SPINNER SPREADER - Gearmore, Inc.

SPINNER SPREADER - Gearmore, Inc.

SPINNER SPREADER - Gearmore, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SPINNER</strong><strong>SPREADER</strong>Operation, Service &Parts ManualFor ModelsS203L, S273L& S503LMay 2006Form: Spnsprdr.PM65

<strong>SPREADER</strong> ASSEMBLYFig. 1 - Bolt the gearbox to the frame.Fig. 2 - Partially install pin into disc beforeassembling to gearbox shaft. Insertthe spinner disc onto the driven outputshaft, and align holes and drive in the rollpin "a", which is lower hole. Drive rollpin in until flush with bushing.Fig. 3 - Insert the roll pins into hole "b".Drive in the pins until the distance is equalon both sides of the shaft.Fig. 4 - Put control lever rods, for meteringgates to the inside of the frame before placinghopper onto the frame.2

<strong>SPREADER</strong> ASSEMBLYFig. 5 - Install metering gates to the sideof the hopper. Connect the control rodsto the metering gates. Center the hopperwith the output shaft.Fig. 6 - Bring the corresponding holes of thehopper and the frame in alignment, and installthe bolts from the inside toward the outside,tightening down on the outside with nuts andlock washers. During the final tightening of thehopper bolts to the frame,check for centering ofthe output shaft with the bottom of the hopper.Fig. 7 - After hopper is installed, attachagitator over output shaft. Check meteringgates, and adjust so they are equallysynchronized fully opened and closed.3

MAINTENANCELUBRICATION -DRIVESHAFT - The driveshaft must be lubricated before the spreader is put into use. After that,grease every 8 hours. It is also necessary, from time to time, to untelescope the driveshaft to cleanand re-grease tubings.GEARBOX - Grease every 40 hours.CLEANING AND STORAGE -- Wash hopper with water after each use.- Never let material buildup on shutters or in the hopper.- Check spreader for needed repairs before using again.SAFETY INFORMATION -Safety Tips:1. Always wear relatively tight and belted clothing when operating spreader.Loose clothing should not be worn, as it could get caught in the moving partsor controls of spreader.2. Spreader should be operated only by qualified personnel.3. When starting spreader, always maintain a safe distance from moving parts.4. Keep hands, feet, and clothing away from all moving parts.4

SAFETY INFORMATIONOPERATIONAL SAFETYIt is absolutely necessary to empty the hopper before lowering the spreader to theground.Guards and safety shields are for your protection. DO NOT operate equipmentunless they are in place.ALWAYS engage tractor PTO at engine idle.Disengage tractor PTO and shift into neutral before attempting to start engine.Read and observe all safety decals on the tractor and spreader.NEVER allow anyone, other than the operator, within 25' of machine while inoperation.DO NOT stop or start suddenly when going uphill or downhill. Avoid operationon steep slopes.Be alert for holes in terrain and other hidden hazards. ALWAYS drive slowly overrough ground.Reduce speed on slopes and in sharp turns to prevent tipping or loss of control. BEcareful when changing directions on slopes.Take all possible precautions when leaving tractor unattended: Disengage PTO,lower spreader, shift into neutral, set parking brake, stop engine, and remove keyfrom ignition.Front tractor weights or front tire ballast should be used to enhance front-end stabilityon small tractors.5

TO OPERATE <strong>SPREADER</strong>WARNINGNEVER put hands or hand held tools in spreader while PTO is engagedand gearbox is turning. Failure to follow warning can result in personalinjury and/or damage to the spreader.A) Make sure spreader is properly assembled and secure to 3-point hitch.B) Before using spreader, make sure that the spreading disc is in a horizontalposition, about 2 1/2 feet from the ground.C) Engage tractor PTO at engine idle.NOTE: Never engage PTO above engine idle.D) Place material to be spread in hopper.E) Set levers in position needed for your spreading application (See page 5for tables).6

SPREADING TABLESThe figures shown in the table, in particular the spreading quantities, have been establishedthrough appropriate practical testing. The figures are only general indications, because a lotof external elements can modify the spreading (the wind, the moisture of fertilizer, etc.).If the tractor is driven at a speed which differs from that shown from the table, it is necessaryto make the right proportions and you must remember that a constant opening and agreater forward speed with constant PTO regime, reduces the quantity of spread for hectar.THE SPREADING OPERATIONIn order to obtain a sufficiently uniform spreadingpattern on both sides, it is simply necessary to movethe main operating lever until the correct opening isreached. (Fig. 1)According to the specific weight of the fertilizer tobe spread, to obtain uniformity of spreading whetherto right or left, it is possible to arrange the distributingblades moving them to the appropriate notch 1-2-3 (Fig. 2).Normally the position of the blades should be asfollows:Blades (A) and (C) on notch no. 2Blades (B) and (D) on notch no. 3By moving all the blades to notch no. 1, there is anincrease of spread to the left of the driver.By moving them to notch no. 3, there is an increaseof spread to the right of the driver.Thus, the adjustment according to the fertilizers used,depends on experience in the use of the machine.7

