.60.60.60.6Possible design configurations13

B103 & B106 SERIESB106Screw head height = screw dia. (mm)Required <strong>hub</strong> OD dependson strength of <strong>hub</strong> material(see Specifications <strong>and</strong> Hub Sizing on Page 24)L 1LD 1L 2D NDBore dia. machined to D -0/+TT= .002” for bores up to 4.724”.003” for bores up to 12.008”.004” for bores over 12.008”d = Shaft dia. machined to d +0/-TSurface finish for <strong>shaft</strong> <strong>and</strong><strong>hub</strong> bore to be 63-125 µIN RMSLocking screws transfer tointegrated push-off holes fordisassembly.Ordering Information:Specify series & <strong>shaft</strong> size(e.g., Locking Assembly Series B106 160mm)Larger sizes <strong>and</strong> sizes not shown are available on request.Metric socket head<strong>locking</strong> screwsDIN 912 grade 12.9(See M A for tighteningtorque).Note:Series B106 also available withoptional integrated spacer sleeve (idealfor very narrow drive elements) byspecifying B106 SP when ordering.Spacers are 0.275″ wide for sizes to<strong>and</strong> including 1½″ (40 mm) <strong>and</strong>0.315″ wide for all other sizes.B103/106 METRIC SPECIFICATIONSLocking ScrewsSize20 x 4722 x 4724 x 5025 x 5028 x 5530 x 5535 x 6040 x 6545 x 7550 x 8055 x 8560 x 9065 x 9570 x 11075 x 11580 x 12085 x 12590 x 13095 x 135100 x 145110 x 155120 x 165130 x 180140 x 190150 x 200160 x 210170 x 225180 x 235190 x 250200 x 260220 x 285240 x 305260 x 325280 x 355300 x 375320 x 405340 x 425360 x 455380 x 475400 x 495d0.7870.8660.9450.9841.1021.1811.3781.5751.7721.9692.1652.3622.5592.7562.9533.1503.3463.5433.7403.9374.3314.7245.1185.5125.9066.2996.6937.0877.4807.8748.6619.44910.23611.02411.81112.59813.38614.17314.96115.748D1.8501.8501.9691.9692.1652.1652.3622.5592.9533.1503.3463.5433.7404.3314.5284.7244.9215.1185.3155.7096.1026.4967.0877.4807.8748.2688.8589.2529.84310.23611.22012.00812.79513.97614.76415.94516.73217.91318.70119.488D 1(B106 only)2.1062.1062.2242.2242.4212.4212.6182.8153.2873.4843.6813.8984.0944.6854.8825.0795.2765.4725.6696.0636.4576.8507.4417.8358.2288.6229.2139.60610.19710.59111.57512.36213.15014.33115.11816.29917.08718.26819.05519.843L0.6690.6690.6690.6690.6690.6690.6690.6690.7870.7870.7870.7870.7870.9450.9450.9450.9450.9450.9451.0241.0241.0241.3391.3391.3391.3391.7321.7321.7321.7321.9691.9691.9692.3622.3622.9132.9133.3863.3863.386(Relaxed)L 10.8860.8860.8860.8860.8860.8860.8860.8861.0431.0431.0431.0431.0431.2011.2011.2011.2011.2011.2011.2991.2991.2991.6141.6141.6141.6142.0082.0082.0082.0082.2442.2442.2442.6382.6383.2283.2283.7013.7013.701L 21.1221.1221.1221.1221.1221.1221.1221.1221.3581.3581.3581.3581.3581.5941.5941.5941.5941.5941.5941.7721.7721.7722.1652.1652.1652.1652.5592.5592.5592.5592.8742.8742.8743.3463.3464.0164.0164.5674.5674.567M t(ft-lbs)2062262963083453705766581,1961,3291,6711,8232,2223,3773,6183,8594,6134,8855,7297,0247,7269,48214,09515,17918,07021,20224,57626,02134,33336,14044,20160,27378,35590,252108,786150,537186,603210,810259,609273,272p H(psi)13,42013,42015,13815,13813,76213,76216,82015,52618,49017,33518,64617,61018,76819,06418,23517,47518,87318,14719,41719,43718,18319,21618,48217,50918,48219,36215,23414,58517,13816,47914,70917,18019,34715,78716,81316,37518,20515,61217,44716,742D N*2.5172.5172.7942.7942.9702.9703.4993.6674.5704.7285.2005.3575.8326.8066.9597.1187.6957.8498.4349.0639.36710.25210.96511.28012.18313.10012.60112.95014.69915.02915.75317.95220.26520.16121.86323.34825.69925.72628.15428.807Qty.556666887788988899108899910111212151512151816181821182121SizeM6 x 20M6 x 20M6 x 20M6 x 20M6 x 20M6 x 20M6 x 20M6 x 20M8 x 25M8 x 25M8 x 25M8 x 25M8 x 25M10 x 30M10 x 30M10 x 30M10 x 30M10 x 30M10 x 30M12 x 35M12 x 35M12 x 35M14 x 40M14 x 40M14 x 40M14 x 40M14 x 40M14 x 40M14 x 40M14 x 40M16 x 45M16 x 45M16 x 45M18 x 50M18 x 50M20 x 50M20 x 50M22 x 60M22 x 60M22 x 60*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)M A [ft-lb]B103 B1061010101010101010252525252550505050505090909013513513513513513513513521921921929029042042056056056012121212121212123030303030606060606060105105105166166166166166166166166257257257350350500500675675675Weight(lbs)0.60.60.70.70.80.70.80.91.51.71.81.92.13.73.84.14.34.54.76.26.67.210121213181922233134365080808510212113414

B103 & B106 SERIESB103Ordering Information:Specify series & <strong>shaft</strong> size(e.g., Locking Assembly Series B103 2 15 /16” )Larger sizes <strong>and</strong> sizes not shown are available on request.B103/106 INCH SPECIFICATIONSNote:Flange of Series B103 <strong>locking</strong> assembliesshould be located inside of <strong>hub</strong> bore.Locking ScrewsD 1(Relaxed)M t p HM A [ft-lb]Size3/47/8d0.7500.875D1.8501.850(B106 only)2.1062.106L0.6690.669L 10.8860.886L 21.1221.122(ft-lbs)196228(psi)13,42013,420D N*2.5172.517Qty.55SizeM6 x 20M6 x 20B1031010B106121211 1/81 3/161 1/41 3/81 7/161 1/21 5/81 11/161 3/41 7/81 15/1622 1/82 3/162 1/42 3/82 7/162 1/22 9/162 11/162 3/42 7/82 15/1633 1/43 3/83 7/163 1/23 3/43 15/1644 7/164 3/44 15/1655 7/165 15/166 7/166 15/1677 7/167 15/1681.0001.1251.1881.2501.3751.4381.5001.6251.6881.7501.8751.9382.0002.1252.1882.2502.3752.4382.5002.5632.6882.7502.8752.9383.0003.2503.3753.4383.5003.7503.9384.0004.4384.7504.9385.0005.4385.9386.4386.9387.0007.4387.9388.0001.9692.1652.1652.3622.3622.5592.5592.9532.9532.9533.1503.1503.1503.3463.3463.5433.5433.7403.7403.7404.3314.3314.5284.5284.7244.9214.9215.1185.1185.3155.7095.7096.1026.4967.0877.0877.4807.8748.8589.2529.2529.84310.23610.2362.2242.4212.4212.6182.6182.8152.8153.2873.2873.2873.4843.4843.4843.6813.6813.8983.8984.0944.0944.0944.6854.6854.8824.8825.0795.2765.2765.4725.4725.6696.0636.0636.4576.8507.4417.4417.8358.2289.2139.6069.60610.19710.59110.5910.6690.6690.6690.6690.6690.6690.6690.7870.7870.7870.7870.7870.7870.7870.7870.7870.7870.7870.7870.7870.9450.9450.9450.9450.9450.9450.9450.9450.9450.9451.0241.0241.0241.0241.3391.3391.3391.3391.7321.7321.7321.7321.7321.7320.8860.8860.8860.8860.8860.8860.8861.0431.0431.0431.0431.0431.0431.0431.0431.0431.0431.0431.0431.0431.2011.2011.2011.2011.2011.2011.2011.2011.2011.2011.2991.2991.2991.2991.6141.6141.6141.6142.0082.0082.0082.0082.0082.0081.1221.1221.1221.1221.1221.1221.1221.3581.3581.3581.3581.3581.3581.3581.3581.3581.3581.3581.3581.3581.5941.5941.5941.5941.5941.5941.5941.5941.5941.5941.7721.7721.7721.7722.1652.1652.1652.1652.5592.5592.5592.5592.5592.5593133523725225746006271,0971,1401,1821,2661,3081,3511,6401,6881,7361,8332,1162,1712,2253,2933,3703,5233,6003,6763,9824,6534,7394,8255,7447,0257,1367,9179,53413,59713,77014,97418,16823,63825,47425,70334,13736,43236,71915,13813,76213,76216,82016,82015,52615,52618,49018,49018,49017,33517,33517,33518,64618,64617,61017,61018,76818,76818,76819,06419,06418,23518,23517,47516,77618,87318,14718,14719,41719,43719,43718,18319,21618,48218,48217,50918,48215,23414,58514,58517,13816,47916,4792.7942.9702.9703.4993.4993.6673.6674.5704.5704.5704.7284.7284.7285.2005.2005.3575.3575.8325.8325.8326.8066.8066.9596.9597.1187.2817.6957.8497.8498.4349.0639.0639.36710.25210.96510.96511.28012.18312.60112.95012.95014.69915.02915.0296668888777777888899988888899910888999910121212151515M6 x 20M6 x 20M6 x 20M6 x 20M6 x 20M6 x 20M6 x 20M8 x 25M8 x 25M8 x 25M8 x 25M8 x 25M8 x 25M8 x 25M8 x 25M8 x 25M8 x 25M8 x 25M8 x 25M8 x 25M10 x 30M10 x 30M10 x 30M10 x 30M10 x 30M10 x 30M10 x 30M10 x 30M10 x 30M10 x 30M12 x 35M12 x 35M12 x 35M12 x 35M14 x 40M14 x 40M14 x 40M14 x 40M14 x 40M14 x 40M14 x 40M14 x 40M14 x 40M14 x 4010101010101010252525252525252525252525255050505050505050505090909090135135135135135135135135135135121212121212123030303030303030303030303060606060606060606060105105105105166166166166166166166166166166*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)Weight(lbs)0.60.60.70.80.70.90.81.01.01.71.61.61.81.71.61.91.82.11.92.22.22.13.83.74.03.94.44.54.34.84.64.76.26.06.37.11111121220202022232115

