Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8August 2003<br />

<strong>SP</strong>/<strong>10</strong>, <strong>SP</strong>/<strong>15</strong> <strong>and</strong> <strong>SP</strong>/20<br />

heavy duty hose pumps<br />

Features<br />

• Highly suitable for:<br />

- abrasive products<br />

- corrosive products<br />

- shear sensitive products<br />

- viscous products<br />

- high density products<br />

• Self priming to 95% vacuum (5 kPa.a.)<br />

• Can run dry, i.e. can pump without fluid<br />

continuously<br />

• Reversible rotation<br />

• Can be used as a metering pump:<br />

repeatable accuracy +/- 1%<br />

• Replacement of hose without<br />

dismantling pump<br />

• Easy to clean: smooth liquid passage<br />

without valves, cavities or gl<strong>and</strong>s<br />

• No metal to metal contact<br />

Bredel<br />

Bredel Hose Pumps B.V.<br />

A member of the Spirax-Sarco Engineering Group<br />

Sluisstraat 7<br />

P.O. Box 47<br />

NL-7490 AA Delden<br />

The Netherl<strong>and</strong>s<br />

Tel.: +31 74 3770000<br />

Fax: +31 74 3761175<br />

Internet: www.bredel.com<br />

E-mail: hosepumps@bredel.com<br />

• Product pumped does not contact<br />

mechanical parts or seals<br />

• Heavy duty bearings, greased for life<br />

• Designed <strong>and</strong> built for high discharge<br />

pressures<br />

• Low noise level<br />

• <strong>10</strong>0% positive flow (no slip)<br />

• Only one wearing part: the pump hose<br />

• Easy maintenance, low cost, short<br />

down time<br />

• Permanent lubrication of pump hose<br />

with specially compounded food<br />

grade lubricant<br />

• Any drive system possible<br />

• Represented all over de world<br />

Option<br />

• High liquid level control

Net motor<br />

power [kW]<br />

0.<strong>15</strong><br />

0.125<br />

0.<strong>10</strong><br />

0.075<br />

Pump speed [r.p.m.]<br />

Capacity [l/h]<br />

<strong>SP</strong>/<strong>10</strong> <strong>and</strong> <strong>SP</strong>/<strong>15</strong><br />

