rheological and tensile properties of sodium hyaluronate hydrogels ...

rheological and tensile properties of sodium hyaluronate hydrogels ...

rheological and tensile properties of sodium hyaluronate hydrogels ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RHEOLOGICAL AND TENSILE PROPERTIES OF SODIUM HYALURONATEHYDROGELS AND FILMSCalles J.A. 1 , Ressia J.A. 1,2 , Llabot J.M. 3 , Allem<strong>and</strong>i D.A. 3 , Palma S.D. 3 , Vallés E.M. 1,#1 Planta Piloto de Ingeniería Química (UNS-CONICET), Cam. La Carrindanga, Km. 7, Bahía Blanca,Argentina.2 Comisión de Investigaciones Científicas de la Provincia de Buenos Aires (CIC), La Plata, Argentina.3 Departamento de Farmacia, Facultad de Ciencias Químicas, Universidad Nacional de Córdoba,Córdoba, Argentina.INTRODUCTIONThe hyaluronic acid <strong>sodium</strong> salt, also called hyaluronan (HA), is a naturally occurring high molecular masslinear polysaccharide, consisting <strong>of</strong> alternating units <strong>of</strong> N-acetyl-β-D-glucosamine (GlmNAct) <strong>and</strong> β-Dglucuronicacid (GlcAc). HA is distributed in the human body forming part <strong>of</strong> synovial fluid, skin, umbilicalcord <strong>and</strong> vitreous humor; <strong>and</strong> widely used in medical practice in many pathological conditions such asosteoarthritis, wound repair <strong>and</strong> eye surgery (1-5). Several studies related to biocompatibility <strong>and</strong>biodegradability (6) have suggested the use <strong>of</strong> HA as a promising biomaterial to design modified drugdelivery systems with ophthalmic applications. In this work we present preliminary studies in order toevaluate <strong>rheological</strong> <strong>and</strong> mechanical <strong>properties</strong> <strong>of</strong> <strong>hydrogels</strong> <strong>and</strong> films based on HA prior to further structuralmodification needed to improve the biomechanical <strong>properties</strong> <strong>of</strong> HA.MATERIALS AND METHODSHA solutions were prepared at 1, 2 <strong>and</strong> 4% w/w concentrations using distilled water as solvent. Additionalsolutions were also prepared containing 2% w/w HA <strong>and</strong> different concentrations - 0.25, 0.5 <strong>and</strong> 1% w/w - <strong>of</strong>polyethyleneglycol 400 (PEG) (Merk). The solutions have pH near 6, avoiding polymer degradation (7,8).Hydrogel films from the 2% w/w HA <strong>and</strong> 2% w/w HA/PEG solutions were prepared by casting at roomtemperature. The <strong>rheological</strong> characterization <strong>of</strong> the different solutions was carried out in small-amplitudeoscillatory shear flow using a rotational rheometer from TA Instruments (AR-G2) 25°C. Stress-strain plotswere obtained in an Instron 3369 tester in traction mode at 2 mm/min at room conditions (23°C <strong>and</strong> 40%relative humidity).RESULTSBoth storage (G´) <strong>and</strong> loss (G´´) modules values increase with HA concentration. In all cases, the module G´´at low frequencies is higher than G´ to certain point where the crossover <strong>of</strong> the G´<strong>and</strong> G” curves occurs.Increasing HA concentration moves the crossover point toward lower frequencies indicating an earliertransition from viscous-like towards elastic behavior. This shift is less significant in HA/PEG solutions. Theincorporation <strong>of</strong> PEG slightly increases the magnitude <strong>of</strong> G´ <strong>and</strong> G´´ on the whole frequency range, althoughno significant difference was observed with different PEG concentrations used in this work.Table 1 shows elongational <strong>properties</strong> for the pure HA films <strong>and</strong> those containig 11, 20 <strong>and</strong> 33% w/w <strong>of</strong>PEG. Multiple dog-bone shaped probes for each sample were tested in order to obtain mean values for eachproperty. Increasing PEG content diminish the elastic modulus inducing a change from fragile to ductilebehavior characterized by a yield zone at low deformations followed by drawing with no significant changesin the nominal stress up to the rupture point.Future adhesion assays will be performed to complete preliminary studies.ACKNOWLEDGMENTSThe authors thank financial support from Universidad Nacional de Sur (UNS), the Consejo Nacional deInvestigaciones Científicas y Técnicas (CONICET), <strong>and</strong> the Comisión de Investigaciones Científicas de laProvincia de Buenos Aires (CIC) .REFERENCES# Corresponding author. Tel +54 291 4861700, fax +54 291 4861600; e-mail: valles@plapiqui.edu.ar