B400 SERIES≥L 1 **Required <strong>hub</strong> OD dependson strength of <strong>hub</strong> material(see Specifications <strong>and</strong> Hub Sizing on Page 24)L 2L 1D NBore dia. machined to D -0/+TT= .002” for bores up to 1.969”.003” for bores up to 4.724”.004” for bores up to 9.252”.005” for bores up to 14.764”D.006” for bores over 14.764”Ld=Shaft dia. machined to d +0/-TSurface finish for <strong>shaft</strong> <strong>and</strong><strong>hub</strong> bore to be 63-125 µIN RMS.Ordering Information:Specify series & <strong>shaft</strong> size(e.g., Locking Assembly Series B400 2 1 / 2 ”)Larger sizes <strong>and</strong> sizes not shown are available on request.B400 METRIC SPECIFICATIONSSize20 x 4722 x 4724 x 5025 x 5028 x 5530 x 5532 x 6035 x 6038 x 6540 x 6542 x 7545 x 7548 x 8050 x 8055 x 8560 x 9065 x 9570 x 11075 x 11580 x 12085 x 12590 x 13095 x 135100 x 145110 x 155120 x 165130 x 180140 x 190150 x 200160 x 210170 x 225180 x 235190 x 250200 x 260220 x 285240 x 305260 x 325280 x 355300 x 375320 x 405340 x 425360 x 455380 x 475400 x 495420 x 515440 x 545460 x 565480 x 585500 x 605d0.7870.8660.9450.9841.1021.1811.2601.3781.4961.5751.6541.7721.8901.9692.1652.3622.5592.7562.9533.1503.3463.5433.7403.9374.3314.7245.1185.5125.9066.2996.6937.0877.4807.8748.6619.44910.23611.02411.81112.59813.38614.17314.96115.74816.53517.32318.11018.89819.685D1.8501.8501.9691.9692.1652.1652.3622.3622.5592.5592.9532.9533.1503.1503.3463.5433.7404.3314.5284.7244.9215.1185.3155.7096.1026.4967.0877.4807.8748.2688.8589.2529.84310.23611.22012.00812.79513.97614.76415.94516.73217.91318.70119.48820.27621.45722.24423.03123.819L0.6690.6690.6690.6690.6690.6690.6690.6690.6690.6690.7870.7870.7870.7870.7870.7870.7870.9450.9450.9450.9450.9450.9451.0241.0241.0241.3391.3391.3391.3391.4961.4961.8111.8111.9691.9691.9692.3622.3622.8352.8353.3073.3073.3073.3073.7803.7803.7803.780(Relaxed)L 10.7870.7870.7870.7870.7870.7870.7870.7870.7870.7870.9450.9450.9450.9450.9450.9450.9451.1021.1021.1021.1021.1021.1021.2991.2991.2991.4961.4961.4961.4961.7321.7322.0472.0472.2052.2052.2052.5982.5983.0713.0713.5433.5433.5433.5434.0164.0164.0164.016L 21.0241.0241.0241.0241.0241.0241.0241.0241.0241.0241.2601.2601.2601.2601.2601.2601.2601.4961.4961.4961.4961.4961.4961.7721.7721.7721.9691.9691.9691.9692.2832.2832.5982.5982.8352.8352.8353.3073.3073.8583.8584.4094.4094.4094.4094.9614.9614.9614.961M t(ft-lbs)2342573163294104395626157788191,3581,4551,5521,6172,0742,2632,8024,1994,5004,8005,8276,1707,3278,7789,65712,03816,30219,31322,57526,08332,13637,12245,71051,55567,74385,277104,696129,013155,501214,016227,403299,461316,110332,739388,186470,039491,393538,413587,541Metric socket head<strong>locking</strong> screwsDIN 912 grade 12.9(See M A for tighteningtorque).(2) or (3) equally spaced zinc platedscrews provided solely to indicate positionof partial pull out threads size d B .p H(psi)15,28215,28216,16116,16116,32416,32417,95717,95719,33819,33822,48322,48321,07821,07823,14421,85823,66623,70522,67521,73023,84122,92424,83424,29122,72424,39621,37722,27723,08723,82023,06524,09121,82522,48522,54424,30625,85222,56624,03323,92822,80222,70621,75020,87122,28921,30120,54720,83621,107D N *2.6352.6352.8672.8673.1673.1673.6043.6044.0524.0525.1125.1125.2355.2355.9096.0236.7107.7797.8838.0008.8778.9789.89110.44210.64011.92211.87912.87113.88014.90315.60416.81816.71417.72219.46021.97524.61324.25626.78928.83829.24331.21731.68632.19934.90035.88836.41838.01739.619Qty.8899101012121414121212121414161414141616181414162022242622242830263034323636363636364040404244** Recommended pre-centering length ininstallations without pilot bushings. Provide aminimum .001” clearance (<strong>hub</strong> concentricitydepends on fit clearance).Locking ScrewsSize M A (ft-lbs)M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M10 x 25M10 x 25M10 x 25M10 x 25M10 x 25M10 x 25M12 x 30M12 x 30M12 x 30M12 x 35M12 x 35M12 x 35M12 x 35M14 x 40M14 x 40M14 x 45M14 x 45M16 x 50M16 x 50M16 x 50M18 x 60M18 x 60M20 x 70M20 x 70M22 x 80M22 x 80M22 x 80M22 x 80M24 x 90M24 x 90M24 x 90M24 x 90111111111111111111112626262626262651515151515191919191919191138138138138214214214293293420420565565565565725725725725d BM8M8M8M8M8M8M8M8M8M8M10M10M10M10M10M10M10M12M12M12M12M12M12M14M14M14M14M14M14M14M16M16M16M16M20M20M20M22M22M24M24M27M27M27M27M30M30M30M30Weight(lbs)0.50.50.50.50.60.60.70.60.70.71.21.21.31.31.41.41.52.72.93.03.13.33.54.75.15.57.78.28.69.412131819242628434564699597101110142148156160*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)16

B400 INCH SPECIFICATIONSSize3/47/811 1/81 3/161 1/41 3/81 7/161 1/21 5/81 11/161 3/41 7/81 15/1622 1/82 3/162 1/42 3/82 7/162 1/22 9/162 5/82 11/162 3/42 7/82 15/1633 1/83 1/43 3/83 7/163 1/23 3/43 7/83 15/1644 3/164 7/164 1/24 15/1655 7/165 1/266 7/166 1/26 15/1677 1/27 7/88d0.7500.8751.0001.1251.1881.2501.3751.4381.5001.6251.6881.7501.8751.9382.0002.1252.1882.2502.3752.4382.5002.5632.6252.6882.7502.8752.9383.0003.1253.2503.3753.4383.5003.7503.8753.9384.0004.1884.4384.5004.9385.0005.4385.5006.0006.4386.5006.9387.0007.5007.8758.000D1.8501.8501.9692.1652.1592.3622.3652.5592.5592.9532.9532.9533.1503.1503.3463.3463.5433.5433.5313.7403.7403.7374.3314.3314.3374.5284.5284.7244.7244.9214.9215.1185.1185.3055.7095.7095.8436.1026.4966.4967.0877.0877.4807.4928.2688.8588.8589.2529.2529.82310.23610.504L0.6690.6690.6690.6690.6690.6690.6690.6690.6690.7870.7870.7870.7870.7870.7870.7870.7870.7870.7870.7870.7870.7870.9450.9450.9450.9450.9450.9450.9450.9450.9450.9450.9450.9451.0241.0241.0241.0241.0241.0241.3391.3391.3391.3391.3391.4961.4961.4961.4961.8111.8111.811(Relaxed)L 10.7870.7870.7870.7870.7870.7870.7870.7870.7870.9450.9450.9450.9450.9450.9450.9450.9450.9450.9450.9450.9450.9451.1021.1021.1021.1021.1021.1021.1021.1021.1021.1021.1021.1021.2991.2991.2991.2991.2991.2991.4961.4961.4961.4961.4961.7321.7321.7321.7322.0472.0472.047L 