How to use the curves: Intermittent duty:<br />

1 Flow required indicates pump speed Maximum 2 hours operation followed by<br />

2 Calculated discharge pressure minimum 1 hour stop<br />

3 Net motor power required<br />

4 Product temperature<br />

5 Calculated discharge pressure<br />

<strong>15</strong> 30 45 60 75 90 <strong>10</strong>5 120<br />

<strong>15</strong><br />

20<br />

30<br />

40<br />

45<br />

60<br />

60<br />

80<br />

6 Maximum recommended pump speed<br />

Net motor<br />

power [kW]<br />

0.35<br />

0.30<br />

0.25<br />

0.20<br />

0.<strong>15</strong><br />

0.<strong>10</strong><br />

3<br />

3<br />

Pump speed [r.p.m.]<br />

Capacity [l/h]<br />

Intermittent duty<br />

Continuous duty<br />

2<br />

5<br />

1 6<br />

750 kPa<br />

75<br />

<strong>10</strong>0<br />

300 kPa<br />

<strong>10</strong>0 kPa = 1 bar<br />

90<br />

120<br />

0 kPa<br />

<strong>10</strong>5<br />

140<br />

4<br />

120<br />

160<br />

<strong>15</strong> 30 45 60 75 90 <strong>10</strong>5 120<br />

Intermittent duty<br />

Continuous duty<br />

<strong>15</strong><br />

75<br />

30<br />

<strong>15</strong>0<br />

2<br />

5<br />

1 6<br />

45<br />

225<br />

750 kPa<br />

60<br />

300<br />

300 kPa<br />

75<br />

375<br />

90<br />

450<br />

0 kPa<br />

<strong>10</strong>0 kPa = 1 bar<br />

<strong>10</strong>5<br />

525<br />

4<br />

120<br />

600<br />

Product<br />

temperature<br />

[°C]<br />

40<br />

50<br />

60<br />

70<br />

80<br />

Product<br />

temperature<br />

[°C]<br />

40<br />

50<br />

60<br />

70<br />

80<br />

Type <strong>SP</strong>/<strong>10</strong><br />

Inner diameter pump hose Ø <strong>10</strong> [mm]<br />

Minimum starting torque 47 [Nm]<br />

Capacity per revolution 0,022 [l]<br />

Maximum discharge pressure 750 [kPa]<br />

7,5 [bar]<br />

Type <strong>SP</strong>/<strong>15</strong><br />

Inner diameter pump hose Ø <strong>15</strong> [mm]<br />

Minimum starting torque 60 [Nm]<br />

Capacity per revolution 0,083 [l]<br />

Maximum discharge pressure 750 [kPa]<br />

7,5 [bar]

Ø C<br />

=G1=<br />

=G2=<br />

=G=<br />

A1<br />

A<br />

<strong>SP</strong>/<strong>10</strong> <strong>and</strong> <strong>SP</strong>/<strong>15</strong><br />

Dimensions <strong>SP</strong>/<strong>10</strong> <strong>and</strong> <strong>SP</strong>/<strong>15</strong><br />

H (8x)<br />

L<br />

X1 Y<br />

D<br />

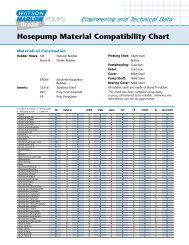

Type A A1 B C D E F F1 G G1 G2 H K L T X1 Y Z d l u t<br />

<strong>SP</strong>/<strong>10</strong> 196 293 116 ø194 117 200 28 55 162.6 67.4 175 ø16 28 90-120 85 14 ø9.0 ø18k6 39 6 20.5<br />

M8<br />

<strong>SP</strong>/<strong>15</strong> 260 403 195 ø288 142 235 33 60 249.5 <strong>10</strong>3.4 175 ø20 33 90-120 85 14 ø9.5 ø22k6 45 6 24.5<br />

All dimensions in [mm]<br />

Principle of operation<br />

A composite, reinforced hose, enclosed within<br />

a casing, has inserts at both ends. These inserts<br />

are connected to the suction <strong>and</strong> discharge lines<br />

of the system.<br />

Within the casing is a pressing rotor with two<br />

specially shaped bulges at opposite points about<br />

its centre line. The pressing rotor is mounted on<br />

a shaft with two bearings. As the pressing rotor<br />

rotates, the hose is totally compressed by the<br />

bulge <strong>and</strong> the product within the hose is pushed<br />

forward. At the front of the pump is a removable<br />

ØK<br />

F1<br />

F<br />

E<br />

B Ø du<br />

l<br />

T<br />

Ø Z (4x)<br />

cover with an inspection facility. The pump casing<br />

is filled to approximately halfway the casing with<br />

a specially compounded (food grade) lubricant<br />

which functions as a coolant as well. The patented<br />

reinforced hose ensures that compression forces<br />

are evenly applied across its full width.<br />

t

Dimensions <strong>SP</strong>/20<br />

Ø C<br />

= G1=<br />

<strong>SP</strong>/20<br />

Type A A1 B C D E F F1 G G1 G2 H K L T X1 Y Z d l u t<br />

<strong>SP</strong>/20 260 403 195 ø288 142 257 33 60 249.5 <strong>10</strong>3.4 175 M8 ø22 33 90-120 85 14 ø9.5 ø22k6 45 6 24.5<br />

