You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

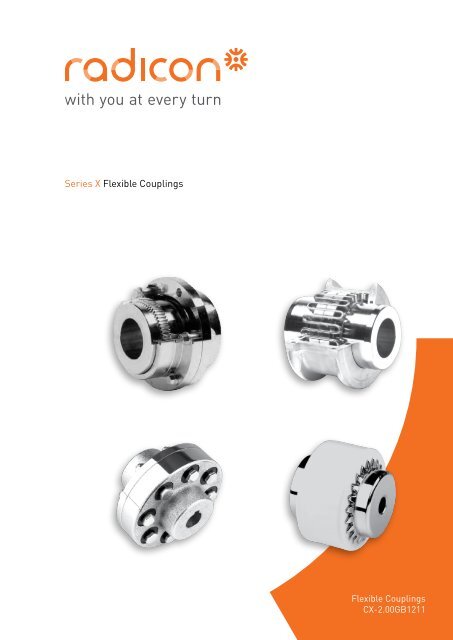

PRODUCTS IN THE RANGEServing an entire spectrum of mechanical drive applications from food, energy, mining and metal; to automotive,aerospace and marine propulsion, we are here to make a positive difference to the supply of drive solutions.<strong>Series</strong> AWorm Gear unitsand geared motorsin single & doublereduction types<strong>Series</strong> BDScrewjack wormgear unit<strong>Series</strong> BSWorm gear unit<strong>Series</strong> CRight angle drivehelical worm gearedmotors & reducers<strong>Series</strong> FParallel angle helicalbevel helical gearedmotors & reducers<strong>Series</strong> GHelical parallel shaft& bevel helical rightangle drive gearunits<strong>Series</strong> HLarge helical parallelshaft & bevel helicalright angle drive units<strong>Series</strong> JShaft mountedhelical speedreducers<strong>Series</strong> KRight angle helicalbevel helical gearedmotors & reducers<strong>Series</strong> MIn-line helical gearedmotors & reducersRoloid Gear PumpLubrication and fluidtransportation pump<strong>Series</strong> XCone RingPin and bushelastomer coupling<strong>Series</strong> XGearTorsionally rigid,high torque coupling<strong>Series</strong> XGridDouble flexing steelgrid coupling<strong>Series</strong> XNyliconGear coupling withnylon sleeve<strong>Series</strong> XTorque LimiterOverload protectiondeviceWe offer a wide range of repair services and many years experience of repairingdemanding and highly critical transmissions in numerous industries.We can create custom engineered transmission solutions of any size and configuration.

ATEXCompliance AssuredTotal compliance with the ATEX Directive safeguarding the use ofindustrial equipment in potentially explosive atmospheres isassured for users of our geared products.Certification is available for standard gearboxes and gearedmotors with badging displaying the CE Mark and the Ex mark,name and location of the manufacturer, designation of series ortype, serial number, year of manufacture, Ex symbol andequipment group/category.ATEX directive 94/9/EC (also known as ATEX 95 or ATEX 100A)and the CE Marking Directive are enforced in all EC memberstates. Compliance is compulsory for designers, manufacturers orsuppliers of electrical and non-electrical equipment for use inpotentially explosive atmospheres created by the presence offlammable gases, vapours, mists or dusts.Ex compliant standard gearboxes can be supplied against Groups2 or 3 for surface industries in designated hazardous locationZones 1 and 2 for gases, vapours and mists; and in Zones 21 and22 for dusts.

General Information- Inch/Metric conversions may not be direct conversions.SERIES XGENERAL INFORMATIONREFERENCE NOTES- Our standards apply unless otherwise specified.- All Dimensions are for reference only and are subject to change without notice unless certified.- Unless otherwise specified, our coupling hubs will be bored for CLEARANCE FIT with a setscrew OVER the keyway orINTERFERENCE FIT without a setscrew.- Torque ratings of couplings utilising Taper-Lock bushings can differ from those that do not. Refer to our Applica tionEngineers for details.- If we are to supply coupling hubs bored for Taper-Lock bushings, the bushing manufacturer MUST be noted on the order.- Consult our Application Engineers when limited end float is required. -Refer to our Application Engineers for bore limitationson hubs requiring Puller Bolt holes.Reference Notes† Peak torque capacity is two times the published rating. Consult our Application Engineers for higher speeds.• Maximum bores are reduced for hubs furnished with an INTERFERENCE FIT and a setscrew OVER the keyway.Recommended key sizes for the listed maximum bores are shown in each of the coupling type sec tions.∆ Minimum bore is the smallest bore to which a RSB hub (rough stock bore) hub can be bored. Depending upon couplingsize, rough stock bore hubs may have only a blind centering hole or a through hole that will permit re-machining of thehubs to the minimum bores specified.◊Sizes 5R - 50R Nylon cover furnished as standard and Epoxy coated steel cover available upon request. For Sizes 60R -80R Epoxy coated steel cover is standard (Nylon cover not available).Cover fasteners are ISO 7380 Socket Button Head Capscrews. Two cover fasteners per coupling.To obtain total weight: Basic Coupling + BE times kg per mm of BE.To obtain total WR 2 : Basic Coupling + BE times WR 2 per mm of BE.Values shown are based on no angular misalignment. The axial centering force restricts motor end float and satisfiesthe requirements of NEMA standards MG1 -14.37, 1-20.81 and 1-21.81.§ Interpolate for intermediate speeds. Maximum BE is based on 70% of critical speed. Refer to our Application Engineersfor higher running speeds.Long Term Grease (LTG)The high centrifugal forces encountered in couplings separate the base oil and thickener of general purpose greases. Heavythickener, which has no lubrication qualities, accumulates in the tooth mesh area of gear couplings resulting in prematuremesh failure unless periodic lubrication cycles are maintained. Long Term Grease (LTG) was developed specifically forcouplings. It resists separation of the oil and thickener and is an extreme pressure grease. Although LTG grease is compatiblewith most other coupling greases, the mixing of greases may dilute the ben efits of LTG.Benefits include: increased coupling life, significantly extended re-lubrication intervals, reduced maintenance costs, reduceddowntime, superior lubrication, high load carrying capabilities and it is usable up to 121 o C (250 o F).4

SERIES XSELECTION PROCEDUREStandard Selection MethodThe standard selection method can be used for mostmotor, turbine, or engine driven applications. The followinginformation is required to select a gear coupling.• Kilowatt (kW) or torque (Nm).• Running rpm.• Application or type of equipment to be connected(motor to pump, drive to conveyor, etc.).• Shaft diameters.• Shaft gaps.• Physical space limitations.• Special bore or finish information and type of fit.Exceptions are High Peak Loads and Brake Applications.For these conditions, use the Formula Selection Methodin the next column, or consult one of our ApplicationEngineers for assistance.1. RATING: Determine system torque. If torque is notgiven, calculate as shown below.System Torque (Nm) = kW x 9549rpmWhere: kW (Kilowatt) is the actual or transmittedpower required by the application (if unknown, usethe motor or turbine nameplate rating) and rpm is theactual speed the coupling is rotating. Applications thatrequire rapid changes in direction or torque reversalsshould be referred to our Application Engineers.1. SERVICE FACTOR: Determine the appropriateservice factor from Table 1, Page 6.2. REQUIRED MINIMUM COUPLING RATING:Determine the required minimum coupling ratingas shown below Minimum Coupling Rating = S.F.(Service Factor) x Torque (Nm)3. SIZE: Turn to appropriate pages for the coupling typechosen and trace down the torque column to a valuethat is equal or greater than that determined in Step 3above. The coupling size is shown in the first column.4. CHECK: Check speed (rpm), bore, gap anddimensions.Formula Selection MethodThe Standard Selection Method can be used for mostcoupling selections. The procedure below should be usedfor:• High Peak Loads• Brake Applications (where the disc brake orbrakewheel is to be an integral part of the coupling,consult our Application Engineers for design options).Providing system peak torque and frequency, duty cycle, andbrake torque rating will allow for a more refined selectionusing the Formula Selection Method.1. HIGH PEAK LOADS: Use one of the followingformulas for applications using motors with torquecharacteristics that are higher than normal;applications with intermittent operations, shockloading, inertia effects due to starting and stoppingand or system induced repetitive high peak torques.System Peak Torque is the maximum torque that canexist in the system.Select a coupling with a torque rating equal to orgreater than selection torque calculated below.A. NON-REVERSING HIGH PEAK TORQUESelection Torque (Nm) = System Peak TorqueorSelection Torque (Nm) = System Peak kW x 9549rpmB. REVERSING HIGH PEAK TORQUESelection Torque (Nm) = 1.5 x System Peak TorqueorSelection Torque (Nm) = 1.5 x Peak kW x 9549rpmC. OCCASIONAL PEAK TORQUES (Non-Reversing)If a system peak torque occurs less than 1000 timesduring the expected coupling life, use the followingformula:Selection Torque (Nm) = .5 x System Peak TorqueorSelection Torque (Nm) = .5 x Peak kW x 9549rpmFor reversing service, select per Step B, above.2. BRAKE APPLICATIONS: If the torque rating of thebrake exceeds the motor torque, use the brake ratingas follows:Selection Torque (Nm) = Brake Torque Rating x S.F.5