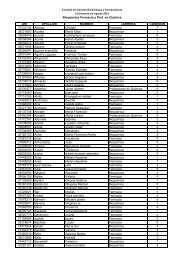

(1) L. Ambrosio, A. Borzacchiello, P.A. Netti <strong>and</strong> L. Nicolais. Properties <strong>of</strong> new materials: Rheological studyon hyaluronic acid <strong>and</strong> its derivative solutions. J. Macromol. Sci. – Pure Appl. Chem 1999; 36: 991–1000.(2) E.A. Balazs <strong>and</strong> J.L. Denlinger, Viscosupplementation: A new concept in the treatment <strong>of</strong> osteoarthritis, J.Rheumatol. Suppl. 1993; 39: 3–9.(3) A. Borzacchiello, L. Mayol, O. Garskog, A. Dahlqvist <strong>and</strong> L. Ambrosio, Evaluation <strong>of</strong> injectionaugmentation treatment <strong>of</strong> hyaluronic acid based materials on rabbit vocal folds viscoelasticity, J. Mater. Sci.– Mater. Med. 2005; 16: 553–557.(4) M. Brown <strong>and</strong> S. Jones, Hyaluronic acid: a unique topical vehicle for the localized delivery <strong>of</strong> drugs to theskin, J. Eur. Acad. Dermatol. Venereol. 2005; 19: 308–318.(5) W.Y.J. Chen <strong>and</strong> G. Abatangelo, Functions <strong>of</strong> hyaluronan in wound repair, Wound Repair Regen. 1999; 7:79-89.(6) Teresio Avitabile, Filippo Marano, Francesco Castiglione, Claudio Bucolo, Melina Cro, Luigi Ambrosio,Carmelo Ferrauto <strong>and</strong> Alfredo Reibaldi, Biocompatibility <strong>and</strong> biodegradation <strong>of</strong> intravitreal hyaluronanimplants in rabbits. Biomaterials. 2001; 22: 195-200.(7) Atoosa Maleki, Anna-Lena Kjøniksen, Bo Nyström, Effect <strong>of</strong> pH on the behavior <strong>of</strong> hyaluronic acid indilute <strong>and</strong> semidilute aqueous solutions, Macromol. Symp. 2008; 274: 131–140.(8) Iuliana Gatej, Marcel Popa, <strong>and</strong> Marguerite Rinaudo. Role <strong>of</strong> the pH on Hyaluronan Behavior in AqueousSolution. Biomacromolecules 2005, 6, 61-67.Table 1. Elongational <strong>properties</strong>SampleThickness Elastic modulus Maximum Tensile Yield Stress (MPa)(m)(MPa)Strain (%)2% HA 38 ± 3 2564 ± 165 10.9 ± 2.3 77.9 ± 2.72% HA – 0.25% PEG 42 ± 3 2061 ± 282 17.1 ± 0.7 65.3 ± 4.52% HA – 0.5% PEG 47 ± 3 1593 ± 158 29.7 ± 2.6 48.1 ± 4.92% HA – 1.0% PEG 59 ± 5 853 ± 91 50.9 ± 4.9 26.4 ± 2.4