All dimensions in [mm]<br />

= G2 =<br />

= G =<br />

A1<br />

A<br />

H (8x)<br />

L<br />

Ø K<br />

B<br />

F1<br />

F<br />

E<br />

X1<br />

D<br />

l<br />

Y<br />

Ø d<br />

T<br />

Ø Z (4x)<br />

u<br />

t

Net motor<br />

power [kW]<br />

A<br />

How to use the curves:<br />

Graph A<br />

• Selection of pump size <strong>and</strong> required motor power.<br />

• Check selection with maximum recommended pump<br />

speed in relation to product temperature<br />

1 Flow required indicates pump speed.<br />

2 Calculated discharge pressure.<br />

3 Net motor power required.<br />

4 Product temperature.<br />

5 Calculated discharge pressure.<br />

6 Maximum recommended pump speed (rpm).<br />

Intermittent duty: = 2 hrs max., 1 hr stop.<br />

B<br />

0.50<br />

0.37<br />

0.25<br />

0.18<br />

0.12<br />

Pump speed [r.p.m.]<br />

Capacity [l/h] 0<br />

High<br />

Low<br />

Pump speed [r.p.m.]<br />

3<br />

Intermittent duty<br />

Continuous duty<br />

1<br />

20<br />

182<br />

9<br />

8<br />

7<br />

2<br />

5<br />

40<br />

365<br />

750 kPa<br />

6<br />

300 kPa<br />

60<br />

547<br />

0 kPa<br />

<strong>SP</strong>/20<br />

80<br />

730<br />

<strong>10</strong>0 kPa = 1 bar<br />

<strong>10</strong>0<br />

912<br />

750 kPa 7.5 bar <strong>10</strong>9 psi<br />

500 kPa 72.5 psi<br />

5.0 bar<br />

250 kPa 2.5 bar<br />

4<br />

120<br />

<strong>10</strong>94<br />

Graph B<br />

• Selection of rotor size<br />

• Determine operating point (rpm/discharge<br />

pressure)<br />

7 Required pump speed<br />

8 When operating in the light red area (= below the<br />

red line) the Low pressure rotor is used<br />

9 When operating in the grey area (= above the<br />

red line) the High pressure rotor is used<br />

Remark<br />

20 40 60 80 <strong>10</strong>0 120<br />

Product<br />

temperature<br />

[°C]<br />

40<br />

50<br />

60<br />

70<br />

80<br />

Type <strong>SP</strong>/20<br />

Inner diameter pump hose Ø 19 [mm]<br />

Minimum starting torque 85 [Nm]<br />

Capacity per revolution 0,<strong>15</strong>2 [l]<br />

Maximum discharge pressure 750 [kPa]<br />

7,5 [bar]<br />

• With a variable speed drive <strong>and</strong> operating in both<br />

areas, the High pressure rotor should be used.

Bredel Hose Pumps<br />

BPD11/08/03<br />

Typical hose pump applications<br />

• In water <strong>and</strong> sewage treatment sludge transportation, sludge thickening, pit/lagoon emptying,<br />

filter press feed, centrifuge feed, digester feed, caustic,<br />

lime slurry, flocculants, ferric chloride, activated coal,<br />

aluminium sulphate, polymers, magnetite.<br />

• In chemical industry ferrite slurry, peroxide, latex, resins, hydrochloric acid,<br />

battery acid, glue, formaldehyde, sulphuric acid.<br />

• In food industry milk products, meat products, jellies, marmalade, mayonnaise,<br />

salads, dressings, tomato paste, fruit juices, caramel, chocolate,<br />

egg yolk, strawberries in yoghurt.<br />

• In breweries yeast, diatomaceous earth, flocculants, stabilizers,<br />

filter press feed.<br />

• In sugar industry sugar syrup, liquid sugar, molasses, glucose slurry,<br />

foamed earth.<br />

• In paper <strong>and</strong> ceramic industry clay slurry, china clay suspension, talcum suspension, pulp,<br />

glue, ink, coatings, pigments, kaolin, titanium dioxide.<br />

• In building industry mortar, foamed mortar, bentonite, cement grout,<br />

cement injection.<br />

• In mining industry nickel slurry, acids, cyanide, grout, coal slurry, pyrite slurry,<br />

thickener underflow, drain cleaning.<br />

• And many others, such as offal, fish waste, potato waste, radio active waste, blood, lye,<br />

pharmaceutical <strong>and</strong> cosmetic products, toothpaste, soap,<br />

detergents.<br />

The information contained in this document is believed to be correct but Bredel Hose Pumps B.V. accepts no liability for any<br />

errors it contains <strong>and</strong> reserves the right to alter specifications without notice.<br />

Bredel is a registered trademark. Bredel: worldwide supplier of industrial high pressure hose pumps.