Table 1 - Coupling Service Factors for Motor ♦ and Turbine DrivesServiceServiceFactorFactorAERATOR ........................................... 2,0 FEEDERS ........................................... 1,75AGITATORSLAUNDRY WASHER ORVertical and HorizontalTUMBLERS ......................................... 2,0Screw, Propeller, Paddle................. 1,0 LINE SHAFTSBARGE HAUL PULLER ..................... 1,5 Any Processing Machinery ............. 1,5BLOWERSCentrifugal ...................................... 1,0MACHINE TOOLSAuxiliary and Traverse Drive .......... 1,0Lobe or Vane .................................. 1,25 Bending Roll, Notching Press,CAR DUMPERS................................... 2,5 Punch Press, Planer, PlateCAR PULLERS ................................... 1,5 Reversing ....................................... 1,5CLARIFIER OR CLASSIFIER.............. 1,0 Main Drive ...................................... 1,5COMPRESSORSCentrifugal ...................................... 1,0MAN LIFTS ............................Not ApprovedMETAL FORMING MACHINESLobe or Vane .................................. 1,25 Continuous Caster .......................... 1,75Rotary, Screw ................................. 1,0 Draw Bench Carriage andReciprocatingMain Drive ...................................... 1,5Direct Connected.. Refer to Application Engineer Extruder .......................................... 2,0Without Flywheel.. Refer to Application EngineerWith Flywheel and Gear betweenForming Machine andForming Mills .................................. 2,0Compressor and Prime MoverSlitters ............................................ 1,01 cylinder, single acting............ 3,0 Wire Drawing of Flattening ............. 1,751 cylinder, double acting........... 3,0 Wire Winder .................................... 1,52 cylinder, single acting............ 3,0 Coilers and Uncoilers ..................... 1,52 cylinder, double acting........... 3,0 MIXERS (see Agitators)3 cylinder, single acting............ 3,0 Concrete ......................................... 1,753 cylinder, double acting........... 2,0 Muller .............................................. 1,54 or more cyl., single acting...... 1,75 PRESS, PRINTING.............................. 1,54 or more cyl., double acting.... 1,75 PUG MILL ........................................... 1,5CONVEYORSPULVERISESApron, Assembly, Belt, ChainHammermill and Hog ...................... 1,75Flight, Screw ................................... 1,0 Roller .............................................. 1,5Bucket ............................................ 1,25Live Roll, Shaker andPUMPSBoiler Feed ..................................... 1,75Reciprocating.................................. 3,0 Centrifugal -CRANES AND HOISTConstant Speed .............................. 1,0Main Hoist ...................................... 1,75 Frequent Speed ChangesSkip Hoist ....................................... 1,75 under Load ..................................... 1,25Slope .............................................. 1,5 Descaling, with accumulators ......... 1,25Bridge, Travel or Trolley.................. 1,75 Gear, Rotary, or Vane ..................... 1,25DYNAMOMETER ................................ 1,0 Reciprocating, Plunger PistonELEVATORS1 cyl., single or double act ....... 3,0Bucket, Centrifugal Discharge ........ 1,25 2 cyl., single acting .................. 2,0Freight or Passenger .........Not Approved 2 cyl., double acting ................. 1,75Gravity Discharge ........................... 1,25 3 or more cylinders .................. 1,5ESCALATORS.................... ....Not Approved Screw Pump, Progressing Cavity ... 1,25EXCITER, GENERATOR .................... 1,0 Vacuum Pump ................................ 1,25EXTRUDER, PLASTIC ....................... 1,0 SCREENSFANSAir Washing .................................... 1,0Centrifugal ...................................... 1,0 Grizzly ............................................ 2,0Cooling Tower ................................. 2,0 Rotary Coal or Sand ....................... 1,5Forced Draft - Across theVibrating ......................................... 2,5Line star .......................................... 1,5 Water .............................................. 1,0Forced Draft Motor Driven thruSKI TOWS & LIFTS ................Not Approvedfluid or electric slip clutch ............... 1,0 STEERING GEAR ............................... 1,0Gas Recirculating ........................... 1,5 STOKER .............................................. 1,0Induced Draft with dampercontrol or blade cleaner .................. 1,25TIRE SHREDDER ............................... 1,50TUMBLING BARREL .......................... 1,75Induced Draft without controls ........ 2,0 WINCH, MANOEUVRINGFEEDERSDredge, Marine ............................... 1,5Apron, Belt, Disc, Screw ................. 1,0 WINDLASS ......................................... 1,5Reciprocating ................................. 2,5 WOODWORKING MACHINERY ........ 1,0GENERATORSWORK LIFT PLATFORMS ...Not ApprovedEven Load....................................... 1,0Hoist or Railway Service ................ 1,5Welder Load ................................... 2,0Table 2 - Engine Drive Service FactorsNo. ofCylindersAlphabetical listing of applicationsFor engine drives, refer to Table 2. Electric motors, generators, engines, compressors andother machines fitted with sleeve or straight roller bearings, usually require limited endfloat couplings. If in doubt, provide axial clearances and centering forces to one of ourApplication Engineers for a recommendation.For balanced opposed design, refer to our Application Engineers.If people are occasionally transported, refer to our Application Engineers for the selectionof the proper size coupling.For high peak load applications (such as Metal Rolling Mills) refer to our ApplicationEngineers.Service Factors for engine drives are those required for applications where good flywheelregulation prevents torque fluctuations greater than ±20%. For drives where torquefluctuations are greater or where the operation is near a serious critical or torsional vibration,a mass elastic study is necessary.4 or 5 6 or moreTable 1 S.F. 1,0 1,25 1,5 1,75 2,0 1,0 1,25 1,5 1,75 2,0Engine S.F. 2,0 2,25 2,5 2,75 3,0 1,5 1,75 2,0 2,25 2,5To use Table 2, first determine application service factor from Table 1. Use that factorto determine ENGINE Service Factor from table 2. When service factor from Table 1.is greater than 2.0 or where 1, 2 or 3 cylinder engines are involved, refer completeapplication details to our Application Engineers for engineering review.6SERIES XSELECTION PROCEDUREAlphabetical listing of applicationsServiceFactorAGGREGATE PROCESSING,CEMENT, MINING KILNS;TUBE, ROD AND BALL MILLSDirect or on L.S. shaft ofReducer, with final driveMachined Spur Gears .................... 2,0Single Helical orHerringbone Gears ......................... 1,75Conveyors, Feeders, Screens,Elevators .................... See GeneralListingCrushers, Ore or Stone .................. 2,5Dryer, Rotary .................................. 1,75Grizzly ............................................ 2,0Hammermill or Hog ........................ 1,75Tumbling Mill or Barrel .................... 1,75BREWING AND DISTILLINGBottle and CanFilling Machines .............................. 1,0Brew Kettle ..................................... 1,0Cookers, Continuous Duty ............. 1,25Lauter Tub ...................................... 1,5Mash tub ......................................... 1,25Scale Hopper, Frequent Peaks ...... 1,75CLAY WORKING INDUSTRYBrick Press, Briquette Machine,Clay Working Machine,Pug Mill ........................................... 1,75DREDGESCable Reel ...................................... 1,75Conveyors ...................................... 1,25Cutter head, Jig Drive ..................... 2,0Manoeuvring Winch ........................ 1,5Pumps (uniform load) ..................... 1,5Screen Drive, Stacker .................... 1,75Utility Winch .................................... 1,5FOOD INDUSTRYBeet Slicer ...................................... 1,75Bottling, Can Filling Machine .......... 1,0Cereal Cooker ................................ 1,25Dough Mixer, Meat Grinder ............ 1,75LUMBERBand Resaw ................................... 1,5Circular Resaw, Cut-off .................. 1,75Edger, Head Rig, Hog .................... 2,0Gang Saw(Reciprocating) .....Refer to Application EngineerLog Haul ......................................... 2,0Planner ........................................... 2,0Planer.............................................. 1,75Rolls, Non-Reversing ..................... 1,25Rolls, Reversing ............................. 2,0Sawdust Conveyor ......................... 1,25Slab Conveyor ................................ 1,75Sorting Table .................................. 1,5Trimmer .......................................... 1,75METAL ROLLING MILLSCoilers )Up or Down) ColdMills only ......................................... 1,5Coilers (Up or Down) HotMills only ......................................... 2,0Coke PlantsPusher Ram Drive ................... 2,5Door Opener ............................ 2,0Pusher or Larry CarTraction Drive........................... 3,0Continuous Caster .......................... 1,75Cold Mills -Strip Mills .......Refer to Application EngineerTemper Mills ..Refer to Application EngineerCooling Beds .................................. 1,5Drawbench ..................................... 1,5Feed Rolls - Blooming Mills ............ 3,0Furnace Pushers ............................ 2,0Hot and Cold Saws ......................... 2,0Hot Mills -Strip or Sheet Mills..Refer to Application EngineerReversing Blooming.Refer to Application EngineerSlabbing Mills .......Refer to Application EngineerEdger Drivers ............Refer to Application EngineerIngot Cars ....................................... 2,0Manipulators ................................... 3,0Merchant Mills ......Refer to Application EngineerMill TablesRoughing Breakdown Mills ...... 3,0Hot Bed or Transfer,non-reversing ........................... 1,5Runout, reversing ........................... 3,0Runout, non-reversing,non-plugging ............................ 2,0Reel Drives ..................................... 1,75Rod Mills ...............Refer to Application EngineerScrewdown ..................................... 2,0Seamless Tube MillsPiercer ..................................... 3,0ServiceFactorThrust Block ............................. 2,0Tube Conveyor Rolls ............... 2,0Reeler ...................................... 2.0Kick Out ................................... 2,0Shear, Croppers ....Refer to Application EngineerSideguards ..................................... 3,0Skelp Mills .............Refer to Application EngineerSlitters, Steel Mills only .................. 1,75Soaking Pit Cover Drives -Lift ............................................ 1,0Travel ....................................... 2,0Straighteners .................................. 2,0Unscramblers (Billet BundleBusters) .......................................... 2,0Wire Drawing Machinery ................ 1,75OIL INDUSTRYChiller ............................................. 1,25Oilwell Pumping (not over150% peak torque) ......................... 2,0Paraffin Filter Press ........................ 1,5Rotary Kiln ...................................... 2,0PAPER MILLSBarker Auxiliary, Hydraulic .............. 2,0Barker, Mechanical ......................... 2,0Barking DrumL.S. shaft or reducer withfinal drive - Helicalor Herringbone Gear ................ 2,0Machined Spur Gear ............... 2,5Cast Tooth Spur Gear .............. 3,0Beater & Pulper .............................. 1,75Bleachers, Coaters ......................... 1,0Calender & Super Calender ........... 1,75Chipper ........................................... 2,5Converting Machine ....................... 1,25Couch ............................................. 1,75Cutter, Felt Whipper ....................... 2,0Cylinder .......................................... 1,75Dryer ............................................... 1,75Felt Stretcher .................................. 1,25Fourdrinier ...................................... 1,75Jordan ............................................ 2,0Log Haul ......................................... 2,0Line Shaft ....................................... 1,5Press .............................................. 1,75Pulp Grinder ................................... 1,75Reel, Rewinder, Winder .................. 1,5Stock Chest, Washer,Thickener ........................................ 1,5Stock Pumps, CentrifugalConstant Speed .............................. 1,0Frequent Speed ChangesUnder Load ..................................... 1,25Suction Roll .................................... 1,75Vacuum Pumps .............................. 1,25RUBBER INDUSTRYCalender ......................................... 2,0Cracker, Plasticator ........................ 2,5Extruder .......................................... 1,75Intensive or Banbury Mixer ............. 2,5Mixing Mill, Refiner or SheeterOne or two in line ..................... 2,5Three or four in line ................. 2,0Five or more in line .................. 1,75Tire Building Machine ..................... 2,5Tire & Tube Press Opener(Peak Torque) ................................. 1,0Tuber, Strainer, Pelletizer ............... 1,75Warming MillOne or two Mills in line ............ 2,0Three or more Mills in line ....... 1,75Washer ........................................... 2,5SEWAGE DISPOSAL EQUIPMENTBar Screen, Chemical Feeders,Collectors, DewateringScreen, Grit Collector ..................... 1,0SUGAR INDUSTRYCane Carrier & Leveler ................... 1,75Cane Knife & Crusher .................... 2,0Mill Stands, Turbine DriverWith all helical orHerringbone Gears ......................... 1,5Electric Drive or Steam EngineDrive with Helical,Herringbone or Spur Gearswith any Prime Mover ..................... 1,75TEXTILE INDUSTRYBatcher ........................................... 1,25Calender, Card Machine ................. 1,5Cloth Finishing Machine ................. 1,5Dry Can, Loom ............................... 1,5Dyeing Machinery ........................... 1,25Knitting Machine ...Refer to Application EngineerMangle, Napper, Soaper ................ 1,25Spinner, Tenter Frame, Winder ...... 1,5

SERIES XSELECTION PROCEDURESERVICE FACTORS: are a guide, based on experienceof the ratio between coupling catalogue rating and systemcharacteristics.The system characteristics are best measured with a torquemeter.The following information is necessary to quote or ship toyour characteristics. exact requirements. Prompt service isassured if this informa tion is given on your inquiry or order.1. Application: Driver & Driven2. Power: Normal kW, Maximum kW or Torque (Nm)Table 3 . Service FactorsTorque DemandsDriven MachineTypical applications forelectric motor or turbinedriven equipmentConstant Torquesuch as CentrifugalPumps, Blowers, andCompressors.Continuous duty withsome torque variationsincluding Extruders,Forced Draft Fans.Light shock loads fromBriquetting Machine,Rubber Calender, orCrane and Hoist.Moderate shock loadingas expected from a CarDumper, Ball Mill, orVibrating Screen.Heavy shock load withsome negative torquesfrom Crushers, HammerMill, and Barking Drum.TypicalServiceFactor11.522.533. Speed (RPM)4. Quantity5. Coupling Size and Type,e. g., Size 1070G206. Shaft Gap or distance between shaft ends (BE Dimension)7. Bore Sizes: Must Specify clearance or interference fits.Bore tolerances will be furnished as per appropriate table forthe coupling type unless specified differently8. Shaft Dimensions as follows: (see diagram below) ForStraight ShaftsFor Straight ShaftsDrivingShaftNote: Provide shaft tolerances if different than thoseshown. Unless otherwise specified, keyway sizesin inch shafts will be furnished based on keysizes listed, to our tolerances; metric keyways willbe furnished per ISO/ R773-1969 and Js9 widthtolerances. For other shaft/bore requirementsconsult our Application Engineers.For Taper Shafts: Specify if keyway is to be parallel to theaxis or to the bore.Diameter U _____________Across Flats__________Length V _____________Corners ZW __________Length W_____________Taper per Foot __________Length X _____________Keyway __________Length YDiameter U ______Length V ______Keyway ___________________DrivenShaftDiameter U ______Length V ______Keyway ______Applications likeReciprocatingCompressors withfrequent torque reversals,which do not necessarilycause reverse rotations.Consult OurApplicationEngineersIf machines arein place furnishgap dimensionGapTaper per lengthon diameter7

