Equipment & Dimensions: EH3500 Performance Data ... - CablePrice

Equipment & Dimensions: EH3500 Performance Data ... - CablePrice

Equipment & Dimensions: EH3500 Performance Data ... - CablePrice

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

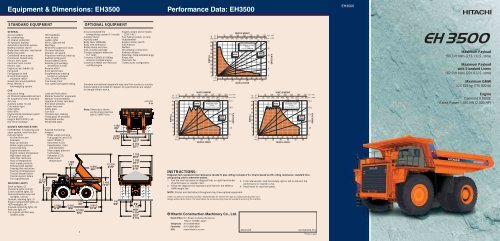

------------------------------<strong>Equipment</strong> & <strong>Dimensions</strong>: <strong>EH3500</strong><strong>Performance</strong> <strong>Data</strong>: <strong>EH3500</strong><strong>EH3500</strong>STANDARD EQUIPMENTOPTIONAL EQUIPMENTGENERALAccess laddersAir conditioningAir cleaner protectionAll-hydraulic brakingAutomatic lubrication systemBattery isolation switchBody down indicator, mechanicalBody prop cableCentralized service panelContinuous heated bodyElectric horn, quadElectronic hoist controlElectric startEngine access ladders (2)Fan guardFuel gauge on tankGround level engineshutdown switchGuard rails around platformHAULTRONIC IIload weighing systemCABAcoustical liningAir filtration/replaceable elementAir suspension seat, 6-positionAsh trayAuxiliary outlet, 12-voltCab interior lightCigar lighterDoor locksEngine starter/shutdown switchFull trainer seatIntegral ROPS/FOPS cabISO driver envelopeGAUGES AND INDICATORSHID headlightsHoist kickoutLadder lightsMirror, right and leftMud flapsNEOCON suspension strutsOn board load boxOperator arm guardPropulsion interlock, body upRadiator grille guardRetard speed controlRetarder grid package,18-element, 3-stepReverse alarmRock ejector barsSupplementary steeringsystem accumulatorTires, 37.00R57(**)E4Tow hooks, frontTwo-speed overspeed settingLoad and hold switchModular heater/AC evaporatorModular instrumentationOperator & trainer seat beltsRoll down windowsRubber floor matSafety glassSun visorTilt/telescopic steeringTinted glass all windowsWindshield washerWindshield wiperCONTRONIC II monitoring and Payload monitoringalarm system, multi-function Gauges:indicator lights:Brake supply pressureAir filter restrictionFuel gauge in cab (LCD)AlternatorHAULTRONIC IIBody up indicatorHourmeter (LCD)Brake supply pressureSpeedometer, milesCentral warningand kilometersEngine oil pressureSteer supply pressureEngine coolant temperature TachometerHigh beam indicatorVoltmeter (LCD)Hoist filter restrictionWheel motorHoist oil temperaturetemperature1 680Hoist supply pressure5'6"Parking brake appliedSteering filter restrictionSteering oil temperatureTraction blower failureTraction system failure58Turn signal/hazard6 370MACHINE LIGHTS 20'11"Back-up lights, (2)5 620Clearance lights, LED (4)18'5"Control cabinet lights, (3)Dual combination stop andtail lights, LED (2)Dynamic retarding light, (1)Engine compartment lights, (2)HID Headlights, (4)2 690 5 640Payload monitoring lights, (6)8'10" 18'6"Rear axle light, (1)Turn signals and four-wayflashers (LED)1 2704'2"12 24040'2"3Ansul centralized fireextinguishing system (12 nozzle)Auxiliary dumpAuxiliary steerBody liners (400BHN)Body side extensionsBuddy dump and steerCab, acoustic packageCanopy spillguard extension(12" total)Cummins K2000E @ 1800hpemission certified engineCummins K1800E non-emissioncertified engineEngine coolant and oil heater(220 V AC)Fast fueling system, on tankHubodometerKeyless starter switchKim HotstartMufflersOil sampling connectionsRadiator shuttersRetarding–7step extended rangeRimex rimsThermatic fanTrolley assist configurationStandard and optional equipment may vary from country to country.Special options provided on request. All specifications are subjectto change without notice.Note: <strong>Dimensions</strong> shownare for empty machinewith 37.00R57 tires.8 86029'1"3 91012'10"5 46017'11"12 63041'5"1 0603'6"4 22013'10"7402'6"5 51018'1"6 75022'1"7 70025'3"7 33024'1"6 60021'8"5'9"1 75014'0"4 25022'2"6 750unit:mmft inRIMPULLINSTRUCTIONS:Diagonal lines represent total resistance (Grade % plus rolling resistance %). Charts based on 0% rolling resistance, standard tiresand gearing unless otherwise stated.1. Find the total resistance on diagonal lines on right-hand border 3. From intersection, read horizontally right or left to intersect theof performance or retarder chart.performance or retarder curve.2. Follow the diagonal line