21.0241.0241.0241.0241.0241.0241.0241.0241.0241.2601.2601.2601.2601.2601.2601.2601.2601.2601.2601.2601.2601.2601.4961.4961.4961.4961.4961.4961.4961.4961.4961.4961.4961.4961.7721.7721.7721.7721.7721.7721.9691.9691.9691.9691.9692.2832.2832.2832.2832.5982.5982.598M t(ft-lbs)2232603344184415576137487801,3341,3861,4371,5401,5911,9162,0362,0952,1552,2752,6692,7372,8054,0004,0954,1904,3814,4764,5714,7625,6605,8775,9866,0957,3468,6408,7798,9199,33711,30811,46715,72715,92619,05219,27124,84530,91031,21036,33936,66645,83351,56252,380p H(psi)15,28215,28216,16116,32416,37217,95817,93519,33819,33822,48322,48322,48321,07821,07823,14423,14421,85821,85821,93423,66623,66623,68623,70523,70523,67122,67522,67521,73021,73023,84123,84122,92422,92424,88024,29124,29123,73322,72424,39624,39621,37721,37722,27722,24223,82023,06523,06524,09124,09121,86922,48521,912D N*2.6352.6352.8673.1673.1613.6043.6064.0524.0525.1125.1125.1125.2355.2355.9095.9096.0236.0236.0156.7106.7106.7087.7797.7797.7827.8837.8838.0008.0008.8778.8778.9788.9789.88710.44210.44210.50410.64011.92211.92211.87911.87912.87112.87814.90315.60415.60416.81816.81816.70117.72217.882Qty.88910101212141412121212121414141414161616141414141414141616161618141414141616202022222622222424283030Locking ScrewsSize M A (ft-lbs)M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M6 x 18M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M8 x 22M10 x 25M10 x 25M10 x 25M10 x 25M10 x 25M10 x 25M10 x 25M10 x 25M10 x 25M10 x 25M10 x 25M10 x 25M12 x 30M12 x 30M12 x 30M12 x 30M12 x 30M12 x 30M12 x 35M12 x 35M12 x 35M12 x 35M12 x 35M14 x 40M14 x 40M14 x 40M14 x 40M14 x 45M14 x 45M14 x 45111111111111111111262626262626262626262626265151515151515151515151519191919191919191919191138138138138138138138d BM8M8M8M8M8M8M8M8M8M10M10M10M10M10M10M10M10M10M10M10M10M10M12M12M12M12M12M12M12M12M12M12M12M12M14M14M14M14M14M14M14M14M14M14M14M16M16M16M16M16M16M16Weight(lbs)0.50.50.50.60.60.70.60.80.71.31.21.21.31.31.51.41.61.51.41.61.61.52.82.82.72.92.83.23.03.33.13.43.43.54.84.75.06.06.05.98.28.08.58.210.213.613.213.713.517.918.818.5*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)PILOT BUSHINGS FOR METRIC LOCKING ASSEMBLIESSET SUITABLE FOR B400 INCHES MMNUMBER LOCKING ASSEMBLY SIZES D W XPB 4565 45 x 75 to 65 x 95 0.589 0.313 M8 x 30PB 7095 70 x 110 to 95 x 135 0.787 0.375 M10 x 35PB 1012 100 x 145 to 120 x 165 0.886 0.375 M12 x 40PB 1316 130 x 180 to 160 x 210 0.984 0.625 M12 x 50PB 1718 170 x 225 to 180 x 235 1.082 0.625 M14 x 55PB 1920 190 x 250 to 200 x 260 1.181 0.625 M14 x 60PB 2224 220 x 285 to 240 x 305 1.279 0.625 M16 x 70PB 2600 260 x 325 1.279 0.625 M16 x 70PB 2830 280 x 355 to 300 x 375 1.476 0.750 M18 x 80PB 3234 320 x 405 to 340 x 425 1.673 0.750 M20 x 90PB 3642 360 x 455 to 420 x 515 1.870 0.750 M22 x 100PB 4450 440 x 545 to 500 x 605 2.067 0.875 M24 x 110PB 5200 520 x 630 to 1000 x 1110 2.165 1.125 M24 x 120(3) Metric SHCSDIN 912 grade 12.9(replacing cadmium plated<strong>locking</strong> screws). See tablefor screw size “x”.DWB-LOC PILOT BUSHINGS: for series B400 Locking Assemblies to provide pre-centering in applications with either straight through <strong>hub</strong> bores or narrow<strong>hub</strong>s. Pilot Bushings are supplied in sets consisting of three (3) bushings <strong>and</strong> three (3) longer screws. Pilot Bushings for inch size Locking Assemblies areidentical to bushings used for related metric units except for outside diameter ”D”.17

B800 SERIESScrew head height = screw dia. (mm)L 1LD 1D 2D NRequired <strong>hub</strong> OD dependson strength of <strong>hub</strong> material(see Specifications <strong>and</strong> Hub Sizing on Page 24)Bore dia. machined to D -0/+TT= .002” for bores up to 2.559”.003” for bores over 2.559”Locking screwstransfer tointegratedpush-off holesfor disassembly.L 2Dd = Shaft dia. machined to d +0/-TSurface finish for <strong>shaft</strong> <strong>and</strong> <strong>hub</strong>bore to be 63-125 µIN RMSOrdering Information:Specify series & <strong>shaft</strong> size(e.g., Locking Assembly Series B800 1 15 / 16 ”)B800 METRIC SPECIFICATIONSIntegrated spacersleeve includedMetric socket head <strong>locking</strong> screwsDIN 912 grade 12.9 (see M A for tightening torque)SIZE6 x 148 x 159 x 1610 x 1611 x 1812 x 1814 x 2315 x 2416 x 2418 x 2619 x 2720 x 2822 x 3224 x 3425 x 3428 x 3930 x 4132 x 4335 x 4738 x 5040 x 5342 x 5545 x 5948 x 6250 x 6555 x 7160 x 7765 x 8470 x 9075 x 9580 x 10085 x 10690 x 11295 x 120100 x 125110 x 140120 x 155130 x 165d0.2360.3150.3540.3940.4330.4720.5510.5910.6300.7090.7480.7870.8660.9450.9841.1021.1811.2601.3781.4961.5751.6541.7721.8901.9692.1652.3622.5592.7562.9533.1503.3463.5433.7403.9374.3314.7245.118D0.5510.5910.6300.6300.7090.7090.9060.9450.9451.0241.0631.1021.2601.3391.3391.5351.6141.6931.8501.9692.0872.1652.3232.4412.5592.7953.0313.3073.5433.7403.9374.1734.4094.7244.9215.5126.1026.496D 1D 2L0.3940.4720.5510.5510.5510.5510.5510.6300.6300.7090.7090.7090.9840.9840.9840.9840.9840.9841.2601.2601.2601.2601.7721.7721.7722.1652.1652.1652.5592.5592.5592.5592.5592.5592.7562.7563.5433.543(Relaxed)L 1L 2M t p H(ft-lbs) (psi) D N*Qty.3344444334444666688888888999991212121412121616Locking ScrewsSize M A (ft-lbs)M4 x 10 3.55M4 x 10 3.55M4 x 10 3.55M4 x 10 3.55M4 x 10 3.55M4 x 10 3.55M4 x 10 3.55M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 18 12M6 x 18 12M6 x 18 12M6 x 18 12M8 x 22 30M8 x 22 30M8 x 22 30M8 x 22 30M8 x 22 30M8 x 22 30M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M12 x 30 105M12 x 30 105M12 x 30 105M12 x 30 105Weight(lbs)0.9060.9451.0241.0241.1021.1021.2991.5751.5751.6541.6931.7321.8901.9691.9692.1652.2442.3232.4412.5982.7172.7953.1503.1893.3863.6223.8584.1344.4494.6854.9215.1575.3945.5916.0246.6147.3627.7560.9841.0631.1421.1421.2601.2601.4961.7321.7321.8501.9291.9692.1262.2052.2052.4022.4412.5592.6772.8352.9533.0713.3863.4253.6223.8584.0944.3704.6854.9615.1575.3945.6695.8666.2996.8507.7958.1890.7480.8660.9450.9450.9450.9450.9451.1611.1611.2801.2801.2801.5751.5751.5751.5751.5751.5751.8501.8501.8501.8502.4412.4412.4412.8742.8742.8743.3863.3863.3863.3863.3863.3863.7013.7014.5284.5280.8660.9841.0631.0631.0831.0831.0831.4371.4371.5551.5551.5551.8501.8501.8501.8501.8501.8502.1262.1262.1262.1262.7562.7562.7563.1893.1893.1893.7803.7803.7803.7803.7803.7804.2134.2135.0395.0391621323639435093991481561641812963083453705265766256586911,3681,4581,5191,8802,0512,2223,7994,0715,7896,1516,5138,02010,53611,59016,85818,26219,93515,50516,61216,61214,76614,76611,55616,75416,75418,33017,65117,02010,72315,13815,13813,19712,55415,96011,40710,72310,1169,74811,93911,36110,8379,1328,4207,7199,6799,16911,61410,95710,37011,29212,56211,21610,5069,8690.8870.8460.9280.9280.9960.9961.1781.3971.3971.5771.6091.6411.6061.9001.9002.0772.1502.4532.3982.5102.6232.6983.0483.1603.2723.4343.6633.9334.4094.5995.1275.3505.5766.1056.5567.1107.7418.1180.30.30.40.40.50.50.60.60.60.60.70.70.80.90.91.01.11.21.41.51.61.72.72.73.13.84.24.96.77.37.67.78.79.812152123*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)18

