Safe use of angle grinders (PDF 1264kb) - WorkSafe Victoria

Safe use of angle grinders (PDF 1264kb) - WorkSafe Victoria

Safe use of angle grinders (PDF 1264kb) - WorkSafe Victoria

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

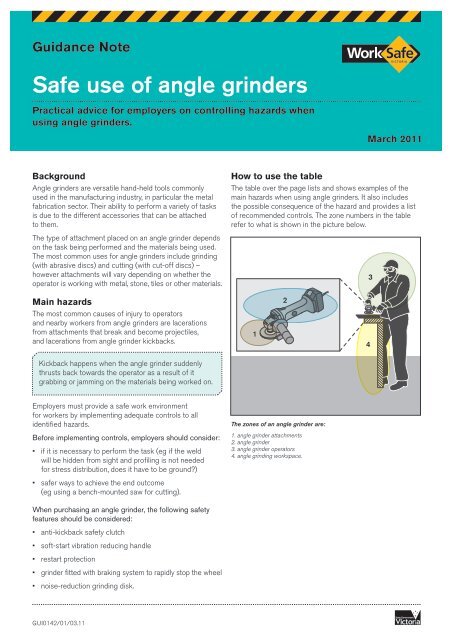

Guidance Note <strong>Safe</strong> <strong>use</strong> <strong>of</strong> <strong>angle</strong> <strong>grinders</strong>Hazard Possible consequence Recommended controlsAttachments <strong>use</strong>d areexcessively worn or damagedGuard has been removedor incorrectly positioned(eg removing the guard to <strong>use</strong>a larger attachment)The flange and centre hole inthe attachment are different sizesFlanges and nuts are wornor damagedWarped or damaged attachmentscan ca<strong>use</strong> excessive vibration,resulting in sprains and strains.Attachments can also break,becoming projectiles and strikingworkers.Debris or hot sparks fly backat the operator, causing burnsor lacerations.Operator’s hand makes contactwith moving parts, resulting inamputations or lacerations.Attachment can detach from the<strong>angle</strong> grinder’s body and laceratethe operator and nearby workers.The <strong>angle</strong> grinder can alsovibrate excessively, resulting insprains and strains.Attachments can becomeprojectiles if they detach fromthe <strong>angle</strong> grinder.• Before <strong>use</strong>, inspect attachments for excessivewear or damage.• Discard worn or damaged attachments.• Never remove guards.• Ensure guards are fitted securely in the correctposition before <strong>use</strong> and are resistant to bendingand twisting.• Ensure the thickness and diameter <strong>of</strong> attachmentsis within the <strong>angle</strong> grinder ratings.• Ensure the flange and hole in the attachmentcentre are the same size (eg buy inserts thatprovide the correct spindle hole).• Ensure flanges and nuts are free from weartor damage before <strong>use</strong>.• Discard worn or damaged flanges or nuts.Zone 2: Angle grinderNo auxiliary handle on <strong>angle</strong>grinderOperators have reduced control<strong>of</strong> the <strong>angle</strong> grinder, which canca<strong>use</strong> lacerations as operatorsmay be unable to stop the <strong>angle</strong>grinder making contact withthem during kickback.• Before <strong>use</strong>, ensure the auxiliary handle is attached.• Ensure operators grip both handles during <strong>use</strong>.• Ensure the handle is adjustable if there are multiple<strong>use</strong>rs (see picture).Outer body <strong>of</strong> <strong>angle</strong> grinderor electrical cord is damagedor has exposed wiresOperators can sustainan electric shock.• Before <strong>use</strong>, inspect <strong>angle</strong> grinder body and leadsfor damage.• Repair or discard damaged <strong>angle</strong> <strong>grinders</strong>.• Use a safety switch or residual current device.3