downward and intersect the NMW or 4. Read down for machine speed.GMW weight line.NOTE: Photos and illustrations throughout may show optional equipment.Under our policy of continuous product improvement, we reserve the right to change specifications anddesign without prior notice. The illustrations do not necessarily show the standard version of the machine.Hitachi Construction Machinery Co., Ltd.RIMPULLHead Office: 5-1 Koraku 2-chome, Bunkyo-ku,Tokyo 112-8563, JapanTelephone : 81-3-3830-8050Facsimile : 81-3-3830-8204URL : www.hitachi-c-m.comGRADE IN %RIMPULLKR-E125PGRADE IN %VEHICLE WEIGHTkg lbs 0 50 100 150 200 250 300 350 kg x 1000x x1000 1000 0 80 160 240 320 400 480 560 640 720 800 lbs x 10003090 200-25PERFORMANCE CHART80180-<strong>EH3500</strong>160-1 492 kW 2,000 bhp2070140-60120-NMWMAXGMW 1550100-4080-103060-20 40-510 20-0 0-0mph 0 4 8 12 16 20 24 28 32 36 40km/h 0 10 20 30 40 50 60VEHICLE SPEEDVEHICLE WEIGHTkg lbs 0 50 100 150 200 250 300 350 kg x 1000x x1000 1000 0 80 160 240 320 400 480 560 640 720 800 lbs x 100017.5 15.045 100-12.5NMWRETARDER CHART4090-<strong>EH3500</strong>80-18 Element Grid/3-Step10.03570-3060-7.525MAX50-GMW2040-5.01530-10 20-2.55 10-0 0-0mph 0 4 8 12 16 20 24 28 32 36 40km/h 0 10 20 30 40 50 60VEHICLE SPEEDVEHICLE WEIGHTkg lbs 0 50 100 150 200 250 300 350 kg x 1000x x1000 1000 0 80 160 240 320 400 480 560 640 720 800 lbs x 100017.5 15.045 100-12.5NMWRETARDER CHART4090-<strong>EH3500</strong>80-18 Element Grid/7-Step10.03570-3060-7.525MAX50-GMW2040-5.01530-10 20-2.55 10-0 0-0mph 0 4 8 12 16 20 24 28 32 36 40km/h 0 10 20 30 40 50 60VEHICLE SPEEDGRADE IN %04.07(KA/KA,FT3)Printed in JapanMaximum Payload193.3 m tons (213.1 U.S. tons)Maximum Payloadwith Standard Liners182.9 m tons (201.6 U.S. tons)Maximum GMW324 324 kg (715 000 lb)EngineCummins K2000ERated Power 1 491 kW (2 000 HP)

Specifications: <strong>EH3500</strong>ENGINEBODY CAPACITYHYDRAULIC SYSTEMCOMMAND CAB IIISUSPENSIONFRAMEMakeCumminsModelK2000E with CENTRYType4 CycleAspirationTurbochargedkW HP Rated Power @ 1900 rpm 1 491 2 000(SAE J1995)Net Power @ 1900 rpm kW HP 1 411 1 892(SAE J1349)Max. Torque @ 1500 rpm N-m lb-ft 7 864 5 800(SAE 1995)No. Cylinders 16Bore & Stroke mm 159 x 159in 6.25 x 6.25Displacement L in 50.3 3 0673StartingElectricELECTRIC DRIVEControlsGeneral Electric Statex III System with latest fuel enhancement featureand wet weather retarding.AlternatorGeneral Electric Model GTA 22M. Direct mounted to engine.Wheel MotorsGeneral Electric Model 788FS motors complete with planetaryassembly in each rear wheel.Planetary Ratio 26.83:1Maximum Speed km/h mph 55.7 34.6Note:Wheel motor and dynamic retarding configuration subject to GEapproval for a given application.TIRESStandard - Front and RearRim Widthin 686 37.00R57(**)E4 Radials mm 27.0Optional - Front and Rear36.00R51(**)E4 Radials mm in 660 26.0Certain job conditions may require higher TKPH (TMPH) in order tomaintain maximum production. Euclid recommends evaluating thejob conditions and consult the tire manufacturer to make proper tireselection. Optional tire types, treads, ply ratings and rims available.ELECTRICAL SYSTEMTwenty-four volt lighting and accessories system. 175 ampalternator with integral transistorized regulator. Eight 12-volt, heavydutybatteries connected in series/parallel.m 3 yd 3Struck (SAE) 79.9 104.5Heap 3:1 103.8 135.8Heap 2:1 (SAE) 115.1 150.5WEIGHTSkglbChassis with Hoist 105 261 232 057Body 25 719 56 700Net Machine Weight 130 980 288 757Front Axle 64 180 141 490Rear Axle 66 800 147 267Maximum GMW:37.00R57(**)E4Including Options, 50% Fuel,Operator & Payload Not to Exceed 324 324 715 000Load Weight DistributionFront - 33% Rear - 67%Maximum Payload 193 344 426 243Note:Maximum GMW subject to GE approval for a given application.Net Machine Weight includes 37.00R57(**)E4 tires.Options: Approximate change in Net Machine Weight:kglbBody Liners, Complete 10 433 23 000Max. Payload with Body Liners, Complete 182 911 403 243Floor mm in 0.7519Sides and front mm in 10 0.39Corners mm in 19 0.75Canopy mm in 6 0.24Top rails mm in 10 0.39STEERING SYSTEMClosed-center, full-time hydrostatic power steering system using twodouble-acting cylinders, pressure limit