The Design of Rolling Bearing Mountings

The Design of Rolling Bearing Mountings The Design of Rolling Bearing Mountings

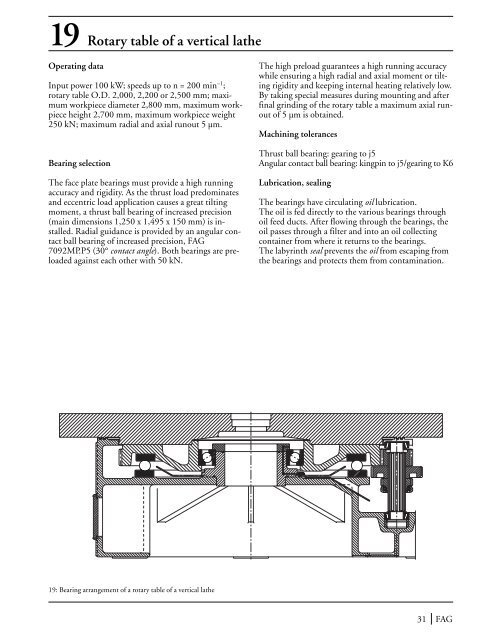

19 Rotary table of a vertical latheOperating dataInput power 100 kW; speeds up to n = 200 min –1 ;rotary table O.D. 2,000, 2,200 or 2,500 mm; maximumworkpiece diameter 2,800 mm, maximum workpieceheight 2,700 mm, maximum workpiece weight250 kN; maximum radial and axial runout 5 µm.Bearing selectionThe face plate bearings must provide a high runningaccuracy and rigidity. As the thrust load predominatesand eccentric load application causes a great tiltingmoment, a thrust ball bearing of increased precision(main dimensions 1,250 x 1,495 x 150 mm) is installed.Radial guidance is provided by an angular contactball bearing of increased precision, FAG7092MP.P5 (30° contact angle). Both bearings are preloadedagainst each other with 50 kN.The high preload guarantees a high running accuracywhile ensuring a high radial and axial moment or tiltingrigidity and keeping internal heating relatively low.By taking special measures during mounting and afterfinal grinding of the rotary table a maximum axial runoutof 5 µm is obtained.Machining tolerancesThrust ball bearing: gearing to j5Angular contact ball bearing: kingpin to j5/gearing to K6Lubrication, sealingThe bearings have circulating oil lubrication.The oil is fed directly to the various bearings throughoil feed ducts. After flowing through the bearings, theoil passes through a filter and into an oil collectingcontainer from where it returns to the bearings.The labyrinth seal prevents the oil from escaping fromthe bearings and protects them from contamination.19: Bearing arrangement of a rotary table of a vertical lathe31 FAG

20 Tailstock spindleOperating dataMaximum speed n = 3,500 min –1Cylindrical roller bearings have a high radial loadcarrying capacity, and angular contact ball bearingswith a 40° contact angle have a high axial load carryingcapacity.Bearing selection, dimensioningThe bearing arrangement must be particularly rigidand have a high load carrying capacity. Other requirementssuch as precision and high-speed suitability aremet by bearings of precision design.At the work end the high radial load is accommodatedby a double-row cylindrical roller bearing FAGNN3014ASK.M.SP. The high axial load is accommodatedat the opposite end by four angular contact ballbearings FAG 7210B.TVP.P5.UL. Three of these bearingsare mounted in tandem arrangement; the fourthbearing is merely for axial counter guidance.The maximum bearing O.D. is dictated by the size ofthe quill.Bearing clearanceThe cylindrical roller bearing with a tapered bore ispreloaded with 2...3 µm by pressing the inner ring onto the tapered shaft seat (taper 1:12).The angular contact ball bearings of universal designUL have a light preload in the O arrangement. The twospacers are identical in width and exclusively serve toprovide a cavity which can accommodate the excessgrease escaping from the bearings.Lubrication, sealingThe bearings are lubricated for life with FAG rollingbearing grease Arcanol L135V. A labyrinth seal preventsdirt from penetrating into the bearings.Machining tolerancesBearing Seat Diameter Form tolerance Axial runout tolerancetolerance (DIN ISO 1101) of abutment shoulderShaft, tapered Taper 1:12 1.5 µm 2 µmCylindrical roller bearing Housing –13 / +2 µm 2.5 µm 4 µmShaft –4 / +4 µm 1.5 µm 2 µmAngular contact ball bearings Housing –4 / +6 µm 2.5 µm 4 µm20: Bearing arrangement of a tailstock spindleFAG 32

- Page 3: PrefaceThis publication presents de

- Page 6 and 7: ContentsExample Title . . . . . . .