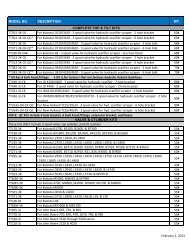

SPREADING TABLESQuick LimeFeedSet2.48 3.72 4.97 6.2 7.4 8.7M.P.H.AmmoniumNitrateFeedSet2.48 3.72 4.97 6.2 7.4 8.7M.P.H.2 251 167 125 100 83 713484021195601413420105933584728070523960434186442124295922217317661146-12613.12 foot5635135937234239581756896814052374117019781002169423 foot56639966426544319483255386212321182275Spreading applicationquantity in LBS/ACREP.T.O.: 540 min.78730982634873551436544131292333052434275320862359Spreading applicationquantity in LBS/ACREP.T.O.: 540 min.7 1190 793 595 476 396 339MagnesiumMariFeedSet2.48 3.72 4.97 6.2 7.4 8.7M.P.H.Rhe-Ka-PhosFeedSet2.48 3.72 4.97 6.2 7.4 8.7M.P.H.13.12 footSpreading applicationquantity in LBS/ACREP.T.O.: 540 min.2 392 261 196 156 130 11134561309276537535854873184325003902654138318762927523110515012343435920125019503737891071167126.2 footSpreading applicationquantity in LBS/ACREP.T.O.: 540 min.34567910248492819127015211726175219441653285468461014115111681296124245409634760863875972991973275076086907007778216327242350657558364770140233326433---Thomas Slag(Phosphate)Feed 2.48 3.72 4.97 6.2 7.4 8.7SetM.P.H.2 260 173 129 103 85 73AmmoniumSulphateFeedSet2.48 3.72 4.97 6.2 7.4 8.7M.P.H.13.12 foot3456872180358112024359013487202896002485142478 1652 1239 990 825 70826.2 foot345634275110321532228501688102119137551576613630041361311325034351097214294437Spreading applicationquantity in LBS/ACREP.T.O.: 540 min.Spreading applicationquantity in LBS/ACREP.T.O.: 540 min.7 1806 1204 902 721 601 514(Granular)Potassium13.12 footSpreading applicationquantity in LBS/ACREP.T.O.: 540 min.Feed 2.48 3.72 4.97 6.2 7.4 8.7SetM.P.H.2 111 74 55 44 37 -3456373816119717952495437981197186407599897149325478718124271398597106232341512ThomasPotassium(Grains)26.2 footSpreading applicationquantity in LBS/ACREP.T.O.: 540 min.FeedSet3456789102.48 3.72 4.97 6.2 7.4 8.7M.P.H.27266497714961812207220932322182442651998120813811396154813633248874890610361046116110926539059872482983792891220325498604690697773771882994235175915976628

SPREADING TABLESGrainedPotassiumFeedSet2.48 3.72 4.97 6.2 7.4 8.7M.P.H.SuperphosphateFeedSet2.48 3.72 4.97 6.2 7.4 8.7M.P.H.2 46 31 23 - - -34154378103253771896215151126-10834160410107273802056416353136-11729.5 footSpreading applicationquantity in LBS/ACREP.T.O.: 540 min.5678910591918109612181237141539461273081282594429545954860961870723536743848649456619630536440641147116826231234735240432.8 footSpreading applicationquantity in LBS/ACREP.T.O.: 540 min.56789106279591110122312551444418639740815837963313479555611627721251383443488502577208319369406417480179273316349358412Ammoniumand CalciumNitrateFeedSet2.48 3.72 4.97 6.2 7.4 8.7M.P.H.N.P.K. TypesFeedSet2.48 3.72 4.97 6.2 7.4 8.7M.P.H.341373279121868163-130-108-9334130345872306417252137-115-9829.5 footSpreading applicationquantity in LBS/ACREP.T.O.: 540 min.567891049478395510821089124232952263772172682824639147854054462119731338143243549616326031736036241314022327230831035431.8 footSpreading applicationquantity in LBS/ACREP.T.O.: 540 min.56789105378421028116411851350358561685976790900268421513582592675214336411465473540178280342387394440153240293332338385CoarseGrainedPotassiumFeedSet2.48 3.72 4.97 6.2 7.4 8.7M.P.H.34135360912406718054144-119-10232.8 foot56550862367575275431219344182287156245Spreading applicationquantity in LBS/ACREP.T.O.: 540 min.7891010691232125014027128218339355345156247014274924995803554104154673053513564009