compensated piston pump,and a brake actuation/steering system reservoir. An accumulatorprovides supplementary steering in accordance with J/ISO 5010.A tilt/telescopic steering wheel with 35 o of tilt and 57.15 mm 2.25"telescopic travel is standard.Steering Angle41 oTurning Diameter (SAE) m ft in 25.6 84.0Steering Pump Output(@ 1900 rpm) L/min gpm 186.5 49.4System Operating kPa psi 20 685 3 000PressureTwo (2) Hitachi three-stage, double-acting cylinders with cushioningin retraction, containing dual rod seals and rubber energizedscrapers, inverted and outboard mounted. Separate reservoir andtandem gear pump connects with a four-position electric pilot controlledhoist valve. Electronic controller is mounted to operator’s seat.Body Raise Time s 17.9Hoist Pump Output@ 1900 rpm L/min gpm 607.0 160.0System ReliefPressure kPa psi 18 961 2 750BRAKE SYSTEMBrake systems meet or surpass SAE J/ISO 3450.ServiceAll-hydraulic actuated braking system provides precise brakingcontrol and quick system response. The system is pressure proportioned,front to rear, for improved slippery road control. Three calipersper front disc, one caliper per rear disc are utilized. The main valvesare conveniently located on the firewall. This placement enhancesservice-ability as all pressure checks and system troubleshooting canbe made at a central location. A primary accumulator stores oil undersufficient pressure to ensure 100% braking capacity is always available.Front Axle - Dry DiscDisc Diameter Each(2 discs/axle) cm in 106.0 42Brake Surface Area cm in 15 001 3252 2 Per Axle 2Lining Area per Axle cm in 6 194 9602 2Brake Pressure (Max.) kPa psi 18 961 2 750Rear Axle - Armature Speed Dry DiscDisc Diameter Each(4 discs/axle) cm in 63.5 25Brake Surface Area cm in 14 298 2162 2 Per Axle 2Lining Area per Axle cm in 2 839 4402 2Brake Pressure (Max.) kPa psi 13 790 2 000OperationTwo independent hydraulic circuits within the service brake systemprovide fully modulated reserve braking capability. The system isautomatically applied when loss of pressure is detected.ParkingSpring-on, hydraulic-off park brake heads provide parking capability.The braking system complies with SAE J/ISO 3450.RetarderRetardation on grades is achieved through D.C. wheel motors inconjunction with the General Electric resistor grid package locatedon the cab deck. Cooling for the grid package is achieved with forcedair flow provided by dual blowers driven by a single electric motor.Three-step extended range retardation package is standard.Maximum dynamic retarding:18 Element Grid kW HP 2 889 3 870(3 step is standard,7 step is optional)Integral ROPS/FOPSCommand Cab IIIintegral ROPS (RolloverProtective Structure) isstandard in accordancewith J/ISO 3471.Double wall constructionof 11 gaugeinner and outer steelpanels produces amore structurallysound cab. Foamrubber lining materialalong with foam rubberbackedcarpeting and multiplelayered floor mat act to absorb sound and control interiortemperature.A properly maintained cab from Hitachi, tested with doors andwindows closed per work cycle procedures in SAE J1166, resultsin an operator sound exposure Leq (Equivalent Sound Level) of 81dB(A). A three-point rubber iso-mount arrangement to the decksurface minimizes vibration to the operator compartment.Monitoring SystemCONTRONIC II monitors and diagnoses all onboard systems includingSiemens drive system and engine. <strong>Data</strong> links offer completeintegration, while a single multi-language Liquid Crystal Display (LCD)clearly details machine functions. Downtime is minimized with fasterand more reliable troubleshooting and analysis.HAULTRONIC II load weighing system offers benefits such as betterequipment utilization on the jobsite, accurate unit and fleetproduction results, and benchmark unit statistics against fleet results.Cycle time, distance, cycle count can all be measured and recordedto furtherand improve job productivity. HAULTRONIC II is fully integrated withCONTRONIC II vehicle monitoring system and display interface,avoiding potential failure or error common in aftermarket systems.Excellent ServiceabilityA removable front closure allows easy access to the service brakevalve and