B800 INCH SPECIFICATIONSSIZE1/45/163/87/161/25/83/47/815/1611 1/81 3/161 1/41 3/81 7/161 1/21 5/81 11/161 3/41 7/81 15/1622 1/82 3/162 3/82 7/162 1/22 5/82 3/42 7/82 15/1633 1/83 1/43 3/83 7/163 1/23 5/83 3/43 7/83 15/1644 1/44 3/84 7/164 1/24 3/44 15/16d0.2500.3130.3750.4380.5000.6250.7500.8750.9381.0001.1251.1881.2501.3751.4381.5001.6251.6881.7501.8751.9382.0002.1252.1882.3752.4382.5002.6252.7502.8752.9383.0003.1253.2503.3753.4383.5003.6253.7503.8753.9384.0004.2504.3754.4384.5004.7504.938D0.5510.5910.6300.7090.9060.9451.0631.2601.3391.3391.5351.6141.6931.8501.9691.9692.1652.3232.3232.4412.5592.7952.7953.0313.0313.3073.3073.5433.5433.7403.7403.7403.9374.1734.1734.4094.4094.4094.7244.9214.9214.9215.5125.5126.1026.1026.1026.496D 1D 2L0.3940.4720.5510.5510.5510.6300.7090.9840.9840.9840.9840.9840.9841.2601.2601.2601.2601.7721.7721.7721.7722.1652.1652.1652.1652.1652.1652.5592.5592.5592.5592.5592.5592.5592.5592.5592.5592.5592.5592.7562.7562.7562.7562.7563.5433.5433.5433.543(Relaxed)L 1L 2M t(ft-lbs)p H(psi)D N*0.8870.8460.9280.9961.1781.3971.6091.6061.9001.9002.0772.1502.4532.3982.5102.5102.6983.0483.0483.1603.2723.4343.4343.6633.6633.9333.9334.4094.4094.5994.5994.5995.1275.3505.3505.5765.5765.5766.1056.5566.5566.5567.1107.1107.7417.7417.7418.118Qty.3344434466668888888889999999999912121212121214121212121216161616Locking ScrewsSize M A (ft-lbs)M4 x 10 3.55M4 x 10 3.55M4 x 10 3.55M4 x 10 3.55M4 x 10 3.55M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 16 12M6 x 18 12M6 x 18 12M6 x 18 12M6 x 18 12M8 x 22 30M8 x 22 30M8 x 22 30M8 x 22 30M8 x 22 30M8 x 22 30M8 x 22 30M8 x 22 30M8 x 22 30M8 x 22 30M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M10 x 25 60M12 x 30 105M12 x 30 105M12 x 30 105M12 x 30 105M12 x 30 105M12 x 30 105M12 x 30 105M12 x 30 105M12 x 30 105Weight(lbs)0.9060.9451.0241.1021.2991.5751.6931.8901.9691.9692.1652.2442.3232.4412.5982.5982.7953.1503.1503.1893.3863.6223.6223.8583.8584.1344.1344.4494.4494.6854.6854.6854.9215.1575.1575.3945.3945.3945.5916.0246.0246.0246.6146.6147.3627.3627.3627.7560.9841.0631.1421.2601.4961.7321.9292.1262.2052.2052.4022.4412.5592.6772.8352.8353.0713.3863.3863.4253.6223.8583.8584.0944.0944.3704.3704.6854.6854.9614.9614.9615.1575.3945.3945.6695.6695.6695.8666.2996.2996.2996.8506.8507.7957.7957.7958.1890.7480.8660.9450.9450.9451.1611.2801.5751.5751.5751.5751.5751.5751.8501.8501.8501.8502.4412.4412.4412.4412.8742.8742.8742.8742.8742.8743.3863.3863.3863.3863.3863.3863.3863.3863.3863.3863.3863.3863.7013.7013.7013.7013.7014.5284.5284.5284.5280.8660.9841.0631.0831.0831.4371.5551.8501.8501.8501.8501.8501.8502.1262.1262.1262.1262.7562.7562.7562.7563.1893.1893.1893.1893.1893.1893.7803.7803.7803.7803.7803.7803.7803.7803.7803.7803.7803.7804.2134.2134.2134.2134.2135.0395.0395.0395.0391721344045981571832943133523725225746006276791,3021,3511,4471,4951,7361,8451,8992,0622,1162,1713,6193,7913,9634,0494,1365,7445,9746,2036,3186,4336,6638,04110,37010,53710,70511,37411,70815,83416,05716,94917,61819,93515,50516,61214,76611,55616,75417,65110,72315,13815,13813,19712,55415,96011,40710,72310,7239,74811,93911,93911,36110,8379,1329,1328,4208,4207,7197,7199,6799,6799,1699,1699,16911,61410,95710,95710,37010,37010,37011,29212,56212,56212,56211,21611,21610,50610,50610,5069,8690.20.30.40.50.50.60.70.80.90.91.01.11.21.41.51.51.72.72.72.73.13.83.84.24.24.94.96.86.77.47.37.27.68.47.89.18.88.69.7121212151521212123*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)Possible design configurationsNote: In applications where spacer sleeve is removed, thedrive element will move axially during installation <strong>and</strong> torqueratings <strong>and</strong> contact pressures increase 58%.19

B112 HEAVY DUTY SERIESScrew head height = screw dia. (mm)L 1L≥ LD NRequired <strong>hub</strong> OD dependson strength of <strong>hub</strong> material(see Specifications <strong>and</strong> Hub Sizing on Page 24)DBore dia. machined to D -0/+TT= .002” for bores up to 4.724”.003” for bores up to 12.008”.004” for bores up to 25.000”.005” for bores over 25.000”Locking screwstransfer tointegratedpush-off holesfor disassembly.d = Shaft dia. machined to d +0/-TSurface finish for <strong>shaft</strong> <strong>and</strong> <strong>hub</strong>bore to be 63-125 µIN RMSOrdering Information:Specify series & <strong>shaft</strong> size(e.g., Locking Assembly Series B112 170mm)Larger sizes <strong>and</strong> sizes not shown are available on request.B112 METRIC SPECIFICATIONSMetric socket head<strong>locking</strong> screwsDIN 912 grade 12.9(see M A for tighteningtorque)Note:Unique staggered slit on seriesB112, B113, <strong>and</strong> B115 sizes200mm <strong>and</strong> larger preventspermanent deformation of thrustcollars that can result fromimproper disassembly.(Relaxed)M t p HLocking ScrewsSize25 x 5530 x 5532 x 6035 x 6040 x 7545 x 7550 x 8055 x 8560 x 9065 x 9570 x 11080 x 12090 x 130100 x 145110 x 155120 x 165130 x 180140 x 190150 x 200160 x 210170 x 225180 x 235190 x 250200 x 260220 x 285240 x 305260 x 325280 x 355300 x 375320 x 405340 x 425360 x 455380 x 475400 x 495420 x 515440 x 535460 x 555480 x 575500 x 595520 x 615540 x 635560 x 655580 x 675600 x 695d0.9841.1811.2601.3781.5751.7721.9692.1652.3622.5592.7563.1503.5433.9374.3314.7245.1185.5125.9066.2996.6937.0877.4807.8748.6619.44910.23611.02411.81112.59813.38614.17314.96115.74816.53517.32318.11018.89819.68520.47221.26022.04722.83523.622D2.1652.1652.3622.3622.9532.9533.1503.3463.5433.7404.3314.7245.1185.7096.1026.4967.0877.4807.8748.2688.8589.2529.84310.23611.22012.00812.79513.97614.76415.94516.73217.91318.70119.48820.27621.06321.85022.63823.42524.21325.00025.78726.57527.362L1.2601.2601.7321.7321.7321.7322.2052.2052.2052.2052.7562.7562.7563.5433.5433.5434.0944.0944.0944.0945.2765.2765.2765.2765.2765.2765.2766.4966.4966.4966.4967.4807.4807.4807.4807.4807.4807.4807.4807.4807.4807.4807.4807.480L 11.5751.5752.1262.1262.1262.1262.5982.5982.5982.5983.1503.1503.1504.0164.0164.0164.5674.5674.5674.5675.8665.8665.8665.8665.9065.9065.9066.9696.9696.9696.9697.9927.9927.9927.9927.9927.9927.9927.9927.9927.9927.9927.9927.992(ft-lbs)6177409211,0072,1272,3933,0383,7604,5584,9378,44310,61313,02619,31623,17929,50137,58647,22454,21161,68079,69590,410101,795107,153132,602160,729182,829263,439313,618351,252390,977491,890543,942624,622655,853687,084718,316874,471910,9071,015,0111,054,0501,165,9621,207,6031,288,283(psi)19,49619,49614,71814,71821,75321,75318,01019,06920,01118,95820,42620,59620,74019,85320,26122,20519,94922,04822,44222,79819,76020,27120,32519,54320,05720,82420,52020,94622,03221,42021,38420,61120,68321,65220,81120,03319,31121,74621,01521,78421,09821,81721,17021,204D N*3.4433.4433.3173.3175.0045.0044.8125.2605.7155.8617.0667.7468.4259.1689.91111.15411.41112.78513.61514.44814.18915.03116.01416.29918.12119.81420.93323.14225.22226.76128.05329.38130.73532.92733.44333.99434.57238.35338.86341.06641.57343.77944.28445.639Qty.66777789101010111211121412141516141516161820211820212221222424242428283030323233SizeM6 x 35M6 x 35M6 x 45M6 x 45M8 x 50M8 x 50M8 x 55M8 x 55M8 x 55M8 x 55M10 x 60M10 x 60M10 x 60M12 x 80M12 x 80M12 x 80M14 x 90M14 x 90M14 x 90M14 x 90M16 x 110M16 x 110M16 x 110M16 x 110M16 x 110M16 x 110M16 x 110M20 x 130M20 x 130M20 x 130M20 x 130M22 x 150M22 x 150M22 x 150M22 x 150M22 x 150M22 x 150M22 x 150M22 x 150M22 x 150M22 x 150M22 x 150M22 x 150M22 x 150*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)M A(ft-lbs)12121212303030303030606060105105105166166166166257257257257257257257500500500500675675675675675675675675675675675675675Weight(lbs)1.00.91.41.32.32.02.72.93.13.36.26.87.6131314202122233638434554576310611213614520020922022924024926026827728829730831720