Guidance Note <strong>Safe</strong> <strong>use</strong> <strong>of</strong> <strong>angle</strong> <strong>grinders</strong>Hazard Possible consequence Recommended controlsNo cut-<strong>of</strong>f switchAir vents are not regularlycleanedOperators are unable to stop the<strong>angle</strong> grinder in an emergency.Build up <strong>of</strong> dust and debris canca<strong>use</strong> the motor to short-circuit,resulting in an electric shock.• Ensure <strong>angle</strong> <strong>grinders</strong> have a cut-<strong>of</strong>f switch.• Regularly clean air vents and maintain <strong>angle</strong><strong>grinders</strong> in good working condition.Zone 3: Angle grinder operatorsOperators are inexperienced(eg apprentices, trainees, youngworkers or experienced workersnew to the task) or not trainedin the safe <strong>use</strong> <strong>of</strong> <strong>angle</strong> <strong>grinders</strong>Angle grinder is the incorrectsize for the taskPressure is applied duringoperationAngle grinder is <strong>use</strong>d in a wetenvironmentAngle grinder is <strong>use</strong>d beforeit reaches speedAngle <strong>grinders</strong> are placed onthe ground or benches while stillrunningRunning <strong>angle</strong> <strong>grinders</strong> arecarried around the workplaceIncorrect <strong>angle</strong> grinder orattachment may be selected(see consequences underZone 1).Unsafe <strong>use</strong> <strong>of</strong> <strong>angle</strong> grindercan result in serious injuries tooperators and nearby workers.Operators can have difficultycontrolling the <strong>angle</strong> grinderand may become injured if itmoves suddenly (eg kickback).Attachments can break underpressure and strike workers.Excessive pressure canalso increase the likelihood<strong>of</strong> kickback.Operators can sustain an electricshock.Kickback can happen orattachments can shatter,resulting in lacerations.Angle <strong>grinders</strong> can move alonga surface while running.The rotating parts can resultin amputations or lacerationsto nearby workers.Moving parts can make contactwith the operator or otherworkers, resulting in amputationsor lacerations.• Ensure operators are provided with trainingand supervision on the safe and correct <strong>use</strong><strong>of</strong> <strong>angle</strong> <strong>grinders</strong>.• Ensure operators demonstrate competencyin performing the task safely.• Only <strong>use</strong> <strong>angle</strong> <strong>grinders</strong> that are an appropriatesize for the task.• Ensure operators do not apply pressureto the <strong>angle</strong> grinder during <strong>use</strong>.• Ensure operators do not <strong>use</strong> liquids when workingwith <strong>angle</strong> <strong>grinders</strong>.• Ensure <strong>angle</strong> <strong>grinders</strong> are <strong>use</strong>d in a dryenvironment.• Before <strong>use</strong>, ensure operators allow the <strong>angle</strong>grinder to run to speed.• Ensure <strong>angle</strong> <strong>grinders</strong> stop turning before beingput down.• Ensure <strong>angle</strong> <strong>grinders</strong> have stopped turning(eg parts are stationary) before they are movedaround the workplace.4

Guidance Note <strong>Safe</strong> <strong>use</strong> <strong>of</strong> <strong>angle</strong> <strong>grinders</strong>Hazard Possible consequence Recommended controlsDusts or vapours remain inthe work area when using <strong>angle</strong><strong>grinders</strong>Flammable substances near<strong>angle</strong> <strong>grinders</strong>Untidy and unorganised workenvironmentWorkers can experiencebreathing difficulties as thegrinding <strong>of</strong> some materials,including those that have beencoated in other substances,can create dangerous fumes.Substances can be ignitedby <strong>angle</strong> grinder sparks, resultingin fires and burns to workers.Workers can slip or trip overworkpieces, materials, leadsand <strong>angle</strong> <strong>grinders</strong>.• Ensure the work area is adequately ventilated(this may require natural airflow or extraction units).• Ensure the work area is regularly cleaned anddusted.• Ensure flammable substances are not placedor stored in areas where <strong>angle</strong> <strong>grinders</strong> are <strong>use</strong>d.• Ensure the work area is regularly inspectedand dust and cuttings are cleared away.• Ensure materials and workpieces not being <strong>use</strong>dare stored until required.• Ensure <strong>angle</strong> <strong>grinders</strong> are not stored on the ground.• Ensure <strong>angle</strong> grinder leads are not too long.Further informationContact the Work<strong>Safe</strong> <strong>Victoria</strong> Advisory Serviceon 1800 136 089 or go to worksafe.vic.gov.auRelated Work<strong>Safe</strong> publicationsA guide to safety in the metal fabrication industryMetal Fabrication – Improving health and safetythrough layout and designNote: This guidance material has been prepared using the best informationavailable to the <strong>Victoria</strong>n WorkCover Authority and should be <strong>use</strong>d for general<strong>use</strong> only. Any information about legislative obligations or responsibilitiesincluded in this material is only applicable to the circumstances describedin the material. You should always check the legislation referred to in thismaterial and make your own judgement about what action you may needto take to ensure you have complied with the law. Accordingly, the <strong>Victoria</strong>nWorkCover Authority cannot be held responsible and extends no warrantiesas to the suitability <strong>of</strong> the information for your specific circumstances;or actions taken by third parties as a result <strong>of</strong> information containedin the guidance material.6