S203L FRAME ASSEMBLYREF # QTY. PART NO. DESCRIPTION1 1 C016019 Hopper2 1 T003049 Frame3 2 D001002 Nut M104 4 V003016 Bolt M10 x 205 2 R004002 Washer6 4 D001002 Nut M107 2 V003002 Carriage Bolt M10 x 208 4 R004002 Washer9 1 R005037 Washer10

S273L/S503L FRAME ASSEMBLYREF # QTY. PART NO. DESCRIPTION1 1 C016033 Hopper S273L1 1 C016035 Hopper S503L2 1 T003100 Frame3 2 T017015 Plug4 1 R005037 Washer5 2 R004002 Washer6 4 D001002 Nut M107 4 V003010 Bolt M10 x 208 4 R004002 Washer9 2 D001002 Nut M1010 2 V003002 Carriage Bolt M10 x 2011

SPREADING DISC ASSEMBLYREF # QTY. PART NO. DESCRIPTION1 1 D002001 Spreading Disc S203L1 1 D002003 Spreading Disc S273L/S503L2 1 T011001 Drag Spindle3 4 P001001 Vane Kit4 1 S006001 Roll Pin M5 x 454 1 S006002 Roll Pin M8 x 4512

LEVER CONTROLSREF # QTY. PART NO. DESCRIPTION1 1 I006001 Grip2 1 L003002 Lever, Left3 1 L003001 Lever, Right4 1 P004002 Pin5 1 C019001 Hair Pin6 1 V003036 Bolt M12 x 457 2 R005001 Washer8 1 D001003 Nut9 1 D001004 Nut10 2 T008001 Tie Rod S203L10 2 T008002 Tie Rod S273L10 2 T008003 Tie Rod S503L11 1 S012001 Shutter, Right Side11 1 S012002 Shutter, Left Side12 4 D001002 Nut13

OPTIONAL AGITATOR ASSEMBLYA002001REF # QTY. PART NO. DESCRIPTION1 1 S004001 Joint2 1 P004003 Pin3 2 C019002 Cotter Key4 1 T003005 Agitator5 1 R005002 Washer6 2 R005003 Washer7 1 R008007 Rubber Wheel8 1 S006003 Cotter Key M4 x 2014

GEARBOX ASSEMBLYG005009REF # QTY. PART NO. DESCRIPTION1 1 A005064 Shaft, Output2 2 L005014 Key 7 x 8 x 203 1 F005001 Cover, Dust4 8 V003003 Bolt M8 x 165 1 S002001 Housing, Upper 1/26 2 R009072 Pinion Gear 11 Tooth7 3 6205 Bearing8 1 6205-2RS Bearing9 1 35x52x10 Oil Seal10 1 A005059 Input Shaft11 1 I002002 Grease Zerk12 3 S011001 Circlip E2513 1 S002002 Housing, Lower 1/214 8 R004001 Washer15 8 D001001 Nut M815

DRIVELINE ASSEMBLYC005210REF # QTY. PART NO. DESCRIPTION1 2 507010351 Yoke 1 3 /8", 6-Spline2 2 41201 Cross Kit #13 1 204016851 Outer Tube Yoke4 1 341036000 Roll Pin5 1 225020933 Outer Drive Tube6 1 225010933 Inner Drive Tube7 1 341037000 Roll Pin8 1 204016852 Inner Tube Yoke9 1 255010005 Outer Shield Bearing10 1 255010006 Inner Shield Bearing11 2 252000001 Safety Chain12 1 5N01086N1 Complete Shield16

LIMITED WARRANTYGEARMORE, INC., warrants each new <strong>Gearmore</strong> product to be free from defects in material andworkmanship for a period of twelve (12) months from date of purchase to the original purchaser.This warranty shall not apply to implements or parts that have been subject to misuse, negligence,accident, or that have been altered in any way.Our obligation shall be limited to repairing or replacement of any part, provided that such part isreturned within thirty (30) days from date of failure to <strong>Gearmore</strong> through the dealer from whomthe purchase was made, transportation charges prepaid.This warranty shall not be interpreted to render us liable for injury or damages of any kind ornature, direct, consequential or contingent, to person or property. This warranty does not extendto loss of crops, loss because of delay in harvesting or any other expenses, for any other reasons.<strong>Gearmore</strong> in no way warranties engines, tires, or other trade accessories, since these items arewarranted separately by these respective manufacturers.<strong>Gearmore</strong> reserves the right to make improvements in design or changes in specification at anytime, without incurring any obligations to owners or units previously sold.Always refer to and heed machine operating warning decals on machine.GEARMORE, INC.13477 Benson Ave.Chino, CA 91710The serial number of this product is stored in our computer database, thussubmitting a warranty registration card is not required.17