B112 INCH SPECIFICATIONSSize11 1/81 3/161 1/41 3/81 7/161 1/21 5/81 3/41 7/81 15/1622 1/82 3/162 1/42 3/82 7/162 1/22 9/162 5/82 11/162 3/42 7/82 15/1633 1/83 1/43 3/83 7/163 1/23 5/83 3/43 7/83 15/1644 1/44 3/84 7/164 1/24 3/44 15/1655 1/45 7/165 1/25 3/45 15/1666 7/166 1/26 15/1677 1/47 7/167 1/27 3/47 15/168d1.0001.1251.1881.2501.3751.4381.5001.6251.7501.8751.9382.0002.1252.1882.2502.3752.4382.5002.5632.6252.6882.7502.8752.9383.0003.1253.2503.3753.4383.5003.6253.7503.8753.9384.0004.2504.3754.4384.5004.7504.9385.0005.2505.4385.5005.7505.9386.0006.4386.5006.9387.0007.2507.4387.5007.7507.9388.000D2.1652.1652.1652.3622.3622.3622.9532.9532.9533.1503.1503.1503.3463.3463.5433.5433.7403.7403.7404.3314.3314.3314.3314.7244.7244.7244.7245.1185.1185.1185.1185.7095.7095.7095.7096.1026.1026.4966.4966.4967.0877.0877.4807.4807.4807.8747.8748.2688.8588.8589.2529.2529.8439.8439.84310.23610.23610.236(Relaxed)L L 11.260 1.5751.260 1.5751.260 1.5751.732 2.1261.732 2.1261.732 2.1261.732 2.1261.732 2.1261.732 2.1262.205 2.5982.205 2.5982.205 2.5982.205 2.5982.205 2.5982.205 2.5982.205 2.5982.205 2.5982.205 2.5982.205 2.5982.756 3.1502.756 3.1502.756 3.1502.756 3.1502.756 3.1502.756 3.1502.756 3.1502.756 3.1502.756 3.1502.756 3.1502.756 3.1502.756 3.1503.543 4.0163.543 4.0163.543 4.0163.543 4.0163.543 4.0163.543 4.0163.543 4.0163.543 4.0163.543 4.0164.094 4.5674.094 4.5674.094 4.5674.094 4.5674.094 4.5674.094 4.5674.094 4.5674.094 4.5675.276 5.8665.276 5.8665.276 5.8665.276 5.8665.276 5.8665.276 5.8665.276 5.8665.276 5.8665.276 5.8665.276 5.866M t(ft-lbs)6277057449141,0051,0512,0262,1952,3642,8942,9913,0873,6903,7984,3414,5824,7034,8234,9448,0418,2338,4248,8079,89910,10910,53110,95212,40712,63712,86613,32618,39819,01219,31819,62522,74723,41627,70928,09929,66036,26036,71944,98046,58747,12252,78354,50458,75076,65477,39888,50889,30598,661101,212102,063105,465108,017108,867p H(psi)19,49619,49619,49614,71814,71814,71821,75321,75321,75318,01018,01018,01019,06919,06920,01120,01118,95818,95818,95820,42620,42620,42620,42620,59620,59620,59620,59620,74020,74020,74020,74019,85319,85319,85319,85320,26120,26122,20522,20522,20519,94919,94922,04822,04822,04822,44222,44222,79819,76019,76020,27120,27120,32520,32520,32519,54319,54319,543D N*3.4433.4433.4433.3173.3173.3175.0045.0045.0044.8124.8124.8125.2605.2605.7155.7155.8615.8615.8617.0667.0667.0667.0667.7467.7467.7467.7468.4258.4258.4258.4259.1689.1689.1689.1689.9119.91111.15411.15411.15411.41111.41112.78512.78512.78513.61513.61514.44814.18914.18915.03115.03116.01416.01416.01416.29916.29916.299Qty.666777777888991010101010101010101111111112121212111111111212141414121214141415151614141515161616161616Locking ScrewsSizeM6 x 35M6 x 35M6 x 35M6 x 45M6 x 45M6 x 45M8 x 50M8 x 50M8 x 50M8 x 55M8 x 55M8 x 55M8 x 55M8 x 55M8 x 55M8 x 55M8 x 55M8 x 55M8 x 55M10 x 60M10 x 60M10 x 60M10 x 60M10 x 60M10 x 60M10 x 60M10 x 60M10 x 60M10 x 60M10 x 60M10 x 60M12 x 80M12 x 80M12 x 80M12 x 80M12 x 80M12 x 80M12 x 80M12 x 80M12 x 80M14 x 90M14 x 90M14 x 90M14 x 90M14 x 90M14 x 90M14 x 90M14 x 90M16 x 110M16 x 110M16 x 110M16 x 110M16 x 110M16 x 110M16 x 110M16 x 110M16 x 110M16 x 110M A(ft-lbs)12121212121230303030303030303030303030606060606060606060606060105105105105105105105105105166166166166166166166166257257257257257257257257257257Weight(lbs)1.01.00.91.51.41.32.42.32.12.92.82.62.92.83.33.13.63.43.36.66.56.25.87.77.46.96.58.28.17.87.3131213121413161614212124222124222640394038474443484544*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)Possible design configurations21

B115 MEDIUM DUTY SERIESLocking screwstransfer tointegratedpush-off holesfor disassembly.Screw head height = screw dia. (mm)L 1L≥ LD NRequired <strong>hub</strong> OD dependson strength of <strong>hub</strong> material(see Specifications <strong>and</strong> Hub Sizing on Page 24)Bore dia. machined to D -0/+TT=.002” for bores up to 4.724”.003” for bores up to 12.008”.004” for bores up to 25.000”D .005” for bores over 25.000”d = Shaft dia. machined tod +0/-TSurface finish for <strong>shaft</strong> <strong>and</strong><strong>hub</strong> bore to be 63-125 µIN RMSOrdering Information:Specify series & <strong>shaft</strong> size(e.g., Locking Assembly Series B115 220mm)B115 METRIC SPECIFICATIONSMetric socket head <strong>locking</strong>screws DIN 912 grade 12.9(see M A for tightening torque)Size70 x 11080 x 12090 x 130100 x 145110 x 155120 x 165130 x 180140 x 190150 x 200160 x 210170 x 225180 x 235190 x 250200 x 260220 x 285240 x 305260 x 325280 x 355300 x 375320 x 405340 x 425360 x 455380 x 475400 x 495420 x 515440 x 535460 x 555480 x 575500 x 595520 x 615540 x 635560 x 655580 x 675600 x 695d2.7563.1503.5433.9374.3314.7245.1185.5125.9066.2996.6937.0877.4807.8748.6619.44910.23611.02411.81112.59813.38614.17314.96115.74816.53517.32318.11018.89819.68520.47221.26022.04722.83523.622D4.3314.7245.1185.7096.1026.4967.0877.4807.8748.2688.8589.2529.84310.23611.22012.00812.79513.97614.76415.94516.73217.91318.70119.48820.27621.06321.85022.63823.42524.21325.00025.78726.57527.362(Relaxed)L L 11.969 2.4411.969 2.4411.969 2.4412.362 2.8352.362 2.8352.362 2.8352.559 3.2282.559 3.2282.559 3.2282.559 3.2283.071 3.6613.071 3.6613.465 4.1343.465 4.1343.780 4.3703.780 4.3703.780 4.3703.780 4.3703.780 4.3704.882 5.3544.882 5.3545.512 6.2995.512 6.2995.512 6.2995.512 6.2995.512 6.2995.512 6.2995.512 6.2995.512 6.2995.512 6.2995.512 6.2995.512 6.2995.512 6.2995.512 6.299M t(ft-lbs)5,1997,4279,19113,51614,86817,84224,60028,38430,41234,60247,29150,07356,37866,76485,055123,717140,728168,979181,049257,492273,586360,590380,623440,721504,826528,865552,904600,983626,024729,193757,239841,376871,425901,475p H(psi)17,60920,17720,48720,26018,95219,58420,31020,61519,58419,89520,15319,29616,29217,62417,25821,50221,18823,33522,09121,59120,57519,13818,33219,35120,29019,53218,82818,93018,29419,82319,19819,94219,35118,794D