SERIES XNOTES8

SERIES XGEARGEARTorsionally rigid, high torque couplingsSERIES X9

SERIES XGEAR COUPLINGSGear <strong>Couplings</strong>A torsionally rigid, lubricated design that offers high torque capacity, application versatility, and where high torque loads existor shaft diameters exceed 100 mm, the lowest initial cost. Available in 28 sizes, and all featuring triple-crowned teeth, our gearcouplings offer the highest torque ratings (over 8 million Nm) and the largest bore capacities (up to 1025 mm) in the industry.Type GC02 & GC05Continuous Sleeve <strong>Couplings</strong>Type G/GF32 SpacerCouplingFeatures a one-piece, lowprofile sleeve encompassing thehubs. Economical and compact.Available in both close coupledand floating shaft models. (seepages 13 and 14)Type G/GF52 Floating ShaftCouplingUsed when distance betweenequipment is too great for spacercouplings. 2 single engagementcouplings with interconnectingshaft. Also available for verticalmounting. (see pages 16 and 17)Special couplings - made to customers requirements (stainless steel etc) can be made upon request toour Application Engineers.Contact our Application Engineers for information on these additional Gear Coupling designs.For pumps and compressorapplications, provide ease ofservicing connected equipment(see page 19)Type G/GF20 Close CoupledDouble EngagementCouplingDesign with 2 flex halves toaccommodate both offset andangular misalignment. Alsoavailable for vertical mounting.(see page 15)Type G52 SingleEngagement CouplingPrimarily used with floatingshafts or 3 bearing drive trains.One (1) flex half and one (1)rigid half, only accepts angularmisalignment.Type GL Slide CouplingDouble and single engagementfor applications requiring axialmovement to accommodatethermal shaft expansion oradjustment.Type GR Shear PinCouplingFor applications subject tojamming. When pins break,equipment is physicallydiscon nected, preventingdamage.Type G70 & G72 Disconnect<strong>Couplings</strong>Used for applications that requirequick disconnection of equip mentor inching drives.InsulatorPlateType G62/G63/G66Brakewheel/Disc Brake<strong>Couplings</strong>Double or single engagement forshoe brake applications, such ascranes, hoists and conveyers.Type GP Insulated CouplingDouble or single engagementand rigid insulated couplings areused to eliminate flow of straycurrent from one shaft to another.Insulator PlateType G82/GV82 RigidCou plingsUsed when there is no needto accommodate misalign mentand where thrust loads aregenerated such as vertical mixerapplications.Type G Large Gear CouplingAvailable in all types for capacitiesup to 8,185,000 Nm(72,450,000 lb-in).10

SERIES XGENERAL DESCRIPTIONGear <strong>Couplings</strong>Low Initial Cost. Highest Bore Capacities & Ratings.InterchangeabilityBecause of their standard sizes,our Gear couplings are one halffor one half inter changeable withother standard gear couplings,regardless of difference insleeve barrel, hub and boredimensions.Gear Types AvailableThe wrong gear coupling can be costly. So we havedeveloped the less expensive solution: <strong>Series</strong> X Type Gcou plings. The low initial cost of Gear <strong>Couplings</strong>, along withthe highest bore capacities and ratings make them the truemoney saving option saving you as much as 35 percent overcompetitive designs.Built to last longer, protect your equipment and save youmoney, our gear couplings are right for a whole world ofapplications.What’s more, our couplings are designed to AGMA sizestandards, and are interchangeable .half for half. with manyother brands.With a wide variety of sizes and capacity ratings, durableGear couplings give users the broadest possible choicerange, no matter what the application, or factory environment.Smart MoneyA large bore capacity andhigh ratings, combined with agear couplings inherent torquedensity, offers a low initial cost.For many applications up to 35percent over other brands.G Standard Flanged SleeveThis general purpose series is used on bulk handlingsystems, paper machines, fans, pumps, cranes, mixers,sugar mills, crusher and many other high torque applications.Largest bore capacity and rating make this coupling aneconomical choice.GC Continuous SleeveThe one piece sleeve is used on high speed equipment withlow inertia requirements, and in applications requiring a lowinitial cost.GF .Steel Mill. Flanged SleeveThis flanged sleeve series is specifically designed for SteelMill requirements on applications such as reversing tables,feed rolls, reel drives, straighteners, drawing equipment andothers.• 205°C (400°F) high temperature seal rings can take theheat, without the high cost of metal seal designs.G Large Flanged SleeveThis larger capacity size is ideal for very high torqueapplications in power plants, mining, cement, steel and metalmills, paper, sugar, rubber and other large industrial plants.Lowest initial cost for high capacity requirements.Our gear couplings are warranted for 3 years when lubri catedwith our Long Term Grease.Longer LifeA longer working life is virtuallybuilt into couplings. Superiorlubrication, grease, and a fourpoint seal, extend life andreduce maintenance.Equipment ProtectionTriple crowned teeth aredesigned with crowns on allworking portions of the teeth,so they can slide freely toaccom modate misalignmentand movement. As a result, connectedequipment is protectedfrom damaging loads.11

SERIES XUNIT DESIGNATIONSDriving HubDriven HubExample1 - <strong>Series</strong> XRange X2, 3, 4, 5 - Size of Couplingeg 1 0 1 0*<strong>Series</strong>Size of CouplingType of Coupling1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17XDriving Hub Bore & KeywayDriving Hub Bore DiameterDriven Hub Bore & KeywayX 1 0 1 0 G - 2 0 M 0 2 0 M 0 2Driven Hub Bore Diameter15, 16, 17 - Driving Hub Bore Diameter(Gear half for single engagement couplings)eg 0 2 06, 7, 8, 9 - Type of CouplingGear - Continuous SleeveTypeGC02 = Double EngagementGC05 = Single Engagement/Floating ShaftGear - Standard Flanged SleeveType (Shrouded and Exposed Bolts)G-10 / 20 = Double Engagement (Shrouded /Exposed)G-51 / 52 = Single Engagement / Floating Shaft (Shrouded /Exposed)GV10 / 20 = Vertical Double Engagement (Shrouded / Exposed)GV51 / 52 = Vert. Single Engage. / Floating Shaft (Shrouded /Exposed)G-62 = Brakewheel Double Engagement (Exposed)G-63 = Disc Brake Double Engagement (Exposed)G-66 = Brakewheel Single Engagement (Exposed)GL20 = Slide Double Engagement (Exposed)GL52 = Slide Single Engagement / Floating Shaft (Exposed)G-70 = Disconnect / Inching DrivesG-72 = Disconnect (Exposed)G-31 / 32 = Spacer (Shrouded/Exposed)GP20 = Insulated Double Engagement (Exposed)GP52 = Insulated Single Engagement / Floating Shaft (Exposed)GP82 = Insulated Rigid (Exposed)G-81 / 82 = Rigid (Shrouded / Exposed)GV82 = Vertical Rigid (Exposed)GR20 = Shear Pin (Exposed)Gear - Steel Mill Flanged SleeveType (Shrouded and Exposed Bolts)GF10 / 20 = Double Engagement (Shrouded / Exposed)GF31 / 32 = Spacer (Shrouded / Exposed)GF51 / 52 = Single Engagement / Floating Shaft (Shrouded / Exposed)Gear - Large Flanged SleeveType (Exposed Bolts Only)G-20 = Double Engagement -Pilot BoreG-52 = Single Engagement / Floating ShaftGV20 = Vertical Double EngagementGV52 = Vertical Single Engagement / Floating ShaftGL20 = Slide Double EngagementG-70 = Disconnect / Inching DrivesG-32 = SpacerG-82 = RigidGV82 = Vertical RigidGR20 = Shear Pin* This Page May Be Photocopied Allowing The Customer To Enter Their Order14 - Driving Hub Bore and Keyway(Gear half for single engagement couplings)MTIBPCSAH11, 12, 13 - Driving Hub Bore Diameter(Rigid half for single engagement couplings)eg 0 2 010 - Driving Hub Bore and Keyway(Rigid half for single engagement couplings)MTIBPCSAH- Metric Bore Parallel Keyway- Metric Bore Taper Keyway- Inch Bore Parallel Keyway- Inch Bore Taper Keyway- Pilot Bore- Customer Specified Metric- Customer Specified Inch- American Square Key- Half Coupling- Metric Bore Parallel Keyway- Metric Bore Taper Keyway- Inch Bore Parallel Keyway- Inch Bore Taper Keyway- Pilot Bore- Customer Specified Metric- Customer Specified Inch- American Square Key- Half Coupling12

Type GC02 Continuous SleeveDouble Engagement Close-Coupled / Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSLubricateThru SleeveMinimumClearanceRequired forAligningGapFlex Hub #1 Flex Hub #2SIZE*TorqueRating(Nm)†AllowSpeed(rpm)Max Bore(mm)•(Inch)•Cpig WtWithNo Bore(kg)LubeDIMENSIONS - MillimetersA B C D J M Gap1010GC 1140 5300 50 1.875 3,54 0,0113 88,9 88,8 42,9 68,6 62,9 65 31015GC 2350 4300 65 2.375 6,17 0,0283 109,2 101,6 49,3 86,4 76,2 81 31020GC 4270 3700 78 2.878 11,4 0,0425 132,1 127,0 62,0 105,2 94,5 99 31025GC 7470 3300 98 3.625 21,5 0,0652 163,6 159,0 77,0 130,6 109,1 116 51030GC 12100 2900 111 4,125 34,1 0,0936 190,5 187,4 91,2 152,4 119,9 126 5* Refer to Page 4 for General Information and Reference Notes.13