- Page 8 and 9: assembly is contracted. Thus the ra

- Page 10 and 11: Current insulationWhere converter c

- Page 12 and 13: 4 Electric motor for domestic appli

- Page 14 and 15: PulleyDrum5: Drum mounting of a dom

- Page 16 and 17: 6: Rotor bearing arrangement of a v

- Page 18: 7: Rotor bearing arrangement of a m

- Page 21 and 22: 9-18 Work spindles of machine tools

- Page 23 and 24: 10 NC-lathe main spindleOperating d

- Page 26 and 27: 13 High-speed motor milling spindle

- Page 28 and 29: 15 Vertical high-speed milling spin

- Page 30 and 31: 17 External cylindrical grinding sp

- Page 34 and 35: 21 Rough-turning lathe for round ba

- Page 36 and 37: 22: Flywheel bearing arrangement of

- Page 38 and 39: 24 Double-shaft circular sawOperati

- Page 40 and 41: Rollbending bearingsA counterbendin

- Page 42 and 43: 27 Spur gear transmission for a rev

- Page 44 and 45: The effects of basing the bearing d

- Page 46 and 47: 29 Bevel gear - spur gear transmiss

- Page 48 and 49: 31 Worm gear pairOperating dataInpu

- Page 50 and 51: at least normal cleanliness (contam

- Page 52 and 53: 33 Manual gearbox for trucksOperati

- Page 54: 34 Final drive of a passenger carOp

- Page 57 and 58: Driven and non-steered rear wheel36

- Page 59 and 60: 38 Steering king pin of a truckA va

- Page 61 and 62: 40 Water pump for passenger car and

- Page 63 and 64: 42 Axle box roller bearings of an I

- Page 65 and 66: 43-44 UIC axle box roller bearings

- Page 67 and 68: 45Axle box roller bearingsof series

- Page 69 and 70: 47Axle box roller bearingsof the Ch

- Page 71 and 72: 48 Axle box roller bearings for an

- Page 73 and 74: 50Axle box roller bearingsaccording

- Page 75 and 76: 52Universal quill drivefor threepha

- Page 77 and 78: 54 Spur gear transmission for the u

- Page 79 and 80: 55 Bevel gear transmission for city

- Page 81 and 82: 56- 57 Spherical roller bearings as

19 Rotary table <strong>of</strong> a vertical latheOperating dataInput power 100 kW; speeds up to n = 200 min –1 ;rotary table O.D. 2,000, 2,200 or 2,500 mm; maximumworkpiece diameter 2,800 mm, maximum workpieceheight 2,700 mm, maximum workpiece weight250 kN; maximum radial and axial runout 5 µm.<strong>Bearing</strong> selection<strong>The</strong> face plate bearings must provide a high runningaccuracy and rigidity. As the thrust load predominatesand eccentric load application causes a great tiltingmoment, a thrust ball bearing <strong>of</strong> increased precision(main dimensions 1,250 x 1,495 x 150 mm) is installed.Radial guidance is provided by an angular contactball bearing <strong>of</strong> increased precision, FAG7092MP.P5 (30° contact angle). Both bearings are preloadedagainst each other with 50 kN.<strong>The</strong> high preload guarantees a high running accuracywhile ensuring a high radial and axial moment or tiltingrigidity and keeping internal heating relatively low.By taking special measures during mounting and afterfinal grinding <strong>of</strong> the rotary table a maximum axial runout<strong>of</strong> 5 µm is obtained.Machining tolerancesThrust ball bearing: gearing to j5Angular contact ball bearing: kingpin to j5/gearing to K6Lubrication, sealing<strong>The</strong> bearings have circulating oil lubrication.<strong>The</strong> oil is fed directly to the various bearings throughoil feed ducts. After flowing through the bearings, theoil passes through a filter and into an oil collectingcontainer from where it returns to the bearings.<strong>The</strong> labyrinth seal prevents the oil from escaping fromthe bearings and protects them from contamination.19: <strong>Bearing</strong> arrangement <strong>of</strong> a rotary table <strong>of</strong> a vertical lathe31 FAG