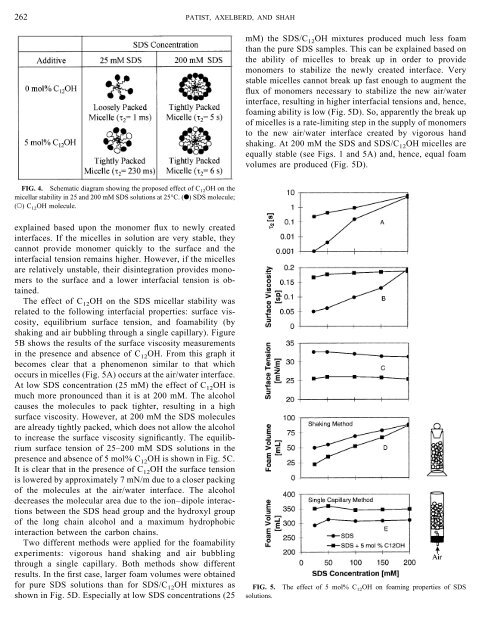

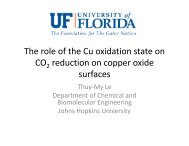

262 PATIST, AXELBERD, AND SHAHmM) the SDS/C 12 OH mixtures produced much less foamthan the pure SDS samples. This can be explained based onthe ability <strong>of</strong> micelles to break up in order to providemonomers to stabilize the newly created interface. Verystable micelles cannot break up fast enough to augment theflux <strong>of</strong> monomers necessary to stabilize the new air/waterinterface, resulting in higher interfacial tensions and, hence,foaming ability is low (Fig. 5D). So, apparently the break up<strong>of</strong> micelles is a rate-limiting step in the supply <strong>of</strong> monomersto the new air/water interface created by vigorous handshaking. At 200 mM the SDS and SDS/C 12 OH micelles areequally stable (see Figs. 1 and 5A) and, hence, equal foamvolumes are produced (Fig. 5D).FIG. 4. Schematic diagram showing the proposed effect <strong>of</strong> C 12 OH on themicellar stability in 25 and 200 mM SDS solutions at 25°C. (F) SDS molecule;(E) C 12 OH molecule.explained based upon the monomer flux to newly createdinterfaces. If the micelles in solution are very stable, theycannot provide monomer quickly to the surface and theinterfacial tension remains higher. However, if the micellesare relatively unstable, their disintegration provides monomersto the surface and a lower interfacial tension is obtained.The effect <strong>of</strong> C 12 OH on the SDS micellar stability wasrelated to the following interfacial properties: surface viscosity,equilibrium surface tension, and foamability (byshaking and air bubbling through a single capillary). Figure5B shows the results <strong>of</strong> the surface viscosity measurementsin the presence and absence <strong>of</strong> C 12 OH. From this graph itbecomes clear that a phenomenon similar to that whichoccurs in micelles (Fig. 5A) occurs at the air/water interface.At low SDS concentration (25 mM) the effect <strong>of</strong> C 12 OH ismuch more pronounced than it is at 200 mM. The alcoholcauses the molecules to pack tighter, resulting in a highsurface viscosity. However, at 200 mM the SDS moleculesare already tightly packed, which does not allow the alcoholto increase the surface viscosity significantly. The equilibriumsurface tension <strong>of</strong> 25–200 mM SDS solutions in thepresence and absence <strong>of</strong> 5 mol% C 12 OH is shown in Fig. 5C.It is clear that in the presence <strong>of</strong> C 12 OH the surface tensionis lowered by approximately 7 mN/m due to a closer packing<strong>of</strong> the molecules at the air/water interface. The alcoholdecreases the molecular area due to the ion–dipole interactionsbetween the SDS head group and the hydroxyl group<strong>of</strong> the long chain alcohol and a maximum hydrophobicinteraction between the carbon chains.Two different methods were applied for the foamabilityexperiments: vigorous hand shaking and air bubblingthrough a single capillary. Both methods show differentresults. In the first case, larger foam volumes were obtainedfor pure SDS solutions than for SDS/C 12 OH mixtures asshown in Fig. 5D. Especially at low SDS concentrations (25FIG. 5.solutions.The effect <strong>of</strong> 5 mol% C 12 OH on foaming properties <strong>of</strong> SDS