N*6.5477.6558.3659.2729.56210.35511.52612.27012.55213.29314.34414.63314.38215.48216.80920.20121.33324.82225.26526.89327.41628.21028.81930.86832.95833.52834.12335.45036.06338.85139.43541.51442.09342.691Qty.8101110101114151516151516181520211515202020202224242425252828303030Locking ScrewsSizeM10 x 50M10 x 50M10 x 50M12 x 60M12 x 60M12 x 60M12 x 70M12 x 70M12 x 70M12 x 70M14 x 80M14 x 80M14 x 80M14 x 80M16 x 90M16 x 90M16 x 90M20 x 90M20 x 90M20 x 110M20 x 110M22 x 130M22 x 130M22 x 130M22 x 130M22 x 130M22 x 130M22 x 130M22 x 130M22 x 130M22 x 130M22 x 130M22 x 130M22 x 130M A(ft-lbs)606060105105105105105105105166166166166257257257500500500500675675675675675675675675675675675675675Weight(lbs)5.05.46.08.89.51014151616232431324245486166106112152161167176179187194200209216222229238B115 INCH SPECIFICATIONS22Size d D L(Relaxed)L 1M t(ft-lbs)p H(psi) D N* Qty. Size2 3/42 15/163 7/163 1/23 15/164 7/164 1/24 15/1655 7/165 15/1666 7/166 15/167 15/1682.7502.9383.4383.5003.9384.4384.5004.9385.0005.4385.9386.0006.4386.9387.9388.0004.3314.5285.1185.1185.7096.4966.4967.0877.0877.4807.8748.2688.8589.25210.23610.2361.9691.9691.9691.9692.3622.3622.3622.5592.5592.5592.5592.5593.0713.0713.4653.4652.4412.4412.4412.4412.8352.8352.8353.2283.2283.2283.2283.2283.6613.6614.1344.1345,1885,5418,9169,07813,51816,75816,99423,73224,03228,00230,57632,95845,48649,01967,30267,83217,60916,84120,48720,48720,26019,58419,58420,30820,30820,61619,58419,89520,15319,29617,62417,6246.5476.7108.3658.3659.27210.35510.35511.52611.52612.27012.55213.29314.34414.63315.48215.482881111101111141415151615151818M10 x 50M10 x 50M10 x 50M10 x 50M12 x 60M12 x 60M12 x 60M12 x 70M12 x 70M12 x 70M12 x 70M12 x 70M14 x 80M14 x 80M14 x 80M14 x 80*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)M A(ft-lbs)60606060105105105105105105105105166166166166Weight(lbs)5.05.46.56.29.01211151515161925253132

B113 EXTRA HEAVY DUTY SERIESScrew head height = screw dia. (mm)≥ LRequired <strong>hub</strong> OD dependson strength of <strong>hub</strong> material(see Specifications <strong>and</strong> Hub Sizing on Page 24)L 1LD NDBore dia. machined to D -0/+TT=.0025” for bores up to 11.220”.003” for bores up to 13.976”.0035” for bores up to 24.213”.004” for bores up to 26.575”.005” for bores over 26.575”d = Shaft dia. machined tod +0/-TSurface finish for <strong>shaft</strong> <strong>and</strong><strong>hub</strong> bore to be 63-125 µIN RMSLocking screws transferto integrated push-offholes for disassembly.Ordering Information:Specify series & <strong>shaft</strong> size(e.g., Locking Assembly Series B113 360mm)Metric socket head <strong>locking</strong>screws DIN 912 grade 12.9(see M A for tightening torque)B113 METRIC SPECIFICATIONSSize180 x 285200 x 305220 x 325240 x 355260 x 375280 x 405300 x 425320 x 455340 x 475360 x 495380 x 515400 x 535420 x 555440 x 575460 x 595480 x 615500 x 635520 x 655540 x 675560 x 695d7.0877.8748.6619.44910.23611.02411.81112.59813.38614.17314.96115.74816.53517.32318.11018.89819.68520.47221.26022.047D11.22012.00812.79513.97614.76415.94516.73217.91318.70119.48820.27621.06321.85022.63823.42524.21325.00025.78726.57527.362(Relaxed)LL 18.071 9.0168.071 9.0168.071 9.0168.189 9.3708.189 9.3708.189 9.3708.189 9.3709.843 11.0249.843 11.0249.843 11.0249.843 11.0249.843 11.0249.843 11.0249.843 11.0249.843 11.0249.843 11.0249.843 11.0249.843 11.0249.843 11.0249.843 11.024M t(ft-lbs)163,972208,207229,017288,534351,636420,785450,825569,197672,000782,660826,175869,634996,1031,043,5731,090,9841,328,1971,383,5091,438,8221,600,9331,660,196p H(psi)20,09221,45520,13520,78522,13522,77321,70220,39321,70422,91022,02021,19722,29121,51520,79223,46822,73022,03622,91022,251D N*18.13820.17420.70923.03625.29927.84328.31129.20131.64534.17034.62635.12637.61338.09838.61843.17743.59844.05846.59547.045Qty.1416161618202018202222222424242828283030SizeM22 x 180M22 x 180M22 x 180M24 x 180M24 x 180M24 x 180M24 x 180M27 x 220M27 x 220M27 x 220M27 x 220M27 x 220M27 x 220M27 x 220M27 x 220M27 x 220M27 x 220M27 x 220M27 x 220M27 x 220*Required <strong>hub</strong> OD for 1045 h.r. steel <strong>hub</strong> assuming 45 ksi Yield Point <strong>and</strong> Stress Reduction Factor C=1 (see Page 24 for details)M A(ft-lbs)6756756758708708708701,3001,3001,3001,3001,3001,3001,3001,3001,3001,3001,3001,3001,300Weight(lbs)136147160193206242257356374391411423446464484501513539554574LOCKING ASSEMBLY CONNECTIONS WITHSHAFT-ADAPTOR SLEEVES:In applications where an existing <strong>shaft</strong> diameter does not fitthe bore of a st<strong>and</strong>ard B-LOC Locking Assembly, werecommend using an adaptor sleeve sized to facilitatethe use of a st<strong>and</strong>ard sized Locking Assembly <strong>and</strong>the existing <strong>shaft</strong>. The maximum wall thickness ofan adaptor sleeve should be approximately 10%of the <strong>shaft</strong> diameter. The minimum thickness willdepend upon the machining process.It is important to note that in order to maximizethe torque capacity of a sleeved Locking Assemblyconnection, the <strong>shaft</strong>/sleeve bore interface shouldbe free of any lubricant, resulting in a coefficient offriction µ = 0.15 <strong>and</strong> making the sleeve OD/LockingAssembly bore the point of lowest torque capacity(provided the sleeve OD is less than 1.25 times the <strong>shaft</strong>diameter). This facilitates full use of the larger Locking Assembly’shigher torque capacity.Notes:1. Sleeve ID = d s -0/+.001“ where d s = <strong>shaft</strong> dia.2. Sleeve OD = d +0/-T for Locking Assembly tobe used.3. Install DRY at <strong>shaft</strong>/sleeve bore interface forcoefficient of friction µ =0.15.4. Torque capacity at sleeve OD = M t forLocking Assembly to be used.d s5. Torque capacity on <strong>shaft</strong> = M t x x 1.25.d6. Sleeve to be manufactured with one lengthwiseslit (after machining) <strong>and</strong> from material equal to orbetter than <strong>shaft</strong> material.7. Sleeve can be installed over existing keyway; positionslit approximately opposite keyway.23