Type GC02 Continuous SleeveFloating Shaft Single Engagement / Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSLubricateThru SleeveLubricateThru SleeveGapBetween Shaft EndsGapFlex Hubs on FloatingShaft (PFFP)Pilot HubGap DiscFlex Hub #1(Sizes 1025GCThru 1030GC only) Flex Hub #1Pilot HubElastomer Gap Disc for Vertical Applications - LowerCoupling Only for All SizesMinimum Clearance Required for AligningLubricateThru SleeveLubricateThru SleeveGapBetween Shaft EndsGapPilot Hubs on FloatingShaft (FPPF)Gap Disc(Sizes 1025GCFlex Hub #1 Pilot HubThru 1030GC only)Pilot HubFlex Hub #1Size*AssemblyTorqueRating(Nm) †Wt -DIMENSIONS - MillimetersMax B One LubeCpig WtBE MinNo Bore (kg) AC D J L M Gap(mm) • (Inch) • (kg)PF-FP FP-PF1010GC 1140 50 1.875 3,49 0,00850 88,9 190 92,2 42,9 68,6 61,2 42,9 65 31015GC 2350 65 2.375 6,40 0,0198 109,2 235 104,9 49,3 86,4 76,2 51,1 81 31020GC 4270 78 2.875 11,7 0,0312 132,1 290 130,3 62,0 105,2 94,5 63,8 99 31025GC 7470 98 3.625 21,8 0,0522 163,6 338 163,6 77,0 130,6 109,1 77,0 116 51030GC 12100 111 4.125 34,6 0,0730 190,5 368 192,0 91,2 152,4 119,9 91,2 126 5Size*AssemblyTorqueRating **(Nm) †SBShaft EndDiameter(mm)SD ShaftDiameter(mm)Weight(kgper mm)WR 2(kgM 2per mm)Maximum (mm) for Various RPM’s §1750 1430 1170 870 720 580540or less1010GC1015GC1020GC1025GC1030GC439 38,1 39,7 0,00964 0,00000196 1371 1524 1676 1955 2159 2387 24631140 47,6 50,8 0,0159 0,00000518 1549 1727 1905 2209 2438 2717 27941170 50,8 54,0 0,0179 0,00000657 1600 1778 1955 2286 2514 2794 28702350 60,3 63,5 0,0248 0,0000126 1752 1930 2133 2463 2717 3022 31242280 63,5 66,7 0,0273 0,0000152 1778 1981 2184 2540 2794 3098 32004270 73,0 76,2 0,0357 0,0000259 1905 2108 2336 2717 2971 3327 34294460 79,4 82,6 0,0420 0,0000357 1981 2209 2438 2819 3098 3454 35567470 92,1 95,2 0,0559 0,0000634 2133 2362 2616 3022 3327 3708 38358500 98,4 101,6 0,0636 0,0000820 2209 2438 2692 3124 3454 3835 396212100 104,8 108,0 0,0718 0,000104 2260 2514 2794 3225 3556 3962 4064* Refer to Page 4 for General Information and Reference Notes.** Limited by coupling size, shaft end diameter or both. Refer to Page 5 - 7 for section procedure14

Type G20 Standard Flanged SleeveDouble Engagement Close-Coupled / Dimensions - MillimetersMinimum Clearance Required for AligningSERIES XDIMENSIONS ANDSPECIFICATIONSGasketGapType G20 Exposed BoltsLubricateThru SleeveFor Sizes 1010G thru 1055G,TypeG10 Shrouded Bolts furnished onlywhen specified on orderSize*TorqueRating **(Nm) †AllowSpeed(rpm)Max BoreCpig Wt WithNo Bore - kg(mm)• (Inch)• G10 G20LubeWt(kg)DIMENSIONS - MillimetersA B C D F H J M Gap1010G 1140 8000 50 1.875 4,08 4,54 0,0408 115,9 88,9 42,9 68,6 83,8 14,0 38,9 51 31015G 2350 6500 65 2.375 7,71 9,07 0,0726 152,4 101,6 49,3 86,4 105,2 19,0 47,8 61 31020G 4270 5600 78 2.875 13,6 15,9 0,113 177,8 127,0 62,0 105,2 126,5 19,0 59,4 77 31025G 7470 5000 98 3.625 24,9 29,5 0,213 212,7 158,9 77,0 130,6 154,9 21,8 71,6 92 51030G 12100 4400 111 4.125 38,6 43,1 0,363 239,7 187,4 91,2 152,4 180,3 21,8 83,8 107 51035G 18500 3900 134 4.875 61,2 68,0 0,544 279,4 218,9 106,4 177,8 211,3 28,4 97,5 130 61040G 30600 3600 160 5.750 88,5 97,5 0,907 317,5 247,3 120,6 209,6 245,4 28,4 111,3 145 61045G 42000 3200 183 6.750 127 136 1,04 346,1 277,7 134,9 235,0 274,1 28,4 122,9 166 81050G 56600 2900 200 7.375 177 191 1,77 388,9 314,3 153,2 254,0 305,8 38,1 140,7 183 81055G 74000 2650 220 8.250 238 249 2,22 425,4 344,3 168,1 279,4 334,3 38,1 158,0 204 81060G 90400 2450 244 9.125 … 306 3,18 457,2 384,4 188,2 304,8 366,0 25,4 169,2 229 81070G 135000 2150 289 10.875 … 485 4,35 527,0 451,5 220,7 355,6 424,9 28,4 195,6 267 10Limited End Float & Standard Gap Disc Dimensions - Millimeters * Refer to Page 4 for General Informationand Reference Notes.DIMENSIONS - MillimetersSIZEBEndFloat **ThicknessGap DiscDiaGap1010G 90,9 2,39 4 75 51015G 103,6 2,39 4 94 51020G 129,8 2,39 5 114 61025G 162,3 2,39 7 141 81030G 191,5 2,39 8 165 91035G 223,3 4,78 8 192 101040G 251,7 4,78 8 227 101045G 283,2 4,78 11 253 131050G 319,8 4,78 11 278 131055G 350,5 4,78 12 305 141060G 392,4 4,78 14 333 161070G 459,7 4,78 16 384 18Gap DiscAxiallyFixedShaftAxiallyMoveableShaftHub GapRotor End Float(One - Half FloatEach Size)** If these values exceed one-half rotor end float or equivalent manufacturer’s specification, refer to our Application Engineers.◊ Gap disc material: Neoprene, 70 durometer15

Type G52 Standard Flanged SleeveSingle Engagement / Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSMinimum Clearance Required for AligningFlex HubRigid HubGapLubricateThru SleeveGasketFor Sizes 1010G thru 1055G, TypeG51 Shrouded Bolts furnished onlywhen specified on orderSize*TorqueRating**(Nm) †AllowSpeed(rpm)Max BoreFlex RigidHubMinBore(mm)Cpig WtWith NoBore - kgHub G51 G52LubeWt(kg)DIMENSIONS - MillimetersA B C D E F H J L M Q Gap1010G 1139 8000 50 65 12,7 4,08 4,54 0,0227 115,9 86,6 42,9 68,6 2,5 83,8 14,0 38,9 39,6 51 42,2 41015G 2350 6500 65 80 19,0 8,16 9,07 0,0408 152,4 99,6 49,3 86,4 2,5 105,2 19,0 47,8 46,2 61 48,8 41020G 4270 5600 78 98 25,4 13,6 15,9 0,0680 177,8 124,5 62,0 105,2 2,5 126,5 19,0 59,4 58,4 76 61,0 41025G 7470 5000 98 118 31,8 24,9 27,2 0,118 212,9 155,4 77,0 130,6 2,5 154,9 21,8 71,6 73,7 91 76,2 51030G 12100 4400 111 140 38,1 38,6 43,1 0,181 239,8 183,9 91,2 152,4 2,5 180,3 21,8 83,8 87,9 107 90,4 51035G 18500 3900 134 163 50,8 61,2 68,0 0,272 279,4 214,1 106,4 177,8 2,5 211,3 28,4 97,5 102,1 130 104,6 61040G 30600 3600 160 196 63,5 90,7 99,8 0,467 317,5 242,8 120,6 209,6 4,1 245,4 28,4 111,3 115,3 145 119,4 71045G 42000 3200 183 216 76,2 129,3 136 0,557 346,0 273,1 134,9 235,0 4,1 274,1 28,4 122,9 130,6 165 134,6 81050G 56600 2900 200 235 88,9 181,4 195 0,907 388,9 309,1 153,2 254,0 5,1 305,8 38,1 140,7 147,3 183 152,4 91055G 74000 2650 220 266 101,6 251,7 263 1,13 425,4 349,5 168,1 279,4 5,1 334,3 38,1 158,0 172,7 203 177,8 91060G 90400 2450 244 290 114,3 … 324 1,70 457,2 385,1 188,2 304,8 6,6 366,0 25,4 169,2 186,4 229 193,0 101070G 135000 2150 289 340 127,0 … 508 2,27 527,0 453,6 220,7 355,6 8,4 424,9 28,4 195,6 220,2 267 228,6 13* Refer to Page 4 for General Information and Reference Notes.16

Type G52 Standard Flanged SleeveFloating Shafts / Dimensions - MillimetersA standard floating shaft assembly consists of two standard singleengagement couplings, two gap discs and a connecting shaft.A floating shaft can eliminate the need for additional bearingsupports along spanning shaft because the shaft is supported atthe ends by connected equipment through the single engagementcouplings.Flex Hubs on Floating Shaft (RFFR)Assembly of the flex hubs on the floating shaft allows for easierreplacement in case of wear and allows the rigid hubs with theirincreased bore capacity to be used on the connected equipmentshafts. This frequently means a smaller coupling size can beutilised.Operating speed - RPMBalancing normallynot requiredBalancing of shaftrequiredDistance between shaft ends - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSRigid Hubs on Floating Shaft (FRRF)When the rigid hubs are on the floating shaft, shorter shaft spanscan be accommodated, since no cover drawback is required. Sincethe flex hubs are outboard, the points of articulation are furtherapart, providing greater offset misalignment capacity.Solid Floating Shaft SelectionSingle Engagement Type G52/GV52 couplings are used withfloating shafts in either horizontal or vertical applications. Forvertical applications select a Type GV52 coupling for the lowercoupling assembly. Select floating shafts as follows:1. Use the Standard or Formula Selection Methods, Page 5 toselect the couplings. Record the Required Minimum CouplingRating from standard selection method or Selection Torquefrom formula selection method.2. From table below select a shaft diameter that has an assemblytorque rating equal to or greater than the system or selectiontorque determined in coupling selection.3. Check maximum ‘BE’ for the shaft diameter selected andrunning speed for shaft length required from table below. Referto graph at left to determine if shaft requires balancing.4. If the application shaft length exceeds the maximum “BE” listed,select the next larger shaft diameter or the next larger sizecoupling. Consult the Factory for higher speeds or longer shaftlengths than listed below.NOTE: For conditions that require a larger size coupling, considera Tubular Shaft Design, refer complete application details toour Application EngineersSize*1010G1015G1020G1025G1030G1035G1040G1045G1050G1055G1060G1070GAssemblyTorqueRating **(Nm) †SB ShaftEndDiameter(mm)SD ShaftDiameter(mm)Weight(kgper mm)WR 2(kgM 2per mm)Floating ShaftMaximum BE (mm) for Various RPM’s §1750 1430 1170 870 720 580540or less493 38,1 39,7 0,00964 0,00000196 1371 1524 1676 1955 2159 2387 24631140 47,6 50,8 0,0159 0,00000518 1549 1727 1905 2209 2438 2717 27941170 50,8 54,0 0,0179 0,00000657 1600 1778 1955 2286 2514 2794 28702350 60,3 63,5 0,0248 0,0000126 1752 1930 2133 2463 2717 3022 31242280 63,5 66,7 0,0273 0,0000152 1778 1981 2184 2540 2794 3098 32004270 73,0 76,2 00,557 0,0000259 1905 2108 2336 2717 2971 3327 34294460 79,4 82,6 0,0420 0,0000357 1981 2209 2438 2819 3098 3454 35567470 92,1 95,2 0,0559 0,0000634 2133 2362 2616 3022 3237 3708 38358500 98,4 101,6 0,0636 0,0000820 2209 2438 2692 3124 3454 3835 396212100 104,8 108,0 0,0718 0,000104 2260 2514 2794 3225 3556 3962 406413300 114,3 120,6 0,0896 0,000163 2413 2667 2946 3403 3759 4191 429218500 123,8 127,0 0,0993 0,000200 2463 2717 3022 3505 3860 4292 441924300 139,7 146,0 0,131 0,000350 2641 2921 3251 3759 4140 4597 474930600 146,0 152,4 0,143 0,000415 2692 2997 3302 3835 4216 4699 485131600 152,4 165,1 0,168 0,000572 2819 3124 3454 3987 4394 4902 502942000 171,5 203,2 0,254 0,00131 3124 3454 3810 4445 4876 5435 558837900 161,9 165,1 0,168 0,000572 2819 3124 3454 3987 4394 4902 502956600 187,3 203,2 0,254 0,00131 3124 3454 3810 4445 4876 5435 558837900 161,9 165,1 0,168 0,000572 2819 3124 3454 3987 4394 4902 502974000 200,0 203,2 0,254 0,00131 3124 3454 3810 4445 4876 5435 558871400 200,0 203,2 0,254 0,00131 3124 3454 3810 4445 4876 5435 558890400 215,9 217,4 0,291 0,00172 3225 3581 3962 4597 5054 5613 579171400 200,0 203,2 0,254 0,00131 3124 3454 3810 4445 4876 5435 5588135000 241,3 242,8 0,363 0,00268 3403 3784 4191 4851 5334 5943 6121* Refer to Page 4 for General Information and Reference Notes.** Assembly torque rating is limited by coupling size, shaft end diameter or both.17

