Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

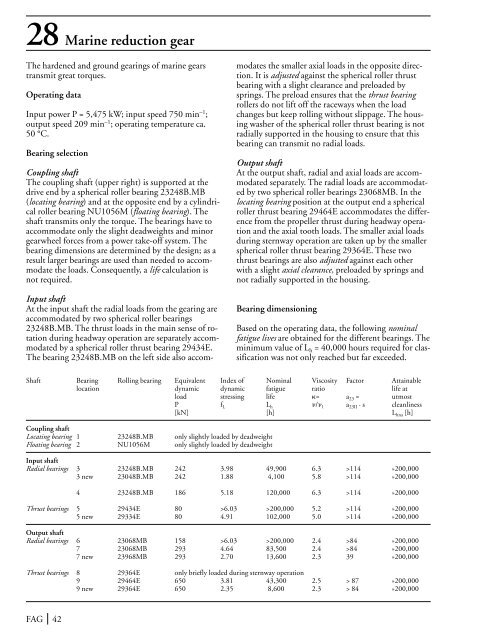

28 Marine reduction gear<strong>The</strong> hardened and ground gearings <strong>of</strong> marine gearstransmit great torques.Operating dataInput power P = 5,475 kW; input speed 750 min –1 ;output speed 209 min –1 ; operating temperature ca.50 °C.<strong>Bearing</strong> selectionCoupling shaft<strong>The</strong> coupling shaft (upper right) is supported at thedrive end by a spherical roller bearing 23248B.MB(locating bearing) and at the opposite end by a cylindricalroller bearing NU1056M (floating bearing). <strong>The</strong>shaft transmits only the torque. <strong>The</strong> bearings have toaccommodate only the slight deadweights and minorgearwheel forces from a power take-<strong>of</strong>f system. <strong>The</strong>bearing dimensions are determined by the design; as aresult larger bearings are used than needed to accommodatethe loads. Consequently, a life calculation isnot required.Input shaftAt the input shaft the radial loads from the gearing areaccommodated by two spherical roller bearings23248B.MB. <strong>The</strong> thrust loads in the main sense <strong>of</strong> rotationduring headway operation are separately accommodatedby a spherical roller thrust bearing 29434E.<strong>The</strong> bearing 23248B.MB on the left side also accommodatesthe smaller axial loads in the opposite direction.It is adjusted against the spherical roller thrustbearing with a slight clearance and preloaded bysprings. <strong>The</strong> preload ensures that the thrust bearingrollers do not lift <strong>of</strong>f the raceways when the loadchanges but keep rolling without slippage. <strong>The</strong> housingwasher <strong>of</strong> the spherical roller thrust bearing is notradially supported in the housing to ensure that thisbearing can transmit no radial loads.Output shaftAt the output shaft, radial and axial loads are accommodatedseparately. <strong>The</strong> radial loads are accommodatedby two spherical roller bearings 23068MB. In thelocating bearing position at the output end a sphericalroller thrust bearing 29464E accommodates the differencefrom the propeller thrust during headway operationand the axial tooth loads. <strong>The</strong> smaller axial loadsduring sternway operation are taken up by the smallerspherical roller thrust bearing 29364E. <strong>The</strong>se twothrust bearings are also adjusted against each otherwith a slight axial clearance, preloaded by springs andnot radially supported in the housing.<strong>Bearing</strong> dimensioningBased on the operating data, the following nominalfatigue lives are obtained for the different bearings. <strong>The</strong>minimum value <strong>of</strong> L h = 40,000 hours required for classificationwas not only reached but far exceeded.Shaft <strong>Bearing</strong> <strong>Rolling</strong> bearing Equivalent Index <strong>of</strong> Nominal Viscosity Factor Attainablelocation dynamic dynamic fatigue ratio life atload stressing life = a 23 = utmostP f L L h / 1 a 23II · s cleanliness[kN] [h] L hna [h]Coupling shaftLocating bearing 1 23248B.MB only slightly loaded by deadweightFloating bearing 2 NU1056M only slightly loaded by deadweightInput shaftRadial bearings 3 23248B.MB 242 3.98 49,900 6.3 >114 »200,0003 new 23048B.MB 242 1.88 4,100 5.8 >114 »200,0004 23248B.MB 186 5.18 120,000 6.3 >114 »200,000Thrust bearings 5 29434E 80 >6.03 >200,000 5.2 >114 »200,0005 new 29334E 80 4.91 102,000 5.0 >114 »200,000Output shaftRadial bearings 6 23068MB 158 >6.03 >200,000 2.4 >84 »200,0007 23068MB 293 4.64 83,500 2.4 >84 »200,0007 new 23968MB 293 2.70 13,600 2.3 39 »200,000Thrust bearings 8 29364E only briefly loaded during sternway operation9 29464E 650 3.81 43,300 2.5 > 87 »200,0009 new 29364E 650 2.35 8,600 2.3 > 84 »200,000FAG 42