TR 73 01 - Sanas

TR 73 01 - Sanas

TR 73 01 - Sanas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>TR</strong> <strong>73</strong>-<strong>01</strong>CRITERIA FOR LABORATORY ACCREDITATION INTHE FIELD OF COORDINATE MEASURINGMACHINES (CMM) CALIBRATIONApproved By: Chief Executive Office: Mike PeetSenior Manager: Mpho PhaloaneDate of Approval: 2008-02-15Date of Implementation: 2008-02-15©SANAS Page 1 of 7

<strong>TR</strong> <strong>73</strong>-<strong>01</strong>CONTENTS:1. Purpose and Scope2. Definitions and References3. Abbreviations4. Environmental Requirements5. General Requirements6. Technical Requirements7. The Accreditation ScheduleAPPENDIX 1:ADDENDUM 1:Example of Accreditation ScheduleAmendment Record©SANAS Page 2 of 7

<strong>TR</strong> <strong>73</strong>-<strong>01</strong>1. Purpose and ScopeThe purpose of this document is to define the specific environmental, general and technicalrequirements to be met by accredited laboratories in the field of coordinate measuring machines (CMM)operating in the 3D mode. This document is applicable to South African National Accreditation System(SANAS) Accredited Laboratories in this field. This document does not address the requirements for thecalibration of portable systems such as laser tracker, photogramatic, theodolites, and articulated armmeasuring systems, or CMM’s operated in the 2D mode.2. Definitions and ReferencesReferences[1] ISO 10360-1 Geometrical Product Specification (GPS) – Acceptance andre-verification tests for coordinate measuring machines (CMM)Part 1 : Vocabulary.[2] ISO 10360-2 Part 2 : CMM’s used for measuring size[3] EA 10/05 Coordinate Measuring Machine Calibration.[4] VDI/VDE 2617 Part 1 to 6 Accuracy of coordinate measuring machines.[5] OHS Act 1993 General Admin Regulations 1994 – Handling of HazardousChemical Substances.DefinitionsAcceptance test (of a CMM)Set of operations agreed upon by the CMM manufacturer and the user to verify that theperformance of a CMM is as stated by the manufacturer. [1].Coordinate Measuring Machine (CMM).Measuring system with the means to move a probing system and capability to determine spatialcoordinates on a workplace surface.[1]• Material standard of size.Either a step gauge or series of gauge blocks, with the longest size being at least 66% of thelongest spatial diagonal of the measuring volume of the CMM, and the shortest being less than30mm. The length of each material standard of size shall be calibrated.[2].• Maximum permissible error of indication of a CMM for size measurementMPE EExtreme value of the error of indication of a CMM for size measurement E, permittedby specifications, regulations etc. for a CMM.[2]Note 1 The maximum permissible error of indication of a CMM for size measurement errorMPE E , is stated in one of three formsa) MPE E = ± minimum of (A + L/K) and B, orb) MPE E = ± (A + L/K), orc) MPE E = ± BWhere:A is a positive constant, expressed in micrometers and supplied by the manufacturer;K is a dimensionless positive constant supplied by the manufacturer;L is the measured size, in millimetres;B is the maximum permissible error MPE E , in micrometers, as stated by themanufacturer.Probing systemSystem consisting of a probe and, where present probe extensions, probe changing system,stylus, stylus changing system and stylus extensions.[1]The probes may be mechanical, touch trigger, contact scanning, optical and laser.©SANAS Page 3 of 7