Type G52 Standard Flanged SleeveSingle Engagement / Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSFlex Hubs on Floating Shaft (RFFR)Rigid HubGasketFlex HubFlex HubRigid HubGapBetween Shaft EndsGapGap DiscGap DiscGasketLubricateThru SleeveRigid Hubs on Floating Shaft (FRRF)Minimum ClearanceRequired for AligningGasketFlex HubGap DiscRigid HubRigid HubGap DiscFlex HubGapBetween Shaft EndsGapLubricateThru SleeveGasketFor Sizes 1010G thru 1055G, Type G51Shrouded Bolts furnished only whenspecified on orderSize*MaxBore (mm)FlexHubRigidHubMaxBore (inch)FlexHubRigidHubWt -One CpigNo Bore - kgLubeWt PerCpigG51 G52 (kg) ABE MinRFFR FRRFDIMENSIONS - MillimetersC D E F H J L M Q Gap1010G 50 65 1.875 2.375 4,08 4,54 0,0227 115,9 133 92 42,9 68,6 2,5 83,8 14,0 38,9 39,6 48 42,2 41015G 65 80 2.375 2.938 8,16 9,07 0,0408 152,4 159 105 49,3 86,4 2,5 105,2 19,0 47,8 46,2 56 48,8 41020G 78 98 2.875 3.625 13,6 15,9 0,0680 177,8 197 129 62,0 105,2 2,5 126,5 19,0 59,4 58,4 69 61,0 41025G 98 118 3.625 4.375 24,9 27,2 0,118 212,7 241 162 77,0 130,6 2,5 154,9 21,8 71,6 73,7 81 76,2 51030G 111 140 4.125 5.125 38,6 43,1 0,181 239,7 279 189 91,2 152,4 2,5 108,3 21,8 83,8 87,9 94 90,4 51035G 134 163 4.875 5.875 61,2 68,0 0,272 279,4 324 219 106,4 177,8 2,5 211,3 28,4 97,5 102,1 107 104,6 61040G 160 196 5.750 7.250 90,7 99,8 0,467 317,5 419 248 120,6 209,8 3,8 245,4 28,4 111,3 115,6 122 119,4 71045G 183 216 6.750 8.125 129,3 136,1 0,557 346,1 508 281 134,9 235,0 3,8 274,1 28,4 122,9 130,8 135 134,6 81050G 200 235 7.375 9.000 181,4 195,0 0,907 388,9 533 316 153,2 254,0 5,1 305,8 38,1 140,7 147,3 152 152,4 91055G 220 266 8.250 10.000 251,7 263,1 1,13 425,4 572 367 168,1 279,4 5,1 334,3 38,1 158,0 172,7 173 177,8 91060G 244 290 9.125 11.000 … 324,3 1,70 457,2 597 397 188,2 304,8 6,6 366,0 25,4 169,2 186,4 183 193,0 101070G 289 340 10.875 13.000 … 508,0 2,27 527,0 673 470 220,7 355,6 8,4 424,9 28,4 195,6 220,2 208 228,6 13* Refer to Page 4 for General Information and Reference Notes.18

Type G52 Standard Flanged SleeveSingle Engagement / Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSMinimum Clearance Required for AligningSpacerGasketExposedBoltsGapType G31 shrouded Boltsfurnished only when specifiedon orderLubricateThru SleeveSize*TorqueRating**(Nm) †AllowSpeed(rpm)MaxBore(mm)• (Inch)•Cpig Wt - kgCpig WtWith NoBoreand MinBEExtraSpacerWt permm ofLength* Refer to Page 4 for General Information and Reference Notes.Lube Wt - kgMin WtLessSpacerPlus permm ofSpacerLengthABE MinDIMENSIONS - MillimetersBE MaxG31 G32 G31& G32C D F H J M1010G 1140 7000 50 1.875 6,80 0,0120 0,0408 … 115,9 82 82 311 42,9 68,6 83,8 14,0 38,9 481015G 2350 5500 65 2.375 13,6 0,0127 0,0726 … 152,4 82 82 311 49,3 86,4 105,2 19,0 47,8 561020G 4270 4600 78 2.875 20,4 0,0166 0,113 0,000536 177,8 82 82 311 62,0 105,2 126,5 19,0 59,4 691025G 7470 4000 98 3.625 38,6 0,0205 0,227 0,00107 212,9 108 95 311 77,0 130,6 154,9 21,8 71,6 811030G 12100 3600 111 4.125 54,4 0,0236 0,363 0,00107 239,8 108 95 311 91,2 152,4 180,3 21,8 83,8 941035G 18500 3100 134 4.875 88,5 0,0359 0,544 0,00214 279,4 130 120 311 106,4 177,8 211,3 28,4 97,5 1071040G 30600 2800 160 5.750 122,5 0,0500 0,907 0,00357 317,5 130 120 311 120,6 209,6 245,4 28,4 111,3 1221045G 42000 2600 183 6.750 166 0,0736 1,04 0,00357 346,1 133 120 311 134,9 235,0 274,1 28,4 122,9 1351050G 56600 2400 200 7.375 238 0,0814 1,77 0,00357 388,9 184 146 311 153,2 254,0 305,8 38,1 140,7 1521055G 74000 2200 220 8.250 306 0,0895 2,22 0,00357 425,4 184 146 311 168,1 279,4 334,3 38,1 158,0 1731060G 90400 2100 244 9.125 358 0,117 3,18 0,00357 457,2 … 146 311 188,2 304,8 366,0 25,4 169,2 1831070G 135000 1800 289 10.875 562 0,141 4,35 0,00357 527,0 … 146 311 220,7 355,6 424,9 28,4 195,6 208Table 4 - Type G32 Standard Stock Spacer LengthsDistance BetweenShaft Ends PumpCoupling SizeStdmm Inches 1010 1015 1020 1025 1030 103589 3.500 ANSI • •111 4.375 ANSI • •114 4.500 MISC • **127 5.000 ANSI • • • • •178 7.000 ANSI • • •** Bolt holes staggered for assembly clearance.19

Type G82 Standard Flanged SleeveRigid / Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSGapType G81 Shrouded Bolts furnished onlywhen specified on order. Sizes 1060Gand 1070G available only as Type G82.Size*TorqueRating(Nm) †AllowSpeed(rpm)MaxBore(mm)MinBore(mm)Cpig Wt WithNo Bore - kgDIMENSIONS - MillimetersG81 G82 A B E F H L Q Gap1010G 1139 8,000 65 12,7 4,08 4,54 115,9 84,3 2,5 83,8 14,0 39,6 42,2 5 1010G1015G 2350 6,500 80 19,0 8,62 9,07 152,4 97,5 2,5 105,2 19,0 46,2 48,8 5 1015G1020G 4270 5,600 98 25,4 13,6 15,9 177,8 121,9 2,5 126,5 19,0 58,4 61,0 5 1020G1025G 7470 5,000 118 31,8 24,9 27,2 212,9 152,4 2,5 154,9 21,8 73,7 76,2 5 1025G1030G 12100 4,400 140 38,1 40,8 43,1 239,8 180,8 2,5 180,3 21,8 87,9 90,4 5 1030G1035G 18500 3,900 163 50,8 61,2 70,3 279,4 209,3 2,5 211,3 28,4 102,1 104,6 5 1035G1040G 30600 3,600 196 63,5 95,3 102 317,5 238,8 4,1 245,4 28,4 115,3 119,4 8 1040G1045G 42000 3,200 216 76,2 132 141 346,0 269,2 4,1 274,1 28,4 130,6 134,6 8 1045G1050G 56600 2,900 235 88,9 188 204 388,9 304,8 5,1 305,8 38,1 147,3 152,4 10 1050G1055G 74000 2,650 266 101,6 268 281 425,4 355,6 5,1 334,3 38,1 172,7 177,8 10 1055G1060G 90400 2,450 290 114,3 … 336 457,2 386,1 6,6 366,0 25,4 186,4 193,0 13 1060G1070G 135000 2,150 340 127,0 … 535 527,0 457,2 8,4 424,9 28,4 220,2 228,6 17 1070GSIZE*20

Type G Standard Flanged SleeveMill Motor & Taper Bores / Metric Equivalent Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSAmount machined fromhub face on gap sideTable 8 - Standard AISE AC & DC Mill Motor Coupling SelectionsMotor Frame Sizes couplingslze*2602603604802A,B&C803804AC1,2 &4606 806 AC8 &121015G1020G1025G... 1015G1020G1025G1030G1020G1025G1030G1035G608 808 ... 1025G1030G1035G1040G610 810 AC180 1025G1030G1035G1040G612 812 AC25&30614 814 AC40&501030G1035G1040G1045G1035G1040G1045G1050G616 816 ... 1035G1040G1045G1050G618 818 ... 1040G1045G1050G620 820 ... 1045G1050G1055G622 822 ... 1045G1050G1055G1060G624 824 ... 1050G1055G1060G1070GE R UG UH Keyway Z ZD ZE ZG2,52,52,52,52,52,52,52,52,52,52,52,52,52,54,12,52,52,54.12,52,54,14,12,54,14,15,12,54,14,15,14,14,15,14,15,15,14,15,15,16,65,15,16,68,47,9 36,5 44,5 12,70x6,35 82,55 23,9 76,2 1,55,612,49,7 41,53 50,80 12,70x6,35 85,73 25,4 88,9 0,04,110,919,19,7 52,91 63,50 12,70x6,35 101,60 28,4 102 1,07,615,725,412,7 64,3 76,20 19,05x6,35 133,35 31,8 114,3 4,612,722,432,012,7 70,64 82,55 19,05x6,35 142,88*35,1 114 1,39,719,329,012,7 78,84 92,08 19,05x6,35 158,75 38,1 127 6,416,025,732,312,7 94,72 107,95 25,40x9,53 174,63 41,1 127 12,722,629,240,615,7 102,92 115,80***117,48117,48117,4831,75x9,53 195,33200,03200,03200,0344,5 124***1401401409,719,325,937,115,7 113,13 127,00 31,75x12,70 212,73 33,5 152 30,537,348,519,1 131,37 149,23 38,10x19,05 247,65 44,5 172 25,937,351,319,1 139,57 158,75 38,10x19,05 247,65 60,2 184 10,221,635,341,719,1 153,34 177,80 38,10x19,05 247,65 60,2 235 21,335,341,759,7ZH+,XXX-,0000,61* Refer to page 4 for General Information and other Reference Notes. Minimum coupling selections are based on couplingbore capacity. Check coupling rating for all selections. Refer to Pages 16, 17 & 18 for coupling dimensions.** Spanner wrench required for Size 1025G.*** For rigid hub only.0,740,740,740,860,860,860,860,970,970,970,97Table 9 - Taper and Counter bore Limitations +SizeFlex HubRigid Hub* P Max+++ UG Min UH Max ZD Max ZE Min Keyway++ P Max+++ UG Min UH Max Z Max ZE Min Keyway++1010G 102 12,7 50 18,5 42,9 14 x 4,5 104 12,7 60 76,2 39,6 18 x 5,51015G 114 19,1 65 25,4 49,3 18 x 5,5 117 19,1 80 85,9 46,2 22 x 71020G 130 25,4 78 29,5 62,0 22 x 7 133 25,4 98 102 58,4 28 x 81025G 149 31,8 98 36,3 77,0 28 x 8 152 31,8 118 143 73,7 32 x 91030G 165 38,1 111 44,5 91,2 32 x 9 168 38,1 140 159 87,9 36 x 101035G 184 50,8 134 54,1 106 36 x 10 171 50,8 163 175 102 40 x 111040G 203 63,5 160 63,8 121 40 x 11 191 63,5 196 213 114 45 x 22,51045G 244 76,2 183 70,4 135 45 x 12,5 249 76,2 216 248 130 50 x 141050G 295 88,9 200 81,8 153 45 x 12,5 300 88,9 235 273 147 56 x 161055G 298 102 220 95,8 168 50 x 14 303 102 266 298 173 63 x 161060G 305 114 244 102 188 56 x 16 311 114 290 330 186 63 x 161070G 310 127 289 120 221 63 x 16 313 127 340 381 220 80 x 20+ This table specifies the taper bore limitations for the usual requirements. For hubs no longer than those listed, refer to our Application Engineers.++ Standard Long Hub length, consult our Application Engineers for longer lengths.+++ Keyway shown is for maximum bore with square key.21

