BETE Chemical Processing - BETE Fog Nozzle, Inc.

BETE Chemical Processing - BETE Fog Nozzle, Inc.

BETE Chemical Processing - BETE Fog Nozzle, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

®Gas Conditioning, HumidificationDrying Kilns, Curing Rooms, Electro-static PrecipitatorsSAXAPJTFLTFXP<strong>BETE</strong> nozzles are frequentlyused to control static electricityin processing lines. <strong>BETE</strong>’ssuperior drip-resistant airatomizing nozzles easilyhumidify ducts, kilns, and curingrooms. When air lines are notavailable, use <strong>BETE</strong> directpressureimpingement nozzles.At higher flow rates, whenclogging is a problem, or whengreater coverage is needed,spiral nozzles may be used.FF Flat Fan• Deflected flat fan spraysideal for directing spray atdifficult spraying locations• High impact 0° - 145°angles available for overlap• Clog-resistant construction• Wide, flat band of sprayexcellent for oxygenating• Good nozzle for wall wash,moving sludge into drainsIS Specialty• Specialty fan designproduces a rectangularpattern when mountedin pairs.• Lower-to-moderate flowrates 0.5 to 164 gpm (1.89to 621 L/min) per pair• Pattern widths of 18” to 120”(46mm to 3048mm) canbe achieved• Excellent for horticulturalbed spraying and wastewater treatment• Good distribution withpressures as low as 0.5 PSI(0.035 BAR)L Spiral• A series of low flow spiralnozzles with flow rates0.14 to 3.84 gpm (0.53 to14.5 L/min)• Very fine hollow cone fogMP MaxiPass TM Whirl• Ultimate in clog-resistant,full cone whirl design• Unique, patented, S-shaped vanes providelargest free passage of anyfull cone nozzle• Uniformly distributed spray.• High reliability underextreme conditions4

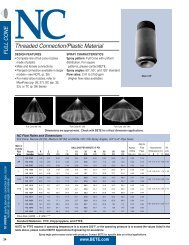

®Distribution, MixingDistribute Liquids on Packing, Horticultural Beds, MixingNC MP SC TC WL<strong>BETE</strong>’s nozzles are designed tohandle many types of mixing anddistribution, including FCCU feeddistribution nozzles, distributingliquids onto packed beds ormixing chemical compounds.Distribution nozzles usuallyfeature wide spray angles, highthrough-put, medium-to-coarseatomization, and moderateoperating pressures. <strong>BETE</strong> hasmany unique designs speciallydeveloped for these applications.NC and SC Whirl• Full cone nozzles availablein a variety of plastic (NC),or metals (SC)• Large range of flow ratesincluding very high flowrates, 2 to 2150 gpm (7.6 to8137 L/min)• Also available with squarepatterns (NCSQ, SCSQ)• 60°, 90°, and 120° sprayangles available• Whirl-plate constructednozzle produces large fullcone spray patternP Impingement• Highly efficient laminar jetimpinges on target pin,generating fine fog• Produces high percentageof droplets in the 60-200micron range• One-piece constructionPJ Impingement• Finest fog of any directpressure nozzle• Produces high percentageof droplets under 50 micronrange• High energy efficiency• One-piece construction5

®Pollution ControlScrub Gases, Evaporate Ponds, and Suppress DustTF TFXP TFXPWMPNCSTXPSTTHSCFFSAXAAir Pollution<strong>BETE</strong> is a world leader in nozzledesign for pollution control anddenoxification.<strong>BETE</strong> nozzles are used forquencher, pre-scrubber, absorber,direct contact, open tower, and misteliminator washing applications.Water PollutionTF, TFXP, and MaxiPass nozzlesgive optimum performance inwastewater aeration in meetingEPA oxygen content requirements.ST, STXP Spiral• Full cone spiral nozzlesproduce the best atomizationand clog resistance of anydirect pressure nozzle.• Standard two- or three-piececonstruction with no internalsfor superior clog resistance.SpiralAir TM Air Atomizing• Used for injecting lime slurry• Two-fluid high flow air atomizersfor superior atomization• Successful operation undervery corrosive conditions• Three-stage atomization forhighest reliability• Low air-to-liquid ratios• Three-stage atomization forhighest reliability• Superior for injectingdeodorants in tower forodor control• Flow rates from 0.3 to 20gpm (1.13 to 75.7 L/min)• Best used in indoor facilitieswhere pressurized air or gasis availableTC Whirl• One-piece body withintegral vanes• Extremely high flow rates upto 8730 gpm (33041 L/min.)6

®Evaporative CoolingCooling Flue Gases, Temperature Sensitive EquipmentSATFTFXPLPXATF and TFXP Spiral• One-piece spiral construction• Very large free passage forgreater clog resistance• Spray angles available from50° to 180°• Produces high percentageof droplets in the 100 -1,000 micron range• Direct pressure nozzle• Excellent when used forevaporative disposal withdirty, stringy liquids• Fine atomizationTH Tangential Whirl• Right-angle mounting• No internal parts• Most even distribution ofany hollow cone whirl inthe industry• Large range of flow rates:5 to 1500 gpm (19 to5677 L/min)WL Whirl• Low flow rates: 0.13 to 59gpm (0.492 to 223 L/min.)• Full cone whirl, medium-tocoarseatomization• Advanced whirl plate designXA Air Atomizing• Large variety of spray patterns• Low flow air atomizermeasured in gallons per hour• Automatic and non-automatichardware options as wellas self-cleaning options• Internal or external mixing ofair and liquid• Complete filter and regulatorkits available• Flow rates from 0.2 to 222gph (0.75 to 840 l/hr)• Excellent for injecting ammoniaor water upstream ofelectro-static precipitators.7

<strong>BETE</strong> FOG NOZZLE, INC.50 GREENFIELD STREETGREENFIELD, MA 01301TEL: 413- 772-0846, FAX: 413-772-6729www.bete.com, email: sales@bete.com©2011 <strong>BETE</strong> <strong>Fog</strong> <strong>Nozzle</strong>, <strong>Inc</strong>. All rights reserved.<strong>BETE</strong> is a registered trademark of <strong>BETE</strong> <strong>Fog</strong> <strong>Nozzle</strong>, <strong>Inc</strong>.MaxiPass and SpiralAir are trademarks of <strong>BETE</strong> <strong>Fog</strong> <strong>Nozzle</strong>, <strong>Inc</strong>.0911 2K