Read/Download - SKB

Read/Download - SKB

Read/Download - SKB

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

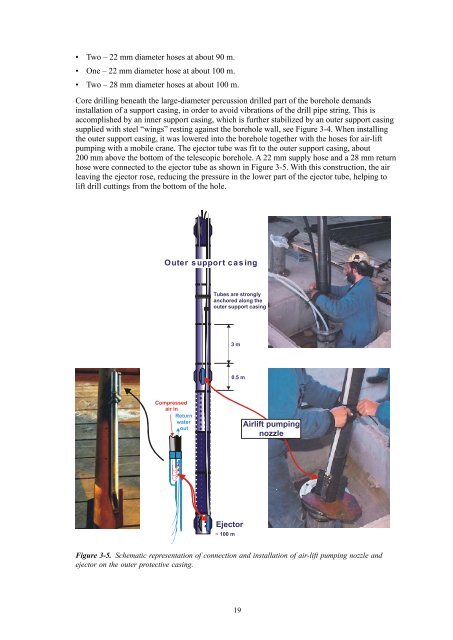

• Two – 22 mm diameter hoses at about 90 m.• One – 22 mm diameter hose at about 100 m.• Two – 28 mm diameter hoses at about 100 m.Core drilling beneath the large-diameter percussion drilled part of the borehole demandsinstallation of a support casing, in order to avoid vibrations of the drill pipe string. This isaccomplished by an inner support casing, which is further stabilized by an outer support casingsupplied with steel “wings” resting against the borehole wall, see Figure 3-4. When installingthe outer support casing, it was lowered into the borehole together with the hoses for air-liftpumping with a mobile crane. The ejector tube was fit to the outer support casing, about200 mm above the bottom of the telescopic borehole. A 22 mm supply hose and a 28 mm returnhose were connected to the ejector tube as shown in Figure 3-5. With this construction, the airleaving the ejector rose, reducing the pressure in the lower part of the ejector tube, helping tolift drill cuttings from the bottom of the hole.Outer s upport c as ingTubes are stronglyanchored along theouter support casing3 m0.5 mCompressedair inReturnwateroutAirlift pumpingnozzleEjector~ 100 mFigure 3‐5. Schematic representation of connection and installation of air-lift pumping nozzle andejector on the outer protective casing.19