Type G20 Steel Mill Flanged SleeveDouble Engagement / Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSMinimum Clearance Required for AligningGapFor Sizes 1010GF thru 1055GF, TypeGF10 Shrouded Bolts furnished onlywhen specified on order.LubricateThru SleeveGasketSize*TorqueRating(Nm) †AllowSpeed(rpm)Max BoreCpig Wt WithNo Bore - kgLubeWt(kg)DIMENSIONS - Millimeters(mm) • (Inch) • GF10 GF20 A B C D F H J M Gap1010GF 1140 8000 50 1.875 4,08 4,54 0,0408 115,9 88,9 42,9 68,6 83,8 14,0 38,9 51 31015GF 2350 6500 65 2.375 7,71 9,07 0,0726 152,4 101,6 49,3 86,4 105,2 19,0 47,8 61 31020GF 4270 5600 78 2.875 13,6 15,9 0,113 177,8 127,0 62,0 105,2 126,5 19,0 59,4 77 31025GF 7470 5000 98 3.625 24,9 29,5 0,213 212,7 158,9 77,0 130,6 154,9 21,8 71,6 92 51030GF 12100 4400 111 4.125 38,6 43,1 0,363 239,7 187,4 91,2 152,4 180,3 21,8 83,8 107 51035GF 18500 3900 134 4.875 61,2 68,0 0,544 279,4 218,9 106,4 177,8 211,3 28,4 97,5 130 61040GF 30600 3600 160 5.750 88,5 97,5 0,907 317,5 247,3 120,6 209,6 245,4 28,4 111,3 145 61045GF 42000 3200 183 6.750 127 136 1,04 346,1 277,7 134,9 235,0 274,1 28,4 122,9 166 81050GF 56600 2900 200 7.375 177 191 1,77 388,9 314,3 153,2 254,0 305,8 38,1 140,7 183 81055GF 74000 2650 220 8.250 238 249 2,22 425,4 344,3 168,1 279,4 334,3 38,1 158,0 204 81060GF 90400 2450 244 9.125 … 306 3,18 457,2 384,4 188,2 304,8 366,0 25,4 169,2 229 81070GF 135000 2150 289 10.875 … 485 4,35 527,0 451,5 220,7 355,6 424,9 28,4 195,6 267 10* Refer to Page 4 for General Information and Reference Notes.22

Type GF52 Steel Mill Flanged SleeveSingle Engagement / Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSMinimum Clearance Required for AligningFlex HubRigid HubGapLubricateThru SleeveGasketFor Sizes 1010GF thru 1055GF, TypeGF51 Shrouded Bolts furnished onlywhen specified on order.Size*MaxBore (mm) •FlexHubRigidHubMaxBore (inch) •FlexHubRigidHubWt -One CpigNo Bore - kgLubeWt PerCpigDIMENSIONS - MillimetersG51 G52 (kg) A C D E F H J L M Q Gap1010GF 50 65 1.875 2.375 4,08 4,54 0,0227 115,9 42,9 68,6 2,5 83,8 14,0 38,9 39,6 48 42,2 41015GF 65 80 2.375 2.938 8,16 9,07 0,0408 152,4 49,3 86,4 2,5 105,2 19,0 47,8 46,2 56 48,8 41020GF 78 98 2.875 3.625 13,6 15,9 0,0680 177,8 62,0 105,2 2,5 126,5 19,0 59,4 58,4 69 61,0 41025GF 98 118 3.625 4.375 24,9 27,2 0,118 212,7 77,0 130,6 2,5 154,9 21,8 71,6 73,7 81 76,2 51030GF 111 140 4.125 5.125 38,6 43,1 0,181 239,7 91,2 152,4 2,5 180,3 21,8 83,8 87,9 94 90,4 51035GF 134 163 4.875 5.875 61,2 68,0 0,272 279,4 106,4 177,8 2,5 211,3 28,4 97,5 102,1 107 104,6 61040GF 160 196 5.750 7.250 90,7 99,8 0,467 317,5 120,6 209,6 3,8 245,4 28,4 111,3 115,6 122 119,4 71045GF 183 216 6.750 8.125 129,3 136,1 0,557 346,1 134,9 235,0 3,8 274,1 28,4 122,9 130,8 135 134,6 81050GF 200 235 7.375 9.000 181,4 195,0 0,907 388,9 153,2 254,0 5,1 305,8 38,1 140,7 147,3 152 152,4 91055GF 220 266 8.250 10.000 251,7 263,1 1,13 425,4 168,1 279,4 5,1 334,3 38,1 158,0 172,7 173 177,8 91060GF 244 290 9.125 11.000 … 234,3 1,70 457,2 188,2 304,8 6,6 366,0 25,4 169,2 186,4 183 193,0 101070GF 289 340 10.875 13.000 … 508,0 2,27 527,0 220,7 355,6 8,4 424,9 28,4 195,6 220,2 208 228,6 13* Refer to Page 4 for General Information and Reference Notes.23

Type G52 Steel Mill Flanged SleeveFloating Shafts / Dimensions - MillimetersA standard floating shaft assembly consists of two standard singleengagement couplings, two gap discs and a connecting shaft.A floating shaft can eliminate the need for additional bearingsupports along spanning shaft because the shaft is supported atthe ends by connected equipment through the single engagementcouplings.Flex Hubs on Floating Shaft (RFFR)Assembly of the flex hubs on the floating shaft allows for easierreplacement in case of wear and allows the rigid hubs with theirincreased bore capacity to be used on the connected equipmentshafts. This frequently means a smaller coupling size can beutilised.Operating speed - RPMBalancing normallynot requiredBalancing of shaftrequiredDistance between shaft ends - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSRigid Hubs on Floating Shaft (FRRF)When the rigid hubs are on the floating shaft, shorter shaft spanscan be accommodated, since no cover drawback is required. Sincethe flex hubs are outboard, the points of articulation are furtherapart, providing greater offset misalignment capacity.Solid Floating Shaft SelectionSingle Engagement Type GF52 couplings are used with floatingshafts in horizontal applications. Select floating shafts as follows:1. Use the Standard or Formula Selection Methods, Page 5to select the couplings. Record the Required MinimumCoupling Rating from standard selection method or SelectionTorque from formula selection method.2. From table below select a shaft diameter that has an assemblytorque rating equal to or greater than the system or selectiontorque determined in coupling selection.3. Check maximum ‘BE’ for the shaft diameter selected andrunning speed for shaft length required from table below. Referto graph at left to determine if shaft requires balancing.4. If the application shaft length exceeds the maximum “BE” listed,select the next larger shaft diameter or the next larger sizecoupling. Consult the Factory for higher speeds or longer shaftlengths than listed below.NOTE: For conditions that require a larger size coupling, considera Tubular Shaft Design, refer complete application details toour Application EngineersSize*1010GF1015GF1020GF1025GF1030GF1035GF1040GF1045GF1050GF1055GF1060GF1070GFAssemblyTorqueRating **(Nm) †SB ShaftEndDiameter(mm)SD ShaftDiameter(mm)Weight(kgper mm)WR 2(kgM 2per mm)Floating ShaftMaximum BE (mm) for Various RPM’s §1750 1430 1170 870 720 580540or less493 38,1 39,7 0,00964 0,00000196 1371 1524 1676 1955 2159 2387 24631140 47,3 50,8 0,0159 0,00000518 1549 1727 1905 2209 2438 2717 27941170 50,8 54,0 0,0179 0,00000657 1600 1778 1955 2286 2514 2794 28702350 60,3 63,5 0,0248 0,0000126 1752 1930 2133 2463 2717 3022 31242280 63,5 66,7 0,0273 0,0000152 1778 1981 2184 2540 2794 3098 32004270 73,0 76,2 0,0557 0,0000259 1905 2108 2336 2717 2971 3327 34294460 79,4 82,6 0,0420 0,0000357 1981 2209 2438 2819 3098 3454 35567470 92,1 95,2 0,0559 0,0000634 2133 2362 2616 3022 3237 3708 38358500 98,4 101,6 0,0636 0,0000820 2209 2438 2692 3124 3454 3835 396212100 104,8 108,0 0,0718 0,000104 2260 2514 2794 3225 3556 3962 406413300 114,3 120,6 0,0896 0,000163 2413 2667 2946 3403 3759 4191 429218500 123,8 127,0 0,0993 0,000200 2463 2717 3022 3505 3860 4292 441924300 139,7 146,0 0,131 0,000350 2641 2921 3251 3759 4140 4597 474930600 146,0 152,4 0,143 0,000415 2692 2997 3302 3835 4216 4699 485131600 152,4 165,1 0,168 0,000572 2819 3124 3454 3987 4394 4902 502942000 171,5 203,2 0,254 0,00131 3124 3454 3810 4445 4876 5435 558837900 161,9 165,1 0,168 0,000572 2819 3124 3454 3987 4394 4902 502956600 187,3 203,2 0,254 0,00131 3124 3454 3810 4445 4876 5435 558837900 161,9 165,1 0,168 0,000572 2819 3124 3454 3987 4394 4902 502974000 200,0 203,2 0,254 0,00131 3124 3454 3810 4445 4876 5435 558871400 200,0 203,2 0,254 0,00131 3124 3454 3810 4445 4876 5435 558890400 215,9 217,4 0,291 0,00172 3225 3581 3962 4597 5054 5613 579171400 200,0 203,2 0,254 0,00131 3124 3454 3810 4445 4876 5435 5588135000 241,3 242,8 0,363 0,00268 3403 3784 4191 4851 5334 5943 6121* Refer to Page 4 for General Information and Reference Notes.** Assembly torque rating is limited by coupling size, shaft end diameter or both.24