HUB SIZINGB-LOC Locking Assemblies transmit torque <strong>and</strong> otherloads by means of mechanical interference generated bypressure exerted on both the <strong>shaft</strong> <strong>and</strong> <strong>hub</strong>, meaningthat consideration must be given to the amount of <strong>hub</strong>material required to prevent permanent expansion (i.e.,yielding). The following information is provided to assistyou in determining the required <strong>hub</strong> OD for any LockingAssembly application.Using the stress equations presented at right, therequired <strong>hub</strong> OD "D N " is determined as follows:THICK WALLED CYLINDERSUBJECTED TO INTERNAL PRESSUREσ tσ rοοPi⊕⊕id d xDTHICK WALLED CYLINDERSUBJECTED TO EXTERNAL PRESSUREPσ tσ ri⊕οο⊕iwhere D = <strong>hub</strong> bore (inches) from specification tables,<strong>and</strong> . . .p = contact pressure (psi) applied to <strong>hub</strong> bore fromHspecification tablesY.P. =24D N = DY.P. + (p x C)HY.P. - (p x C)yield point (psi) of <strong>hub</strong> material (see below)C = Stress Reduction Factor, considering therelationship of actual <strong>hub</strong> width "B" (asdetermined by customer) to Locking Assemblycontact length "L" (per specification tables),determined as follows (assumes <strong>locking</strong>assembly collar in contact with <strong>hub</strong> bore iscentered in <strong>hub</strong>):For Series B103, B106, B109, B400 <strong>and</strong> B800C = 1.0 for B = LC = 0.8 for B = 1.5 x LC = 0.6 for B = 2.0 x LFor Series B112, B113 <strong>and</strong> B115C = 1.0 for B = LC = 0.8 for B = 1.25 x LC = 0.6 for B = 1.50 x LThis equation can also be expressed as D N =DK, whereY.P. + (p x C)HK represents the expression .Y.P. - (p x C)HThe table at right provides these “K” factors for variouscombinations of Y.P., p , <strong>and</strong> C. To use the table,Hdetermine the Yield Point (in psi) of your <strong>hub</strong> material,find the p value for the Locking Assembly you’veHselected from the appropriate specification table (roundup to the nearest 1,000 psi), <strong>and</strong> determine the value ofC based on your component’s length-thru-bore (LTB).Then, find the K factor from the table <strong>and</strong> multiply by theLocking Assembly OD to calculate the minimum required<strong>hub</strong> OD for your application.H⎡ 2Q D ⎤⎢ +oσ tx = P 1 ⎥1−Q2⎢⎣d x ⎥⎦1+Qσ ti = P1−QQσ to = 2P1−QQQσ rx = P1−∆d i =Pd iσ ri = −Pσ ro = 0∆D o =2P⎡ 2D ⎤⎢ −o1 ⎥2⎢⎣d x ⎥⎦(v+1)+(v-1)*QvE(1-Q)D o QE(1-Q)TANGENTIAL STRESSES “σ t “RADIAL STRESSES “σ r “σ⎡ 2P d ⎤⎢ +itx = − 1 ⎥1−Q 2⎢⎣d x ⎥⎦σ2Pσ ti = − 1 − Q⎡ 2P d ⎤⎢ −irx = − 1 ⎥1−Q 2⎢⎣d x ⎥⎦σ ri = 0σ ro = −PCOMBINED HUB STRESSES IN SHRINK DISC APPLICATIONS “σ v “i = inside of <strong>hub</strong>o = outside of <strong>hub</strong>v = poisson's ratio (.3003 for steel)E = modulus of elasticity (30x10 6 for steel)PRESSURE EXERTED ON HUB (psi)C =7,0008,0009,00010,00011,00012,00013,00014,00015,00016,00017,00018,00019,00020,00021,00022,00023,00024,00025,0000.61.141.161.191.211.231.261.281.311.341.361.391.421.451.481.521.551.591.621.66EXPANSION/CONTRACTIONKEYd∆d i =2P iE(1-Q)∆D o =PD(v-1)+(v+1)*QovE(1-Q)P = pressure (psi)τ = torsional <strong>hub</strong> stress2⎛ d ⎞Q = ⎜ ⎟⎝ D ⎠“K” FACTORS FOR HUB MATERIAL WITH Y.P. EQUAL TO32,000 psi 45,000 psi 90,000 psi0.81.191.221.261.291.331.361.401.441.481.531.571.621.681.731.791.861.932.002.081.01.251.291.341.381.431.481.541.601.661.731.811.891.982.082.202.322.472.652.850.61.101.111.131.141.161.181.191.211.221.241.261.281.301.311.331.351.371.391.412( σ ∗σ) τ2 2σv= σt+ σr−t r+0.81.131.151.181.201.221.241.271.291.311.341.371.391.421.451.481.511.541.581.611.01.171.201.221.251.281.311.351.381.411.451.491.531.571.611.661.711.761.811.871+Qσ to = −P1−Q0.61.051.051.061.071.081.081.091.101.111.111.121.131.141.141.151.161.171.181.180.81.061.071.081.091.101.111.121.131.141.151.161.181.191.201.211.221.231.241.251.01.081.091.111.121.131.141.161.171.181.201.211.221.241.251.271.281.301.311.33

B-LOC EXTERNAL DEVICES:SHRINK DISCS & WK SERIES RIGID SHAFT COUPLINGSDESIGN FEATURESTORQUEExternal <strong>locking</strong> <strong>devices</strong> for keyless <strong>frictional</strong> <strong>shaft</strong>/<strong>hub</strong>connections on <strong>shaft</strong>s from 5/8” to 40” diameter,B-LOC Shrink Discs . . .• Provide a high capacity interference fit with all thepositive features of conventional interference fits, butwithout their assembly <strong>and</strong> dismounting problems.• Offer extremely concentric <strong>and</strong> well-balancedconnections, ideal for high-speed applications.• Permit simple axial <strong>and</strong> angular timing.• Are available in st<strong>and</strong>ard, light, <strong>and</strong> heavy-dutyseries to suit any application.WORKING PRINCIPLEThe double tapered inner ring of a B-LOC Shrink Discprovides a high-ratio conversion of screw clamp loadsinto radial contact pressures when the outer collars arepulled together by tightening of the integrated highstrength<strong>locking</strong> screws. These radial contact pressuresin turn accomplish the following:1. Contract the inner ring <strong>and</strong> <strong>hub</strong> to bridgethe clearance between <strong>shaft</strong> <strong>and</strong> <strong>hub</strong> bore.2. Generate a defined <strong>shaft</strong>/<strong>hub</strong> contact pressure fora high capacity mechanical interference fit.This <strong>frictional</strong> bond transmits torque, bending <strong>and</strong>/orthrust loads directly from the <strong>hub</strong> to the <strong>shaft</strong>; theShrink Disc itself does not carry any torque or thrustload.M t = rated torque capacity of (1) B-LOC Shrink Discwith all screws tightened to specified torque M A aslisted in specifications, based on a coefficient of frictionµ = 0.15 <strong>and</strong> specified tolerances <strong>and</strong> clearances.Torque capacities for Half Shrink Discs = M t / 2.• Torque capacities for connections using <strong>shaft</strong>diameters between the minimum <strong>and</strong> maximum sizeslisted can be approximated through interpolation.• Transmissible torque decreases if tolerances <strong>and</strong>/orclearances are larger than specified; or if hollow <strong>shaft</strong>swith bores exceeding 35% of <strong>shaft</strong> diameter are used.THRUSTF ax = transmissable thrust, determined by using thefollowing equation:24 x MF ax = 24 t, where d = <strong>shaft</strong> diameter (in)dTORQUE AND THRUST COMBINEDRELEASEABILITYSimultaneous transmission of torque <strong>and</strong>thrust requires calculating a resultant torque:M tres = T 2 + (F x D / 2) 2 , where:T = peak drive torque (ft-lbs)F = peak thrust load (lbs)D = <strong>shaft</strong> diameter (ft)Select a unit where M t ≥ M tres .BENDING MOMENTSMATERIALLUBRICANTSShrink Discs will generally transmit a continuousbending moment equal to 25% of rated torquecapacity M t.Since the tapers of a B-LOC Shrink Disc are selfreleasing<strong>and</strong> stresses from radial contractions of the<strong>hub</strong> are well within elastic limits, relaxing of the <strong>locking</strong>screws results in <strong>hub</strong> expansion back to its originaldimensions, thereby restoring fit clearance for simpledisassembly.Shrink Disc inner rings are manufactured fromhigh-carbon steel. Outer rings are made from forged<strong>and</strong> heat treated alloy steel.Shrink Discs are supplied with Molybdenum Disulphidebased lubricant applied to the tapers <strong>and</strong> to the <strong>locking</strong>screw threads <strong>and</strong> head contact areas.SHAFT AND HUB MATERIALListed specifications assume <strong>shaft</strong> <strong>and</strong> <strong>hub</strong> materialwith a yield point of at least 45,000 psi. Cast iron<strong>hub</strong>s are well suited for compressive stresses exerted byB-LOC Shrink Discs. However, a lower torsional <strong>hub</strong>strength generally requires the selection of a ShrinkDisc at least one size larger than listed if full torque(i.e., that applicable to a steel <strong>hub</strong>) is to be transmitted.26