heater connections. The upper dash utilizes four (4)removable panels that house gauges and customer options, eachindividually accessible. A removable closure located behind the seatprovides easy access to the shifting control, CONTRONIC II, and allelectrical junction points.Comfort and Ease of OperationA wrap-around style dashboard positions controls within easyreach and visual contact. A full complement of easy-to-readgauges, CONTRONIC II monitoring and warning system, aspacious environment, six-way adjustable air seat, tilt/telescopicsteering wheel, filtered ventilation, door locks, and a full sizetrainer seat, all contribute to operator safety and comfort.Front SuspensionIndependent trailing arm for each front wheel. NEOCON strutscontaining energy-absorbing gas and compressible NEOCON-Efluid are mounted between the trailing arms and frame. Variabledamping and rebound feature included.Rear Suspension“A” frame structure, integral with axle housing, links drive axle toframe at forward center point with pin and spherical bushing. Atrack rod provides lateral stability between the frame and driveaxle. Heavy-duty rear-mounted NEOCON struts containingenergy-absorbing gas and compressible NEOCON-E fluid suspendthe drive axle from the frame. Integral reboundfeature included.Maximum wheel oscillation 8°The Hitachi frame and suspension are designed to work in unisonto provide maximum structural integrity and operator comfort. Thefabricated rectangular frame rail construction provides superiorresistance to bending and torsional loads while eliminatingunnecessary weight. The unique trailing arm front suspensionabsorbs haul road input, minimizing suspension-induced frametwisting while providing independent tire action. NEOCON ridestruts are mounted with spherical bushings, eliminating extremesidewall forces by insuring a purely axial input to the ride strut.The wide track stance of the suspension system and the longwheel base assure a more stable, comfortable ride.The unique Hitachi NEOCON struts both front and rear combinethe energy absorption characteristics of two different compressiblemedia: NEOCON-E liquid and helium gas. They provide nearly twicethe energy absorption as Nitrogen over Oil struts. The result is morecomfort for the operator, maximum protection for the hauler frame,and excellent stability and control. NEOCON-E has also beenapproved by the US EPA and does not violate codes definedby TSCA Section 5.The NEOCON strut outperforms competitive strut designs byimproving isolation, stability, and control. Improved isolation meansreduced impact loading on structural members of the machine andgreater operator comfort, resulting in longer equipment life andproductivity. Improved stability means more consistent dynamicresponse of the machine to fluctuating load energy, resulting inpredictable machine performance. Improved control also meansbetter machine maneuverability.The box section main frame rails are bridged by three crossmembers,front bumper and front suspension tube. The rails are constant taper,constructed of 690 N/mm 2 100 000 psi yield strength steel. Two rearcrossmembers have integral suspension and drive axle mountings.Crossmember to frame rail junctions employ large radii transitionsto minimize stress concentrations.BODYThe body has a flat floor, sloped tailchute, and is continuouslyexhaust-heated. Extended canopy protects service deck area.High yield strength, 690 N/mm 2 100 000 psi alloy steel is usedin the following thicknesses:mm inFloor 19 0.75Front 10 0.39Sides 10 0.39Canopy 6 0.24High strength 690 N/mm 2 100 000 psialloy steel is also used for the canopyside members and floor stiffeners.The body is rubber cushionedon the frame.The Hitachi horizontal stiffenerdesign minimizes stressconcentrations, by dissipating loadshocks over the entire body length. Closely spaced stiffenersprovide additional protection by minimizing distances betweenunsupported areas.SERVICE CAPACITIESL U.S.galCrankcase (incl. filters)Cummins K2000E 209.7 55.4Cooling System 322.7 85.3Fuel Tank 2 838.8 750.0HydraulicsHoist System 565.9 149.5Steering System 189.3 50.0GE788 wheel motor (per wheel) 39.7 10.5Windshield washer 3.8 1.0245