Type GF32 Steel Mill Flanged SleeveSpacer / Dimensions - MillimetersMinimum Clearance Required for AligningSERIES XDIMENSIONS ANDSPECIFICATIONSSpacerBetweenShaft EndsLubricateThru SleeveGasketSize*TorqueRating**(Nm) †AllowSpeed(rpm)MaxBoreCpig Wt - kgCpig WtWith NoBoreand MinBEExtraSpacerWt permm ofLengthLube Wt - kgMin WtLessSpacerPlus permm ofSpacerLengthDIMENSIONS - MillimetersBE Min(mm)• (Inch)•AG31 G32C D F H J M1010GF 1140 7,000 50 1.875 6,80 0,0120 0,0408 … 115,9 82 82 42,9 68,6 83,8 14,0 38,9 481015GF 2350 5,500 65 2.375 13,6 0,0127 0,0726 … 152,4 82 82 49,3 86,4 105,2 19,0 47,8 561020GF 4270 4,600 78 2.875 20,4 0,0166 0,113 0,000536 177,8 82 82 62,0 105,2 126,5 19,0 59,4 691025GF 7470 4,000 98 3.625 38,6 0,0205 0,227 0,00107 212,9 108 95 77,0 130,6 154,9 21,8 71,6 811030GF 12100 3,600 111 4.125 54,4 0,0236 0,363 0,00107 239,8 108 95 91,2 152,4 180,3 21,8 83,8 941035GF 18500 3,100 134 4.875 88,5 0,0359 0,544 0,00214 279,4 130 120 106,4 177,8 211,3 28,4 97,5 1071040GF 30600 2,800 160 5.75 122,5 0,0500 0,907 0,00357 317,5 130 120 120,6 209,6 245,4 28,4 111,3 1221045GF 42000 2,600 183 6.75 166 0,0736 1,04 0,00357 346,1 133 120 134,9 235,0 274,1 28,4 122,9 1351050GF 56600 2,400 200 7.375 238 0,0814 1,77 0,00357 388,9 184 146 153,2 254,0 305,8 38,1 140,7 1521055GF 74000 2,200 220 8.25 306 0,0895 2,22 0,00357 425,4 184 146 168,1 279,4 334,3 38,1 158,0 1731060GF 90400 2,100 244 9.125 358 0,117 3,18 0,00357 457,2 … 146 188,2 304,8 366,0 25,4 169,2 1831070GF 135000 1,800 289 10.875 562 0,141 4,35 0,00357 527,0 … 146 220,7 355,6 424,9 28,4 195,6 208* Refer to Page 4 for General Information and Reference Notes.Table 7 - Type GF32 Standard Stock Spacer LengthsDistance BetweenShaft Ends PumpCoupling SizeStdmm Inches 1010 1015 1020 1025 1030 103589 3.500 ANSI • •111 4.375 ANSI • •114 4.500 MISC • **127 5.000 ANSI • • • • •178 7.000 ANSI • • •** Bolt holes staggered for assembly clearance.26

Type GF Standard Flanged SleeveMill Motor & Taper Bores / Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSAmount machined fromhub face on gap sideTable 8 - Standard AISE AC & DC Mill Motor Coupling SelectionsMotor Frame Sizes couplingslze*2602603604802A,B&C803804606 806 AC8 &12AC 1015GF1,2 &4 1020GF1025GF... 1015GF1020GF1025GF1030GF1020GF1025GF1030GF1035GF608 808 ... 1025GF1030GF1035GF1040GF610 810 AC180 1025GF1030GF1035GF1040GF612 812 AC25&30614 814 AC40&501030GF1035GF1040GF1045GF1035GF1040GF1045GF1050GF616 816 ... 1035GF1040GF1045GF1050GF618 818 ... 1040GF1045GF1050GF620 820 ... 1045GF1050GF1055GF622 822 ... 1045GF1050GF1055GF1060GF624 824 ... 1050GF1055GF1060GF1070GFE R UG UH Keyway Z ZD ZE ZG2,52,52,52,52,52,52,52,52,52,52,52,52,52,54,12,52,52,54.12,52,54,14,12,54,14,15,12,54,14,15,14,14,15,14,15,15,14,15,15,16,65,15,16,68,47,9 36,5 44,5 12,70x6,35 82,55 23,9 76,2 1,55,612,49,7 41,53 50,80 12,70x6,35 85,73 25,4 88,9 0,04,110,919,19,7 52,91 63,50 12,70x6,35 101,60 28,4 102 1,07,615,725,412,7 64,3 76,20 19,05x6,35 133,35 31,8 114,3 4,612,722,432,012,7 70,64 82,55 19,05x6,35 142,88**35,1 114 1,39,719,329,012,7 78,84 92,08 19,05x6,35 158,75 38,1 127 6,416,025,732,312,7 94,72 107,95 25,40x9,53 174,63 41,1 127 12,722,629,240,615,7 102,92 115,80***117,48117,48117,4831,75x9,53 195,33200,03200,03200,0344,5 124**1401401409,719,325,937,115,7 113,13 127,00 31,75x12,70 212,73 33,5 152 30,537,348,519,1 131,37 149,23 38,10x19,05 247,65 44,5 172 25,937,351,319,1 139,57 158,75 38,10x19,05 247,65 60,2 184 10,221,635,341,719,1 153,34 177,80 38,10x19,05 247,65 60,2 235 21,335,341,759,7ZH+,XXX-,0000,61* Refer to page 4 for General Information and other Reference Notes. Minimum coupling selections are based on couplingbore capacity. Check coupling rating for all selections. Refer to Pages 21 thru 25 for coupling dimensions.** Spanner wrench required for Size 1025G.*** For rigid hub only.0,740,740,740,860,860,860,860,970,970,970,97Table 9 - Taper and Counter bore Limitations +SizeFlex HubRigid Hub* P Max+++ UG Min UH Max ZD Max ZE Min Keyway++ P Max+++ UG Min UH Max Z Max ZE Min Keyway++1010GF 102 12,7 50 18,5 42,9 14 x 4,5 104 12,7 60 76,2 39,6 18 x 5,51015GF 114 19,1 65 25,4 49,3 18 x 5,5 117 19,1 80 85,9 46,2 22 x 71020GF 130 25,4 78 29,5 62,0 22 x 7 133 25,4 98 102 58,4 28 x 81025GF 149 31,8 98 36,3 77,0 28 x 8 152 31,8 118 143 73,7 32 x 91030GF 165 38,1 111 44,5 91,2 32 x 9 168 38,1 140 159 87,9 36 x 101035GF 184 50,8 134 54,1 106 36 x 10 171 50,8 163 175 102 40 x 111040GF 203 63,5 160 63,8 121 40 x 11 191 63,5 196 213 114 45 x 22,51045GF 244 76,2 183 70,4 135 45 x 12,5 249 76,2 216 248 130 50 x 141050GF 295 88,9 200 81,8 153 45 x 12,5 300 88,9 235 273 147 56 x 161055GF 298 102 220 95,8 168 50 x 14 303 102 266 298 173 63 x 161060GF 305 114 244 102 188 56 x 16 311 114 290 330 186 63 x 161070GF 310 127 289 120 221 63 x 16 313 127 340 381 220 80 x 20+ This table specifies the taper bore limitations for the usual requirements. For hubs no longer than those listed, refer to our Application Engineers.++ Standard Long Hub length, consult our Application Engineers for longer lengths.+++ Keyway shown is for maximum bore with square key.27

SERIES XENGINEERING DATATable 10 - Recommended Commercial Keys for Bores with One KeyMillimeters & InchesShaft DiameterShaft DiameterShaft DiameterShaft DiameterKeyKeyKeyOver Through Over Through Over Through Over ThroughKey6 8 2 x 2 38 44 12 x 8 95 110 28 x 16 260 290 63 x 328 10 3 x 3 44 50 14 x 9 110 130 32 x 18 290 330 70 x 3610 12 4 x 4 50 58 16 x 10 130 150 36 x 20 330 380 80 x 4012 17 5 x 5 58 65 18 x 11 150 170 40 x 22 380 440 90 x 4517 22 6 x 6 65 75 20 x 12 170 200 45 x 25 440 500 100 x 5022 30 8 x 7 75 85 22 x 14 200 230 50 x 28 … … …30 38 10 x 8 85 95 25 x 14 230 260 56 x 32 … … …INCHES (Bores per BS 1916, Keyway to BS 46 : Part 1 : 1958)Shaft DiameterShaft DiameterShaft DiameterShaft DiameterKeyKeyKeyOver Through Over Through Over Through Over ThroughKey.438 .562 .125 x .125 1.750 2.250 .500 x .500 4.500 5.500 1.250 x 1.250 11.000 13.000 3.000 x 2.000.562 .875 .188 x .188 2.250 2.750 .625 x .625 5.500 6.500 1.500 x 1.500 13.000 15.000 3.500 x 2.500.875 1.250 .250 x .250 2.750 3.250 .750 x .750 6.500 7.500 1.750 x 1.500 15.000 18.000 4.000 x 3.0001.25 1.375 .312 x .312 3.250 3.750 .875 x .875 7.500 9.000 2.000 x 1.500 18.000 22.000 5.000 x 3.5001.375 1.750 .375 x .375 3.750 4.500 1.000 x 1.000 9.000 11.000 2.500 x 1.750 … … …Table 11 - Shaft Diameters & Ratings for50 Hertz Metric Motors & NEMA 60 Hertz Motors50 HERTZ METRIC MOTORS (kW)Frame Size 80 90S 90L 100L 112M 132S 132M 160M 160L 180M 180L 225S 225M 250S 250M 280S 280MShaft Dia19 24 24 28 28 38 38 42 42 48 48 55 5560556060,657060,657065,758065,75803000 rpm0,751,101,5 2,2 3,0 4 5,57,5111518,5 22 30 37 45 45 55 55757590901101500 rpm0,550,751,1 1,5 2,23,04 5,5 7,5 11 15 18,5 22 30 374545 55 55757590901101000 rpm0,370,550,75 1,1 1,5 2,2 3 45,57,5 11 15 18,52230 30 37 374545505575750 rpm0,180,250,37 0,55 0,751,11,5 2,2 3 45,57,5 11 15 18,5 22 30 303737454555NEMA 60 HERTZ MOTORS (hp)Frame SizeT FramesTS Frames143 145 182 184 213 215 254 256 284 286 324 326 364 365 404 405 444 445 284 286 324 326 364 365 404 405 444 445Shaft Dia 0.88 0.88 1.13 1.13 1.38 1.38 1.63 1.63 1.88 1.88 2.13 2.13 2.38 2.38 2.88 2.88 3.38 3.38 1.63 1.63 1.88 1.88 1.88 1.88 2.13 2.13 2.38 2.383600 rpm1800 rpmDrip Proof 1 5 7 10 15 20 25 30 40 50 60 75 100 125 150 200 250 30 40 50 60 75 100 125 150 200 250Enclosed 1 2 3 5 7 10 15 20 25 30 40 50 60 75 … 100 125 150 25 30 40 50 60 75 … 100 125 150Drip Proof 1 1 -2 3 5 7 10 15 20 25 30 40 50 60 75 100 125 150 200 25 30 40 50 60 75 100 125 150 200Enclosed 1 1 -2 3 5 7 10 15 20 25 30 40 50 60 75 … 100 125 150 25 30 40 50 60 75 … 100 125 150Drip Proof &1200 rpmEnclosed 1 1 2 3 5 7 10 15 20 25 30 40 50 60 75 100 125 15 20 25 30 40 50 60 75 100 125900 rpmDrip Proof &Enclosed 1 1 2 3 5 7 10 15 20 25 30 40 50 60 75 100 10 15 20 25 30 40 50 60 75 10028