<strong>TR</strong> <strong>73</strong>-<strong>01</strong>• Probing system qualificationEstablishment of the parameters of a probing system necessary for subsequent measurements.Reference sphereSpherical material standard of size placed within a measuring volume of a CMM for the purposeof probing system qualification. [1].3. Abbreviations• Test sphereSpherical material standard of size used for acceptance test and re-verification test. [1].SANAS South African National Accreditation SystemMSDS Material Safety Data SheetsCMM Coordinate Measuring MachinemmmillimetreGUM Guide to the Expression of Uncertainty of Measurement2DTwo dimensional3DThree dimensional4. Environmental RequirementsThe calibration of coordinate measuring systems takes place in the location where the machine hasbeen installed. The applicable environmental conditions including temperature, humidity and vibrationare normally specified by the manufacturer for acceptance tests, or when unavailable specified by theuser.4.1 The laboratory should ensure that vibration levels are such that they do not cause undueinfluence on the operation of the CMM, and affect the accuracy of the measurement results.4.2 Humidity levels shall be consistent with requirements for dimensional measurement and shall benon-condensing.4.3 The laboratory shall monitor and report the ambient temperature during the calibration of theCMM. The temperature shall be recorded using a thermometer having an expanded uncertaintynot exceeding ± 0,5ºC. Corrections shall be applied to the temperature measurement.4.4 The calibration procedures of the laboratory shall address an appropriate interval required forthe stabilization of the artefacts in the same environment as the CMM.5. General Requirements5.1 The laboratories’ procedures shall specify or make reference to• Machine start-up/warm up cycles,• Probing or stylus system configuration,• Cleaning of the stylus tip,• Probing system qualification. [2].5.2 The laboratories’ procedures shall include a requirement for the cleaning of the stylus tip andreference sphere prior to the qualification of the probing system where relevant [2].5.3 The uncertainty of measurement shall be determined in accordance with the principlescontained in the GUM.5.4 Whenever an acceptance test is performed to determine compliance with a standard orspecification the uncertainty of measurement shall be taken into account.[2].6. Technical Requirements6.1 The laboratory is required to have MSDS for all standards fluids, and chemicals and cleaningmaterials used within the laboratory.[5]©SANAS Page 4 of 7

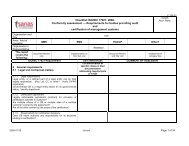

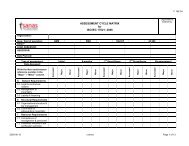

<strong>TR</strong> <strong>73</strong>-<strong>01</strong>APPENDIX 1S C H E D U L E O F A C C R E D I T A T I O NCOORDINATE MEASURING MACHINE CALIBRATIONLaboratory Accreditation Number: 0XXPermanent Address of LaboratoryThe Laboratory9 Newton StreetScientific ParkPostal AddressP O Box 222333Big City6123Technical SignatoriesNominated Representative: Mr M. Easure: Mrs D. ImensionTel: (099) 123 4567Fax: (099) 123 4568Email: thelab@scientific.co.zaIssue noDate of IssueExpiry Date:ITEM FUNCTION NOMINAL RANGE5. PRECISION INS<strong>TR</strong>UMENTS5.6 3D Coordinate Measuring Machines: 1: Month 200X: Month 200X + 5BEST MEASUREMENTCAPABILITIES EXPRESSED ASAN UNCERTAINTY (±)Linear Displacement Up to 40 m 0,5 µm + 1,5 µm/mVolumetric Displacement Up to 40 m 1,0 µm/mProbing Error N/A 0,5 µmFlatness Up to 30 m 1,0 µm/mStraightness Up to 30 m 1,0 µm/mSquareness Up to 15 m 2,0 µm/mParallelism Up to 15 m 1,0 µm/mOriginal date of accreditation: Month 200x Page 1 of 1The BMC, expressed as an expanded uncertainty of measurement, is stated as the standard uncertainty of measurementmultiplied by a coverage factor k = 2, corresponding to a confidence level of approximately 95%©SANAS Page 6 of 7

<strong>TR</strong> <strong>73</strong>-<strong>01</strong>ADDENDUM 1.AMENDMENT RECORDProposed By: Section ChangeCEO Page 1 Changed to new logo & Front pageFMChanged from R <strong>73</strong> (Requirement) to <strong>TR</strong> (Technical Requirement)document.©SANAS Page 7 of 7