FOAMING PROPERTIES OF SDS/LONG CHAIN ALCOHOL MIXTURES263Foamability measurements performed by blowing airthrough a single capillary yielded different results. Figure 5Eshows that the foam volume <strong>of</strong> the SDS/C 12 OH mixtures isconsistently higher than that <strong>of</strong> pure SDS solutions, irrespective<strong>of</strong> the SDS concentration. Apparently, by using a singlecapillary the surfactant molecules have enough time to diffuseand stabilize the newly created air/water interface. Therefore, alower dynamic surface tension is obtained. The relation betweenthe dynamic surface tension and the amount <strong>of</strong> foamcreated is given by (17)W A, [2]where W is the work done, the interfacial tension at theair/water interface, and A the change in interfacial area.The same relation holds for emulsification processes (18).Obviously, when the same amount <strong>of</strong> work is applied, alower surface tension results in more interfacial area (eitherby decreasing the bubble size or by increasing foam volume),provided the presence <strong>of</strong> a surface active specie.Since the surface tension <strong>of</strong> the SDS/C 12 OH mixtures issignificantly lower than that <strong>of</strong> pure SDS (Fig. 5C), theformer one will produce more foam using the single capillaryfoam column.The results <strong>of</strong> the foamability measurements were evaluatedby a more quantitative experiment, namely, dynamicsurface tension by the maximum bubble pressure method.The understanding <strong>of</strong> dynamic surface tension is importantin any technological application where a new gas/liquidinterface is rapidly being created in a surfactant solution. Inmost cases the equilibrium surface tension is never reachedand the actual surface tension experienced at the air/waterinterface is much higher. The dynamic surface tension dependson several factors: monomer concentration (CMC),micellar stability, diffusion rate <strong>of</strong> the surfactant moleculeto the interface, and surfactant concentration. The measurement<strong>of</strong> dynamic properties is relevant to technologicalprocesses where an air/water interface is being formed, suchas foaming or film formation, as well as situations wheresurfactants diffuse to a new liquid/liquid interface, such asemulsification, or to a solid/liquid interface, such as fabricwetting. In this study two solutions <strong>of</strong> 15 mM SDS and onecontaining SDS 5 mol% C 12 OH were investigated. Aconcentration <strong>of</strong> 15 mM was chosen, since at too highsurfactant concentrations, deviations from equilibrium surfacetension are negligible at the bubble frequencies accessiblewith the current setup. The dynamic surface tension asa function <strong>of</strong> bubble lifetime (reciprocal value <strong>of</strong> bubblefrequency) is given in Fig. 6.The effect <strong>of</strong> 5 mol% C 12 OH is clearly visible: at higherbubble lifetimes the SDS/C 12 OH mixture shows a surfacetension significantly lower than that <strong>of</strong> pure SDS, indicatingthat the equilibrium surface tension <strong>of</strong> the SDS/C 12 OHFIG. 6. Dynamic surface tension ( D ) <strong>of</strong> SDS and SDS/C 12 OH mixturesat 25°C (15 mM SDS, 5 mol% C 12 OH).solution is much lower, which was observed earlier (Fig.5C). However, when the bubble lifetime decreases and thusthe bubble frequency increases, the curves are getting closerto each other up to a bubble life time <strong>of</strong> approximately0.15 s where they actually cross (Fig. 6). This means that atbubble life times smaller than 0.15 s (frequencies higherthan 7 s 1 ), the SDS/C 12 OH mixed micelles are not ableto augment the flux <strong>of</strong> monomers necessary to stabilize thenewly formed bubbles as compared to pure SDS. In thisregion the micellar stability, and thus the ability <strong>of</strong> micellesto break up fast enough, determines surface tension lowering.During the formation <strong>of</strong> bubbles, surfactant monomersadsorb onto the freshly created interface from the bulksolution. If the monomer is depleted by the adsorptionprocess, micelles must break up to provide additional monomers.If the micelles in solution are very stable, they cannotprovide monomer quickly enough and the dynamic surfacetension remains higher. However, if the micelles are relativelyunstable, their disintegration resupplies the depletedmonomer and lower dynamic surface tensions are obtained.In conclusion, for long bubble lifetimes the equilibriumsurface tension determines the interfacial tension at theair/water interface. However, when the bubble lifetime decreases,more and more monomer is depleted from the bulksolution and thus micelles have to break up in order toprovide additional monomers. In that case the break up <strong>of</strong>micelles, and thus the micellar stability, determines thesurface tension lowering.To show the importance <strong>of</strong> micellar break up in the dynamicsurface tension measurement, a dimensionless parameter wasintroduced, D eq w eq, [3]