SERIES XENGINEERING DATATable 12 - Recommended Bore TolerancesCoupling Hubs - MillimetersNominalUp to 50Over 50 to 80Over 80 to 100Over 100 to 200Over 200 to 355Over 355 to 500Bore Diameter ToleranceM7K7K7K7K7K7Coupling MisalignmentMaximum life and minimum maintenance for the coupling and connected machinery will result if couplings are accurately aligned. Couplinglife expectancy between initial alignment and maximum operating limits is a function of load, speed and lubrication. For applications requiringgreater misalignment, refer to our Application Engineers.Table 13 - Type G and GC Gear CouplingAngular Misalignment Capacity **Types Installation OperationalG 0,12 0,75GC 0,12 0,75ANGULAR MISALIGNMENTAngular misalignment is expressed in degrees and as thedifference between the value of X minus Y, as illustrated.** Degrees listed are per gear meshTable 14 - Floating Shaft (Solid) BalancingOperating speed - RPMBalancing normallynot requiredBalancing of shaftrequiredPARALLEL OFFSET MISALIGNMENTParallel misalignment is the distance P between shaftcenterlines as shown.Distance between shaft ends - Millimeters29

SERIES XNOTES30

SERIES XGRIDGRIDDouble flexing steel grid couplingsSERIES X31

SERIES XGRID TYPE COUPLINGSGrid <strong>Couplings</strong>A general purpose, lubricated design that combines the economy and high torque capacity of a coupling with the, torsionalflexibility of an elastomer coupling. Backed by a 5-year lubrication warranty, our Grid couplings require no periodic maintenancewhen lubricated with our LTG (Long Term Grease) at installation. Featuring 25 sizes, Grid couplings can accommodate torqueloads of 932 000 Nm and shaft diameters of 508 millimeters.Type T10 Close CoupledA double flexing, close-coupleddesign for use in four bearingsystems. Features a horizontallysplit cover which allows forgrid replacement without themovement of the connectedequipment. (See Page 35)Type T20 Close CoupledCoupling -A double flexing design featuringa vertically split steel cover. Idealfor higher running speeds. (SeePage 36)Type T31 Full SpacerComplete centre section dropsout for easy service of connectedequipment bearings and seals.Ideal for pump applications. (SeePage 37)Type T35 Half SpacerCouplingAn economical spacer designfor easy service of connectedequipment bearings and seals.Ideal for pump applications. (SeePage 38)Type T50 Floating ShaftCouplingDouble piloted design forconnecting equipment where thedistance between shafts is toolarge for a spacer type coupling.(See Pages 39 - 40)Contact our Application Engineers for information on these additional Grid Coupling designsType T70 High SpeedCouplingDesigned for operating speedsbeyond those of the T10 and T20designs. Features a one-piececover and balanced components.Type T50 Piloted CouplingFor use on line shaft applications.Can be used in place of singleengagement gear couplings toprovide torsional resiliency andlower overall operating cost.Type T10/G82 SpacerCouplingA combination of two standardcouplings. Utilizes readilyavailable components for aneconomical price and shorterlead time than T31/T35couplings.Type T41/T44 ControlledTorque Coupling -Provides adjustable slippingaction to protect connectedequipment from shock, jams, ortemporary overloads.Type T90 Flywheel Coupling -Used primarily to connect theflywheel of an engine to thedriven machinery. It providesfor higher torque ratings withresulting smaller sizes and lowercosts than elastomer couplings.Warning! Mixing grid coupling componentsfrom different manufacturers may causepremature failure and possible personalinjury or property damage from flying debris.Type T63 Disc BrakeCou plingsProven to be far superior todrum-type brakes in cost,construction and performance.Type BW BrakewheelCoupling -Provides a built-in brakingsurface right at or near thecenterline of the coupling ...saves space and money.32

SERIES XGENERAL DESCRIPTIONGrid <strong>Couplings</strong>The Simplest, Most Cost- Effective <strong>Couplings</strong> For HighTorque Applications.With overall savings in initial costs, spare parts costs, andlabour costs for installation, alignment and replacement -plus improved ratings and a 5 Year Heavy-Duty Warranty- it’s easy to see what our Grid <strong>Couplings</strong> have over thecompetition. No other coupling in the torque range cantouch our Grid couplings for cost-effective performance andreliability.Features That Give Grid <strong>Couplings</strong> The Lowest LifetimeOperating CostLonger LifeTapered grids, made of high strength alloy steel, arequenched and tempered to spring hardness. The gridsurface is then precision shot peened to compress thesurface molecules.The effect is a dramatic increase in rating, providing reservestrength for longer life or allowing a smaller size coupling tobe selected. This precision technology was originally used inthe production of sophisticated aircraft components.Extended Maintenance PeriodsNow you can install our Grid couplings and lubricate it withour Long Term Grease (LTG) and forget periodic, routinemaintenance. Our LTG Grease was developed specificallyfor couplings. It resists the separation of the oil andthickening agent that occurs in typical greases. The initialuse of LTG Grease will eliminate routine lubrication cycles.Quick, Easy Installation ... Replace-In-Place DesignThe grid is the wearing member of our Grid coupling andit is a fraction of the complete coupling cost. Tapered gridsare accessible through the quickly removable cover. Thereplace-in-place design of the replacement grids allowsthem to be dropped in without the need to replace hubsor move and realign shafts and connected equipment asrequired with gear couplings and many elastomer designs.Equipment Protection Against Shaft Misalignment DesignThe grid is free to rock, pivot and float within the hubteeth. Generous misalignment capacity is provided withoutproducing detrimental bearing side loads created by othercoupling types.Light LoadHeavy LoadContact IncreasesLow ContactPivotsFloatsRocksEquipment Protection Against Shock / Vibratory LoadsTorsional flexibility is the ability of our Grid <strong>Couplings</strong> totorsionally deflect when subjected to normal shock orvibratory loads, providing flexible accommodation to changingload conditions. It absorbs impact energy by spreading it overan increment of time. It damps vibration and reduces peak orshock loads by a much as 30%. It is a true shock absorber forrotary motion.Versatile DesignsTwo cover designs are available in the popular sizes.Standard spacer, piloted, high speed, brake wheel or disc,and controlled torque designs are also available.Worldwide AvailabilityGrid couplings and component parts, in popular sizes andtypes, are available from our worldwide distribution networkwith the largest stock of any shaft coupling on the market. Ourgrid couplings are warranted for 5 Years when lubricated withour LTG Long Term Grease.33

SERIES XUNIT DESIGNATIONSDriving HubDriven Hub1 - <strong>Series</strong> XRangeXExample*<strong>Series</strong>Size of CouplingType of CouplingDriving Hub Bore & KeywayDriving Hub Bore DiameterDriven Hub Bore & KeywayDriven Hub Bore Diameter1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17XX 1 0 2 0 T - 1 0 M 0 2 0 M 0 22, 3, 4, 5 - Size of Couplingeg 1 0 2 015, 16, 17 - Driven Hub Bore Diametereg 0 2 06, 7, 8, 9 - Type of CouplingGrid Coupled14 - Driven Hub Bore and KeywayM - Metric Bore Parallel KeywayT - 1 0 Close Coupled (Horizontal Cover)T - 1 0 Close Coupled (Vertical Cover)T - 1 0 Full SpacerT - 1 0 Half Spacer10 - Driven Hub Bore and KeywayM - Metric Bore Parallel KeywayT - Metric Bore Taper KeywayTIBPCSAH- Metric Bore Taper Keyway- Inch Bore Parallel Keyway- Inch Bore Taper Keyway- Pilot Bore- Customer Specified Metric- Customer Specified Inch- American Square Key- Half CouplingIBPCSAH- Inch Bore Parallel Keyway- Inch Bore Taper Keyway- Pilot Bore- Customer Specified Metric- Customer Specified Inch- American Square Key- Half Coupling11, 12, 13 - Driving Hub Bore Diametereg 0 2 0* This Page May Be Photocopied Allowing The Customer To Enter Their Order34

Type T10Close-Coupled Coupling / Dimensions - MillimetersSERIES XDIMENSIONS ANDSPECIFICATIONSGridHubGapSizes 1020 - 1140Sizes 1150 - 1200Sizes 1210 - 1230 Sizes 1240 - 1260LubePlugsSizes 1020 thru 1230T10 covers are cast aluminium alloy;Sizes 1240 thru 1260T10 are fabricated steel.SIZE*TorqueRating(Nm)†AllowSpeed(rpm)Max Bore(mm) • (Inch) •Cpig WtWithNo Bore(kg)LubeWt(kg)DIMENSIONS - MillimetersA B C D F J S Gap1020T 52 4500 28 1.125 1,91 0,0272 97,0 98,2 47,6 39,7 … 66,7 39,1 31030T 149 4500 35 1.375 2,59 0,0408 105,7 98,2 47,6 49,2 … 68,3 39,1 31040T 249 4500 43 1.625 3,36 0,0544 114,3 104,6 50,8 57,2 … 69,9 40,1 31050T 435 4500 50 1.875 5,44 0,0680 135,1 123,6 60,3 66,7 … 80,9 44,7 31060T 684 4350 56 2.125 7,26 0,0862 147,8 130,0 63,5 76,2 … 93,5 52,3 31070T 994 4125 67 2.500 10,4 0,113 158,8 155,4 76,2 87,3 … 96,8 53,8 31080T 2050 3600 80 3.000 17,7 0,172 190,5 180,8 88,9 104,8 … 115,6 64,5 31090T 3730 3600 95 3.500 25,4 0,254 211,1 199,8 98,4 123,8 … 122,2 71,6 31100T 6280 2440 110 4.000 42,2 0,426 251,0 246,2 120,6 142,1 … 155,4 … 51110T 9320 2250 120 4.500 54,4 0,508 269,7 259,0 127,0 160,3 … 161,5 … 51120T 13700 2025 140 5.000 81,2 0,735 307,8 304,4 149,2 179,4 … 191,5 … 61130T 19900 1800 170 6.000 121 0,907 345,9 329,8 161,9 217,5 … 195,1 … 61140T 28600 1650 200 7.250 178 1,13 384,0 374,4 184,2 254,0 … 201,2 … 61150T 39800 1500 215 8.000 227 1,95 453,1 371,8 182,9 269,2 391,2 271,5 … 61160T 55900 1350 240 9.000 309 2,81 501,9 402,2 198,1 304,8 436,9 278,4 … 61170T 74600 1225 280 10.000 448 3,49 566,9 437,8 215,9 355,6 487,2 307,3 … 61180T 103000 1100 300 11.000 619 3,76 629,9 483,6 238,8 393,7 554,7 321,1 … 61190T 137000 1050 335 12.000 776 4,40 675,6 524,2 259,1 436,9 607,8 325,1 … 61200T 186000 900 360 13.000 1057 5,62 756,9 564,8 279,4 497,8 660,4 355,6 … 61210T 249000 820 390 14.000 1424 10,5 844,6 622,6 304,8 533,4 750,8 431,8 … 131220T 336000 730 420 15.000 1785 16,1 920,8 663,2 325,1 571,5 822,2 490,2 … 131230T 435000 680 450 16.000 2267 24,0 1003,3 703,8 345,4 609,6 904,7 546,1 … 131240T 559000 630 480 17.000 2950 33,8 1087,1 749,6 368,3 647,7 … 647,7 … 131250T 746000 580 ** 18.500 3833 50,1 1181,1 815,6 401,3 711,2 … 698,5 … 131260T 932000 540 ** 20.000 4682 67,2 1260,9 876,6 431,8 762,0 … 762,0 … 13* Refer to Page 4 for General Information and Reference Notes.** Consult our Application Engineers35