LENGTH OF FITThe most recent research on length of fit for a Shrink Discconnection* indicates that the <strong>hub</strong> bore-to-<strong>shaft</strong> interfaceshould be relieved using a non-toleranced clearanceexcept for that portion directly under the Shrink Disc innerring, for a fit length equal to “L” for a st<strong>and</strong>ard Shrink Disc(see illustration at right). This approach eliminates frettingcorrosion between <strong>shaft</strong> <strong>and</strong> <strong>hub</strong> which can make theseparation of components difficult.*(see Casper, Thomas:Reibkorrosionsverhalten von Spanelementverbindungen -Aachen: Mainz, 1999)RecommendLength of FitEquals “L”LOCATING AGAINST HUB FACEIn applications subjected to reversing bendingmoments, we recommend the configuration at rightwhich requires a <strong>hub</strong> undercut where R ≥ e for smoothtransition.eR ≥ eREGARDING SINGLE TAPER SHRINK DISCSWe generally do not advocate this design due to thefollowing limitations:• Reduced effective contact length results insignificantly higher dynamic fit pressures inapplications with bending moments• Shallow taper angle means units are not selfreleasing;removal can be difficultWe offer Single Taper Shrink Discs only upon request.27

SHRINK DISCSSTANDARD, LIGHT, AND HEAVY DUTY EXTERNAL LOCKING DEVICESHDLd 1ed<strong>shaft</strong>diameter*Shaft SizesTo <strong>and</strong>Over IncludingMaximumDiametricalClearance BetweenShaft <strong>and</strong> Hub Bore1 1/81 15/164 3/4710141 1/81 15/164 3/4710140.00100.00150.00200.00300.00400.00500.0060Metric hex head <strong>locking</strong> screwsDIN 931 grade 10.9 (see M Afor tightening torque)St<strong>and</strong>ard Shrink Disc*See table at left for maximumdiametrical clearance between <strong>shaft</strong><strong>and</strong> <strong>hub</strong> bore. Surface finish for<strong>shaft</strong> <strong>and</strong> bore, as well as for <strong>hub</strong>OD, to be 63-125 µIN RMS.SD SERIES 10 SPECIFICATIONS(Shrink Discbore/<strong>hub</strong> OD)Size d24-10 0.94530-10 1.18136-10 1.41744-10 1.73250-10 1.96955-10 2.16562-10 2.44168-10 2.67775-10 2.95380-10 3.15090-10 3.543100-10 3.937110-10 4.331125-10 4.921140-10 5.512155-10 6.102165-10 6.496175-10 6.890185-10 7.283195-10 7.677200-10 7.874220-10 8.661240-10 9.449260-10 10.236280-10 11.024300-10 11.811320-10 12.598340-10 13.386350-10 13.780360-10 14.173380-10 14.961390-10 15.354420-10 16.535440-10 17.323460-10 18.110480-10 18.898500-10 19.685Hub ODtolerance+ 0 / - 0.002+ 0 / - 0.002+ 0 / - 0.002+ 0 / - 0.002+ 0 / - 0.002+ 0 / - 0.002+ 0 / - 0.002+ 0 / - 0.002+ 0 / - 0.002+ 0 / - 0.002+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.004+ 0 / - 0.005+ 0 / - 0.005+ 0 / - 0.005+ 0 / - 0.005+ 0 / - 0.005+ 0 / - 0.005+ 0 / - 0.005+ 0 / - 0.005+ 0 / - 0.006+ 0 / - 0.006+ 0 / - 0.006+ 0 / - 0.006+ 0 / - 0.006Shaft DiameterRangemin max0.625 0.7740.750 0.9670.875 1.1611.125 1.4191.375 1.6131.500 1.7731.750 1.9991.875 2.1922.125 2.4192.375 2.5802.500 2.9022.875 3.2243.125 3.5473.500 4.0304.000 4.5144.500 4.9984.875 5.3205.250 5.6435.625 5.9655.875 6.2876.250 6.4496.375 7.0937.000 7.7397.625 8.3838.375 9.0299.000 9.6739.625 10.31810.250 10.96310.875 11.28611.250 11.60811.500 12.25312.250 12.57512.500 13.54213.500 14.18814.125 14.83214.750 15.47715.375 16.122min.<strong>shaft</strong>1391783217009901,0401,7501,8002,8103,4404,7807,1008,88013,51019,55027,38037,53041,39056,50071,53080,25091,740130,080161,480209,640256,150309,170390,360430,780449,460534,650632,820685,090768,260936,2401,046,4001,167,170STANDARD DUTYM t (ft-lbs) formax.<strong>shaft</strong>2794096781,2201,6001,7402,4202,6504,0904,3607,1809,64012,43019,26026,31033,88046,89049,74065,63084,46086,650115,770161,120204,390252,360305,450358,200460,420472,150485,630622,650673,460829,050852,1501,053,2401,175,6101,307,490Locking ScrewsM AQty. Size (ft-lbs)675788101077101291210128810121215121416182024242420212424283024M5 x 16M5 x 18M6 x 20M6 x 20M6 x 22M6 x 25M6 x 25M6 x 25M8 x 25M8 x 25M8 x 30M8 x 35M10 x 40M10 x 40M12 x 45M12 x 50M16 x 55M16 x 55M16 x 65M16 x 65M16 x 65M16 x 75M20 x 80M20 x 90M20 x 100M20 x 100M20 x 100M20 x 110M20 x 110M20 x 110M24 x 120M24 x 120M24 x 130M24 x 130M24 x 130M24 x 150M27 x 1503.63.68.78.78.78.78.78.72222222244447474185185185185185185362362362362362362362362620620620620620620922BoltCircleDia.1.4171.7322.0472.4022.7562.9533.3863.3863.9373.9374.4884.8825.3546.2996.8907.5598.2688.6619.2919.6859.68510.63011.61412.63813.62214.33115.19716.06317.00817.00818.03118.42519.84320.74821.53522.44123.228D1.972.362.833.153.543.944.334.535.435.716.106.697.288.469.0610.3611.4211.8112.9913.7813.7814.5715.9516.9318.1119.1020.4822.4422.8423.2325.4025.9927.1729.5330.3231.5033.46L0.5510.6290.7000.7870.8660.9050.9050.9050.9840.9841.1811.3381.5351.6531.8111.9682.2042.2042.7952.7952.7953.4643.6224.0554.4884.8034.8035.2765.5115.5115.6695.6696.4566.7716.7717.4017.401(Relaxed)H e0.710.790.870.941.021.141.141.141.221.221.491.691.932.042.282.442.672.673.343.343.344.064.224.695.205.525.526.146.306.306.466.467.257.567.568.398.390.0780.0780.0780.0780.0780.1180.1180.1180.1180.1180.1570.1770.1970.1970.2360.2360.2360.2360.2360.2360.2360.3150.3150.3150.3540.3540.3540.3940.3940.3940.3940.3940.3940.3940.3940.4920.492d 11.0231.2591.4961.8502.0862.2832.5982.8343.1103.3073.7004.0944.4885.2755.7086.4966.8897.2837.6778.1108.1108.8979.76310.51111.33812.12512.91313.70014.48814.48815.27615.62916.92917.71618.42519.29119.999a0.0980.0980.0980.0980.0980.0980.0980.0980.1970.1970.1970.1970.1970.1970.1970.1970.1970.1970.1970.1970.1970.2950.2950.2950.3940.3940.3940.3940.3940.3940.3940.4920.4920.4920.4920.5910.591R1/161/161/161/161/163/323/323/321/81/81/81/81/81/83/163/163/163/163/163/163/161/41/41/45/165/165/165/165/165/165/163/83/83/83/81/21/2Weight(lbs)0.50.70.91.41.82.42.93.03.84.27.3101318233149508291901191481812252602884094294495265726308359241,1101,265Notes:1. Inner Rings of all Shrink Discs are supplied with (1) lengthwise slit2. Shrink Discs are available for <strong>shaft</strong>s up to 40” dia. <strong>and</strong> in a varietyof special designs.3. Max. <strong>shaft</strong> sizes listed for Series 10 <strong>and</strong> Series 30 Shrink Discs reflectdequal section moduli of <strong>shaft</strong> <strong>and</strong> <strong>hub</strong> (max. <strong>shaft</strong> dia.= )1.22128Screw SizeSplit Shrink DiscHalf Shrink Disc HTSpecifications for Web Clearance Holes (diameter in inches)M5 M6 M8 M10 M12 M16 M20 M24 M270.2810.2190.3280.2660.4060.3590.5000.4380.5940.5310.7500.7190.9060.8751.0631.0311.1881.156